0

1INTRODUCTION .....................................................................4

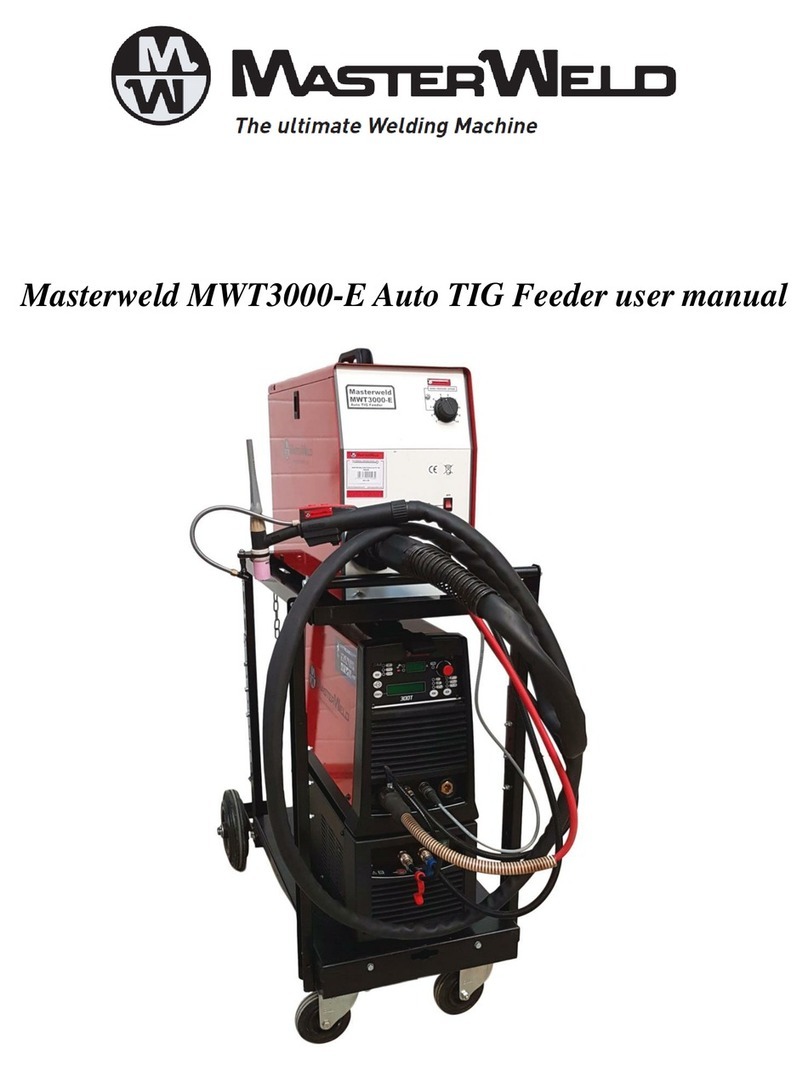

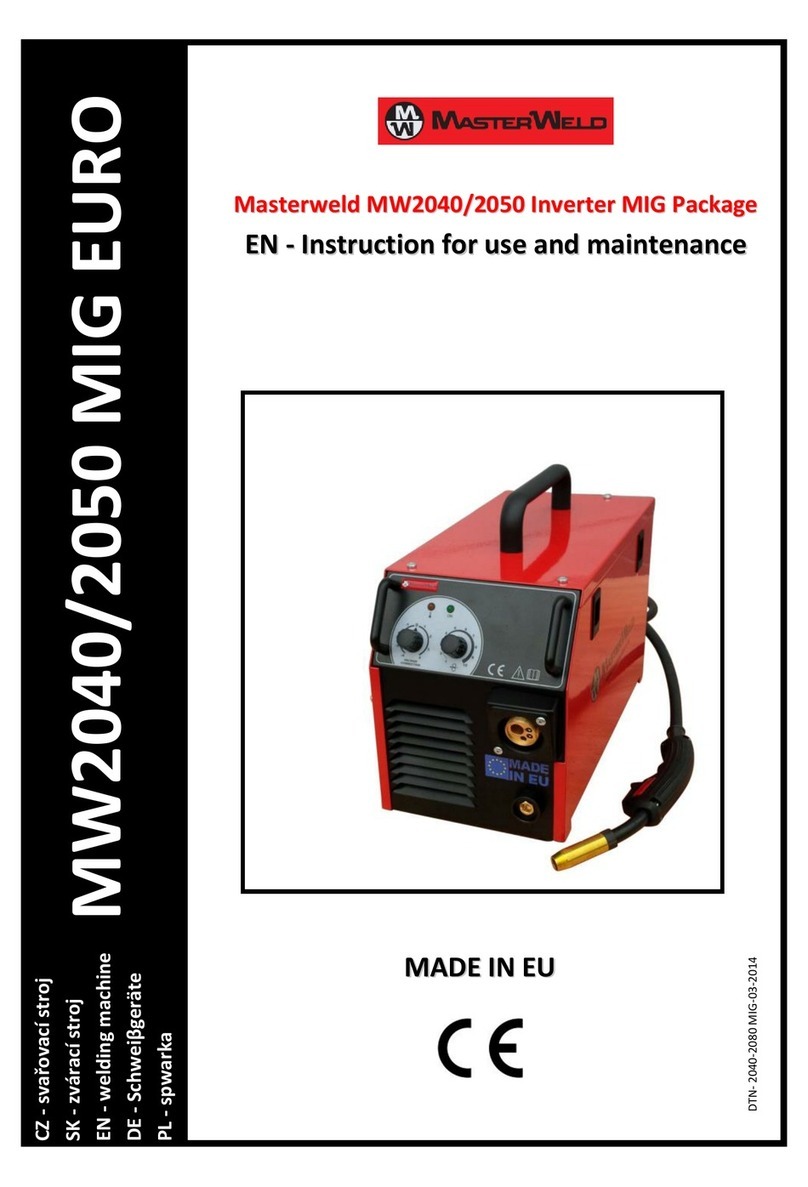

2FRONT PANEL .......................................................................4

3REAR PANEL .........................................................................5

4INSTALLATION ......................................................................5

4.1 UNIT ASSEMBLY....................................................................5

4.2 CONNECTIONS TO THE ELECTRICAL MAINS NETWORK.6

4.3 WIRE SPOOL POSITIONING .................................................6

4.4 POSITIONING THE WIRE IN THE WIRE FEEDER................6

4.5 CONNECTIONS TO SOCKETS..............................................7

5USER INTERFACE .................................................................9

6UNIT POWER-UP..................................................................11

7RESET (LOAD FACTORY SETTINGS)................................11

7.1 PARTIAL RESET...................................................................11

7.2 TOTAL RESET ......................................................................11

8SET-UP (INITIAL SET-UP OF THE WELDING POWER

SOURCE) ..............................................................................12

COOLER ACTIVATION ....................................................................12

REMOTE CONTROLLER SELECTION ...........................................12

ADJUSTMENTS BLOCK SELECTION.............................................12

PUSH PULL ......................................................................................12

SELECTION OF BURN TYPE..........................................................12

8.1 LOCKING PROCEDURE.......................................................13

Enabling ............................................................................................13

Disabling ...........................................................................................13

8.2 TORCH LOADING.................................................................14

9ALARMS MANAGEMENT ....................................................14

AL. HEA. ...........................................................................................14

AL. COO. ..........................................................................................14

Err. C0...............................................................................................14

Err. C1...............................................................................................14

Err. C2...............................................................................................14

Err. C4...............................................................................................14

Err. C11.............................................................................................14

Err. C12.............................................................................................14

10 PARAMETERS ACTIVATION...............................................15

Working voltage ................................................................................15

Welding inductance...........................................................................15

Wire feed rate ...................................................................................15

