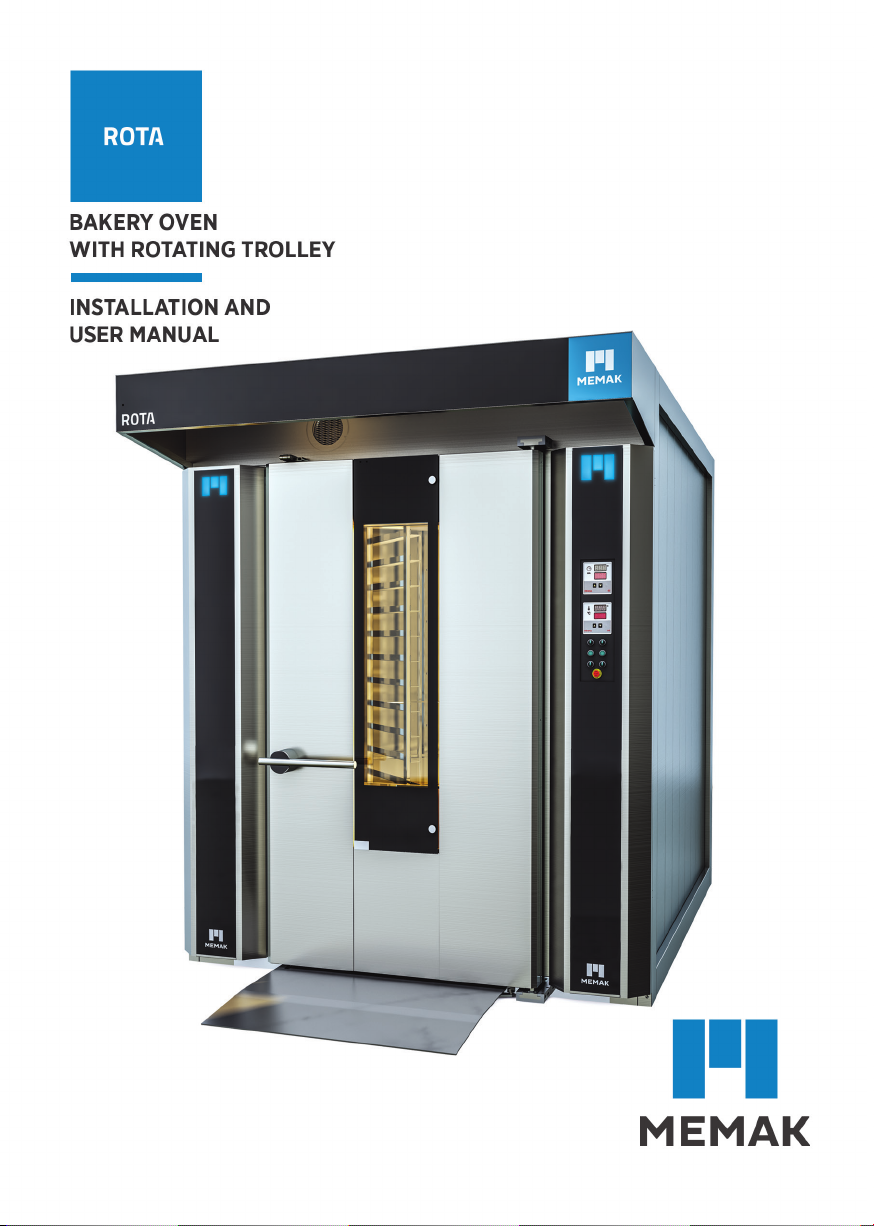

Memak Rota Series User manual

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I1

2I memak.com

2I memak.com

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I3

STELLA COMBINE FIRIN KURULUM VE KULLANIM KILAVUZU I3

4I memak.com

INSTALLATION AND

USER MANUAL

INTRODUCTION 6

Warning Signs Used 7

Warranty 8

Manufacturer Company 9

Product Information 9

Product Definition 10

Product Operating Principle 10

Manufacturing Site Design 11

Product Specifications 12

Product Dimensions 12

PRODUCT COMMISSIONING 13

General Rules on Unpacking the Machine 13

Load Structure 15

Product Transport 15

General Rules for Lifting and Transporting the Machine 15

Rules on Machine Stocking 17

PRODUCT INSTALLATION 18

Fresh Water Installation 20

Waste Water Installation 22

Fuel Connection Installation (Burner) 24

Electrical Connection Rules 24

Shaft Installation Connection 27

Dismounting and Reassembly 29

CONTROL PANEL USE 29

Pre Heating (Preparation) 30

Cooking 30

Cooling 30

Issues to be Considered During Use 30

POINTS TO BE CONSIDERED TO ENABLE THE OVEN TO HAVE LONGLASTING SERVICE LIFE 31

PERSONNEL PROTECTIVE EQUIPMENT 32

Safety Systems Controlling 33

Waste (Residue) Hazards 33

Burning Hazard 33

Solutions 33

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I5

Electrical Hazard 33

Solutions 33

Physical Hazards 34

Solutions 34

Fire Hazard 34

Solutions 34

Gas Accumulation Hazard 34

GENERAL CLEANING 34

Hygienic Areas 34

Cleaning Planning 34

Water Installation Cleaning 35

MAINTENANCE AND SETTING 36

Cooking Period and Temperature Setting 36

Steam Injection Setting 36

Routine Maintenance 36

General Rules 36

Regular Maintenance Procedures 37

Lamp Changing 37

Door Seal Changing 38

Door Glass Changing 39

Door Mechanism Lubricating 41

Reducer Shaft Bearing Lubricating 42

Door Lock Mechanism Lubricating 43

Door Ramp Lubricating 44

POSSIBLE FAILURE AND CAUSES 45

6I memak.com

Introduction

Manual

• Installation instructions are part of the device and contain

information for the safe device use.

• Installation instructions must be fully read before

installation.

• Installation instructions must always be ready to be

accessed by the installer at the installation site.

