PERFECT page 2

1. Contents

1. Contents......................................................................................................................................................................2

2. General notes and safety notes ....................................................................................................................................4

2.1 Material quality from MEMMERT:.......................................................................................................................4

2.2 Transport ...........................................................................................................................................................5

2.3 Initial start-up....................................................................................................................................................5

2.4 Oven load..........................................................................................................................................................5

2.5 Safety check ......................................................................................................................................................5

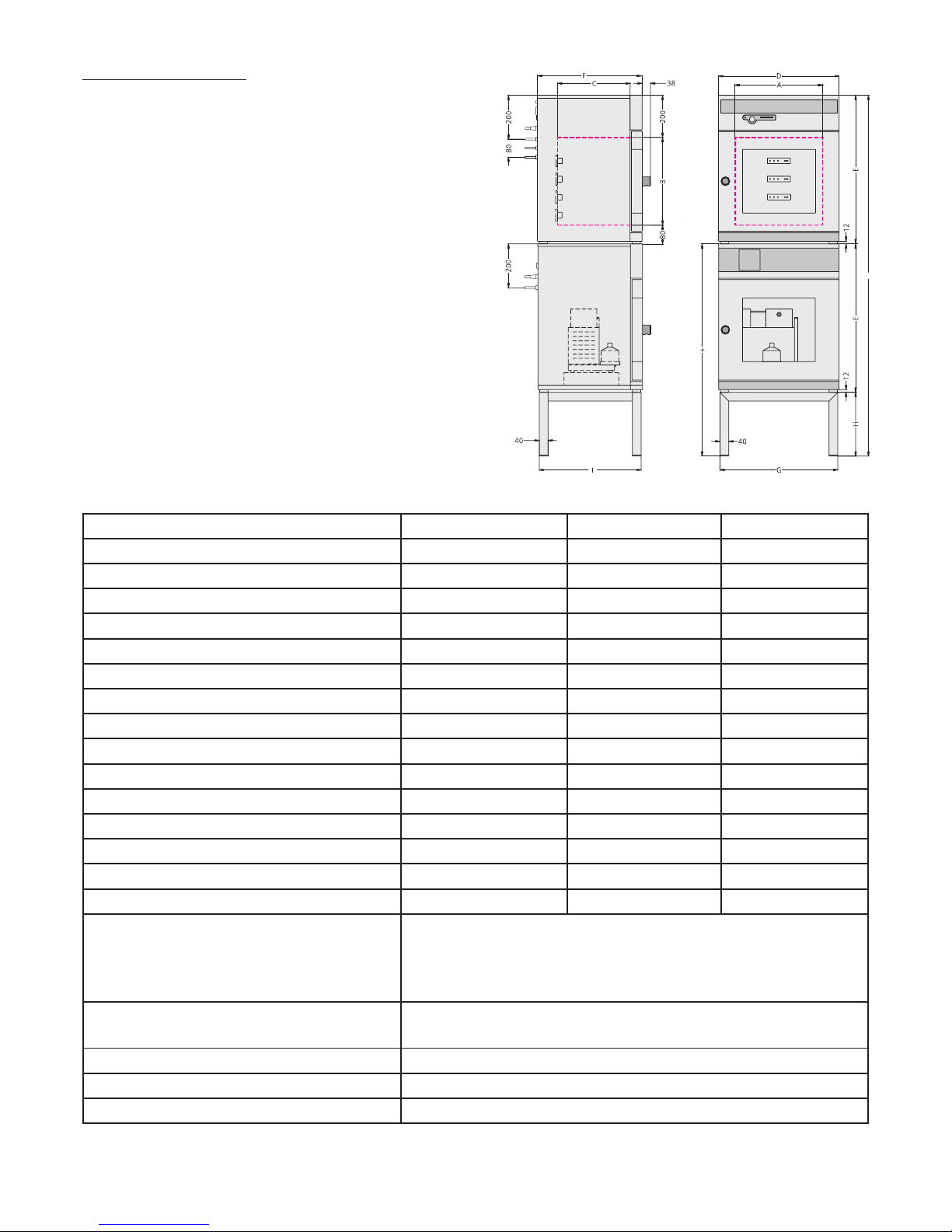

3. Technical data..............................................................................................................................................................6

3.1 Standard equipment of VO-ovens ......................................................................................................................7

3.2 Electrical equipment ..........................................................................................................................................8

3.3 External connection ...........................................................................................................................................8

4. Installation facilities (accessories)..................................................................................................................................9

4.1 Subframe...........................................................................................................................................................9

4.2 Stackable version ...............................................................................................................................................9

