Megmeet MC5000 Series User manual

1

MC5000 8 axis output module user

quick check manual

Thank you for using Megmeet MC5000 series PLC. Before using the

PLC product, please carefully read this booklet so as to better

understand it, fully use it, and ensure safety.This user manual is to offer

you a quick guide to the design, installation, connection and

maintenance of MC5000-4TC/8TC module, convenient for on-site

reference. Briefly introduced in this booklet are the hardware specs,

features, and usage of MC5000-4TC/8TC module, plus the optional

parts and FAQ for your reference.

This manual for the following members:

MC5000-8PO

Version 1.0

Revision date April 2, 2019

BOM

If you need more detailed product information, please refer to MC5000

series PLC user manual and MC5000 series PLC programming

reference manual issued by our company. If necessary, may consult the

supplier, or go to www.megmeet.com to download

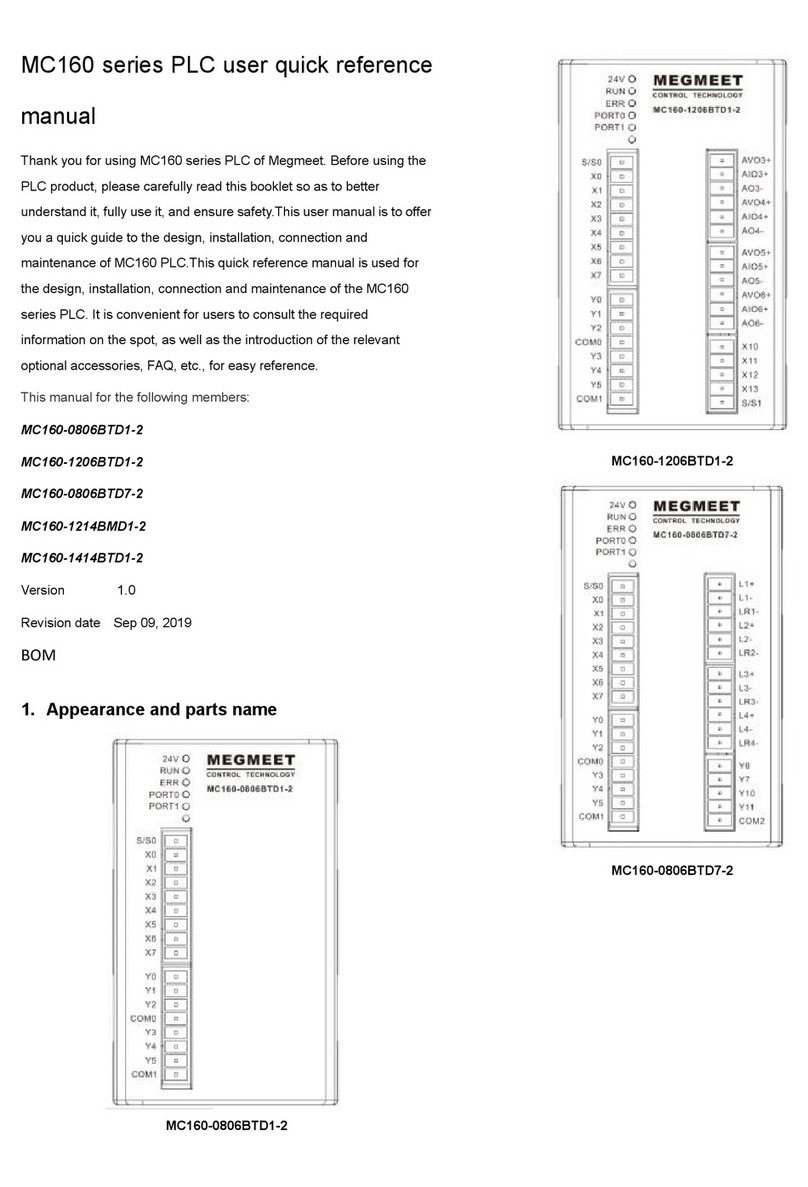

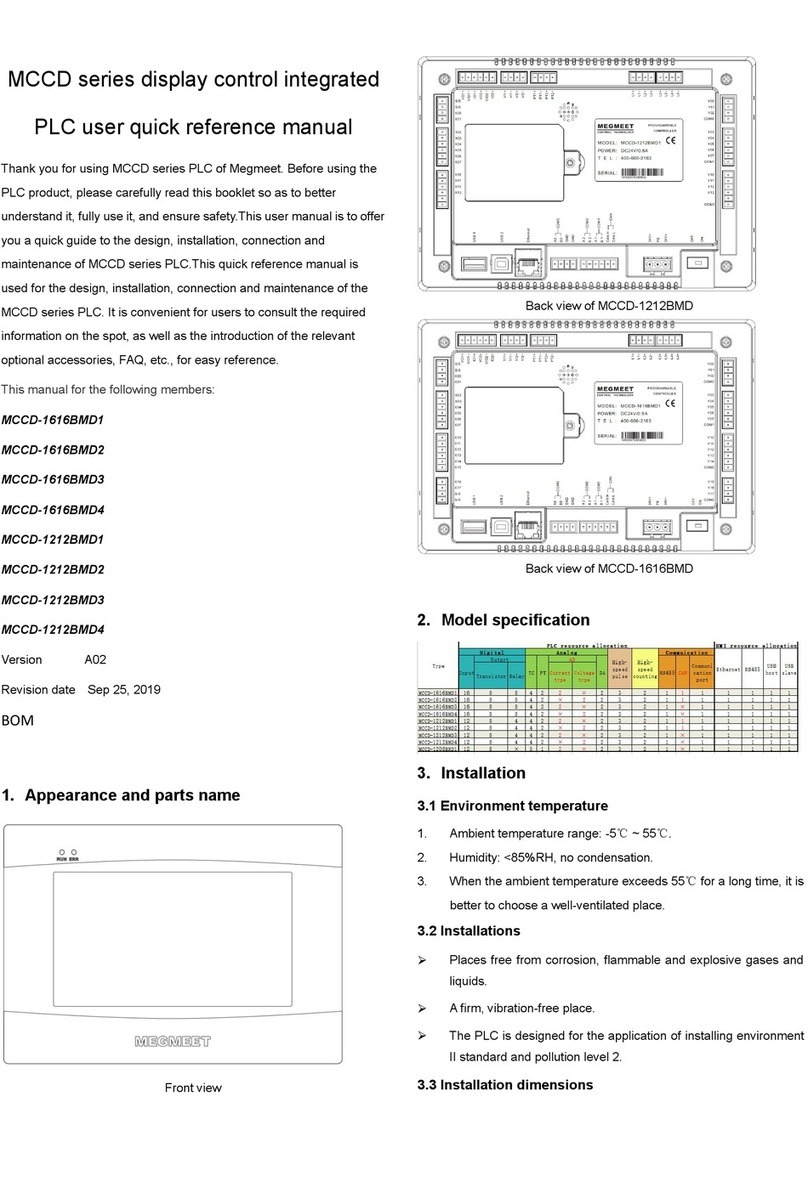

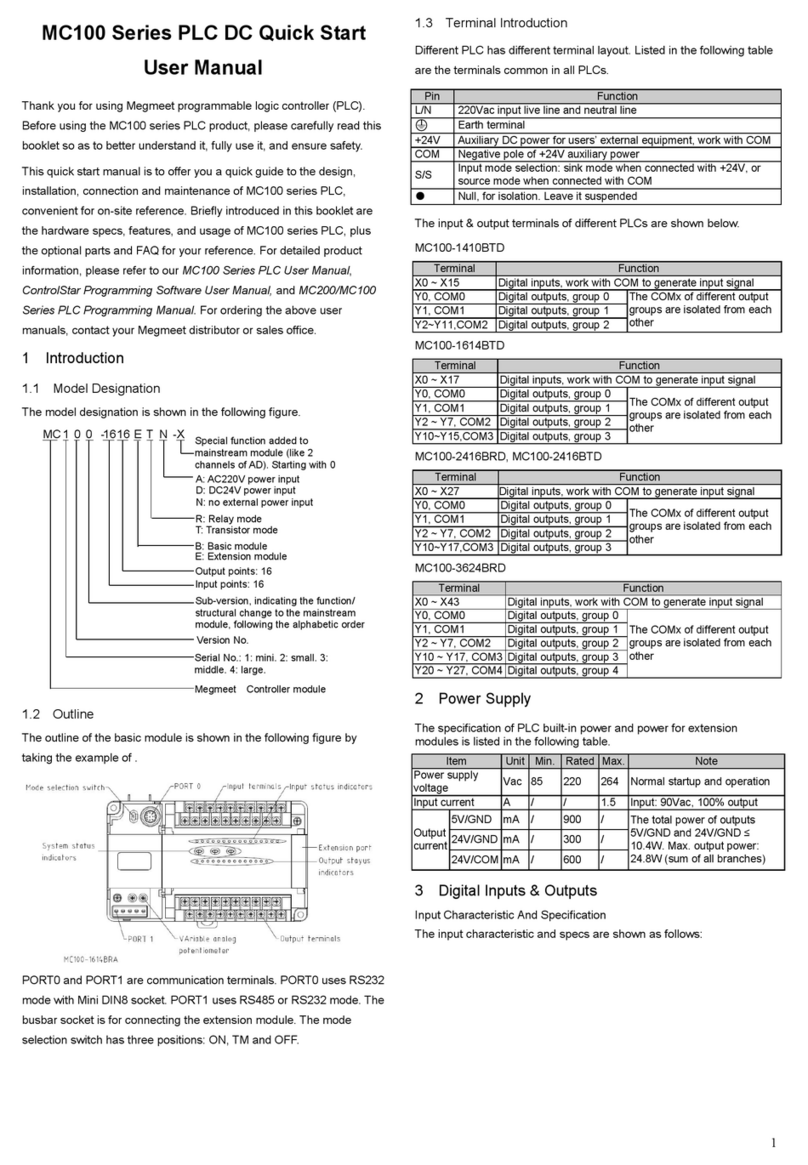