• Installation instructions must be maintained along the

device service life.

• MEMAK MAKİNA shall not be held responsible for the

problems arising from unintended use of the oven.

• Installation instructions must be delivered device’s

subsequent operators.

Figure

• All figures given in this manual are exemplary.

• It may show dierences according to the current device.

The company reserves its rights for technical modifications for

development!

©2018 MEMAK TECHNICAL SERVICE. All Rights Reserved. Transfer of

product-specific information to third parties is prohibited.

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I7

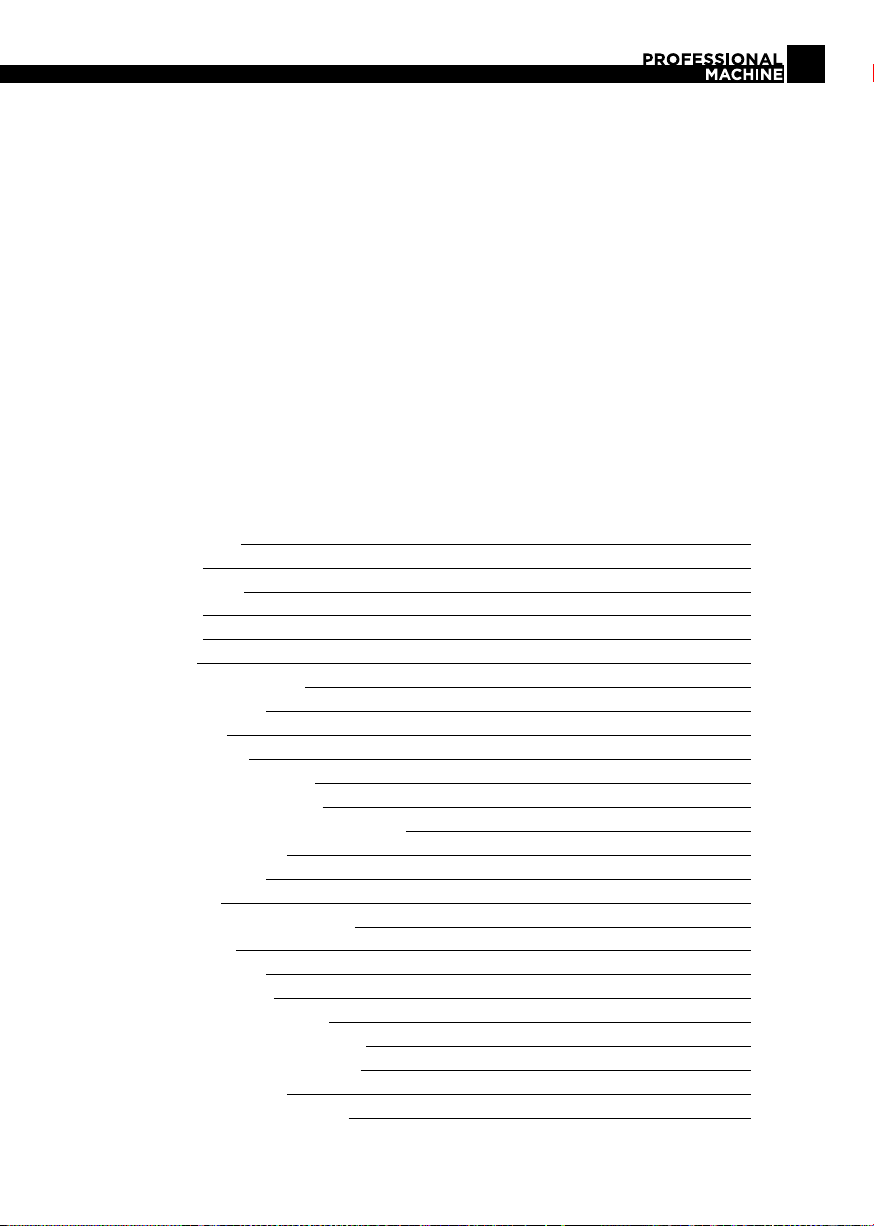

Ths way up Move n a manner as the drecton looks upwards wth the

arrow sgn.

Fragle Handle the package wth care.

Keep t dry Packed so as not to contact wth open ar.

CE Mark The machne meets the basc safety requrements.

Center of Weght Indcates the pont where the machne should be lfted.

Hanger Pont Indcates where to attach ropes or chans.

Warnng A hazardous stuaton, t may result n severe njury and

death.

Fre Fre hazard!

Hgh Voltage Attenton, Death Rsk

Hgh Temperature Door, glass and ts vcnty reach hgh temperatures when

the oven s operatng.

Operating

Mechanical Parts

Do not perform mantenance or repar work on movng

parts.

Warning Signs Used

8I memak.com

Warranty

Those not covered by the warranty;

• Glass damages, ampoules and seals.

• Unintended use of the device,

• Modifications or technical modifications to the device by person and

persons not authorized by the manufacturer,

• Avoiding use of the manufacturer company’s original parts,

• Damages with mechanical impacts during the oven transportation by

the customer.

• Losses due to the insuciency of all network systems supplying the

oven.

• Faults that may occur due to user’s neglect of the oven.

• No person other than MEMAK MAKİNE’s authorized personnel or

authorized services should under any circumstances interfere with

the repair and modification of the device.

• Due to the failures in electric motors.

• Due to the failures those may occur with the entire electricity

materials.

• In cases of tempering and damaging settings on oven.

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I9

Manufacturer Company Information

Manufacturer: MEMAK PLASTİK GIDA MAKİNA SAN. TİC. A.Ş

Address: 4.Organize Sanayi Böl. Kayacık Mah. 103. Cad.

