Maxon 297890-01G User manual

Other Maxon Automobile Accessories manuals

Maxon

Maxon TE-25 User manual

Maxon

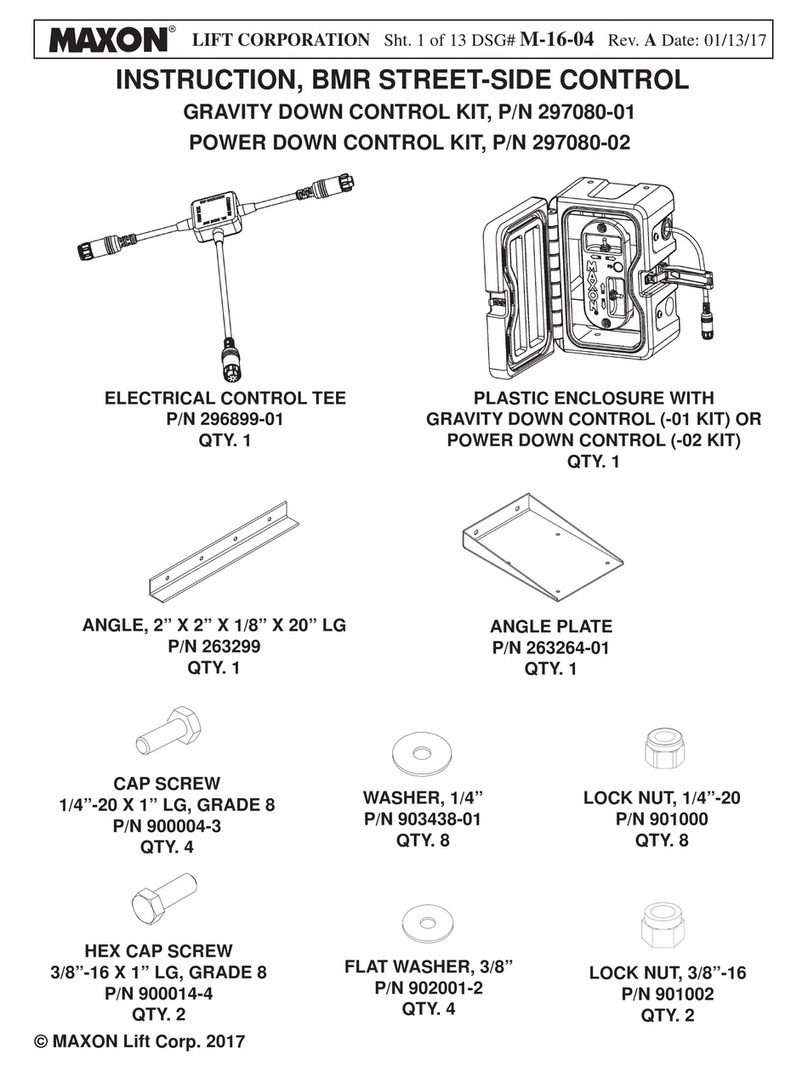

Maxon 297080-01 User manual

Maxon

Maxon DMD series User manual

Maxon

Maxon Railift Series User manual

Maxon

Maxon GPTWR-25 Operating and maintenance instructions

Maxon

Maxon DMD-22 Operating instructions

Maxon

Maxon 49-HX User manual

Maxon

Maxon DMD-22 User manual

Maxon

Maxon 49-SX User manual

Maxon

Maxon TUK-A-WAY Series User manual