Megmeet L6 Series User manual

1

L6 Series Controller

Document Version: V1.0

Archive Date: 2021/09/02

BOM Code:

Shenzhen Megmeet Drive Technology Co., Ltd. provides full technical support for our

customers,customers can contact local Megmeet offices or customer service centers, or

directly contact Megmeet headquarters.

Shenzhen Megmeet Drive Technology Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Shenzhen Megmeet Drive Technology Co., Ltd.

Address: 5th Floor, Block B, Unisplendor Information Harbor, Langshan Rd., Science &

Technology Park, Nanshan District, Shenzhen, 518057, China

Website: www.megmeet-drivetech.com

Tel: +86-755-86600500

Fax: +86-755-86600562

2

Foreword

Thank you for choosing L6 series controller manufactured by Shenzhen Megmeet Drive Technology Co., Ltd.

L6 series controller has the following features for low voltage motors:

1. Optimized PID control algorithm implementation;

2. Adopt the electric differential speed control, which saves the front axle and differential and makes the

control more flexible;

3. Advanced pulse width modulation technology to ensure high efficiency of battery utilization and reduce loss

of motor energy consumption and torque conversion;

4. The online programming of the controller can guarantee the upgradeability of the product;

5. Through accurate speed closed loop and position closed loop control, tire wear can be minimized and the

service life of the equipment can be extended;

6. Using the CAN bus communication technology used in the automobile, it has the characteristics of large

communication data, fast communication speed, good fault tolerance and high reliability;

7. By detecting the steering angle of the steering wheel and different vehicle speeds, the control strategy

independently developed by MEGMEET is used to realize different functions such as turning, speed limiting

and braking recovery. In addition, according to the different needs of customers, ESP electronic body

stabilization function can be realized;

8. Battery electrode reverse connection protection, output drive short circuit, charging fault alarm, overheat

protection, contactor adhesion alarm provides protection for motor and electronic control;

9. With the development of automation and intelligence in the future, the technology and products can be

applied to high-power AGV systems, automatic forklift control systems, battery touring buses, golf carts, lawn

mowers, cleaning vehicles, etc., realizing intelligent, unmanned development;

10. It can be directly connected to the host computer to monitor the running status of the vehicle in real time;

11. The product is completely autonomous design and can be customized according to customer needs.

Highlight the customer's product features;

12. Compared with foreign products, this product has higher cost performance and the overall cost can be

close to the counterbalance forklift, but the flexibility is better than the counterbalance forklift.

The relevant precautions during the installation, wiring, parameter setting, troubleshooting and daily

maintenance will be detailed in this manual. To ensure the correct installation and operation of the L6 series

controller as well as its high performance, please read carefully this user manual before installing the

equipment. This manual shall be kept properly and delivered to the actual users of the drive.

Precautions for unpacking inspection

Please check carefully when unpacking the product:

·Whether the product has the damage signs;

·Whether the rated value in the nameplate is consistent with your order requirement.

3

We have implemented strict inspection on the manufacturing, package and delivery of the product. If there is

any error, please contact us or your distributor immediately.

We are engaged in the continuous improvement of controller. The relevant manuals provided by us are

subject to change without prior notice.

Safety precautions

Operation without following instructions can cause death or severe personal injury.

Operation without following instructions can cause medium or slight personal injury or

damage to the product and other equipment.

·Please install the product on the incombustible materials (e.g., metal), otherwise, fire may be caused.

·Do not place any combustible material near the product, otherwise, fire may be caused.

·Do not install the product in the environment with explosive gas, otherwise, explosion may be caused.

·Only qualified personnel can wire the drive, otherwise, electric shock may be caused.

·Never wire the controller unless the input AC supply is completely disconnected, otherwise, electric shock

may be caused.

·The grounding terminal of the controller must be reliably grounded, otherwise, electric shock may be

caused.

·The cover must be properly closed before power-up, otherwise, electric shock and explosion may be

caused.

·When powering up the controller that has been stored for over 2 years, the input voltage must be gradually

increased with the voltage regulator, otherwise, electric shock and explosion may be caused.

·Do not touch the terminals when the product is powered up, otherwise, electric shock may be caused.

·Do not operate the controller with wet hands, otherwise, electric shock may be caused.

·Maintaince operation can not be conducted until 10 minutes has passed after disconnecting the power

supply. Meanwhile, be sure to confirm that the chage LED is completely off and the DC bus voltage is

below 36V, otherwise, electric shock may be caused.