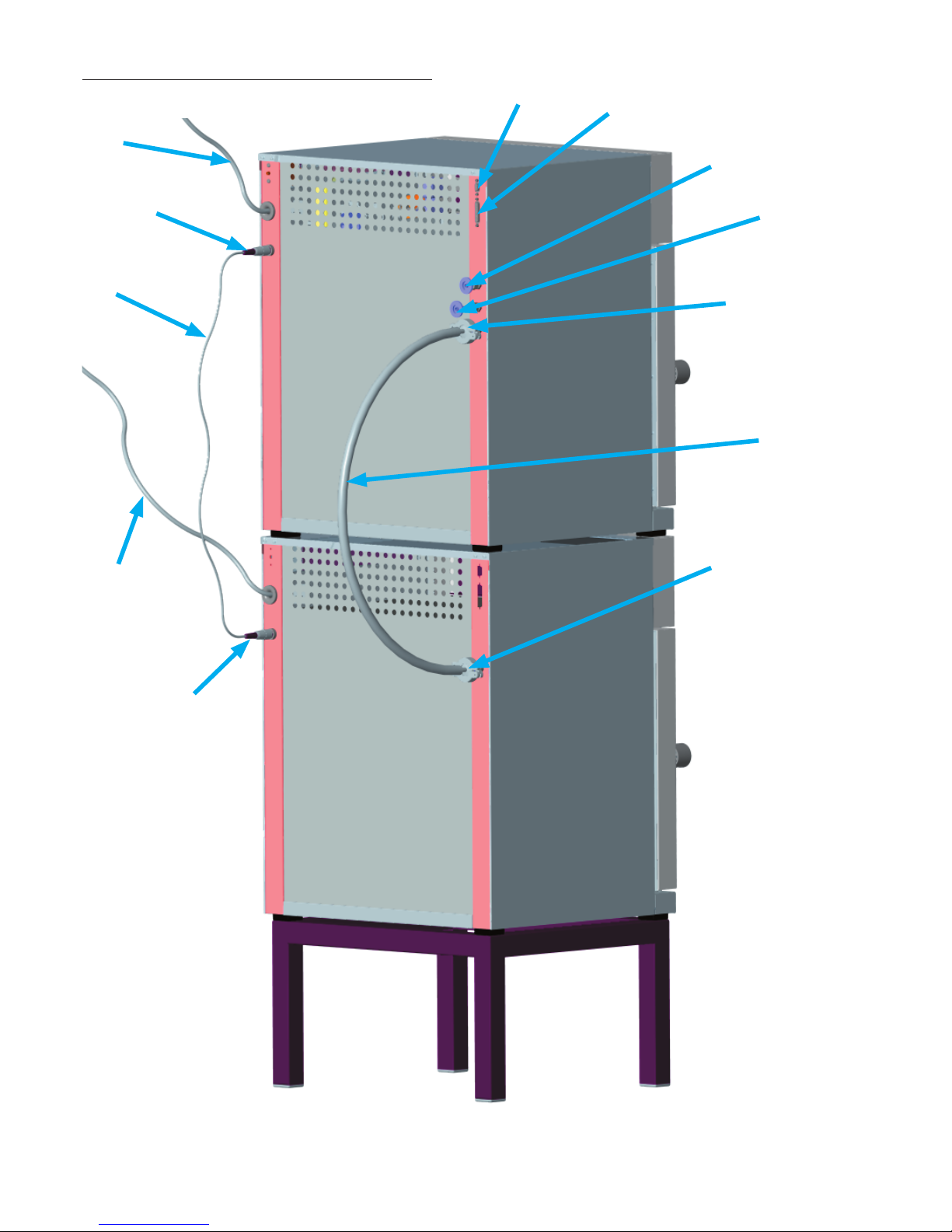

5. Oven construction and connections............................................................................................................................10

6. Starting up ................................................................................................................................................................12

7. Switching output for external vacuum pump purge valve and pump control...............................................................13

7.1 Vacuum pump purge valve ..............................................................................................................................13

7.2 Demand-controlled vacuum pump shut-down .................................................................................................13

8. Loading and Inertgas .................................................................................................................................................14

9. Guidelines for evaporating liquids in Memmert-vacuum ovens....................................................................................15

10. Controls and indications.............................................................................................................................................16

11. Operating the door....................................................................................................................................................16

12. Switching on .............................................................................................................................................................16

13. Setting the temperature.............................................................................................................................................16

14. Quick venting function...............................................................................................................................................17

15. Status indication for the heating levels .......................................................................................................................17

16. Selecting the operating mode ....................................................................................................................................18

17. Setting the parameters............................................................................................................................................... 18

18. Normal operation ............................................................................................................................................19

Setting example “Normal operation“..........................................................................................................................20

19. Weekly programmer ........................................................................................................................................21

Programming example “Weekly programmer“............................................................................................................22

20. Programme operation ......................................................................................................................................23

20.1 Closure commands for ramp segments ............................................................................................................25

Programming example programme operation ............................................................................................................26

21. Printer

PRINT .............................................................................................................................................................29

22. Basic oven settings SETUP ...........................................................................................................................................30

22.1 Real-time clock ................................................................................................................................................31