LIFT CORPORATION Sht. 7 of 13 DSG# M-16-04 Rev. ADate: 01/13/17

© MAXON Lift Corp. 2017

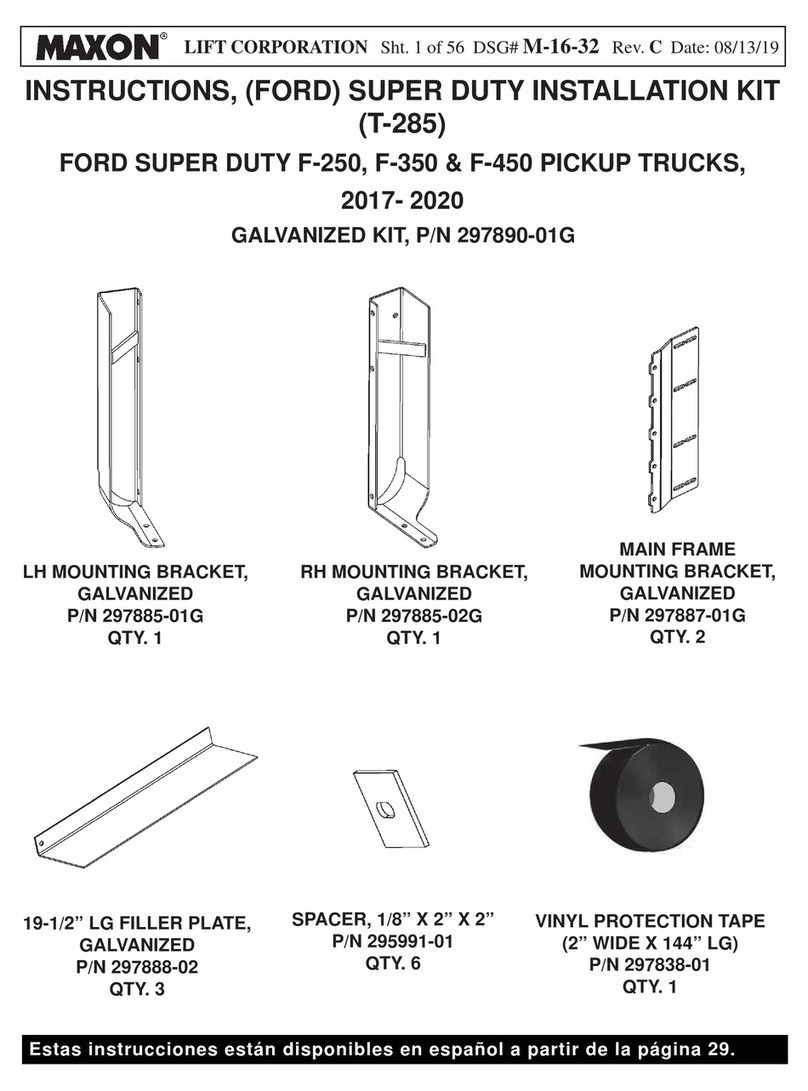

7. Disconnect interconnect harness from control switch

cable on the RH column (FIG. 7-1). Then, connect

tee to control switch cable in the RH column and

interconnect harness (FIG. 7-1).

PLASTIC

ENCLOSURE

CONTROL

SWITCH

CABLE

TEE

CONNECTING CABLES TO CONTROL TEE

FIG. 7-1

8. Connect tee to the control switch cable connector

extending from plastic enclosure (FIG. 7-1).

STREETSIDE SWITCH

ASSEMBLY

RH COLUMN

6. Route the tee (Kit item) to the

RH column (FIG. 7-1).

9. Reconnect battery power to the

hydraulic pumps by turning ON the

master disconnect switch at the

pump box. Refer to BMR Operation

Manual for detailed instructions.

LOCKING RING

CONNECTORS

INTERCONNECT

HARNESS

LOCKING RING

CONNECTORS

NOTE: Refer to Sheet 4 for important information

about locking ring electrical connectors.

PUMP ASSEMBLY

(REF)

CONTROL

SWITCH CABLE