Matrix STRENGTH User manual

Other Matrix Fitness Equipment manuals

Matrix

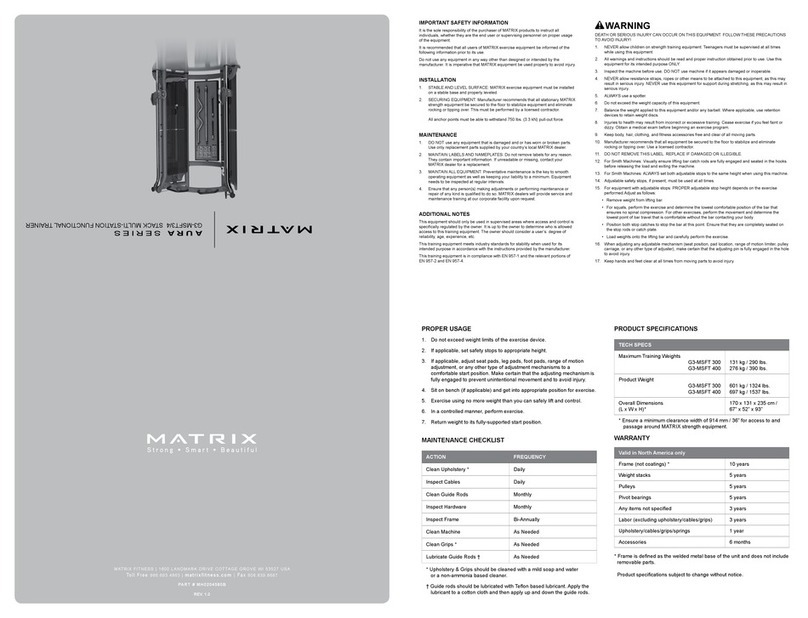

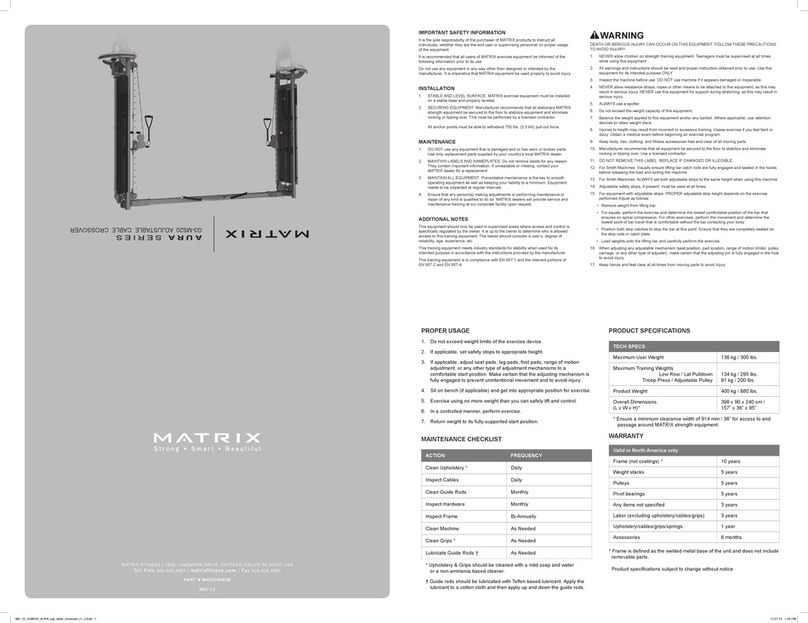

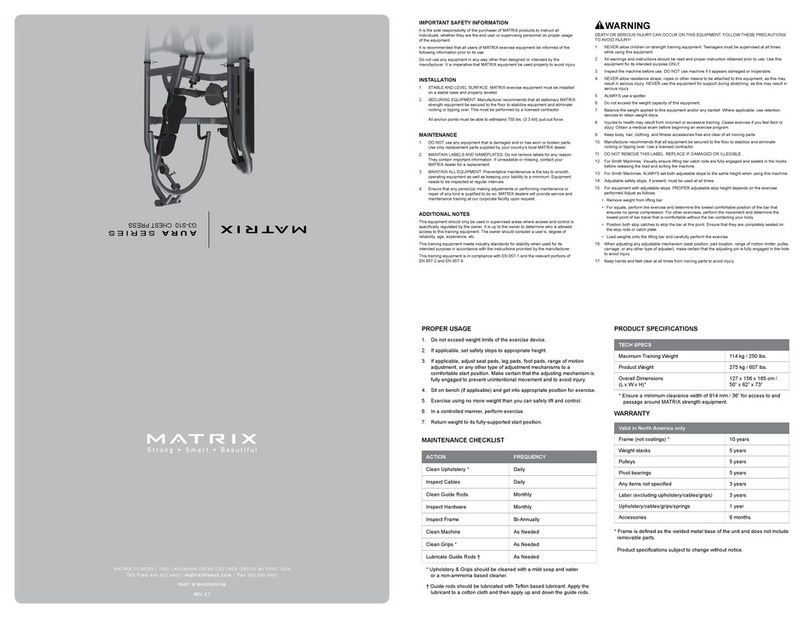

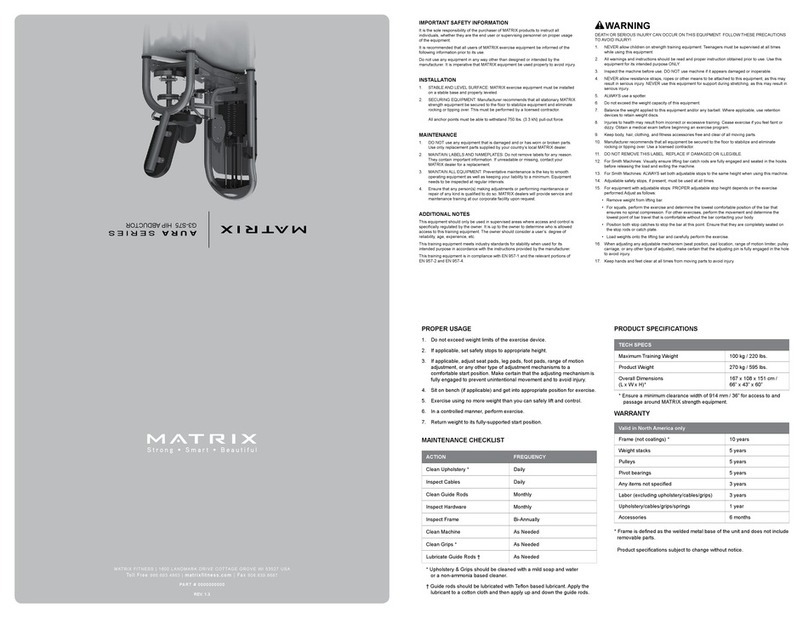