No: 10 Selçuklu/KONYA/TURKEY

Telephone: +90 332 345 36 16

Fax: +90 332 345 36 26

Web: www.memak.com

E-Mail: [email protected]om

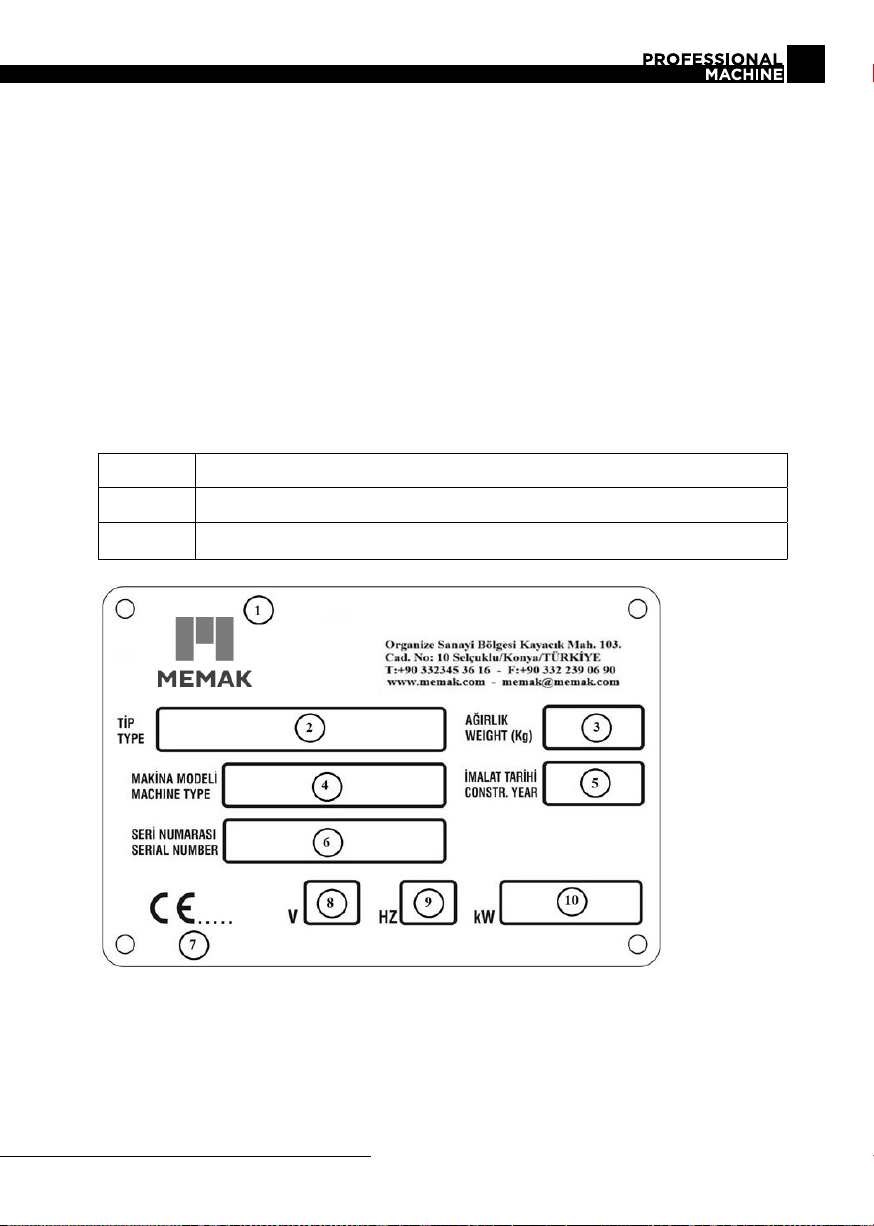

Product Information

TYPE Bakery Oven wth Rotary Trolley

SERIAL ROTA

MODEL 507, 608, 609, 810

LABEL INFORMATION

1. Manufacturer company information

2. Machine type

3. Machine weight

4. Machine model

5. Production date

6. Serial number

7. CE mark

8. Operating voltage

9. Operating frequency

10. Operating power

10 I memak.com

Product Definition

ROTA is a Bakery Oven with a rotary trolley with rear heat exchanger, fast air circulation. Cooking reservoir and body

components is made with 304 quality while heat exchanger is made of 310 quality stainless steel which is the most

resistant stainless steel to heat.

The oven is equipped with the necessary Safety systems during operation and maintenance. Exterior coating metal

sheet is coated with insulation material against heat loss. Cooking cell door and the combustion chamber are made

of stainless steel.

Product Working Principle

ROTA Bakery Oven with Rotary Trolley is equipped with indirect heated air recirculation and rotary

pan trolley is all-purpose and economic ovens enabling bakery products to be cooked in line with the

requested cooking characteristics.

Air inside the oven is circulated on outer surfaces of indirect air heater heated by a burner via a

circulation fan leaves a particular amount of heat received from heater to steam generators while

leaves a particular amount on product on the rotary trolley arrives to heater in the burning cell and air

circulation continues in this way by reheating.

It provides convenience in terms of easily loading and unloading also for bakery oven with rotary

trolley. Rotary table is driven with a reducer system installed on the top part of the oven.

ROTA, both for the manufacturing of various types of bread and also most ecient cooking of the

pastry products has been designed by using all engineering branches.

It is designed in dierent sizes and can meet the needs of small, medium and large enterprises. Thanks

to specially designed air circulation system and steam generators (thanks to placement in dierent

parts of the cooking chamber) balanced distribution of hot air and steam in every point of the cooking

reservoir thus stable leavening and bulkiness and cooking ensured for the product.

Oven external circuit elements are equipped with plug-and-socket system for ease of service and

maintenance. Lamps resistant to 350 ° C are used for furnace illumination. Oven’s control panel is on

the right when viewed from the front. Panels are fully sealed. In the event of a person staying inside the

oven to be used in case of emergency under the Machine Directive, a safety door handle is designed in

order to open the door from the inside. Again in this context, there is an EMERGENCY STOP BUTTON

stopping oven operation when an emergency stop is required. Signal lamps for the oven operation and

failures are considered within the scope of the machinery directive.

