Metos Multigen User manual

Other Metos Commercial Food Equipment manuals

Metos

Metos Corolla M930A User manual

Metos

Metos Futura HD 100L User manual

Metos

Metos WD-215T User manual

Metos

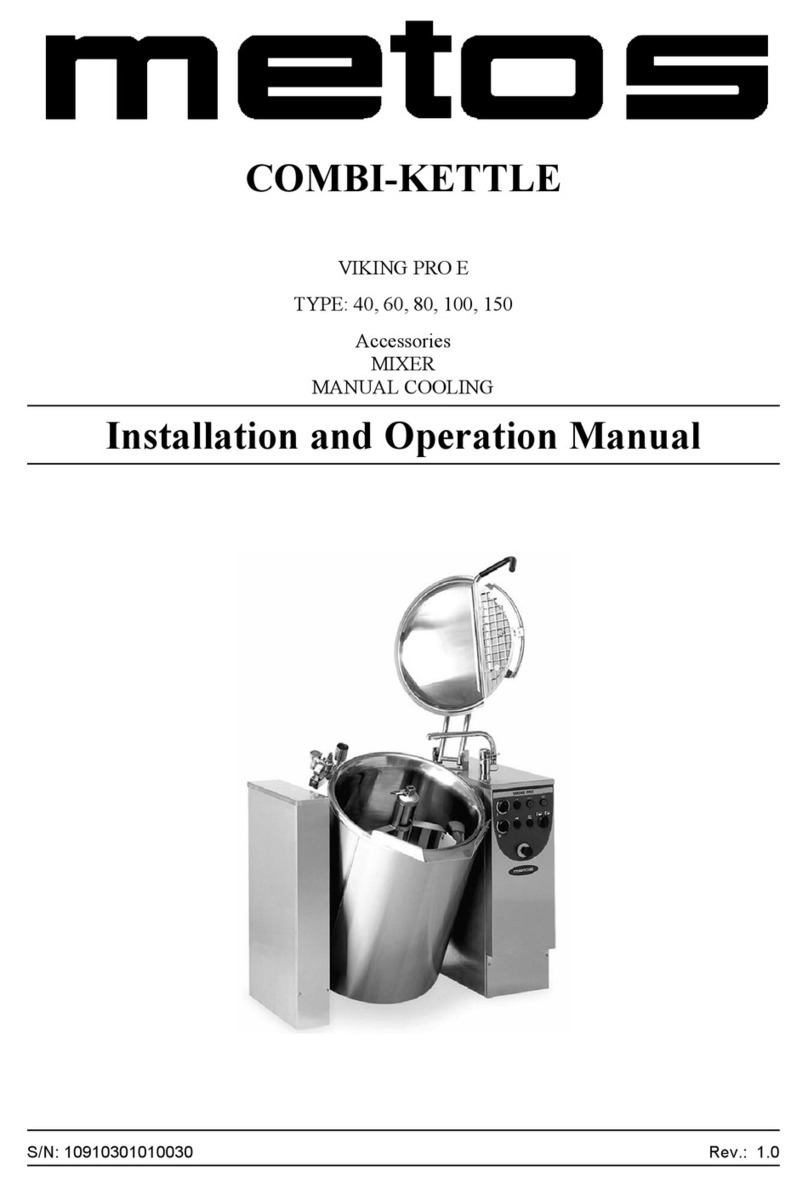

Metos VIKING PRO E User manual

Metos

Metos AGN301 GN1/1 User manual

Metos

Metos 74EFT Series User manual

Metos