Matrix AURA Series User manual

Matrix

Matrix planet fitness ASCENT User manual

Matrix

Matrix MX-FW63 User manual

Matrix

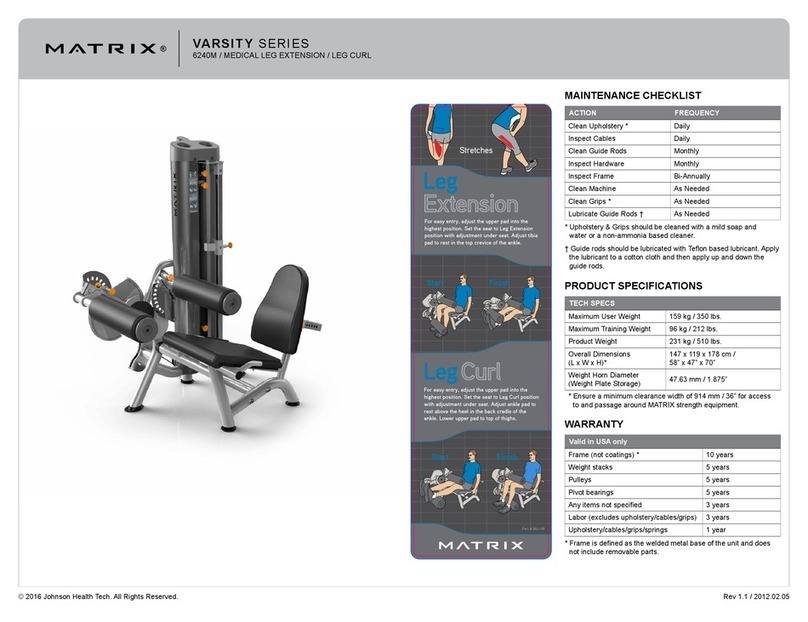

Matrix VARSITY Series User manual

Matrix

Matrix RXP User manual

