1. Study this instruction before use.

2. Please wear gloves and goggles when working.

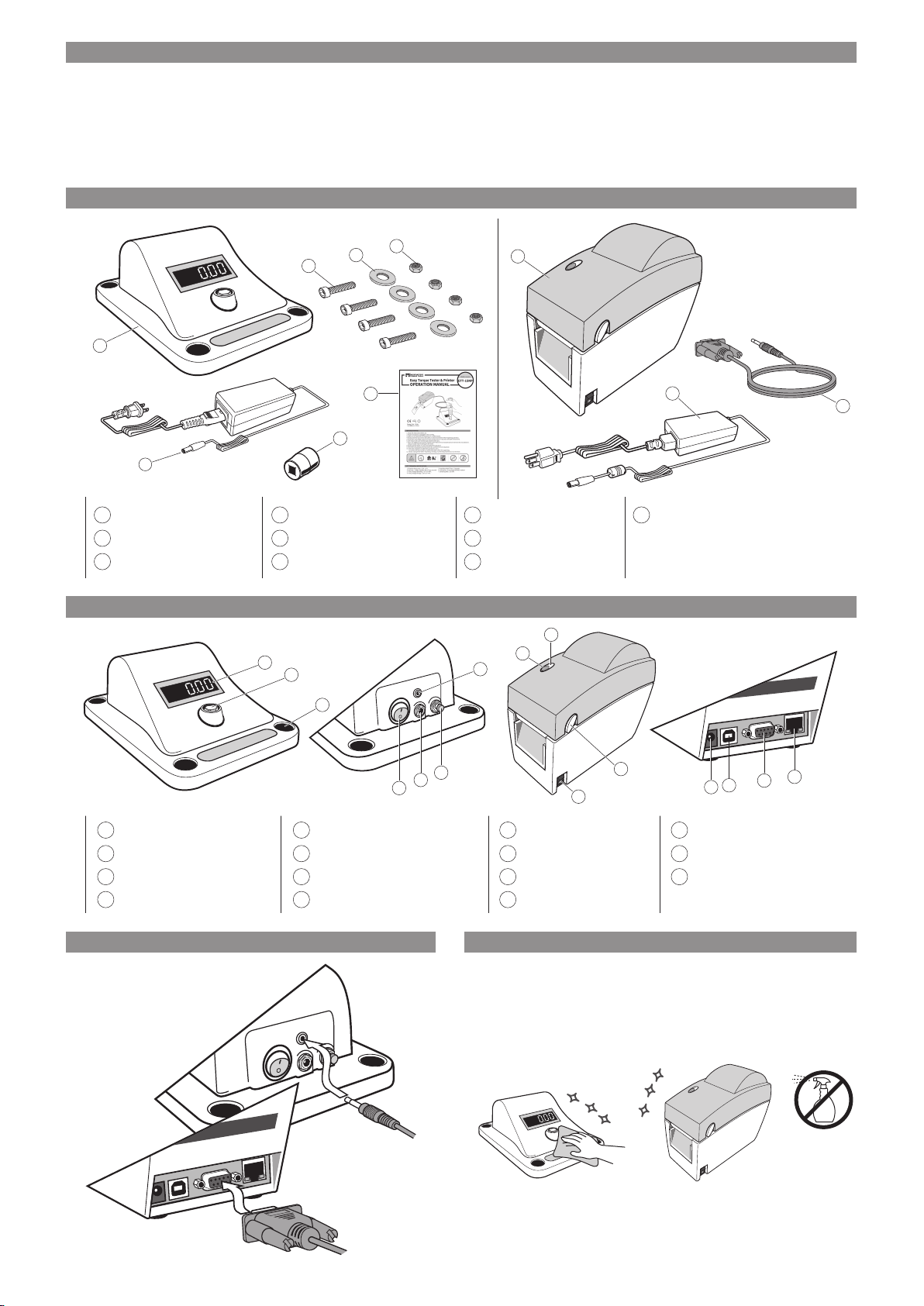

3. Make sure to install the test equipment in a stable locatio.

4. Always check for loose wires and cables on and around tester before beginning operation.

5. Keep tester and charger away from water, always store in a dry place and safe environment.

6. Over torque will cause tool damage and personal injury.

7. Never use additional accessories with this tester that were not included and are not from this manufacturer,

doing so could result in damage to the tester.

