GA 5752 1555 DE 28

4

Table of contents

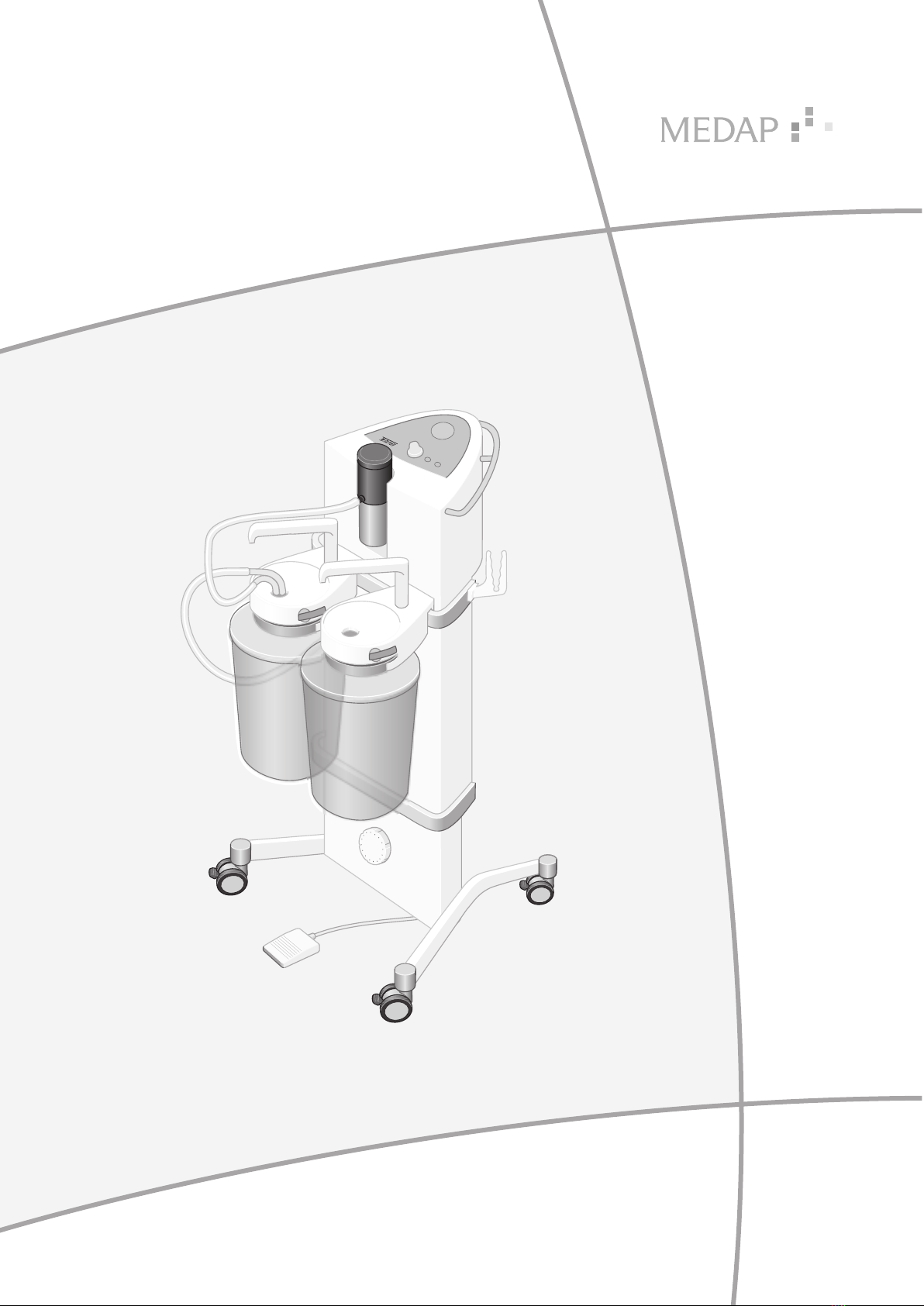

3.2 Scope of delivery...................................................................................................................................... 19

3.3 Mounting the stand................................................................................................................................... 20

3.4 Mounting the tube holder..........................................................................................................................23

3.5 Mounting the foot switch...........................................................................................................................23

3.6 Overflow protection device/tube connector .............................................................................................. 23

3.6.1 Mounting the mechanical overflow protection device (REF 5752 1775).................................... 24

3.6.1.1 Inserting the overflow protection device .................................................................. 24

3.6.2 Mounting the hydrophobic bacterial and viral filter (REF 5752 1783) in the mechanical overflow

protection device (REF 5752 1775) ........................................................................................... 25

3.6.3 Inserting the tube connector ...................................................................................................... 25

3.7 Mounting point for rail clamp (REF 5752 2048)........................................................................................ 26

3.8 Mounting the switch valve (REF 5752 2049)............................................................................................ 27

3.9 Mounting the tubes................................................................................................................................... 27

3.9.1 Mounting the tube to the overflow protection device.................................................................. 28

3.9.2 Mounting the tube to the tube connector ................................................................................... 28

3.9.3 Tube connection of overflow protection device with septic fluid jar cap (REF 5750 0390) ........ 29

3.9.4 Tube connection of overflow protection device with septic fluid jar cap (REF 5750 5362) ........ 29

3.9.5 Tube connection of overflow protection device with septic fluid jar cap (REF 5752 5432) ........ 30

3.9.6 Tube connection for vacuum shift (REF 5752 2049).................................................................. 30

3.10 Connecting/disconnecting the mains cable..............................................................................................31

4 Operation ................................................................................................................................................33

4.1 Functional test..........................................................................................................................................33

4.2 Suction .....................................................................................................................................................33

4.2.1 Switching on the aspirator.......................................................................................................... 35

4.2.2 Setting the vacuum level............................................................................................................ 35

4.2.3 Operating the footswitch ............................................................................................................ 36

4.2.4 Setting the vacuum shift............................................................................................................. 36

4.3 Replacing the bacterial filter paper........................................................................................................... 36

5 Taking the unit out of operation............................................................................................................ 38

5.1 Completing the aspiration process...........................................................................................................38

5.2 Emptying the septic fluid jar ..................................................................................................................... 38

5.3 Disassembly.............................................................................................................................................39

5.3.1 Detaching tubes ......................................................................................................................... 39

5.3.2 Removing the overflow protection device .................................................................................. 39

6 Cleaning and disinfection...................................................................................................................... 40

6.1 Cleaning ...................................................................................................................................................40

6.1.1 General ...................................................................................................................................... 40

6.1.2 General ...................................................................................................................................... 41

6.1.3 Cleaning procedure.................................................................................................................... 42

6.2 Disinfection...............................................................................................................................................42

6.2.1 General ...................................................................................................................................... 42