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I11

Production Area Design

1. In the entire area, there should be some room to allow for inspection and cleaning when

manufacturing equipment is installed.

2. When placing the machines, all connections must be closed so that there are no openings.

3. The floor on which the machines are placed should be accessible from the point of view of the

cleaning operation or should be completely closed.

4. In cases where equipment passes through sections such as ceiling, floor, wall, sucient floor

should be provided between equipment and wall for cleaning or machine should be mounted on

the wall not to permit any gap.

5. Auxiliary equipment must be removable and can be reassembled to facilitate cleaning.

6. Production base should be covered with hard, smooth, easy to clean and non-absorbent material.

7. For insulation, non-absorbent materials should be used. These surfaces should be accessible.

8. Stacking should be made on palettes to let minimum 100 mm distance with the floor when

storing the products.

9. Vessels used to collect waste products and waste water should be made of easy to clean materials

and should have sucient volume.

10. Doors and windows opening out of the plant should be isolated to prevent any outsourced

contamination.

11. Sucient ventilation should be ensured in the washing rooms.

12. Water and water vapor that come into direct contact with the products should be of drinkable

quality.

13. Pipes, valves and fittings used for liquid materials: Either “on-site cleaning” programs should be

implemented for these sections or systems allowing easy disassembly and assembly should be

used.

14. All fixed pipes should be isolated to prevent condensation.

15. Drainage systems for wastewater must be installed in areas where cleaning is required.

16. Floor slope should be such as to prevent water accumulation on the surface.

17. Illumination lamps should be protected as to prevent falling and breaking.

18. Power cables should be stabilized (their contact with the ground should be prevented)

19. Machine’s electrical components should be closed to prevent dust formation. Water should be

prevented from entering electrical panels.