·Only qualified personnel can replace the components. Do not leave any wire or metal parts inside the

drive, otherwise, fire may be caused.

·After changing the control board, the parameters must be properly set before operating the drive,

otherwise, property damage may be caused.

·The bare parts of the terminal lugs in the main circuit must be wrapped with insulation tape, otherwise,

electric shock may be caused.

4

·When carrying the drive, protect the operation panel and the cover against any stress, otherwise, the drive

may drop and cause human injury or property damage.

·Please install the controller on the place that can withstand the weight of the drive, otherwise, the drive

may drop and cause human injury or property damage.

·Do not install the controller in the environment with water splash (e.g., near the water pipe), otherwise, you

may suffer the property loss.

·Take care not to drop any foreign objects, such as the screws, gaskets and metal bars, into the controller,

otherwise, fire and property damage may be caused.

·Do not install and operate the controller if it is damaged or its components are not complete, otherwise, fire

and human injury may be caused.

·Do not install the product in the place exposed to direct sunlight, otherwise, property damage may be

caused.

·Cable lugs must be firmly connected to the terminals of main circuit, otherwise, property damage may be

caused.

5

Contents

Chapter 1 Introduction of L6 Series Controller..............................................................................6

1.1 Introduction................................................................................................................................................................. 6

1.2 Product model............................................................................................................................................................6

1.3 Product nameplate....................................................................................................................................................6

1.4 Product series............................................................................................................................................................ 7

1.5 Technical specifications of product........................................................................................................................8

1.6 Outline, mounting dimensions and gross weight of controller........................................................................ 9

1.7 MEGMEET controller instrumentation................................................................................................................14

1.8 Product use environment and installation requirements................................................................................20

Chapter 2 Wiring of Controller.......................................................................................................22

2.1 Wiring and configuration of main circuit terminals...........................................................................................22

2.2 Wiring and configuration of control circuit......................................................................................................... 27

Chapter 3 Quick Operation Guide for Controller........................................................................ 30

3.1 Controller operation panel.....................................................................................................................................30

3.2 LED description....................................................................................................................................................... 30

3.3 Introduction to operation panel keys...................................................................................................................31

3.4 Identification of LED display symbols.................................................................................................................32

3.5 LED interface definition......................................................................................................................................... 32

Chapter 4 Parameter List............................................................................................................... 33

4.1 Basic menu function code parameter table.......................................................................................................33

Chapter 5 L6 Series Controller Debugging Steps...................................................................... 59

5.1 L6 series controller installation preparation...................................................................................................... 59

5.2 L6 series controller detection............................................................................................................................... 59

5.3 L6 series controller debugging.............................................................................................................................61

5.4 Controller and motor matching.............................................................................................................................63

5.5 Measurement........................................................................................................................................................... 64

Chapter 6 Troubleshooting.............................................................................................................66

6.1 LED indicator display mode..................................................................................................................................66

6.2 Alarm code table......................................................................................................................................................66

6.3 Fault code table.......................................................................................................................................................67

6.4 DIDO function definition.........................................................................................................................................69

Appendix 1 Precautions..................................................................................................................71

Appendix 2 Warranty and Service................................................................................................ 73

6

Chapter 1 Introduction of L6 Series Controller

1.1 Introduction

This series of controller is a low voltage DC input, high current output AC motor controller, powered by a

battery system, can be used in electric forklifts, battery touring buses, golf carts, lawn mowers, cleaning cars,

AGV cars and various small passenger cars.