8. Always operate tester in a clean and organized work place.

9. This tester should always be kept clean, dry, and free from oil and grease.

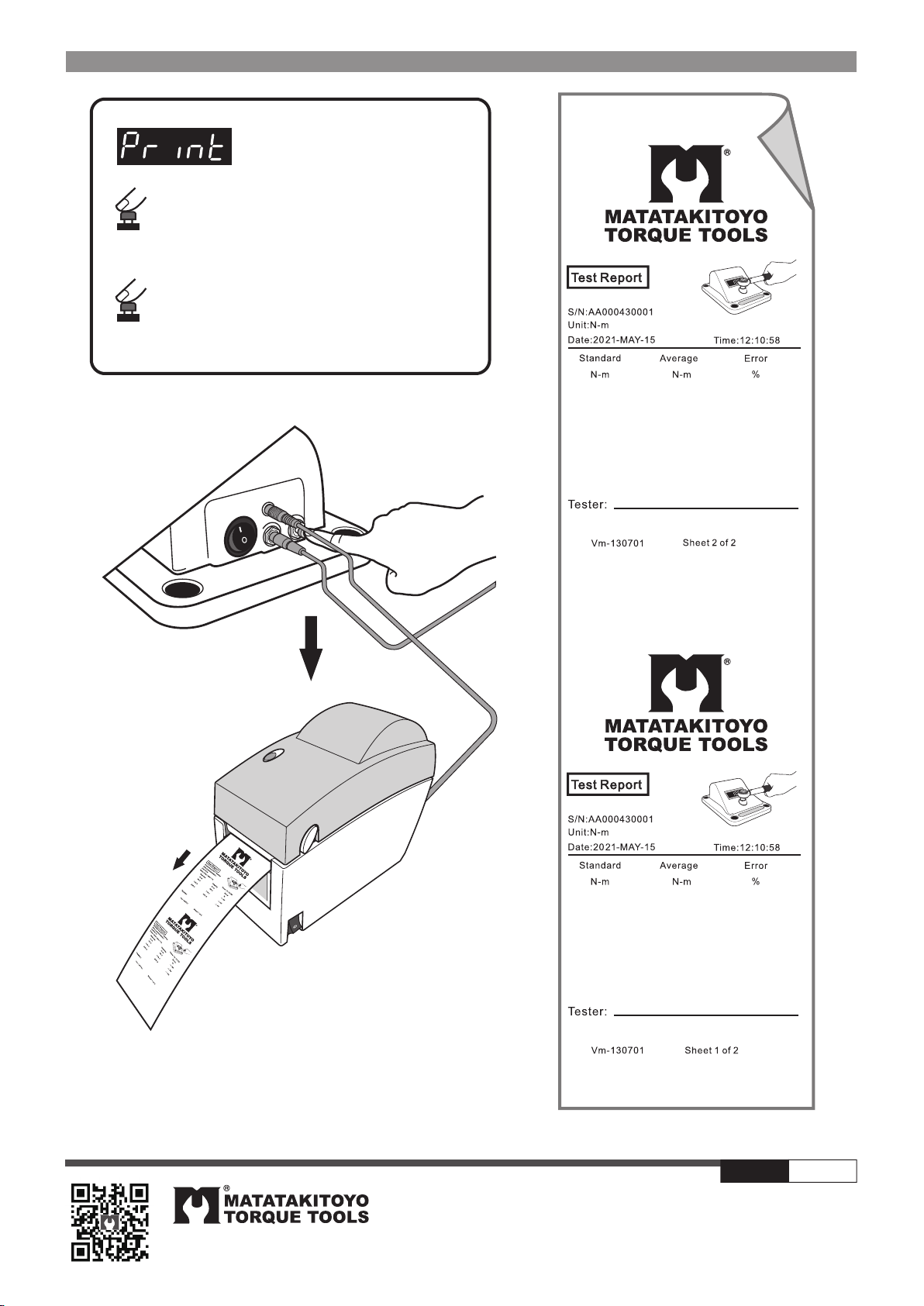

10. This tester should be recalibrated a period of 1 years.

To contact with local vendor, an authorized repair center for supporting.