20. Machine parts such as fan, motor should be accessibly mounted.

21. Motor and other auxiliary equipment should be placed not to touch the floor.

12 I memak.com

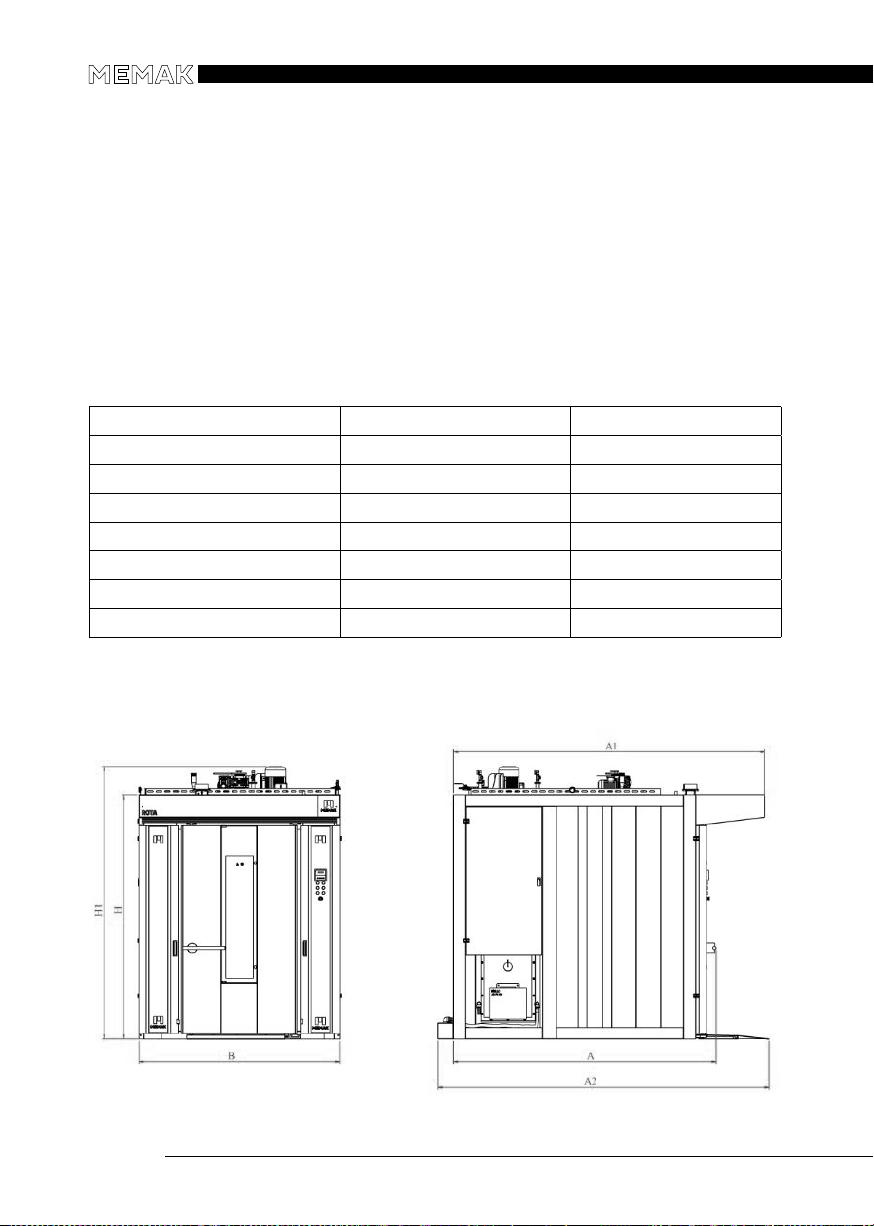

Product Techncal Detals

ROTA810 ROTA609

Capacty (peces / 8 hours) 3000 2400

Cookng Area (m2) 14,4 8,6

Weght (kg) 2750 2100

Electrcty power (kw) 4 4

Cookng Temperature (C°) 280-300 280-300

Tray Szes (mm) 800x1000 600x900

Number of Trays (peces) Max 18 Max 18

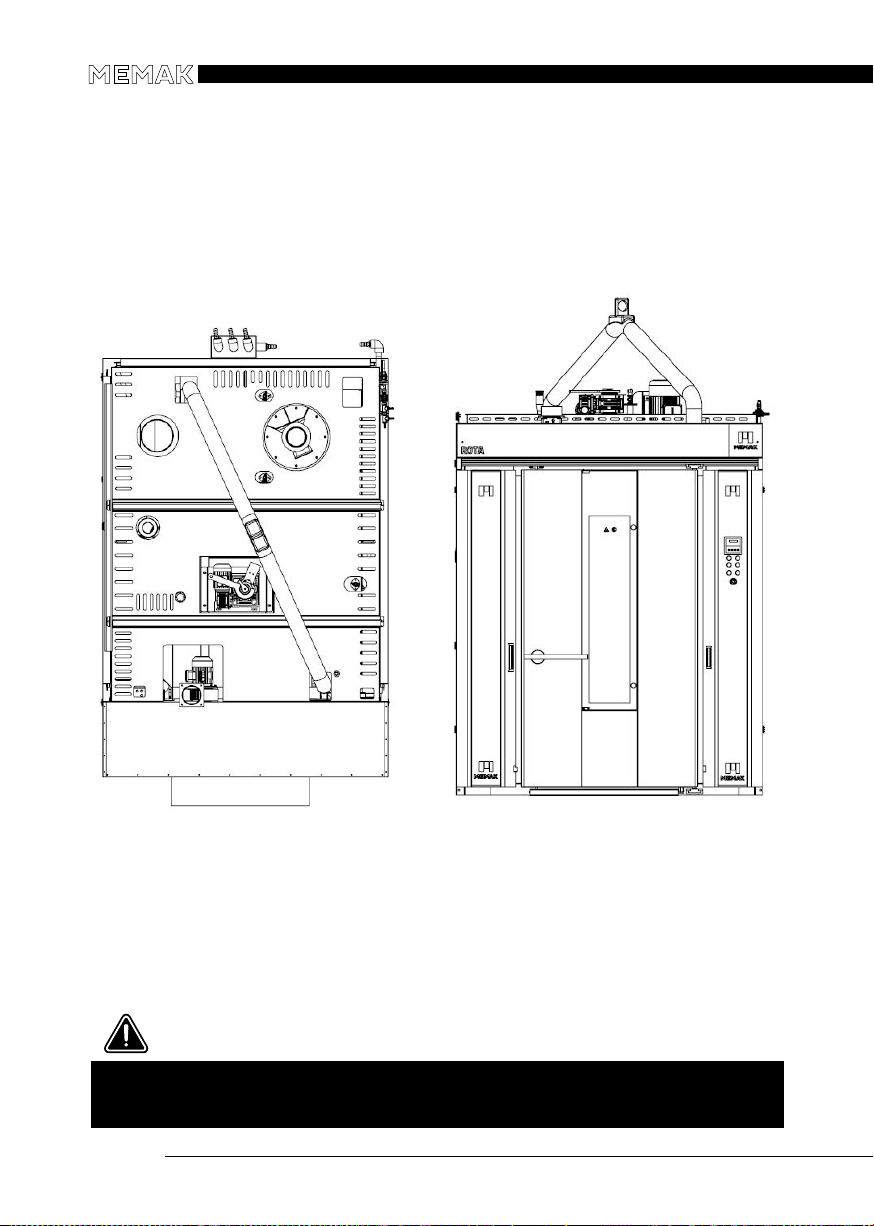

Product Dmensons

(Fgure1)

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I13

ROTA810 ROTA609

DEPTH ( A ) mm / nc

(A1) mm / nc

2496

2960

2217

2680

WIDTH ( B ) mm / nc 1950 1711

HEIGHT ( H ) mm / nc

(H1) mm / nc

2320

2590

2320

2595

PRODUCT COMMISSIONING

• Installaton s carred out by the manufacturer’s personnel or by the personnel authorzed by the

manufacturer.

• Manufacturer s not responsble for any falure caused by unauthorzed personnel. Manufacturer

s not responsble for any malfunctons caused by unauthorzed personnel durng the nstallaton,

despte the labor guarantee.

• Manufacturer cannot be held responsble for the place and techncal and legal sutablty of the

machne.

• All operatons must be carred out n accordance wth the drectves of a sole authorzed person.

• Operators and people under ther command must wear protectve clothng n complance wth

the operaton.

Manufacturer s not lable for accdents, damage and machne falures caused by the falure to comply

wth the rules n ths secton.

General Rules on Unpackng the Machne

• Inspect the machine for damages during transportation before unpacking. Check that all parts

listed in the shipping documents are present. If there are missing parts, manufacturer must be

informed within 24 hours.

• Dispose of the packaging material in accordance with the applicable legal regulations when the

machine is fully installed.