Welding current.................................................................................15

Thickness..........................................................................................15

Programs ..........................................................................................15

Hot Start............................................................................................15

Crater Filler .......................................................................................15

3 Levels Slope ..................................................................................15

Soft Start ...........................................................................................15

Motor Slope.......................................................................................15

Bourn Back .......................................................................................15

Post gas time ....................................................................................15

Pre gas time......................................................................................15

10.1 WELDING PARAMETERS ....................................................16

11 WELDING SETTINGS...........................................................17

11.1 MIG/MAG WELDING.............................................................17

11.1.1 SETTING MIG/MAG PARAMETERS (MAIN WELDING

PARAMETERS) ................................................................................17

11.1.2 MIG/MAG PARAMETERS SETTING (2ND LEVEL).........................18

11.1.3 MIG/MAG PARAMETERS SETTING (GAS MENU).........................18

12 JOBS MANAGEMENT..........................................................19

12.1 SAVING A JOB......................................................................19

12.2 LOADING A USER JOB OF FACTORY SET JOB ................19

12.3 DELETING A JOB .................................................................19

13 TORCH TRIGGER MODES ..................................................20

13.1 2T MIG/MAG WELDING........................................................20

13.2 4T MIG/MAG WELDING........................................................20

13.3 3 LEVEL MIG/MAG WELDING..............................................20

14 TECHNICAL DATA...............................................................21

15 SPARE PARTS .....................................................................22

15.1 321 HDP ................................................................................22

15.2 WIRE FEEDER MOTOR .......................................................24

15.3 WIRE FEEDER ROLLS......................................................... 25

16 ELECTRICAL DIAGRAM ..................................................... 26

16.1 321 HDP................................................................................26

16.2 REMOTE CONTROLLER .....................................................27

16.2.1 RC03: ELECTRICAL DIAGRAM ...................................................... 27

16.2.2 RC04: ELECTRICAL DIAGRAM ...................................................... 27

16.2.3 RC05: ELECTRICAL DIAGRAM ...................................................... 28

16.2.4 RC06: ELECTRICAL DIAGRAM ...................................................... 28

16.3 PUSH-PULL (OPTIONAL).....................................................28