Page 4 1330SE - Service & Parts Manual

November 2021

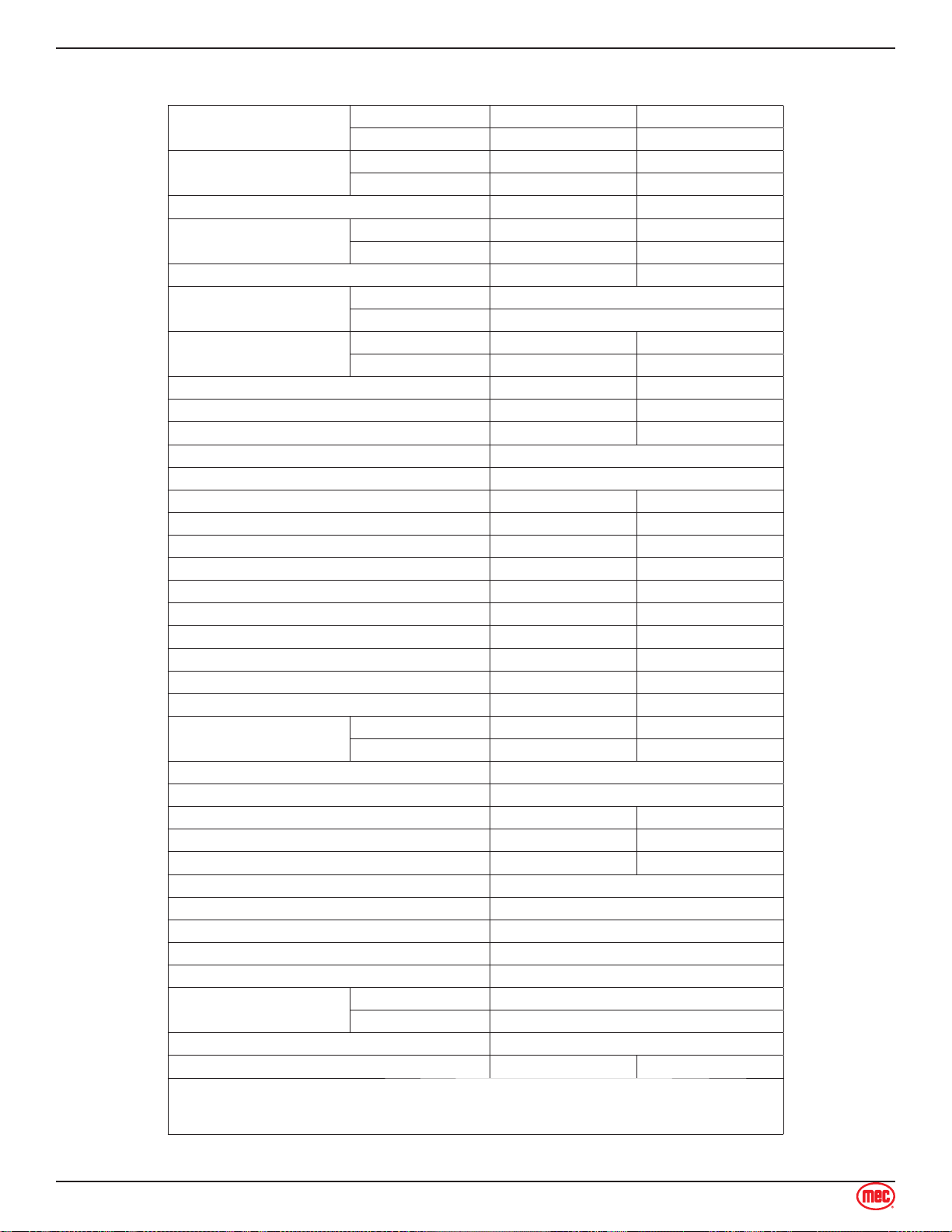

Specifications

Maximum Working Height* Indoor 19 ft 6 m

Outdoor 16 ft 4.9 m

Maximum Platform Height Indoor 13 ft 3.9 m

Outdoor 10 ft 3 M

Maximum Drive Height 13 ft 4 m

Stowed Height Top Guardrail 74 in 1.9 m

Platform Floor 35 in 0.9 m

Guardrail Height 39 in 1 m

Personnel Capacity Indoor 2

Outdoor 1

Manual Force Indoor 90 lbs 400 N

Outdoor 45 lbs 200 N

Toeboard Height 6 in 15 cm

Machine Weight** (Unloaded) 1,980 lbs 900 kg

Maximum Lift Capacity 500 lbs 227 kg

Deck Extension Capacity 1 Person / 250 lb (113 kg)