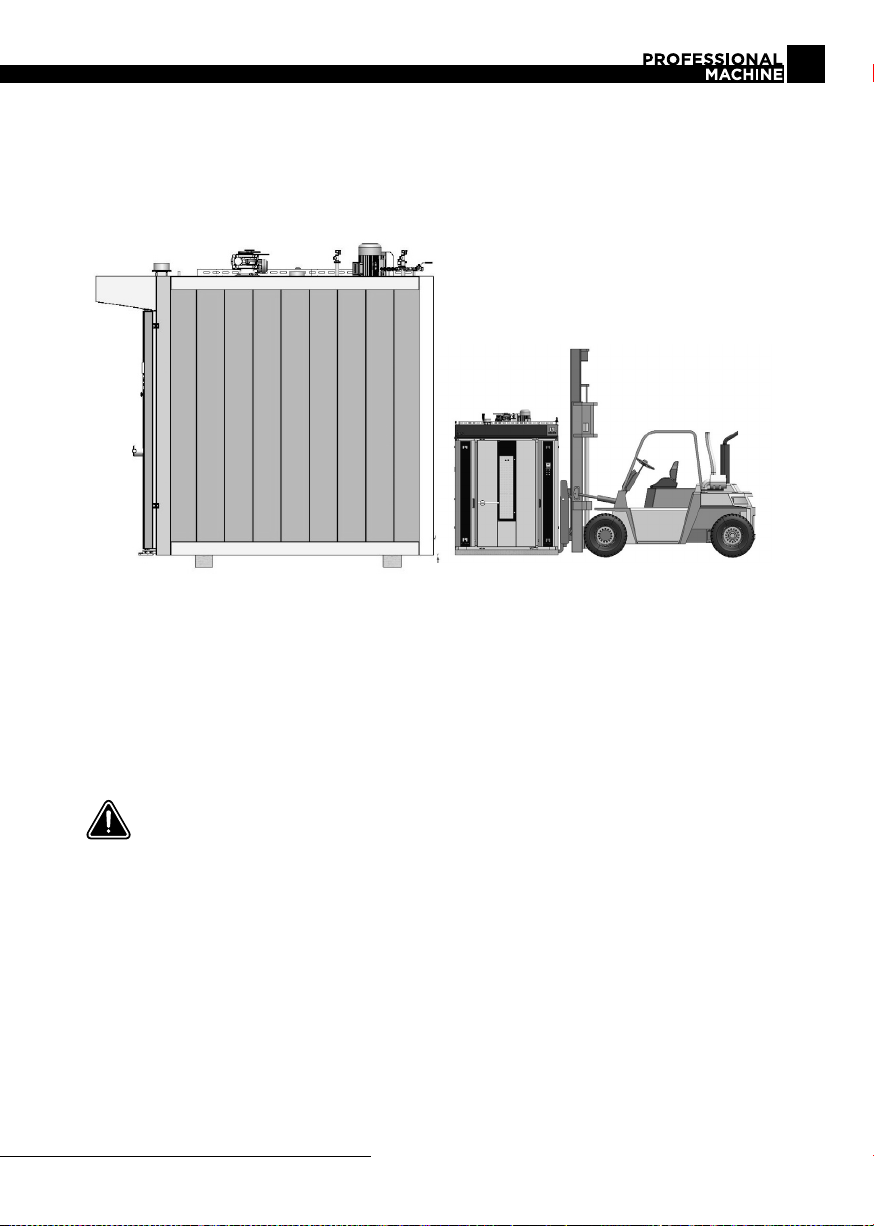

• Store the materials used for lifting the machine in a suitable place for future use. (Figure 2 and

Figure 3)

14 I memak.com

(Fgure2)

(Fgure3)

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I15

Load Structure

Machne can be shpped n form as stated below:

• Completely assembled;

• Partally assembled;

• Not completely assembled; parts are stacked on the pallet or optonally on top of any wooden

structure.

The vehcle to be transported must have the requred lftng capacty. (Please see machne’s techncal

nformaton chart.). Furthermore, vehcle’s mnmum loadng areas should be as follows. (Wdth: 2300

mm; Length: 5000 mm)

Lftng devce used to rase the machne; should have sucent lftng capacty and fork length.

Product Transport

General Rules on Lftng and Transportng the Machne

• Before startng the operaton, desgnate and nspect the entre transport area, the parkng area of

the vehcle carryng the transport and the area where the machne wll be nstalled. Ensure there

s no hazardous stuaton.

• Make sure that the vehcle to carry out the machne’s lftng and transport procedure of the

machne has sucent lftng capacty. Weghts are stamped on the packagng and / or are

avalable n ths manual.

• Check that the hostng ropes and chan types are approved and that the capacty nstructed by

the manufacturer s clearly wrtten on the ropes. Check whether there s a damage and corroson

wth the lftng ropes before use.

• Do not knot or twst the lftng ropes and follow the rules wrtten n ths manual by the

manufacturer. Same rules apply to chans and belts.

• Partcular attenton should be pad for lftng the machne centrally.

• Do not clmb over and pass under when the machne s loaded and movng.

• Care must be pad that unauthorzed personnel are not n the loadng area.

• In order not to cause any accdent and njures; all operators must stand at a safe dstance when

lftng the machne.

• Specal care must be pad to keep the system stable when realzng machne lftng procedure.

16 I memak.com

Transport Wth Crane

(Fgure4)

WARNING: Take necessary cautons durng transport! Start wth the lftng procedures after

ensurng that hangers are fully nstalled.

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I17

Transport wth Forklft

(Fgure5) (Fgure6)

Lftng devce used to lft the machne; should have sucent lftng capacty and fork length.

The packaging structure of the product is made according to the world and European norms. It is made

ready for the shipping procedure by placing into cases packed with nylon and design in compliance

with standards by compressing with nylon with bubble pack. (Figure 5 and Figure 6)

PLEASE CHECK THE STATUS OF PACKING WITH CARE BEFORE RECEIVING THE PRODUCT.

DO NOT TAKE OVER PRODUCT WITH DESTROYED PACKAGE, DAMAGED CASE AND BEING

CRUSHED AND SCRATCHED. MOREOVER, INFORM THIS SITUATION IMMEDIATELY TO

MANUFACTURER BY TAKING PHOTO AND WITH A BRIEF NOTE.

Rules for Machne Storage

• Machne must be stored n ndoors away from dust, mosture and heat.

• Permssble ambent values for storage are as follows: Temperature: -5 C° to 45 C°

• Maxmum mosture: 60 %

• It should be ensured that the place where the machne s stored bears no rsk of vehcle crash.

• Guarded parts must be checked regularly.

• Do not stack machnes on top of each other.

• If the machne s stored wthout a package, t must be rased from the ground wth the help of

wooden pallets. Cover to prevent dust and drt accumulaton.

18 I memak.com

PRODUCT ASSEMBLY

Ready assembled machne:

Machne arrves as ready assembled requres specal nstallaton settngs n specal areas assgned to

t. Sem assembled or unassembled machne:

If the machne shpped as unassembled or sem-assembled; the assembly operaton must be

performed by the personnel authorzed by the manufacturer.