11. Always unplug tester before inspecting, cleaning, or performing maintenance on the tester.

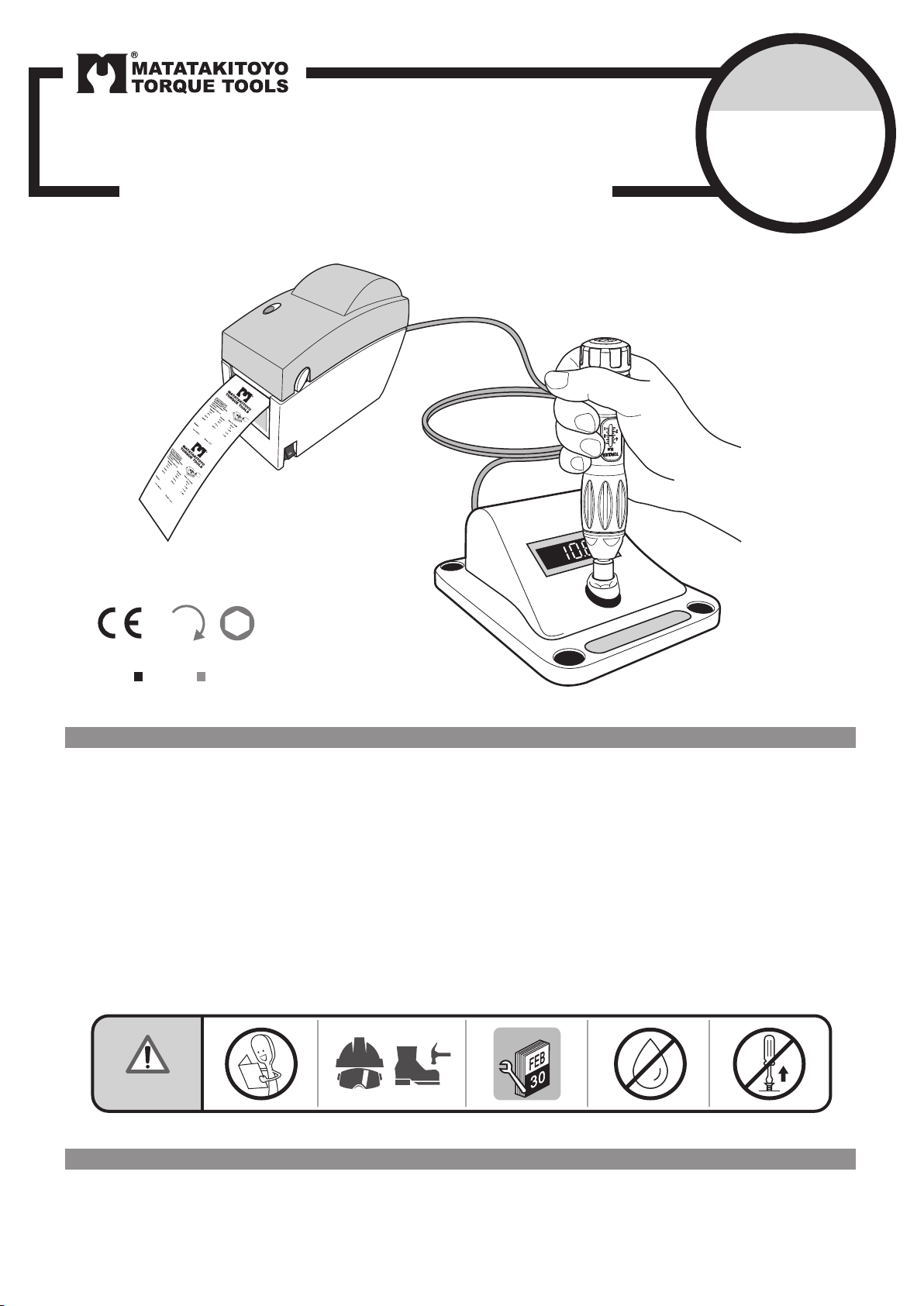

BEFORE STARTING

ETT TECHNICAL SPECIFICATION

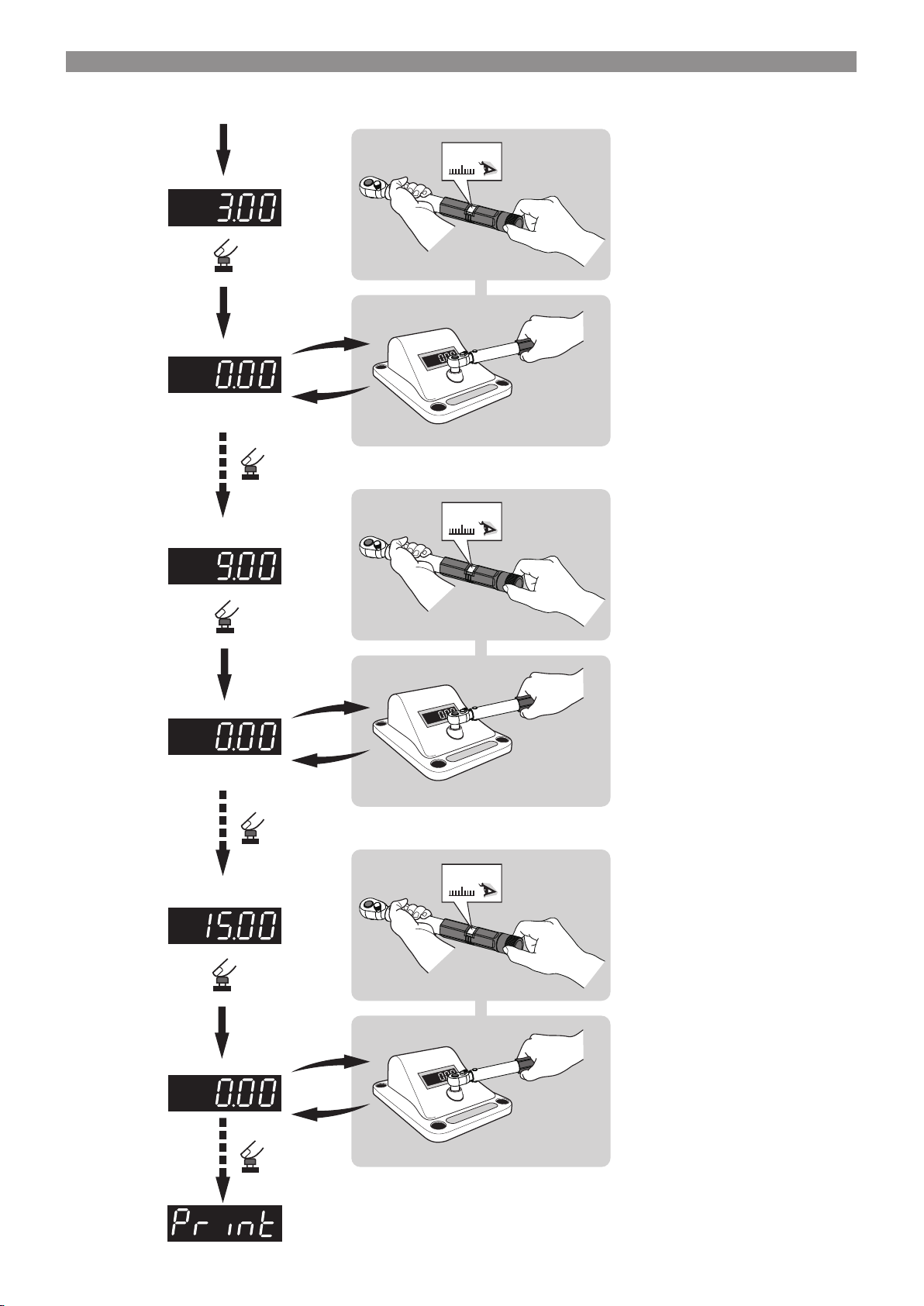