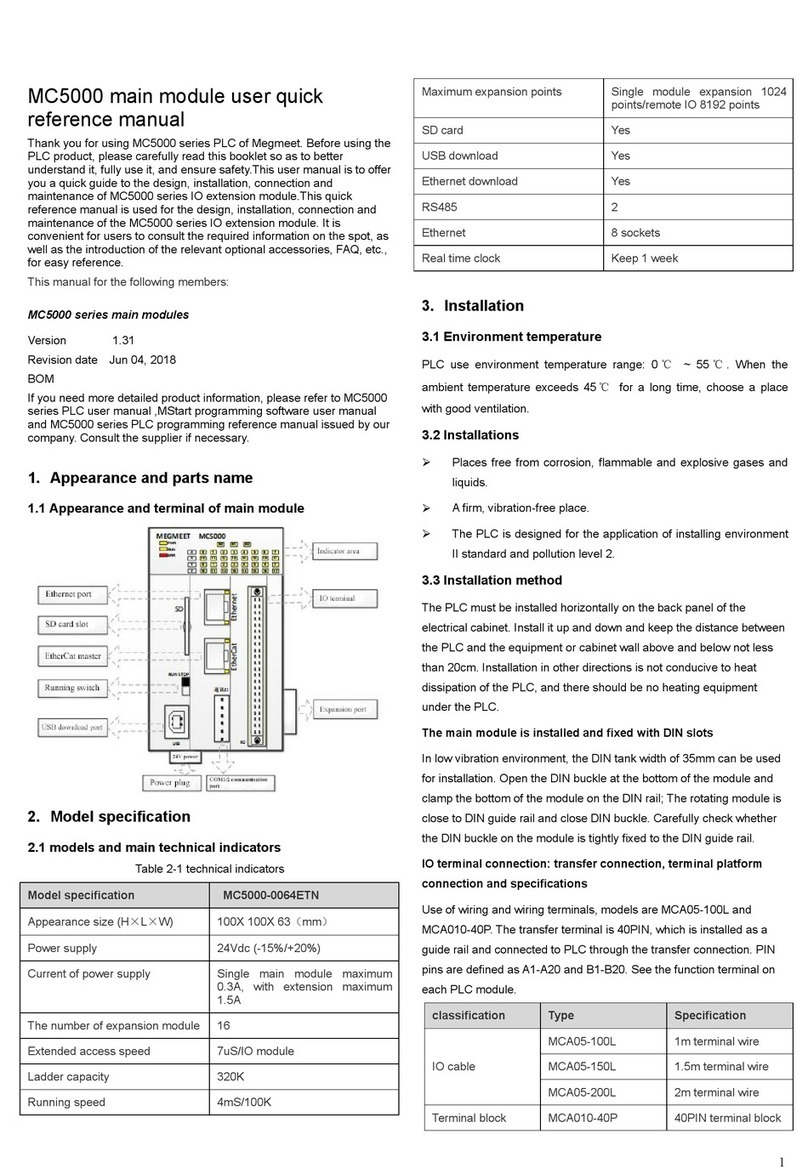

1. Appearance and part name

1.1 module appearance and terminal

Figure 1-1 Appearance and terminal

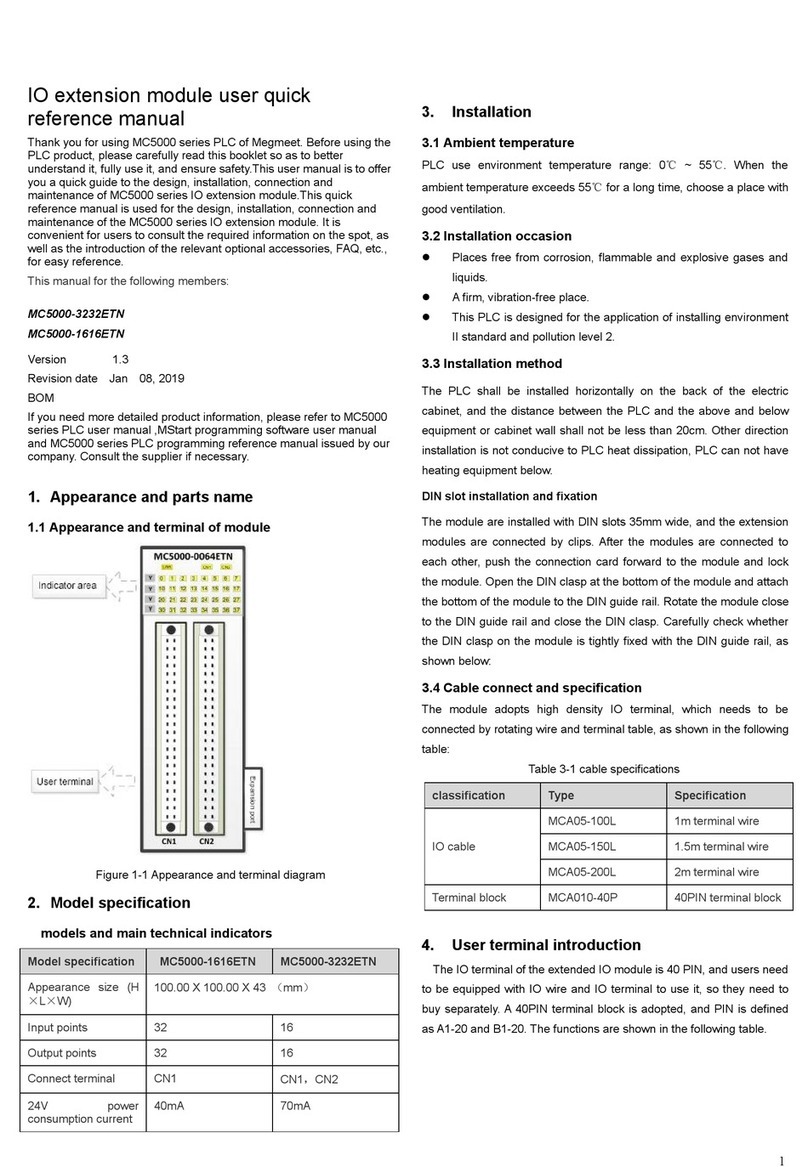

2. Model specification

2.1 model and main technical indicators

Table 2-1 technical indicators

Specification

MC5000-8PO

Appearance size (H ×L×W)