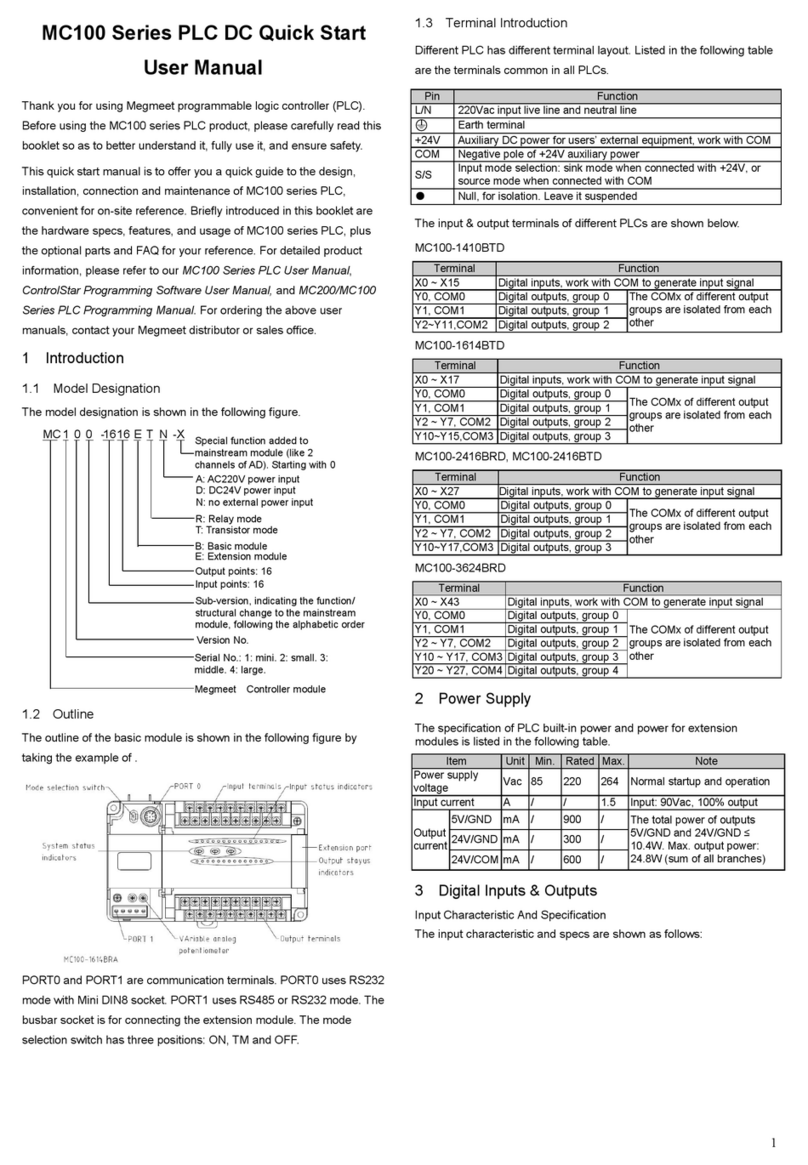

1.2 Product model

The description of the controller model on the nameplate indicates the information of the product, such as

product series, voltage class of power supply, power class, the software/hardware code of customized

product, etc.

1.3 Product nameplate

Shenzhen Megmeet Drive Technology Co., Ltd.

MODEL

VOLTAGE

CURRENT

S/N

: L 6 3 6 -4 8 4 5 -P

: 4 8 V

: 4 5 0 A

0100 0000 0100 0000

E6120009820187000019 L636-4845-P

:

