LIFT CORPORATION Sht. 10 of 56 DSG# M-19-12 Rev. -Date: 01/06/20

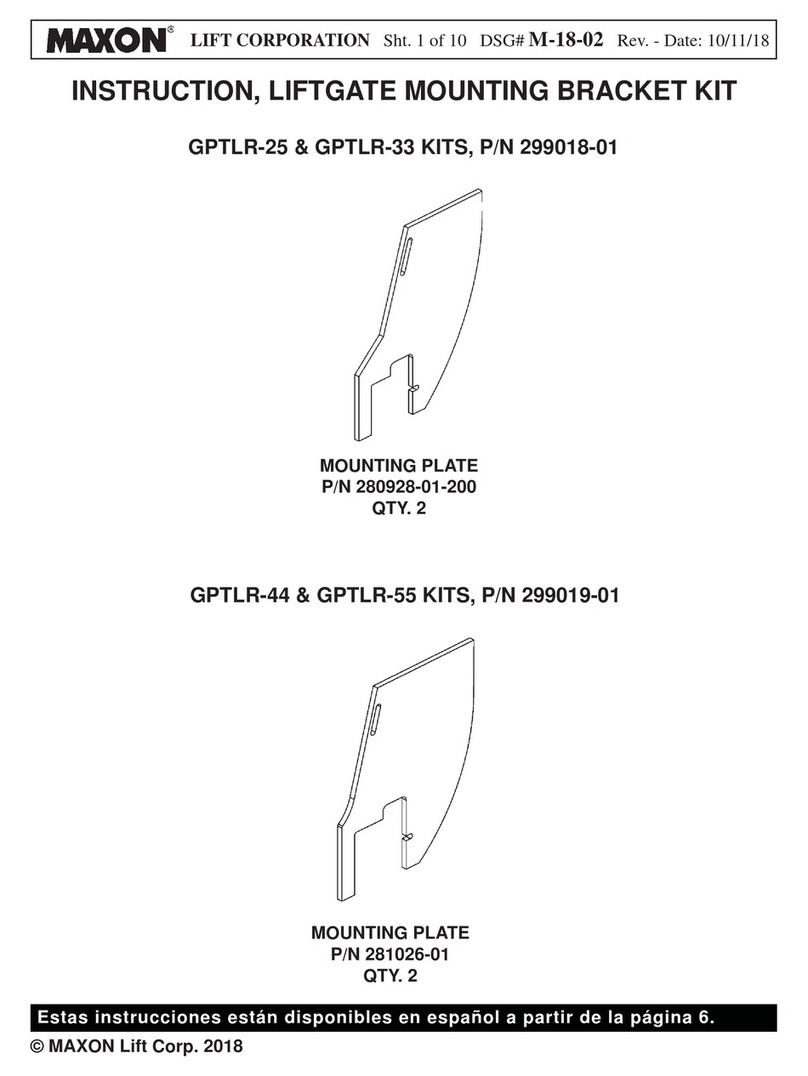

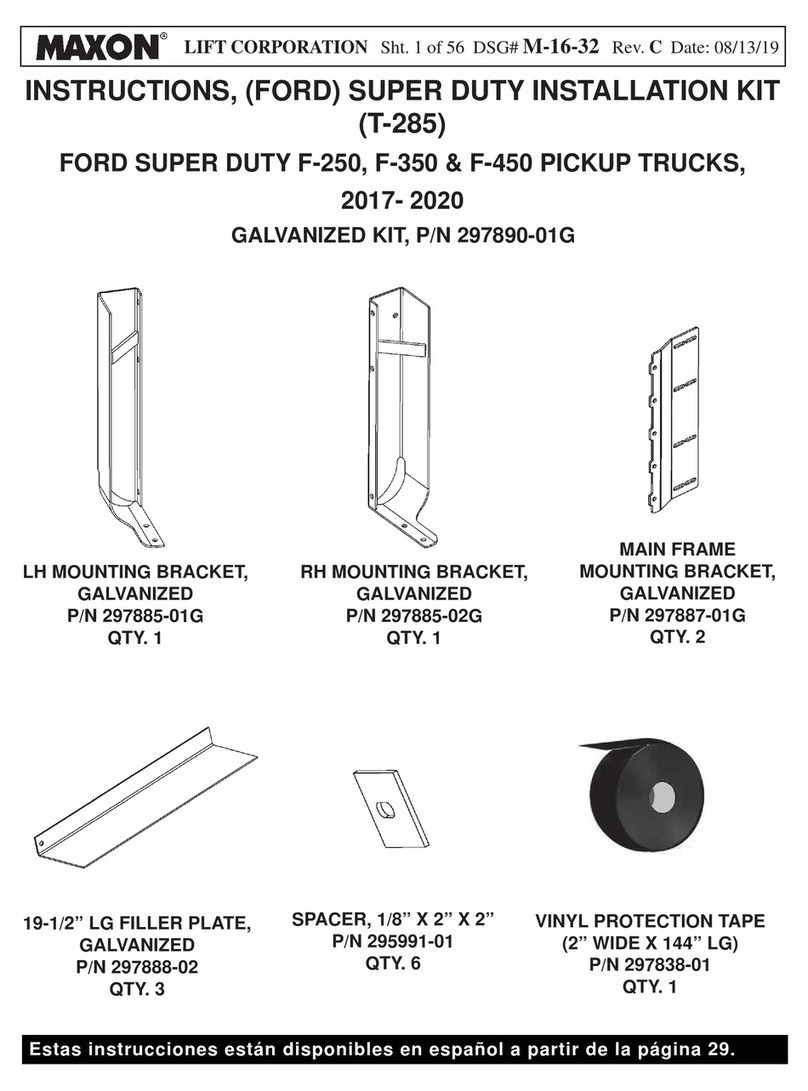

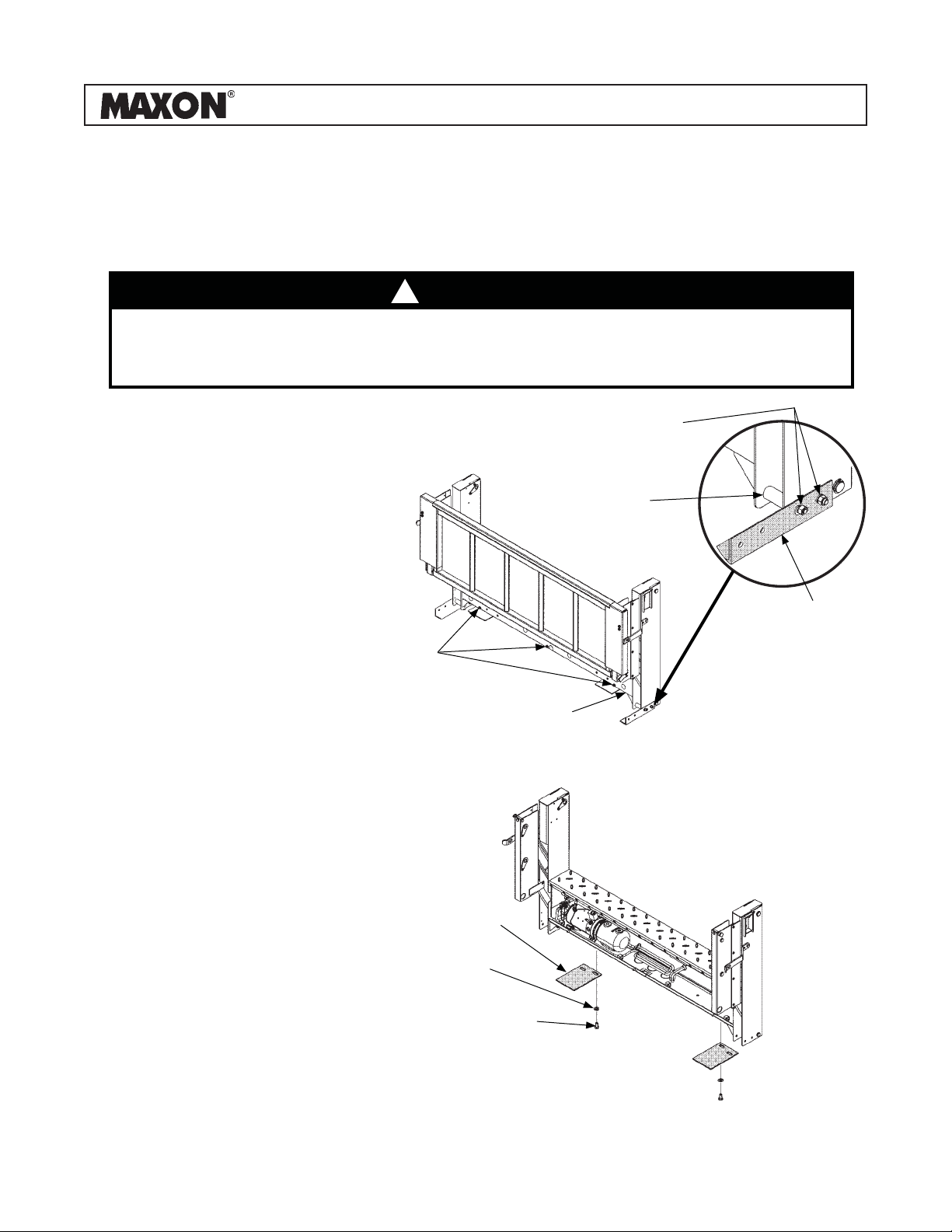

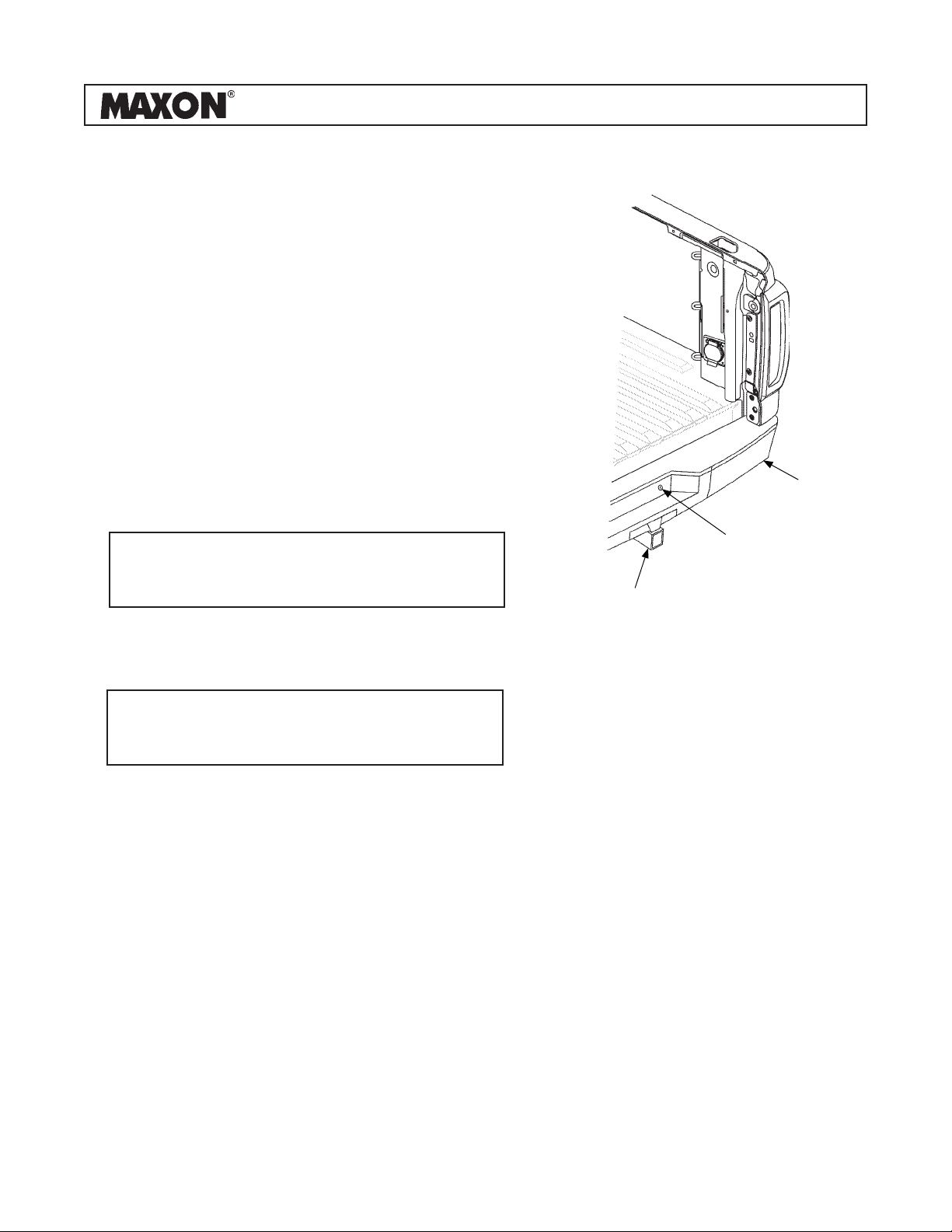

PREPARING PICKUP TRUCK

1. Use truck igniton key to unlock the spare

tire access plug (FIG. 10-1). Remove the

plug.

2. Remove spare tire from truck (FIG. 10-1).

Refer to instructions in the owner’s manual

and use the tools provided with truck.

4. Support rear bumper and trailer hitch

(FIG. 10-1) before unbolting the bumper

and hitch.

5. Unbolt and remove trailer hitch (FIG. 10-1).

6. Disconnect the wiring clips from rear bumper

(FIG. 10-1).

7. Unbolt and remove rear bumper (FIG. 10-1).

3. Unbolt the tailgate and supports (FIG. 10-1).

8. If an aftermarket hitch is to be installed, install new

hitch now.

NOTE: If truck is equipped with dual rear

wheels, side marker lamps may have

to be disconnected and rewired.

NOTE: When Liftgate is installed on the truck

tailgate, trailer hitch, and rear bumper

cannot be reinstalled.

REMOVING TAILGATE, REAR

BUMPER & TRAILER HITCH

FIG. 10-1

REAR

BUMPER

SPARE TIRE

ACCESS PLUG

TRAILER

HITCH