Maximum Occupants 2

Length-Stowed (Overall) 58 in 1.5 m

Length-Stowed (Ladder Removed) 51 in 1.3 m

Platform Length (Extended) 75 in 1.9 m

Platform Length (Retracted) 51 in 1.3 m

Width (Overall) 30 in 76 cm

Platform Width (Outside) 27.5 in 70 cm

Wheel Base 41 in 1 m

Turning Radius - Inside 18 in 45 cm

Ground Clearance - Stowed 2.5 in 6 cm

Ground Clearance - Elevated 0.6 in 1.5 cm

Drive Speed (Proportional) Stowed 0-2.5 mph 0-4.0 km/h

Raised or Extended 0-0.7 mph 0-1.1 km/h

Gradability 25%/14°

Maximum Side Slope - Stowed 5°

Ground Pressure/Wheel 112 psi 7.9 kg/cm2

Maximum Wheel Load 750 lbs 340 kg

Occupied Floor Pressure 234 psf 1,138 kg/m2

Maximum Operating Wind Speed 28 mph / 12.5 m/sec (45 km/h)

Tire Size 9 x 3 inch / 230 x 80mm

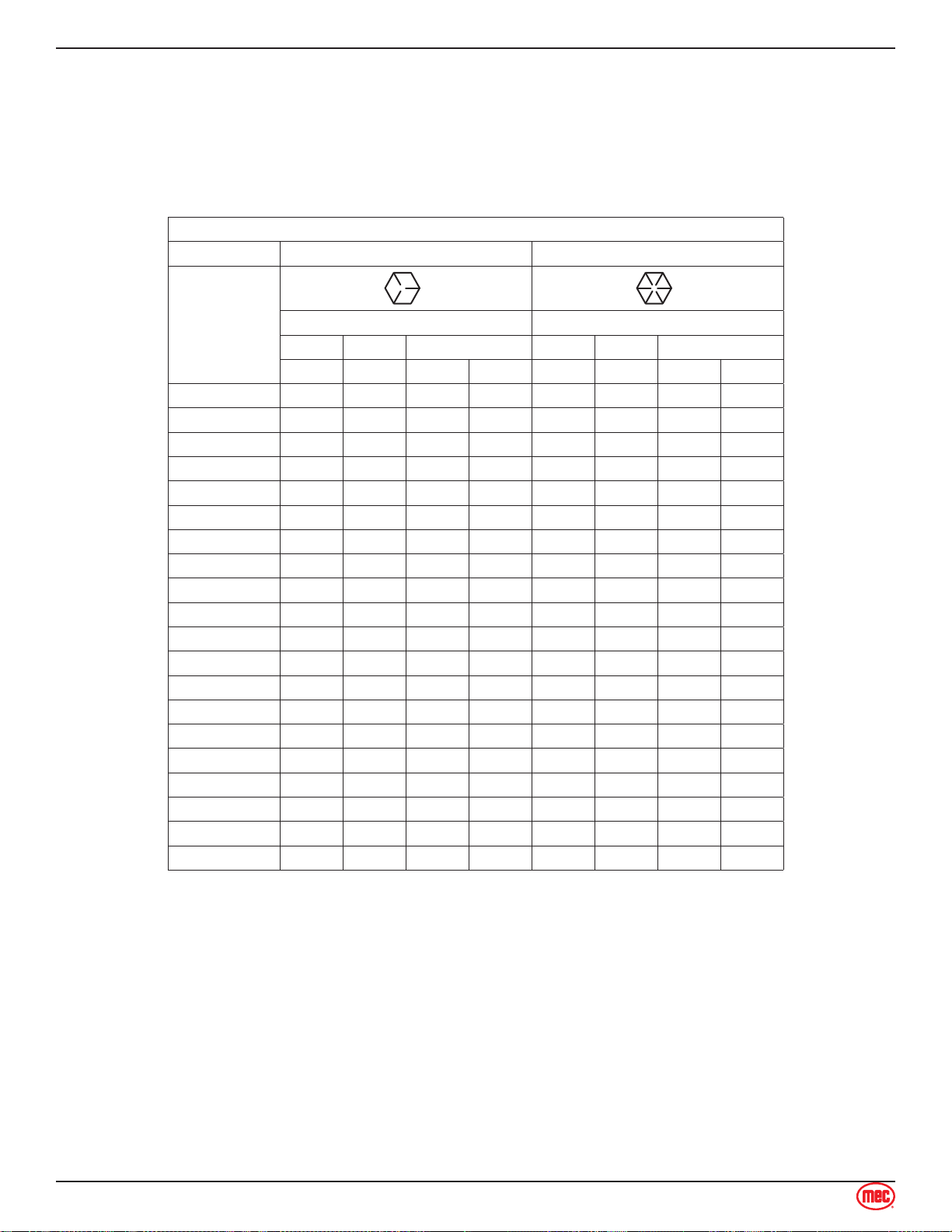

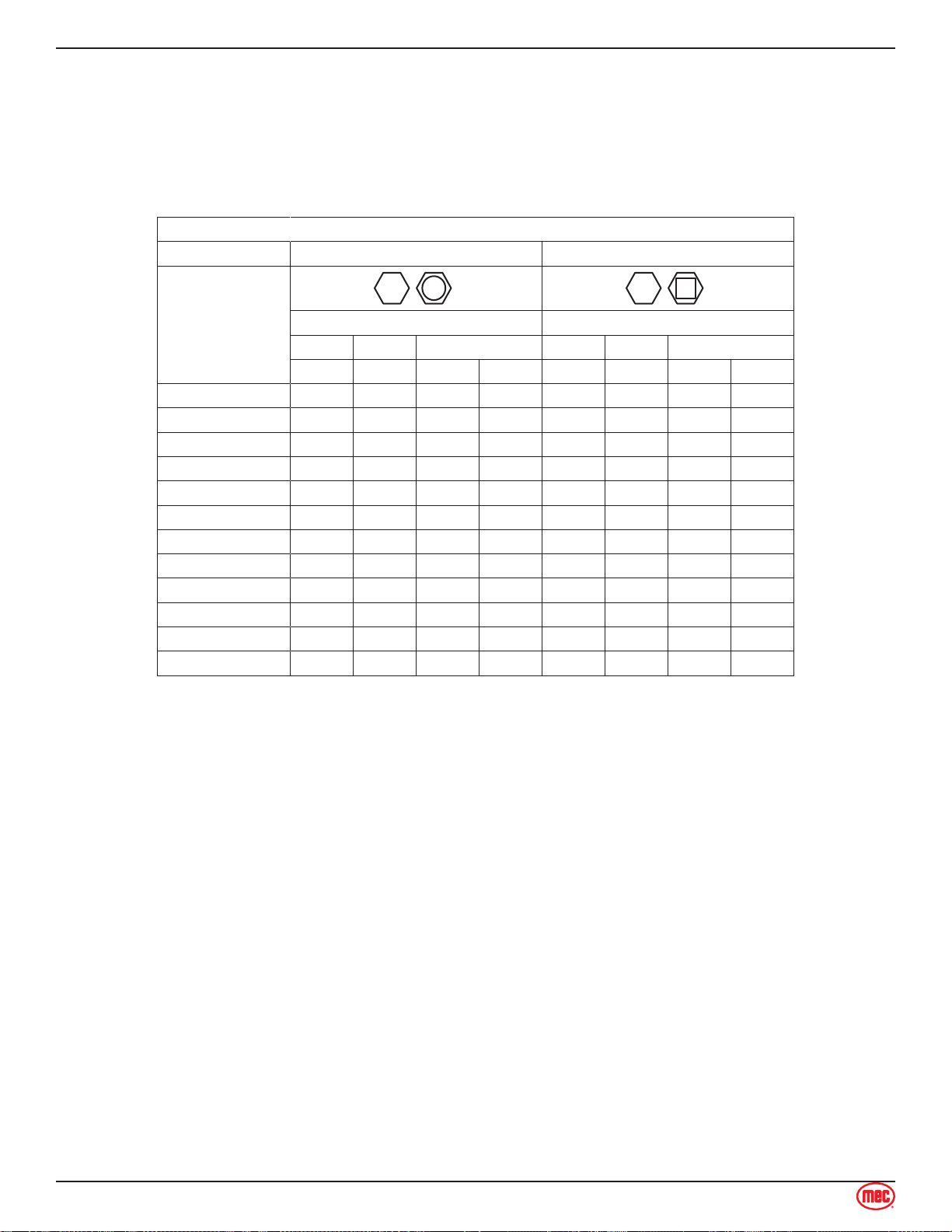

Lug Nut Torque 19 ft-lb / 25.5 Nm, secured with cotter pin

Hydraulic Pressure 2,250 psi / 155 bar

Power System Voltage 24 Volt DC

Battery Charger Input 110-230 V AC, 50-60 Hz

Output 24 Volt DC

Batteries Two 12-Volt deep cycle; 85Ah

Chassis Inclination 1.5 Side 3.0 Inline

Meets requirements of ANSI A92.20-2020 and CSA B354.6-2019.

*Working Height adds 6 feet (2 m) to platform height.

**Weight may increase with certain options.

Section 3 - Specifications Specifications