6

RECOMMENDED DAILY OPERATION CHECKS

Make sure batteries are fully charged, battery terminal connections are

clean and tight, and battery box is undamaged.

Visually check that main frame housing cover is bolted on securely and

undamaged. Look for hydraulic fl uid leaks from main frame and columns.

Before operating the Liftgate, the operator should do the following:

Visually check that handheld and power opener controls are in place

and undamaged.

Visually check that all decals are in place (see DECALS page). Make

sure decals are legible, clean, and undamaged.

NOTE: Before you check the Liftgate, park vehicle on fl at ground

and set the parking brake.

NOTE: If any of the following operation checks reveal a need to

service or repair Liftgate, do not operate the Liftgate until a

qualifi ed mechanic services or repairs the Liftgate.

Make sure cab cutoff switch is ON, if equipped.

Follow the visible routing of hydraulic hoses from cylinders to main

frame housing . Make sure all hoses are connected at both ends and

there are no cracks, chafi ng, and fl uid leaks.

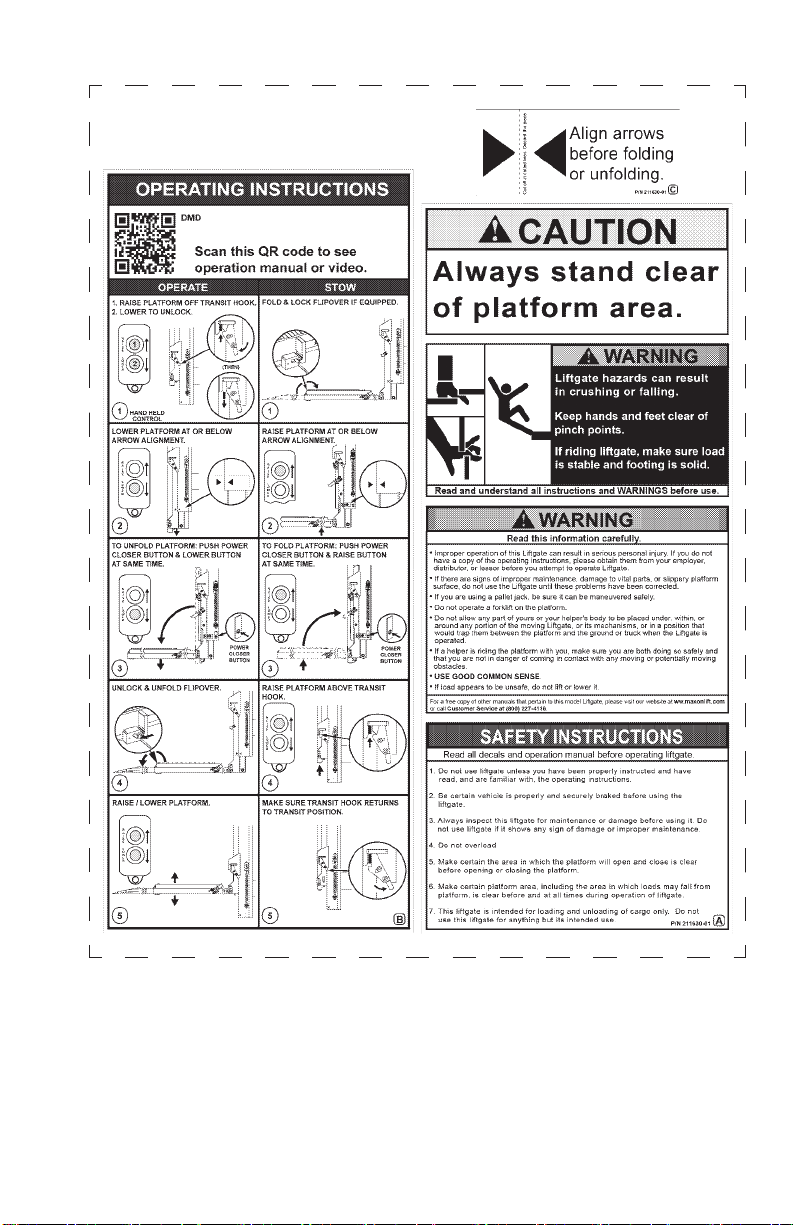

Use the operation instructions in this manual to unfold the platform.

