Page 9

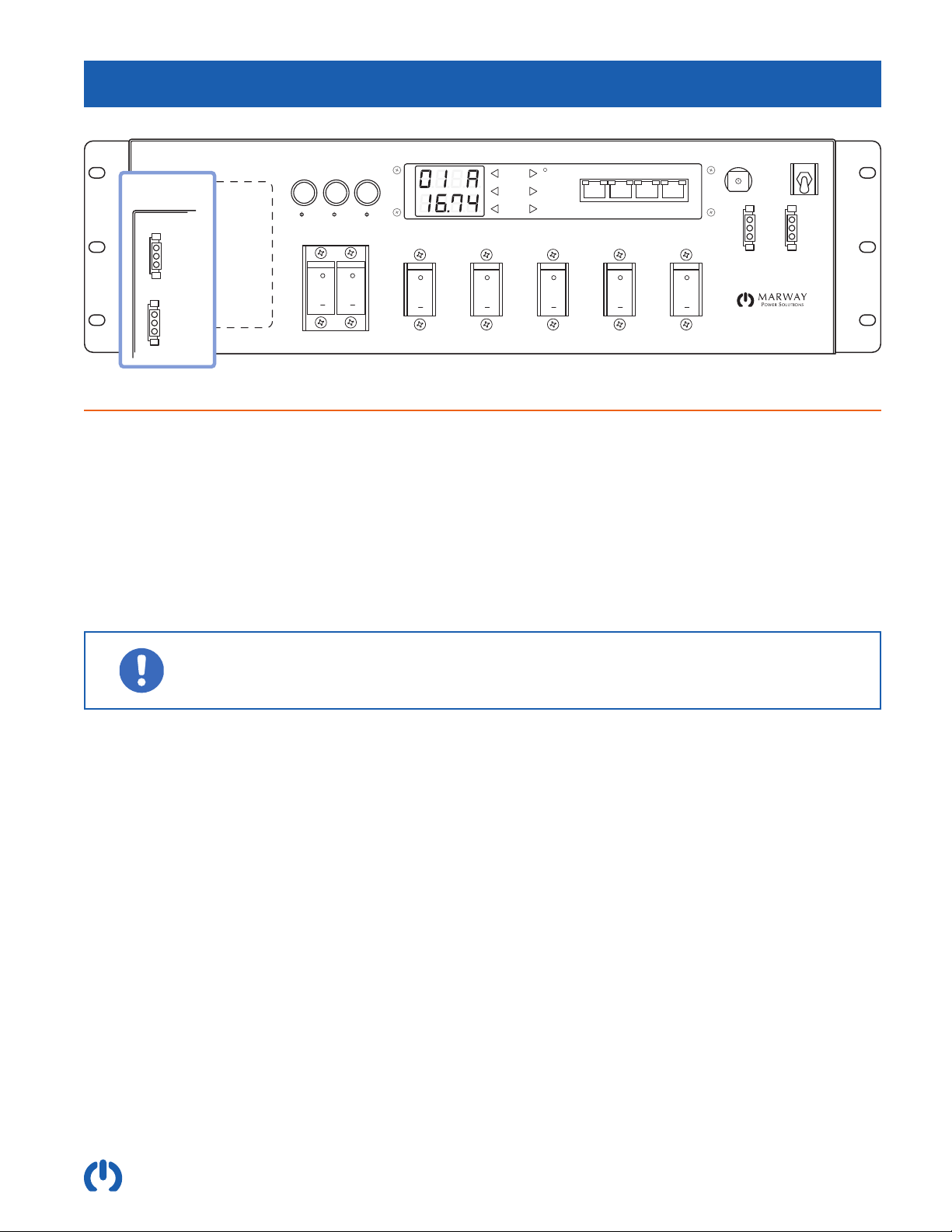

Optima 820 Series

5. Switch the PDU’s Main Breaker to the On position, and the ΦA, ΦB, ΦC indicators will be lit. These indicators do not

necessarily mean power is applied to the outlets. They simply means the main breaker is on and power is available to

all the branch breakers. The internal outlet control relays, branch breakers, and remote switching/EPO system are able

to prevent power from reaching the outlets.

6. Switch each branch breaker to the On position. The internal outlet control relays, and remote switching/EPO system

are able to prevent power from reaching the outlets. However, with a factory default setup, power should now be

applied to all outlets.

I there is not an EPO panel connected to the PDU, leave the Remote Override switch to the up position.

If there is a remote EPO panel connected to the PDU, such as Marway’s Commander UCP 5000, ip the switch to the

down Remote position. This system is discussed in detail farther down, as well as in the Optima RCM User Guide :

Software and Basic Controls Reference located on our website.

The PDU can continue to be used in this way as long as needed. The software can be congured later, or can be left

uncongured if it will not be used.

3.1.2 Startup to Congure the Software

The document Optima RCM User Guide : Software and Basic Controls Reference located on our website at http://www.

marway.com/docs is the complete resource for the process of conguring the network settings, and other software

features of the PDU. Obtain that document, and review the Getting Started chapter.

In effect, prepare the Serial and Ethernet connections to the PDU as described in the Software Guide, then use the

startup process described above in “3.1.1 Startup Without Conguring the Software” on page 8.

3.2 Ethernet and Serial Control

The document Optima RCM User Guide : Software and Basic Controls Reference located on our website at http://www.

marway.com/docs is the complete resource for how to setup, congure, and operate the Optima RCM software over serial,

Telnet, SSH, HTTP, SNMP, and RESTful API.

The Ethernet connection supports 10/100 Base-T, IPv4 DHCP and manual addressing. It is recommended to use a

manual address, or DHCP in conjunction with MAC ID reservations so that the IP address stays consistent.

The Serial interface is RS-232 implemented in an RJ45 connector. A protocol conversion cable with a USB connection at

one end and an RJ45 at the other end is ideal for connecting a computer to the Serial port. Marway offers these cables as

part number 311118-000. They can also be found on many online cable retailer web sites.

3.3 Breaker Controls

3.3.1 Main Breaker

The Main Breaker prevents or enables power to all PDU outlets. When Main Breaker is switched on, the indicators

labeled ΦA, ΦB, ΦC will be lit.

This breaker includes a breaker guard with a lockout feature. Attaching a small padlock (not included) through the guard

hole will prevent the breaker from being switched on.

Be aware that when the Remote Override mode switch is in the Off position, power is disconnected from the switched

outlets even if the main breaker is on.