7

1.4 Product series

Table 1-1 Name and model of controller

Model

Voltage

level

Operating

voltage range

Power supply

starting voltage

Output current

IP

rating

Cooling

method

1

hour

2 min

1 min

30 s

L632-2420

24VDC

20V~28V

18V

150A

200A

*

*

IP65

Natural

cooling

L632-2437

24VDC

20V~28V

18V

185A

375A

*

*

IP65

Natural

cooling

L632-4827

48VDC

33V~60V

28.8V

120A

275A

*

*

IP65

Natural

cooling

L632-4835

48VDC

33V~60V

28.8V

175A

350A

*

*

IP65

Natural

cooling

L636-4845

48VDC

33V~60V

28.8V

150A

450A

*

*

IP65

Natural

cooling

L636-8035

80VDC

56V~96V

48V

120A

350A

*

*

IP65

Natural

cooling

L636-8045

80VDC

56V~96V

48V

150A

450A

*

*

IP65

Natural

cooling

L636-9620

96VDC

72V~120V

65V

90A

200A

*

*

IP65

Natural

cooling

L636-1420

144VDC

105V~165V

100V

90A

200A

*

*

IP65

Natural

cooling

L638-4865

48VDC

33V~60V

28.8V

200A

650A

*

*

IP65

Natural

cooling

L638-8050

80VDC

56V~96V

48V

155A

500A

*

*

IP65

Natural

cooling

L638-8065

80VDC

56V~96V

48V

200A

650A

*

*

IP65

Natural

cooling

L638-9650

96VDC

72V~120V

65V

155A

500A

*

*

IP65

Natural

cooling

L638-1435

144VDC

105V~175V

96V

100A

350A

*

*

IP65

Natural

cooling

L638-1450

144VDC

105V~175V

96V

135A

*

500A

*

IP65

Natural

cooling

L640-4D12

300VDC

250V~410V

*

53A

*

110A

*

IP67

Natural

cooling

L640-4D20

300VDC

250V~410V

*

96

*

192A

*

IP67

Air

cooling

L640-4D30

320VDC

250V~410V

*

120A

*

*

260A

IP67

Water

cooling

L650-5D60

500VDC

450V~600V

*

150A

*

*

300A

IP67

Water

cooling

8

L650-5D90

500VDC

450V~600V

*

225A

*

*

450A

IP67

Water

cooling

L650-5DB0

500VDC

450V~600V

*

300A

*

*

600A

IP67

Water

cooling

Note: 96V and 144V models are being developed, * indicates that there is no such parameter.

1.5 Technical specifications of product

Table 1-2 Technical specifications of controller

Control

features

Control mode

Closed loop vector, IF mode, VF mode

Maximum output

frequency

300Hz

Product

functions

Basic frequency

0Hz~300.0Hz

Startup

frequency

0Hz~60.00Hz

PWM frequency

16kHZ

Logic input

current

<10mA

Over

temperature

protection

Pre-alarm at 75°C, cut off at 95°C

Radiator

insulation

strength

500Vac

Protection

degree

IP65

Cooling mode

Natural cooling (vehicle large heat sink), otherwise forced air cooling is required

Application

place

Used for a variety of electric vehicles, including material handling vehicles, industrial

vehicles, golf carts, off-highway vehicles and other low-speed vehicles.

Battery status

Have

Timer function

Have

Host computer

detection

function

Waveform status detection, IO port status detection, parameter online upload,

download

CANopen

communication

High-speed CAN communication, stable and timely monitoring of the working status of

the controller

Handheld

controller

Programmable control of the controller through the handheld controller

Protection

function

Over-voltage protection; over-current protection; over-temperature protection; power-on open circuit

protection; tire angle sensor fault; accelerator pedal fault; overload protection; contactor suction fault;

contactor open fault; long charging time protection; charging failure protection; current detection abnormal

protection; KSI startup abnormal protection; encoder fault; CAN communication fault.

Environment

Operating site

No condensation, icing, rain, snow, hail, etc., solar radiation is less than 700W/m2, air

9

pressure is 70~106kPa.

Altitude

Used at the place lower than 1000m (derated at the place above 1000m, derated 1%

for every increase of 100m)

Ambient

temperature

-30℃~+50℃(derated when used in the ambient temperature of 40℃~50℃)

Humidity

5%~95%RH, non-condensing

Vibration

Less than 9.8m/s2(1g)

Storage

temperature

-40℃~+70℃

1.6 Outline, mounting dimensions and gross weight of controller

The dimensions of the controller are as follows:

Fig. 1-1 Outline, mounting dimensions of L632

10

Fig. 1-2 Outline, mounting dimensions of L636

11

Fig. 1-3 Outline, mounting dimensions of L638

12

Fig. 1-4 Outline, mounting dimensions of L640

13

Fig. 1-5 Outline, mounting dimensions of L650

Table 1-3 Outline, mounting dimensions and gross weight

Model

Gross weight (kg)

Dimension(mm)

L632-2420

2.23

180*140*73.5

L632-2437

L632-4827

L632-4835

L636-4845

4.12

244*165*92

L636-8035

L636-8045

L636-9620

L636-1420

L638-4865

6

244*275*92

L638-8050

L638-8065

L638-9650

14

L638-1435

L638-1450

L640-4D12

5.6

322*242*271.5

L640-4D20

5.6

322*242*127.5

L640-4D30

5.4

322*242*131.5

L650-5D60

11.5

417*280.4*175

L650-5D90

L650-5DB0

Note: 96V and 144V models are being developed.

1.7 MEGMEET controller instrumentation

1.7.1 Product model description

1.7.2 Product series

Model

Voltage

level

Operating

voltage range

Power supply

starting voltage

IP rating

Operating

ambient

temperature

Cooling method

P6-24

24VDC

11V~48V

11V

IP65

-20℃~+70℃

Natural cooling

P6-80

80VDC

48V~90V

48V

1.7.3 Features

15

Description of fault light flashing

No.

Fault light

Fault description

Troubleshooting

1

Communication fault

light flashing

The communication between

the instrumentation and the

controller is abnormal.