Range: 1 Nm - 15 Nm

TORQUE

Color: Black or Silver

1. Direction & Accuracy : C.W. ±1%

2. Indicator : 5 Digits (update rate of 5 per second)

3. Temp. Range-Operating : +5℃ to +40℃

4. Temp. Range-Storage : -20℃ to +70℃

5. Auto Reset Hold Time : 2 Seconds

6. Calibration : According to BS7882 method

7. Sampling Rate : 333 SPS

Manual

WARNING

1 Years

ETT-15NP

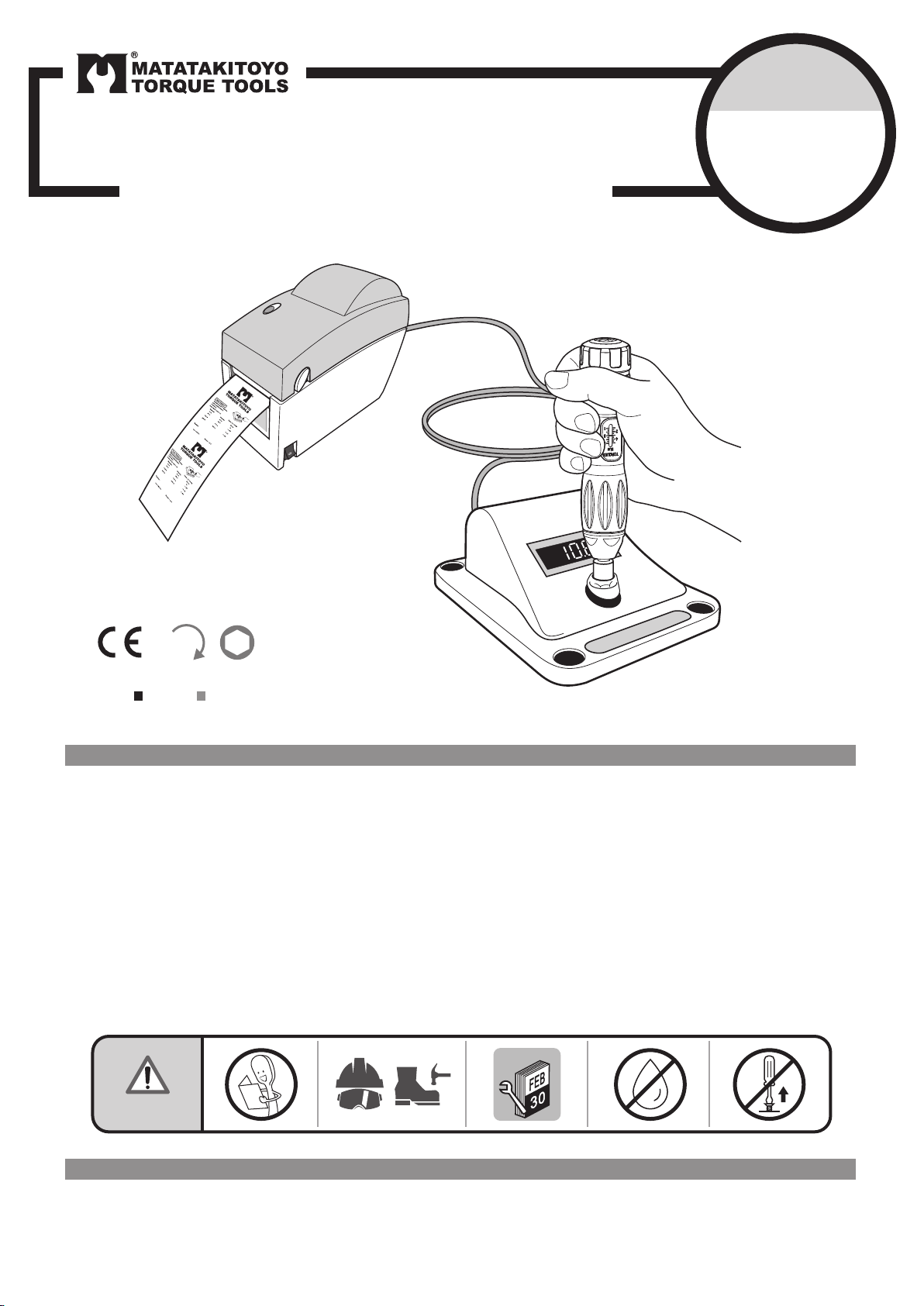

OPERATION MANUAL

Easy Torque Tester & Printer

Models covered