102.00 ×34.20 ×103.50(mm)

Input channel

Ordinary high-speed input: 6 - way

high-speed input

Encoder input: two A,B,Z

difference, single-end encoder

input

Output channel

Normal high-speed output: 16

channels

Axis output: 8 axis (support AB

phase, pulse + reverse, positive

and negative pulse)

Terminal

CN1(40PIN harness connector)

24V power consumption current

35 mA

3. Installation

3.1 Install and fix with DIN slot

The module are installed with DIN slots 35mm wide, and the extension

modules are connected by clips. After the modules are connected to

each other, push the connection card forward to the module and lock

the module. Open the DIN clasp at the bottom of the module and attach

the bottom of the module to the DIN guide rail. Rotate the module close

to the DIN guide rail and close the DIN clasp. Carefully check whether

the DIN clasp on the module is tightly fixed with the DIN guide rail, as

shown below:

Table 3-1 Module connection diagram

3.2 Cable connection and specification

The module adopts high density IO terminal, which needs to be

connected by rotating wire and terminal table, as shown in the following

table:

Table 3-1 cable specifications

classification

Type

Specification

IO cable

MCA05-100L

1m terminal wire

MCA05-150L

1.5m terminal wire

MCA05-200L

2m terminal wire

Terminal block

MCA010-40P

40PIN terminal block

3.3 User terminal introduction

2

Module IO Block Wiring terminal

The IO terminal CN1 of Mc5000-8po is defined in table 3-2

Table 3-2 CN1 terminal definition table

Funct

ion

defini

tion

Signal name

Terminal

silk screen

Function

definition

Funct

ion

defini

tion

IN0+

A0 input

positive

B20

A20

A1 input positive

IN3+

IN0D+

A0 differential

input positive

B19

A19

A1 differential

input positive

IN3D+

IN0-

A0 differential

input negative

B18

A18

A1 differential

input negative

IN3-

IN1+

B0 input

positive

B17

A17

b1 input positive

IN4+

IN1D+

B0 differential

input positive

B16

A16

b1 differential

input positive

IN4D+

IN1-

B0 differential

input negative

B15

A15

b1 differential

input negative

IN4-

IN2+

Z0 input

positive

B14

A14

Z1 input positive

IN5+

IN2D+

Z0 differential

input positive

B13

A13

Z1 differential

input positive

IN5D+

IN2-

Z0 differential

input negative

B12

A12

Z1 differential

input negative

IN5-

/

B11

A11

/

PUL0

Axis 0 pulse

output

B10

A10

Axis 4 pulse

output

PUL4

DIR0

Axis 0 direction

output

B9

A9

Axis 4 direction

output

DIR4

PUL1

Axis 1 pulse

output

B8

A8

Axis 5 pulse

output

PUL5

DIR1

Axis 1 direction

output

B7

A7

Axis 5 direction

output

DIR5

COM0

Command

terminal

B6

A6

COM0

Comm

and

termin

al

PUL2

Axis 2 pulse

output

B5

A5

Axis 6 pulse

output

PUL6

DIR2

Axis 2 direction

B4

A4

Axis 6 direction

DIR6

output

output

PUL3

Axis 3 pulse

output

B3

A3

Axis 7 pulse

output

PUL7

DIR3

Axis 3 direction

output

B2

A2

Axis 7 direction

output

DIR7

COM0

Command

terminal

B1

A1

COM0

Comm

and

termin

al

6 channels input

6 high-speed input: X0 ~X5 correspond to IN0 ~IN5 (single

point common terminal)

2 encoder input: A0 ~Z0, B1 ~Z1, (supports differential /

single-ended wiring

16 channels /8 axis high speed output

Axis8 output: Axis0 ~ Axis8 (COM0 public)

16-way high-speed output: Y0 ~ Y17 corresponds to PUL0 ~

DIR7 (COM0 public terminal)

Note: there is one COM in the output circuit of the module, and there

are altogether 4 COM wiring points. Users should use COM wiring

points in A reasonable grouping according to the actual load situation.