Check for smooth operation as platform unfolds and as runners lower

the platform to the ground.

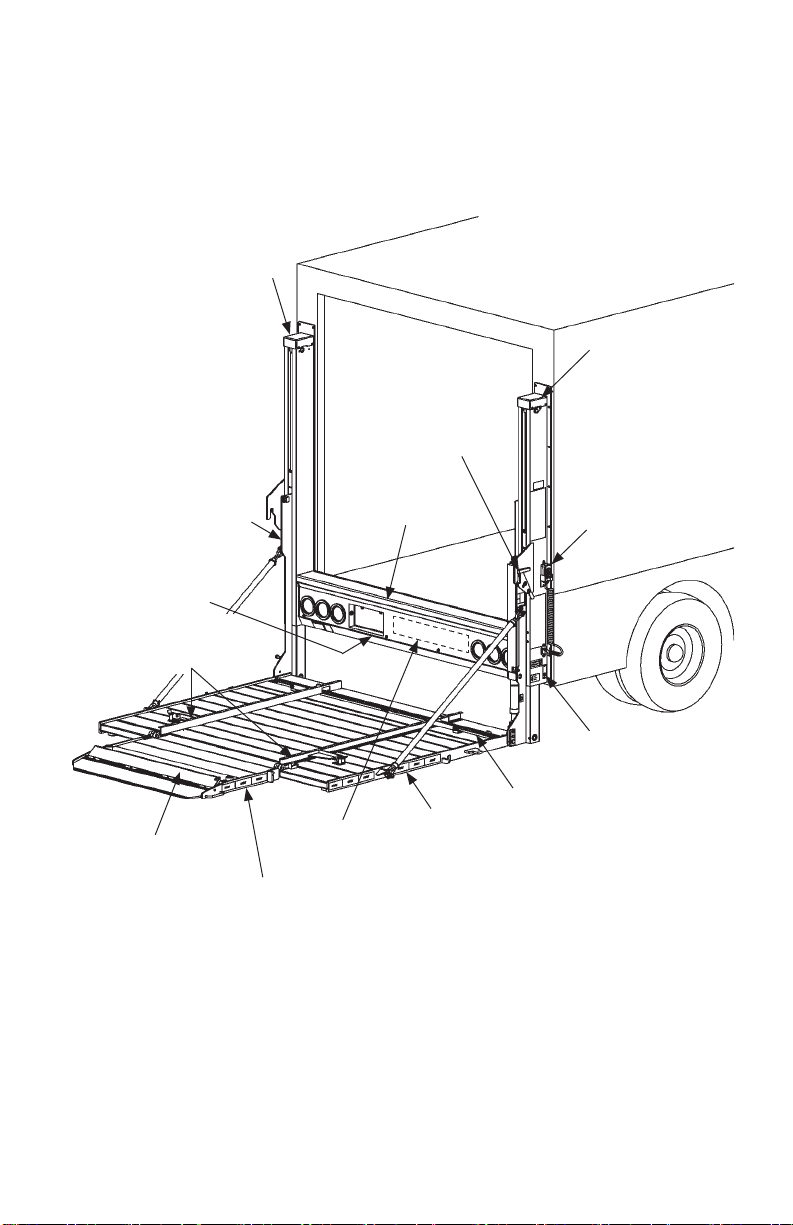

Check main frame housing, columns, runners and platform

openers for cracks and bends. Make sure platform chains are undam-

aged and connected securely at both ends. Also, make sure all bolts

and pins are in place and undamaged.

Check platform and fl ipover for cracks, holes, and bends on the load-

carrying surfaces and side plates. Also, make sure carts stops and

guide rails are undamaged and are not missing parts.

Position top surface of platform at vehicle bed level. Check if platform

surface is even with liftgate main housing across the width of the plat-

form. If platform is uneven, press RAISE button on control switch until

platform stops. Hold for 10 seconds more to get platform even.