Check whether the communication

cable is connected correctly

2

Handbrake light stays

on

The handbrake switch is pulled

up

Release the handbrake switch

3

Seat fault light

flashing

Driver leaves the seat

The driver needs to be seated

correctly in the driver's seat

4

Battery fault light

flashing

Battery level is below 15%

Need to charge the battery

1.7.4 Main interface

Enter the menu

Back to previous menu level

Cursor up

Cursor down

Communication

fault light

Hand brake light

Seat switch fault

light

Low battery fault

light

16

1. Battery level display, display value is 0% ~ 100%;

2. WORKED: The instrumentation 's working time is counted, and it starts to count after power on;

3. T: The communication status with the main drive is displayed, OK is displayed when the communication is

normal, and a corresponding fault function code appears when the communication is abnormal;

4. P: The communication status with the pump drive is displayed, OK is displayed when the communication is

normal, and a corresponding fault function code appears when the communication is abnormal;

5. ●: Gear status display. When the lever is turned, three states ( forward), ●(neutral) and

(backward) are displayed.

6. 0.0Km / h: Vehicle running speed display.

1.7.5 Menu interface

1.First-level menu bar

In hours

Communication with

the main drive

Communication with

pump drive

High and low

speed modes

Forward, backward and

neutral position display

Battery level display

Speed display

Icon display bar

17

Entry method: In the case of the main interface, press key once to enter the first-level menu. The first-level

menu includes the “TESTER” and “SETTING” second-level menus.

Exit method: Press once to exit the menu and return to the main interface.

2. TESTER second-level menu bar

Entry method: With the cursor in "TESTER", press the key once to enter the second-level menu; the

"TESTER" submenu includes "CURRENT (output current)", "MOTOR SPEED (motor speed)", "MOTOR

TEMP ( Motor temperature), CNTRL TEMP (drive temperature).

Exit method: press key once to return to the first-level menu, press again to exit the menu and return to

the main interface.

3. SETTING second-level menu bar

The second-level menu bar is mainly used to modify the parameters. You need to enter the password before

changing the parameters.

18

Entry method: In the case of the main interface, press once, then press ▼again, move the cursor to

SETTING, and then press to enter the hour meter clear input password interface, press ▲key, enter the

first password, and then press ▼to enter into the second password change, input the four digit password in

sequence, and press the confirm button to clear the hour meter.

Exit method: press key once to return to the first-level menu, press again to exit the menu and return to

the main interface.

1.7.6 Dimensions

Length * width * height = 180MM * 120MM * 58.5MM

19

1.7.7 Terminal definition

Pin

Definition

Description

J1-PIN1

BATTERY+

Connect to battery positive, 18-90V DC input

J1-PIN2

BATTERY-

Connect to battery negative, 0V

J1-PIN3

SENDER1

0-3.3V analog input

J1-PIN4

SENDER2

0-3.3V analog input

J1-PIN5

SENDER3

0-5V analog input

J1-PIN6

SENDER4

0-5V analog input

J1-PIN7

Switched-input1

Digital input 1, active high

J1-PIN8

Switched-input2

Digital input 2, active high

J1-PIN9

Switched-input3

Digital input 3, active high

J1-PIN10

Switched-input4

Digital input 4, active high

J1-PIN11

Switched-input5

Digital input 5, active high

J1-PIN12

Switched-input6

Digital input 6, active high

J1-PIN13

KEY-Switched-input

Key switch input, active high

J1-PIN14

Mosfet-out1

Drive output 1, open collector

J1-PIN15

Mosfet-out2

Drive output 2, open collector

J1-PIN16

Mosfet-out3

Drive output 3, open collector

J1-PIN17

NC

20

J1-PIN18

SENDER

0-5V analog input

J1-PIN19

NC

J1-PIN20

NC

Pin

Definition

Description

J2-PIN1

CAN-H

Communication with the drive CAN-H

J2-PIN2

CAN-L

Communication with the drive CAN-L

J2-PIN3

GND

Connect to battery negative

J2-PIN4

J2-PIN5

CAN-H

CAN communication terminal resistance strobe, short

with J2-PIN6 when needed

J2-PIN6

CAN-TERM

CAN communication terminal resistance strobe, short

with J2-PIN5 when needed

J2-PIN7

RS485-

Reserved for 485- communication, for external card

charging terminal

J2-PIN8

RS485+

Reserved for 485+ communication, for external card

charging terminal

J2-PIN9

J2-PIN10

GND

Grounding

J2-PIN11

J2-PIN12

+7Vout

7V power output, output current 0.1A

1.8 Product use environment and installation requirements

When selecting the installation environment, the following issues should be taken into account:

• The controller should be fixed on a clean and flat metal plate, and evenly apply a proper amount of thermal

silica between the bottom of the controller and the metal plate. The metal plate is generally selected from an

aluminum plate.