Matrix

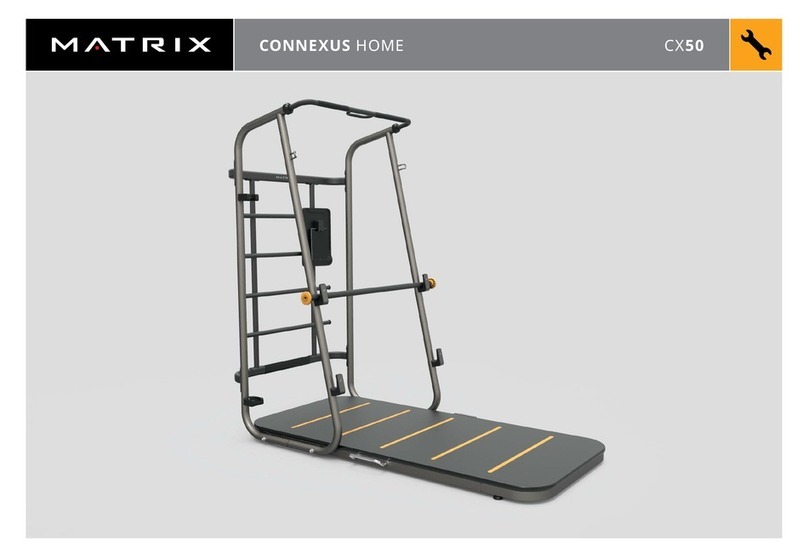

Matrix CONNEXUS HOME CX50 User manual

Matrix

Matrix AURA Series User manual

Matrix

Matrix G3-MSFT3-02 User manual

Matrix

Matrix C50 Parts list manual

Matrix

