Contents

Contents

1 General guidelines ...............................................................................................................................................................6

Symbols used.......................................................................................................................................................................6

Formatting rules ...................................................................................................................................................................6

Disposal ...............................................................................................................................................................................6

2 Safety.....................................................................................................................................................................................7

3 Performance specifications ................................................................................................................................................9

Intended use ........................................................................................................................................................................9

User benefits ........................................................................................................................................................................9

Program sequence.............................................................................................................................................................10

Process agents ..................................................................................................................................................................11

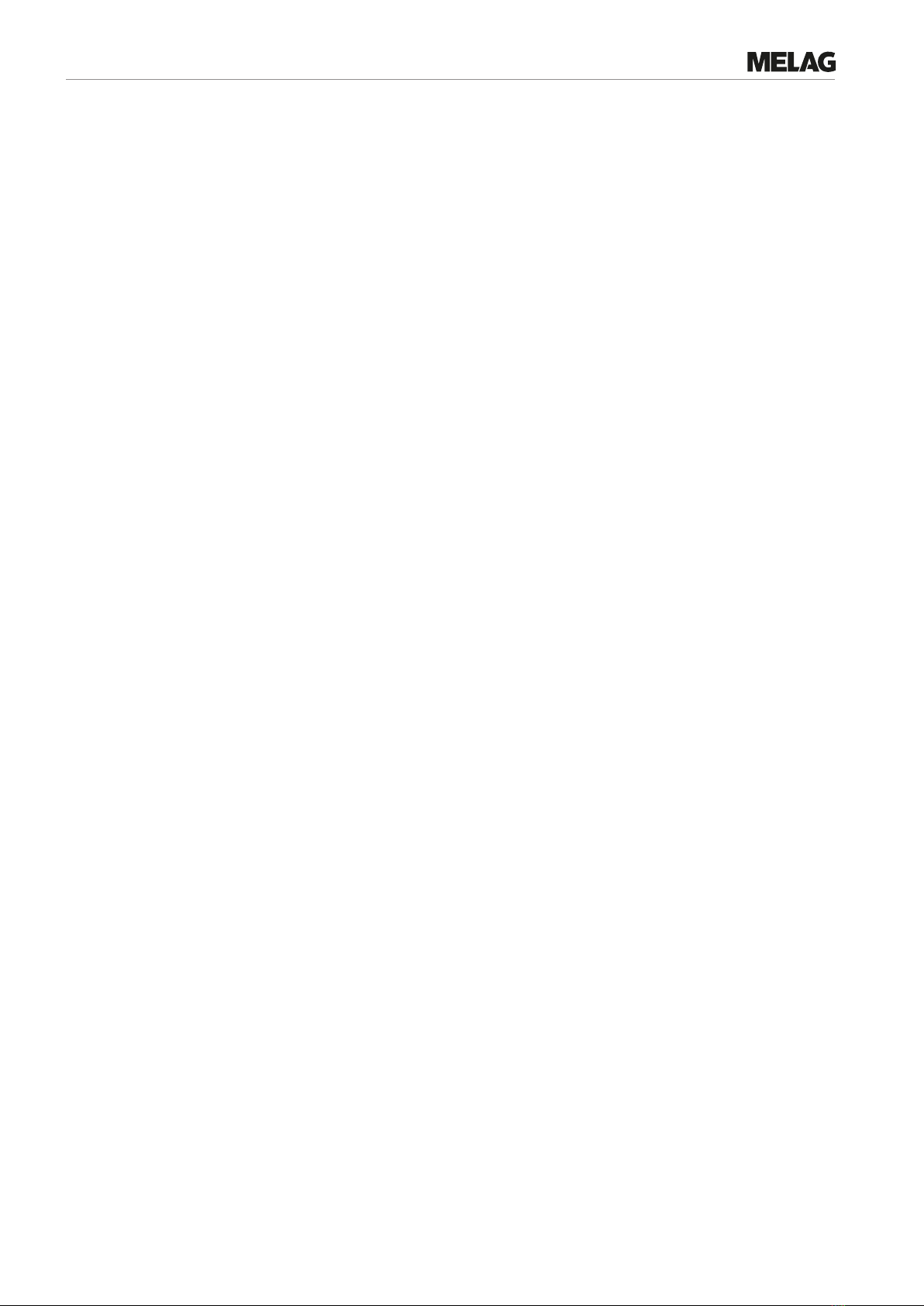

4 Description of the device...................................................................................................................................................12

Scope of delivery................................................................................................................................................................12

Views of the device ............................................................................................................................................................12

Symbols on the device .......................................................................................................................................................14

Operating panel and acoustic signal ..................................................................................................................................16

Menu structure ...................................................................................................................................................................19

Water softening unit ...........................................................................................................................................................20

5 First steps ...........................................................................................................................................................................21

Setup and installation.........................................................................................................................................................21

Water supply ......................................................................................................................................................................21

Switching the device on and off .........................................................................................................................................22

Video tutorials ....................................................................................................................................................................22

MELAconnect App .............................................................................................................................................................23

Opening and closing the door ............................................................................................................................................23

Manual door emergency-opening ......................................................................................................................................24

Inserting the basis basket ..................................................................................................................................................24

Filling the regenerating salt ................................................................................................................................................25

Regenerating the water softening unit ...............................................................................................................................26

Metering process agents....................................................................................................................................................26

Holding process agents ready............................................................................................................................................27

Removing air from the metering system ............................................................................................................................29

6 Cleaning and disinfection..................................................................................................................................................30

Type of load .......................................................................................................................................................................30

Wet/dry storage..................................................................................................................................................................30

Preparation and pre-cleaning.............................................................................................................................................30

Arranging the load..............................................................................................................................................................31

Reprocessing hollow-body instruments .............................................................................................................................31

Reprocessing dental transmission instruments..................................................................................................................32

Reprocessing ophthalmological instruments......................................................................................................................33

Overview of programs ........................................................................................................................................................34

Selecting, starting and following the program ....................................................................................................................35

Manual program abort........................................................................................................................................................36

Authentication and batch approval.....................................................................................................................................37