• The installation position of the controller should be selected where the ventilation and heat dissipation are

good.

• Keep the controller and its vicinity clean.

• The ambient temperature should be within -20℃~50℃. If the temperature exceeds 50℃, external forced

cooling or derating is required.

• The humidity should be less than 95%RH, non-condensing.

• The vibration at the installation place should be less than 5.9m/s2(0.6g).

• The device should be protected from the direct sunlight.

• Do not install the device in the place with corrosive gas and explosive gas.

Electrical connection requirements:

• The main fuse and control loop fuse must be installed, and the specifications should match the maximum

current value of the controller;

This manual suits for next models

21

Table of contents

Other Megmeet Controllers manuals

Megmeet

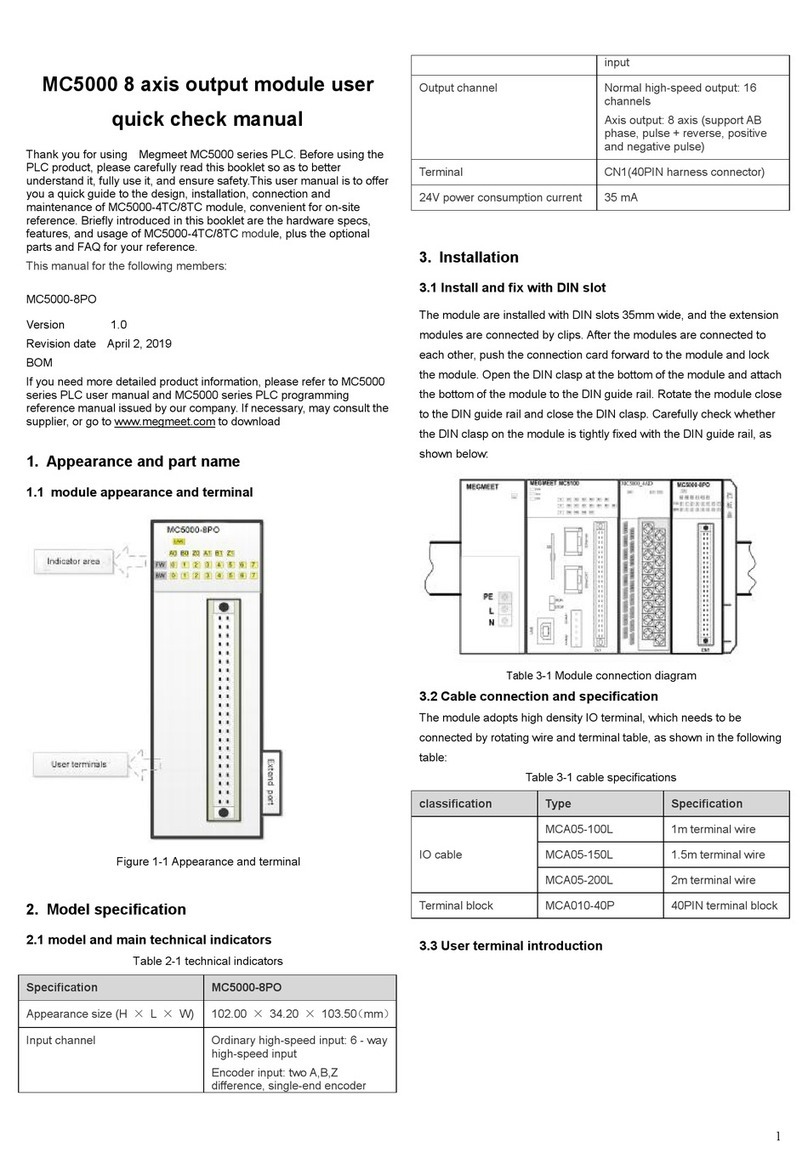

Megmeet MC5000 Series User manual

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MCCD Series Service manual

Megmeet

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC100 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MC200E Series Manual