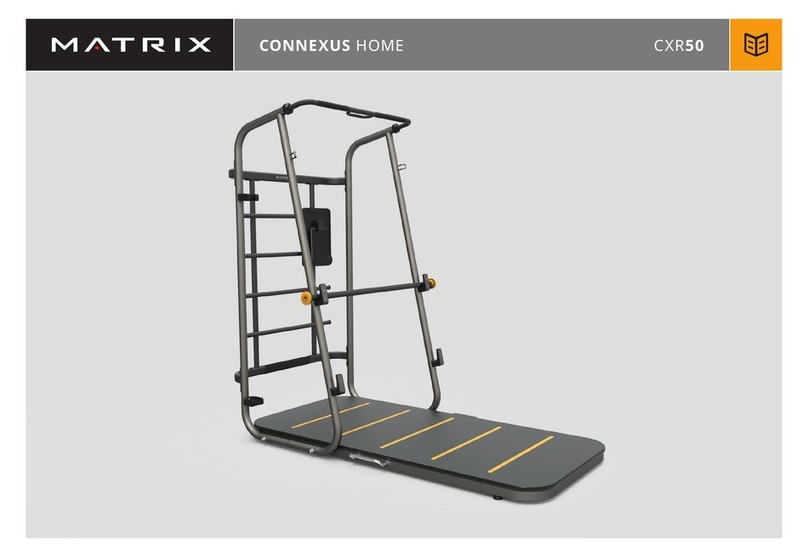

Matrix Connexus CXR50 User manual

Matrix

Matrix VARSITY VY-D47-05 User manual

Matrix

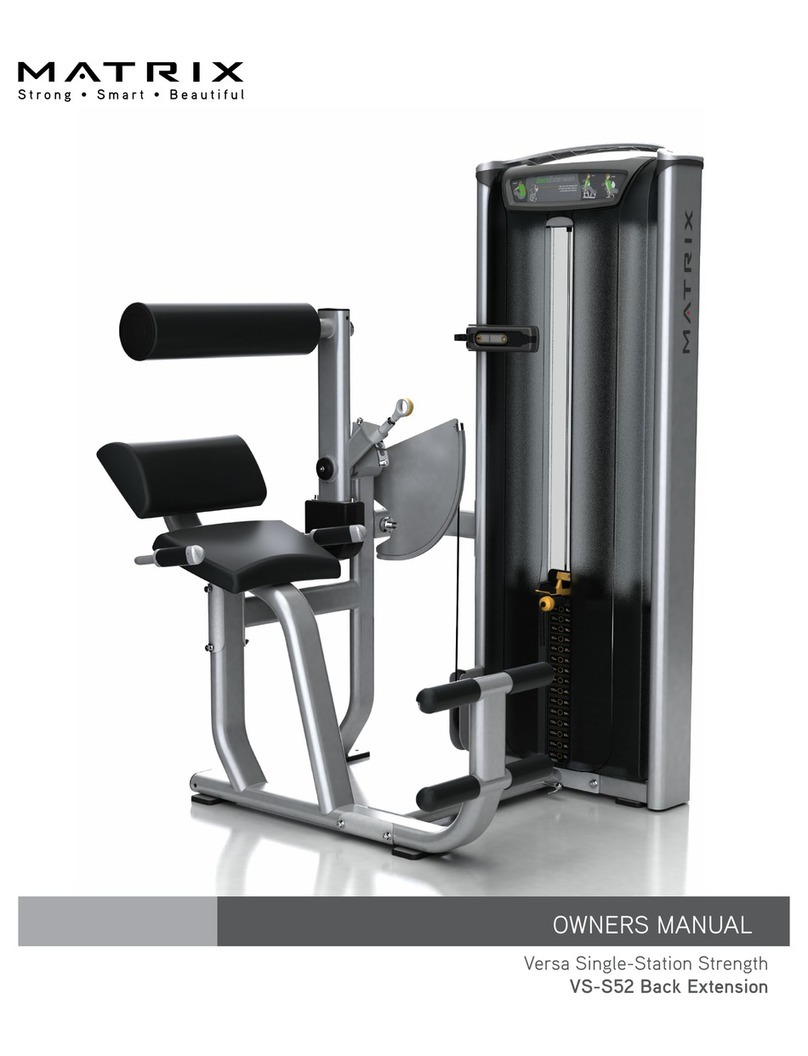

Matrix VS-S52 User manual

Matrix

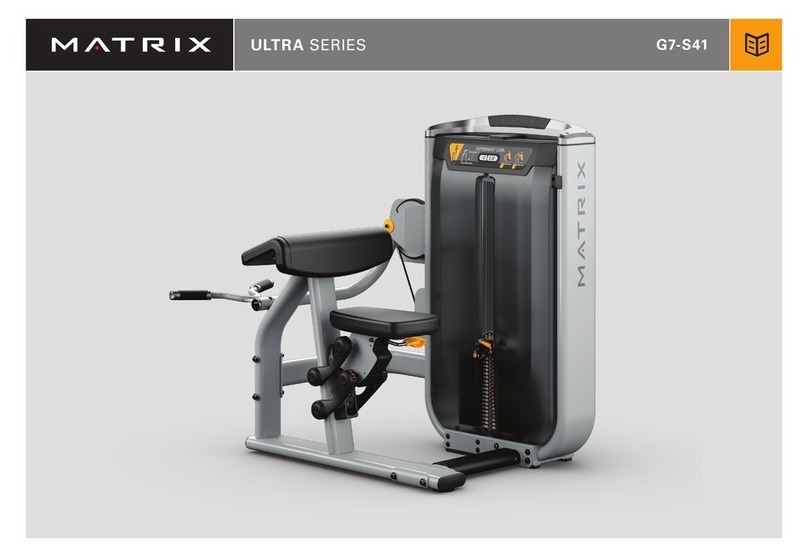

