GA 5752 2806 GB 10 3

Table of contents

Table of contents

1 Introduction ..............................................................................................................................................5

1.1 Foreword ....................................................................................................................................................5

1.2 How to use these operating instructions .................................................................................................... 5

1.2.1 Abbreviations ............................................................................................................................... 5

1.2.2 Symbols ....................................................................................................................................... 5

1.2.2.1 Cross-references ....................................................................................................... 5

1.2.2.2 Actions and responses .............................................................................................. 5

1.2.3 Definitions .................................................................................................................................... 6

1.2.3.1 Design of safety notes ............................................................................................... 6

1.2.3.2 Structure of notes ...................................................................................................... 6

1.2.4 Symbols used .............................................................................................................................. 6

1.3 Disposal......................................................................................................................................................8

1.3.1 Packing ........................................................................................................................................ 8

1.3.2 ATMOS products.......................................................................................................................... 8

1.4 Overview ....................................................................................................................................................9

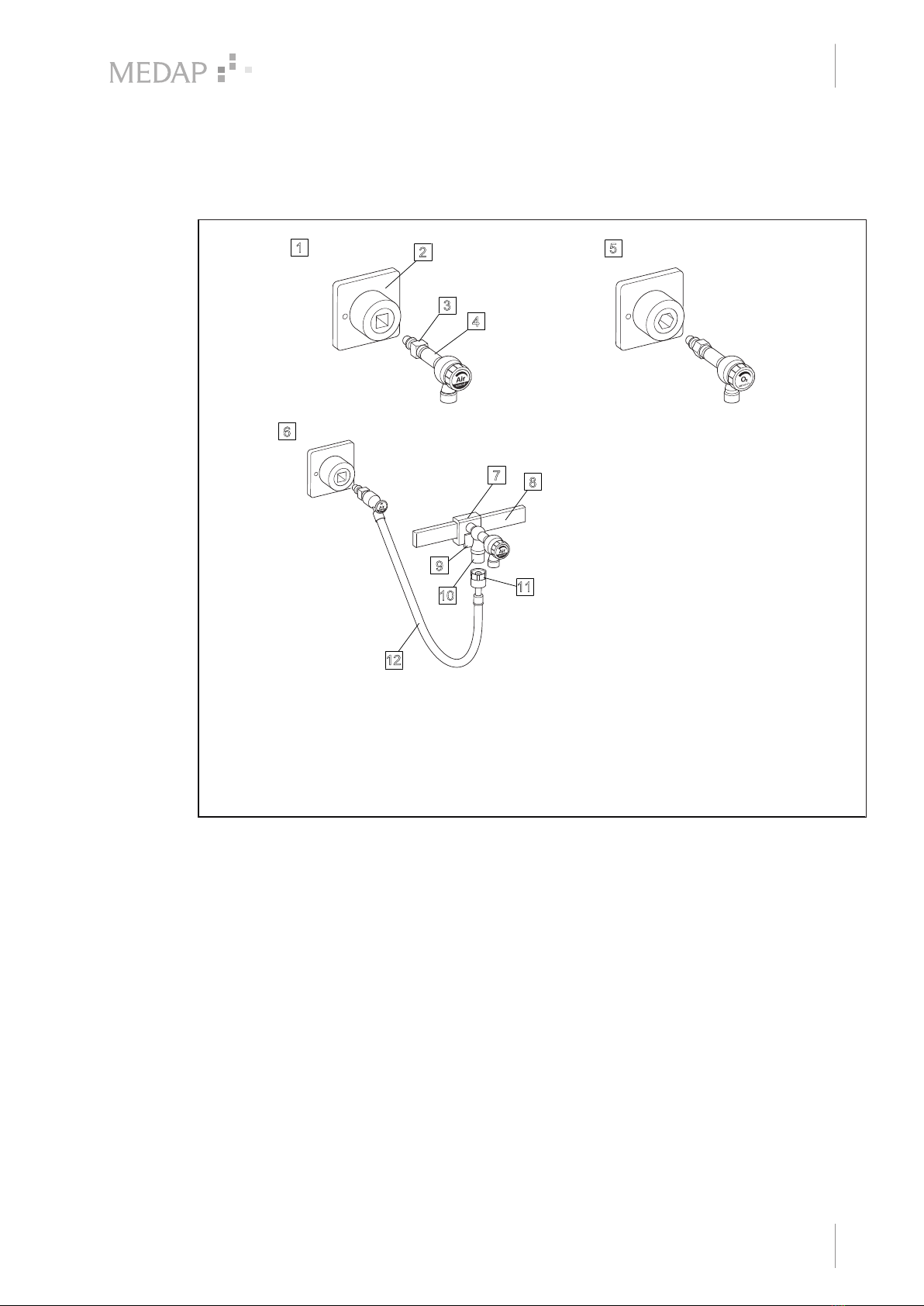

1.4.1 Overview of FINA fine regulator O2 / AIR .................................................................................... 9

1.4.2 Overview of FINA fine regulator versions, O2 / AIR ................................................................... 10

1.5 Basic requirements...................................................................................................................................10

1.5.1 Use in accordance with the intended purpose ........................................................................... 10

1.5.2 Applicable standards.................................................................................................................. 11

1.5.3 Intended purpose ....................................................................................................................... 11

1.5.4 Versions of FINA fine regulator O2 / AIR.................................................................................... 12

1.5.5 Possible applications ................................................................................................................. 13

1.5.6 Interface description................................................................................................................... 13

1.5.6.1 Approved interface for compressed gas supply ...................................................... 13

1.5.6.2 Dimensions for the gas type specific connection for compressed gas .................... 13

1.5.6.3 Fine regulator outlet................................................................................................. 13

1.5.6.4 Connection tube ...................................................................................................... 13

1.5.6.5 Tube adapter for Air and O2 .................................................................................... 14

1.5.6.6 Gas jet pump for Air and O2, with and without gauge ............................................. 14

2 Safety notes............................................................................................................................................15

2.1 General safety notes ................................................................................................................................ 15

2.2 Product safety notes.................................................................................................................................15

3 Initial operation.......................................................................................................................................17

3.1 Product testing .........................................................................................................................................17

3.2 Connection to the terminal unit.................................................................................................................17

3.2.1 General ...................................................................................................................................... 17

3.2.2 Version A.................................................................................................................................... 17