Popular Controllers manuals by other brands

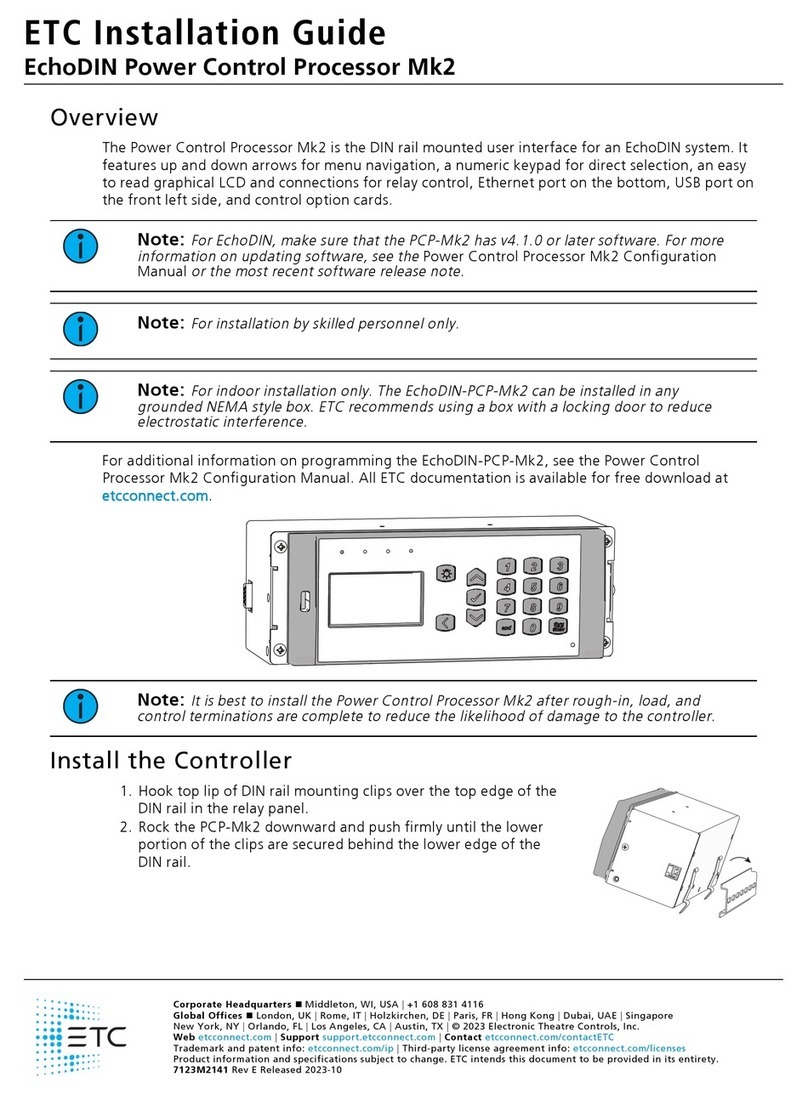

ETC

ETC EchoDIN Power Control Processor Mk2 installation guide

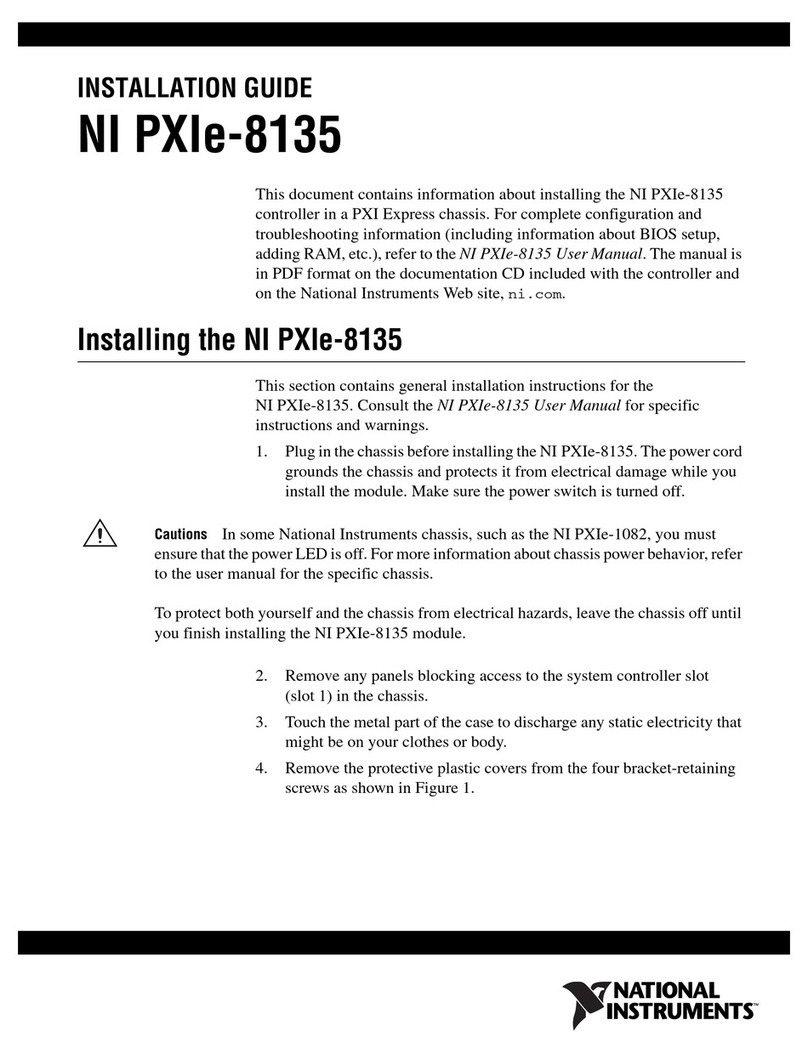

National Instruments

National Instruments NI PXIe-8135 installation guide