Matrix ULTRA User manual

Matrix

Matrix VERSA Series User manual

Matrix

Matrix AURA Series User manual

Matrix

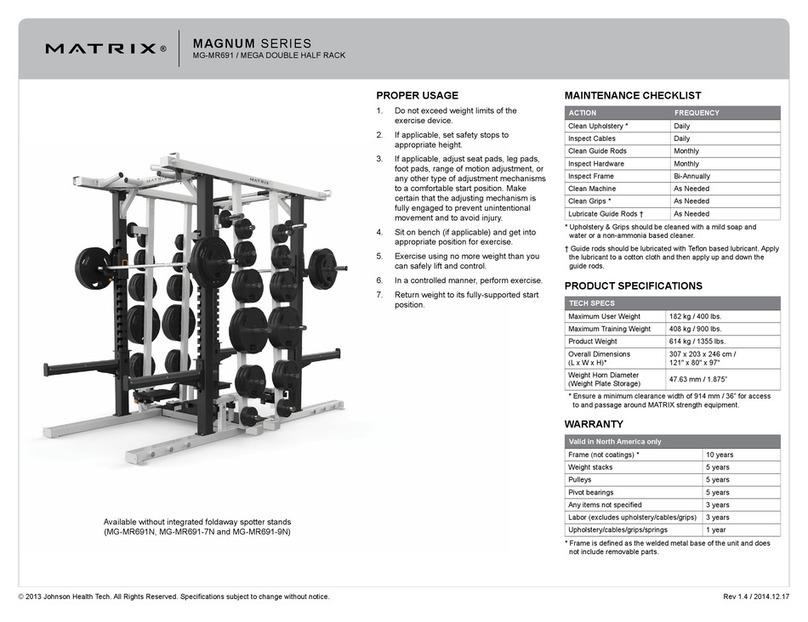

Matrix MAGNUM MG-MR691 User manual

Matrix

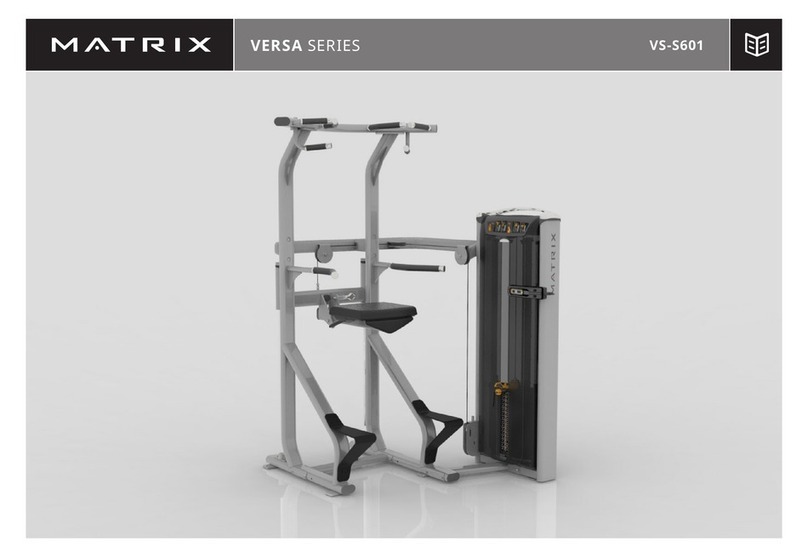