Each COM wiring point can carry 1.5a load, and each four-point COM

wiring point can carry 6A in total.

3.4 Wiring

Figure 3-2 Schematic diagram of single-ended input wiring

3

Figure 3-3 Schematic diagram of differential input wiring

Figure 3-4 Schematic diagram of output wiring

Wiring precautions

When connecting the cable, avoid being tied with the power line

(high voltage line, high current) and other cables that transmit

strong interference signals. Separate the drive line and avoid

parallel running.

It is recommended to use shielded cable to improve

anti-interference capability.

4.Technical Parameters

4.1Environmental index

PLC use environment temperature range: 0℃~ 55℃. When the

ambient temperature exceeds 55℃for a long time, choose a

place with good ventilation.

Places free from corrosion, flammable and explosive gases and

liquids.

A firm, vibration-free place.

This PLC is designed for the application of installing environment

II standard and pollution level 2.

4.2 Performance

Table 4-1 Performance

Item

specification

Input channels

6

Out put axis

8

Input/output connect mode

40PIN harness connector

Input channel specification

Input method

Support for SINK and SOURCE

Input type

Digital input

Single-end

ed input

Input voltage

class

24V DC (-15% ~ +20%) or 5VDC

differential signal

Input current

5mA (typical)

ON voltage

> 15VDC

OFF voltage

< 5 VDC

Terminal filter

time

1ms ~ 64ms (default 8ms, adjustable

by programming software)

The input

impedance

3.3 k Ω

Differential

input

Signal

EIA standard RS-422 differential line

drive level

Signal frequency

Single-ended input: 200KHz

AB phase input: 100KHz

Command mode

Single point independent public

Isolation method

Optocoupler isolation

Input action display

LED display

Output channel specification

Output control method

Normal high speed, pulse + direction,

forward and reverse (FW / BW), A / B

phase

Output form

Single-ended

Output polarity

Sink output

Rated load current

0.2A / channel

Maximum turn-on voltage

drop

0.3V

Signal frequency

200kHz

Control circuit voltage

DC5V ~24V

Command mode

Each group of independent public

Isolation method

Optocoupler isolation

Input action display

LED display

5.Indicator definition

Table 5-1 function description table of panel indicator light

4

Item

Function Description

Troubleshooting

Lnk indicator

(yellow-green)

The extension module is

connected with the main

module, successful: ON

connection failed: OFF

1. Check whether the

supply voltage of the

main module is

normal.

2. Check whether the

expansion clasp is

clamped tightly.

3. Check whether the

baffle cover is

installed firmly.

Input indicator

A0、B0、Z0、

A1、B1、Z1

The input indicator light

changes with the input

state of A,B and Z, and is

on when there is input.

Output indicator

The FWn lights ON when

PULn outputs.

The BWn lights ON when

the DIRn is output.

1. Warranty scope refers to the programmable controller body.

2. The warranty period is 18 months. If the product breaks down or is

damaged during normal use, our company will repair it free of charge.

3. The warranty period starts from the date the product is manufactured.

Machine code is the only basis for judging the warranty period.

Equipment without machine code shall be treated as under warranty.

4. Even within the warranty period, a maintenance fee will be charged

if:

Failure of the machine caused by failure to operate in accordance

with the user's manual.

Damage to machinery caused by fire, flood, abnormal voltage,

etc.

Damage caused when a programmable controller is used for

abnormal functions.

Self-disassemble the programmable controller.

5. The service fee shall be calculated according to the actual cost. If

there is another contract, the contract shall take precedence.

6. If you have any questions, please contact the agent or our company

directly.

SHENZHEN MEGMEET CONTROL TECHNOLOGY CO.,LTD

Add:floor 5, tower B, qinghua information port, langshan road, north

district, science and technology park, nanshan district, shenzhen

Tel:400-6662163

Fax:(+86)0755-26897197

Zip code:518067

Web:www.megmeet.com

This manual suits for next models

1

Other Megmeet Controllers manuals

Megmeet

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC200E Series Manual

Megmeet

Megmeet MCCD Series Service manual

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MC100 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet L6 Series User manual