Computer Automation

Computer Automation CAT-200B manual

Evco

Evco EVRS225 manual

Rockwell Automation

Rockwell Automation PowerFlex 700S installation instructions

Siemens

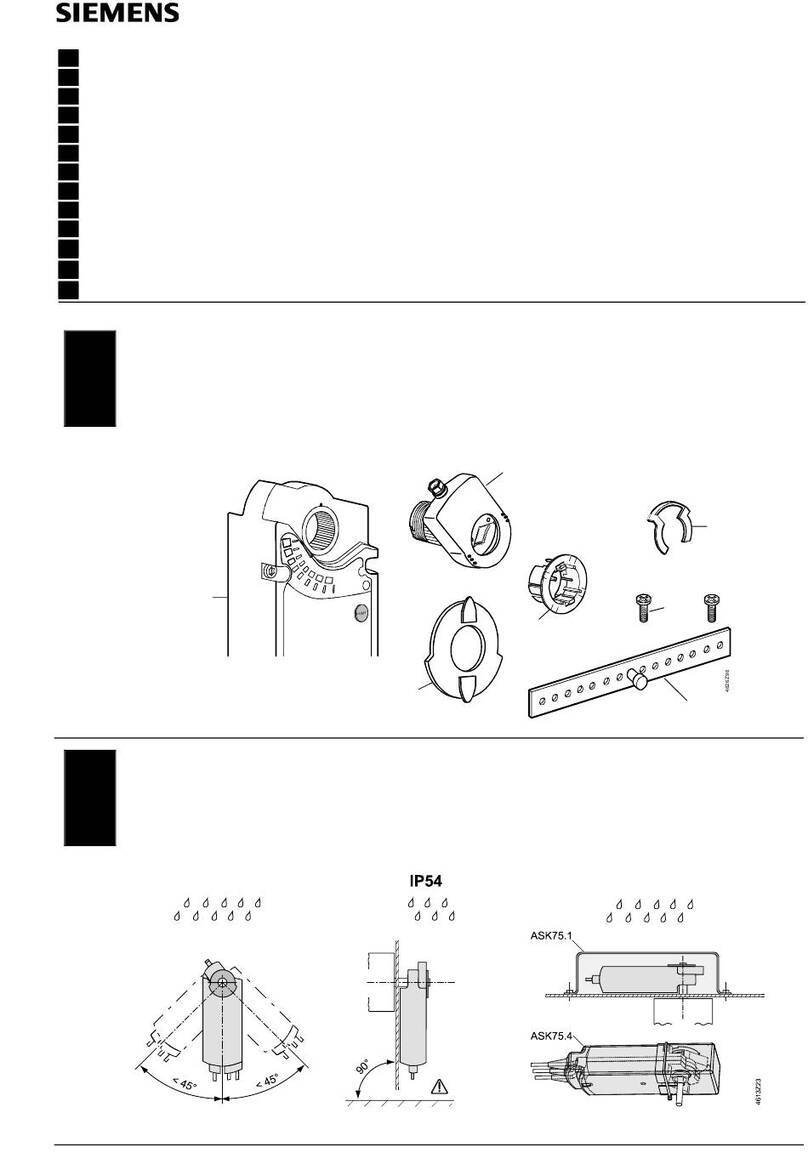

Siemens GBB 1E Series Mounting instructions