Matrix VS-S601 User manual

Matrix

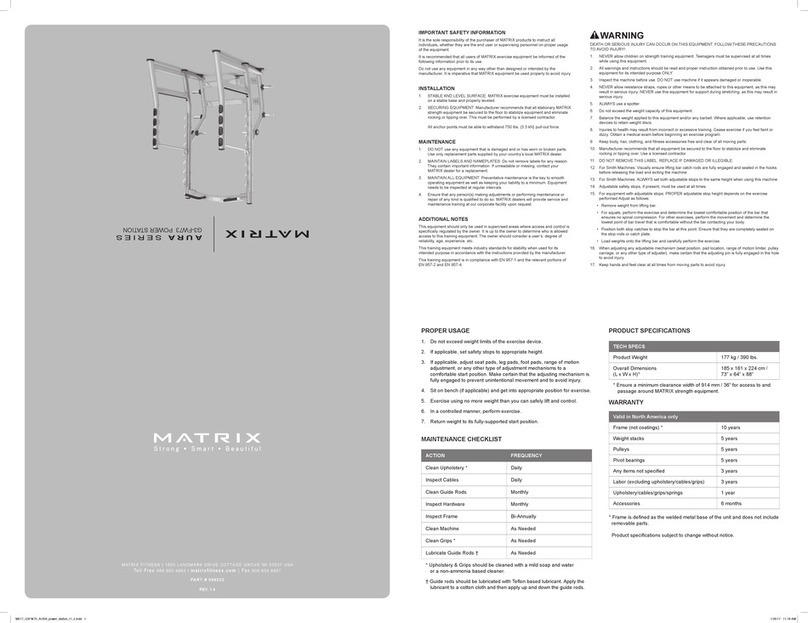

Matrix AURA Series User manual

Matrix

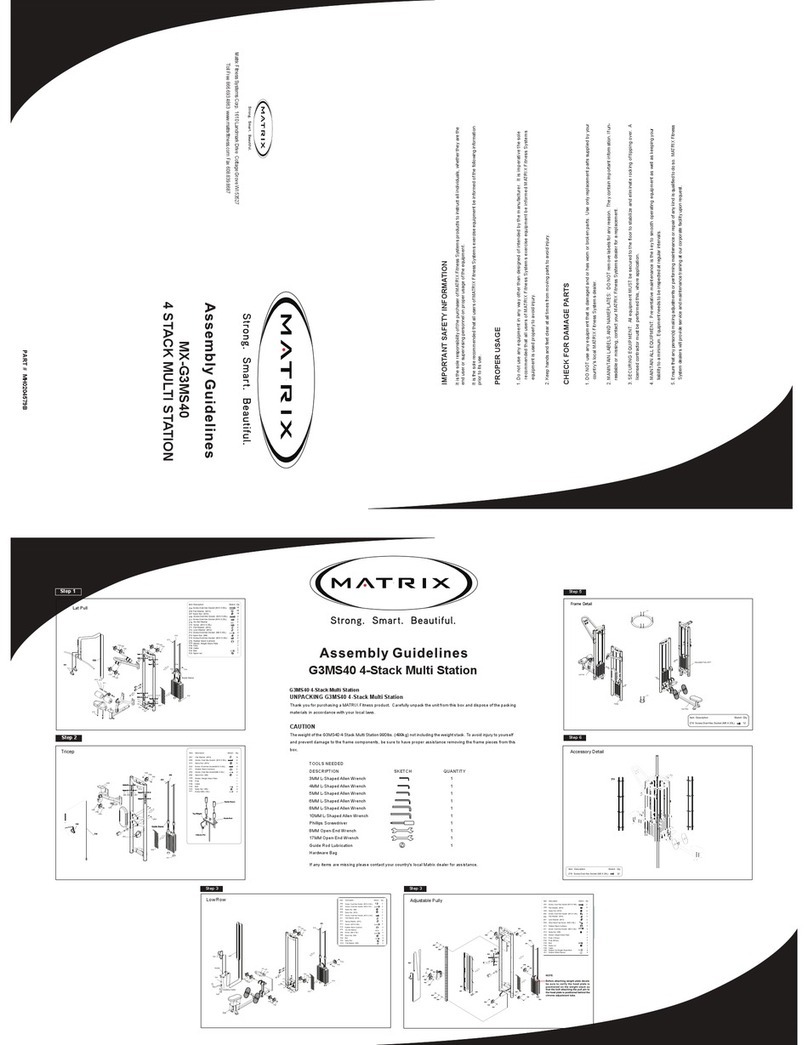

Matrix MX-G3MS40 Instruction Manual

Matrix

Matrix G7-S74 User manual