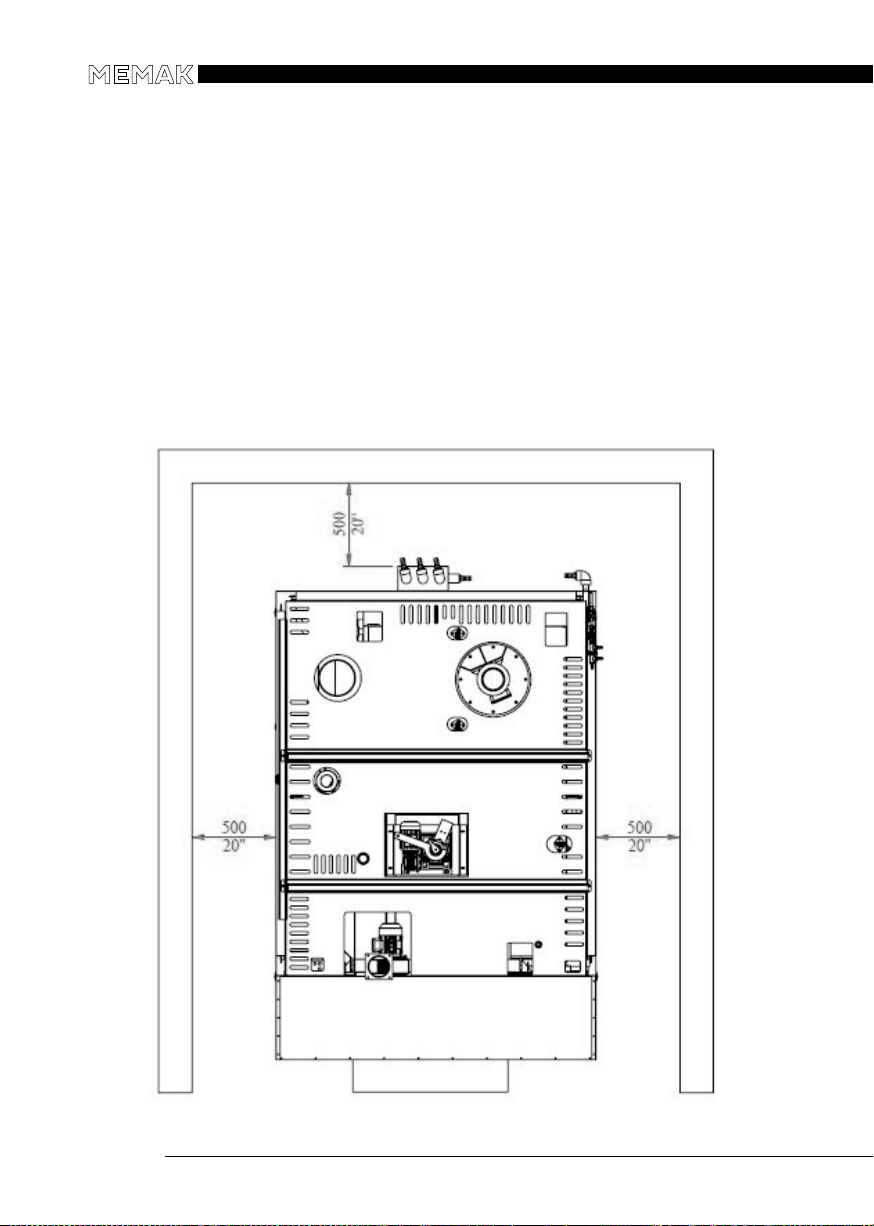

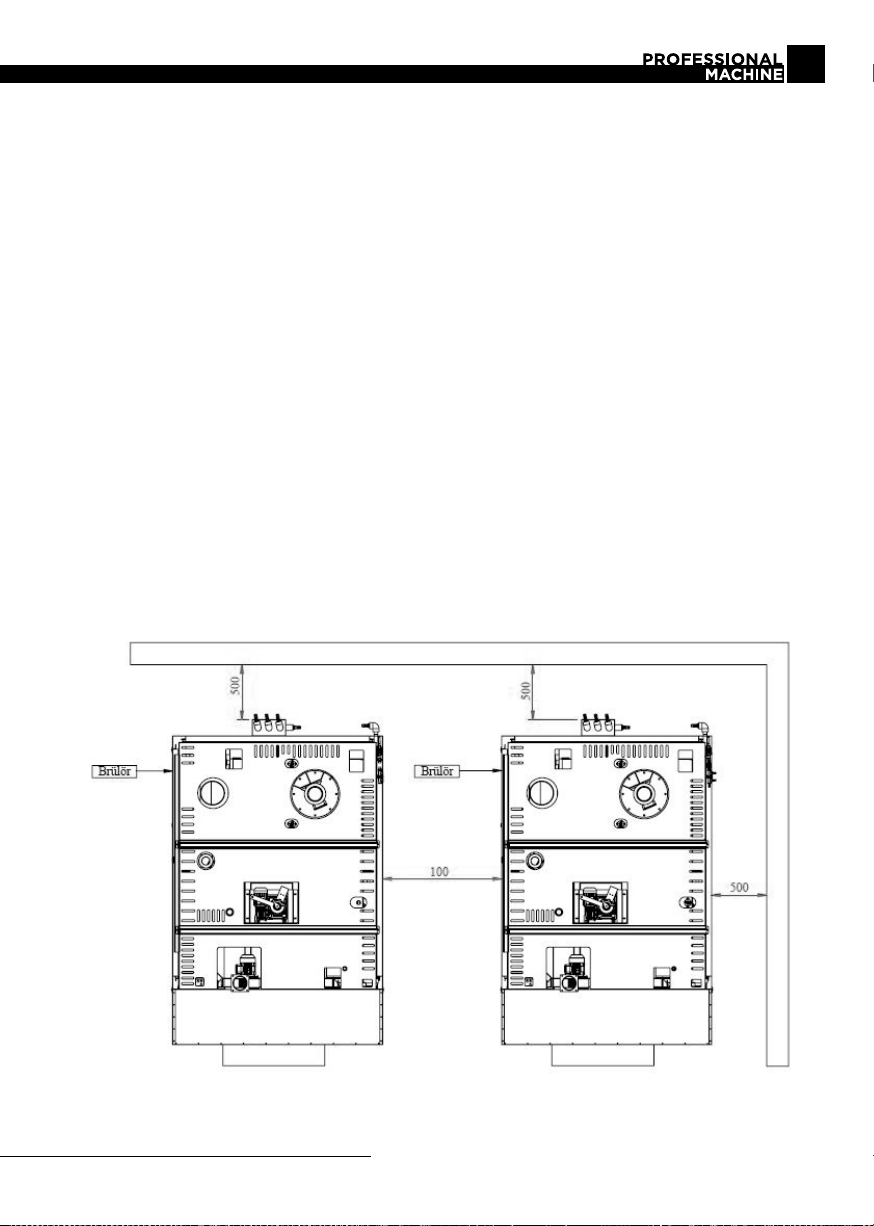

1. If there s no prevous layout desgned for the ovens, oven shall be sutably placed. (Fgure-7)

IMPORTANT: Distance between the oven and wall should be at least 500 mm (half meter).

(Fgure7)

INSTALLATION AND USER MANUAL FOR BAKERY OVEN WITH ROTATING TROLLEY I19

2. It should be investigated if multiple ovens are to be installed. (Figure 8)

(Fgure8)

There are fve types of nstallatons n rotary ovens as water, fuel, electrcty and shaft nstallaton.

20 I memak.com

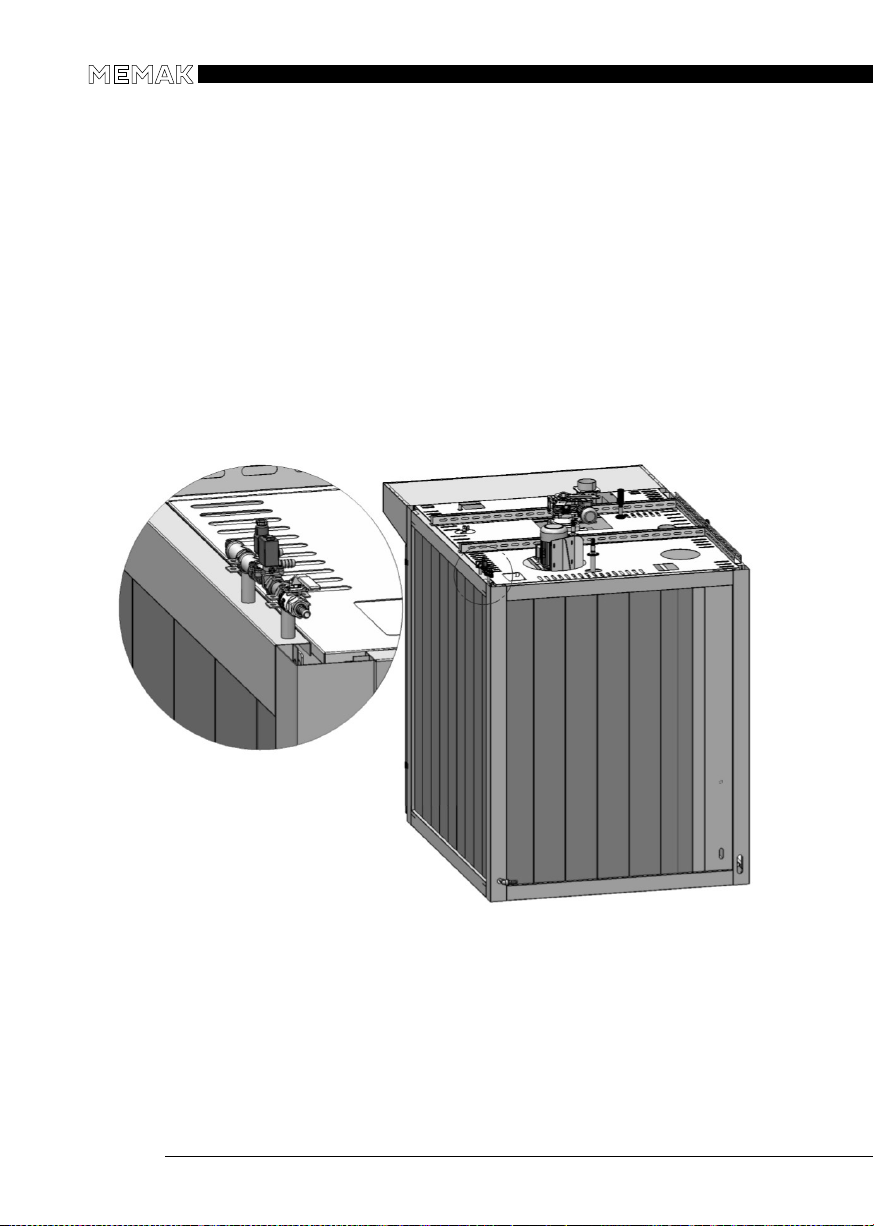

Fresh Water Installaton

Water connection for ROTA810 bakey ovens with rotary torlley is done with ½ “ steel pipes. Fresh water

is delivered to water distribution robot via hose and from here water is distributed to steam generators.

Water from robot to water generators is supplied via ½” industry hoses. Fresh water installation is

brought to the proximity of of the oven by the customer. It should be tightened with brackets after

installing water inlets. Operating pressure is 1-3 bars (Figure 9).

(Fgure9)

Notes:

• Make the connecton wth a flexble hose to absorb the pressure from the man swtch.

• If necessary, nstall a manually controlled valve n order to nstantly shut down the system.

• After usng the oven on the frst day, check whether the flters are drty or not accordng to the

procedures. (Fgure 10).

This manual suits for next models

4

Table of contents

Other Memak Commercial Food Equipment manuals