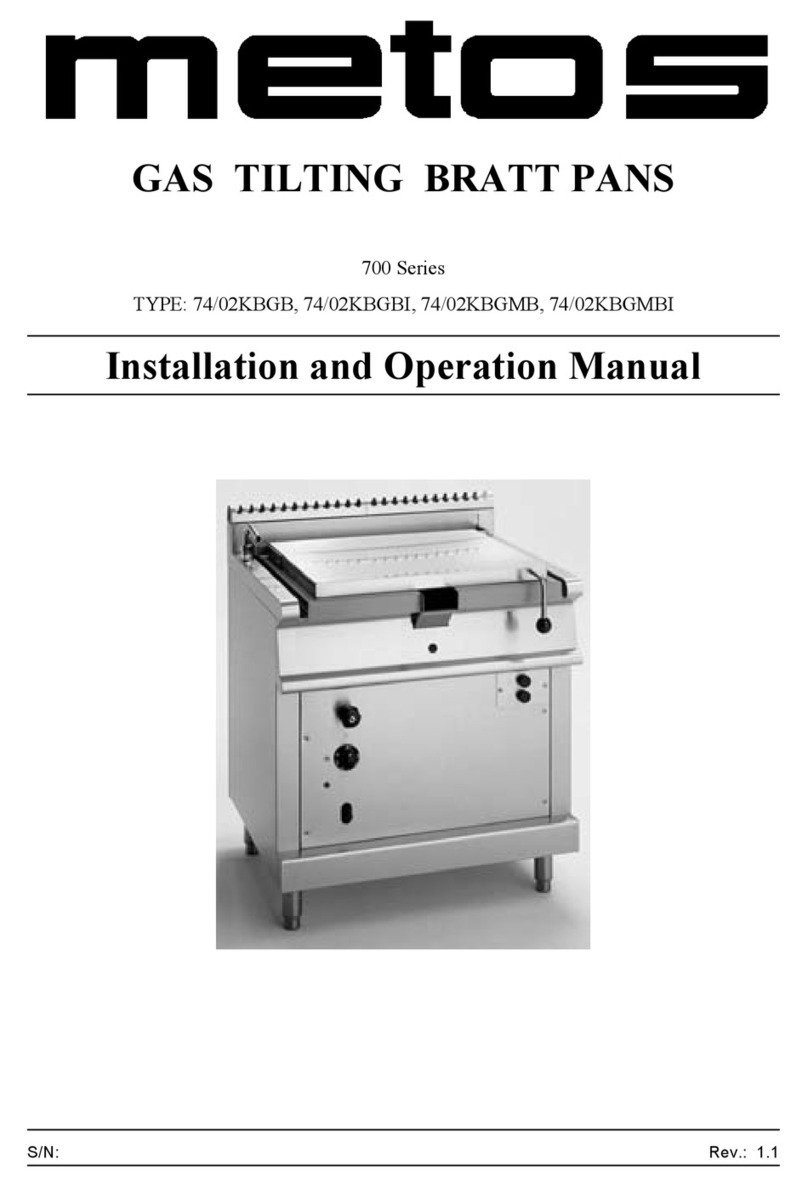

Metos 700 Series User manual

Metos

Metos WD-100GR User manual

Metos

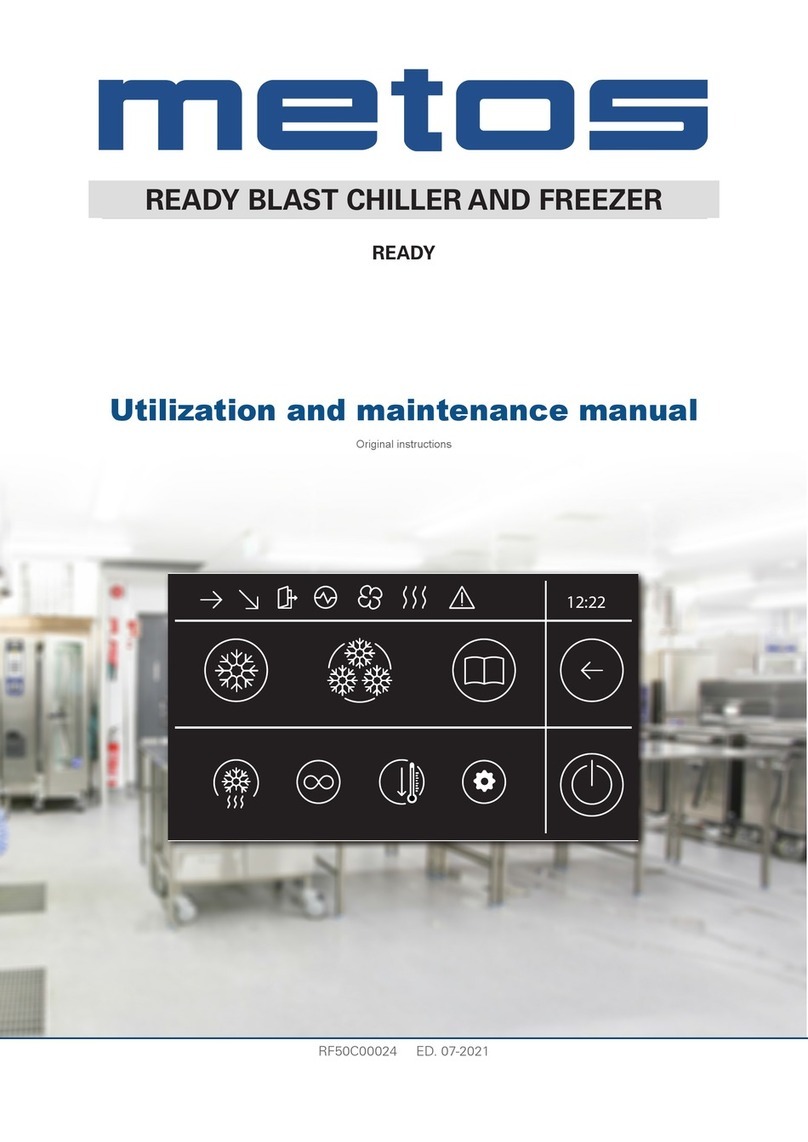

Metos HALO Series User manual

Metos

Metos 700 Series User manual

Metos

Metos 7210TCBG User manual

Metos

Metos PROFF User manual

Metos

Metos 051R User manual

Metos

Metos 700 Series User manual

Metos

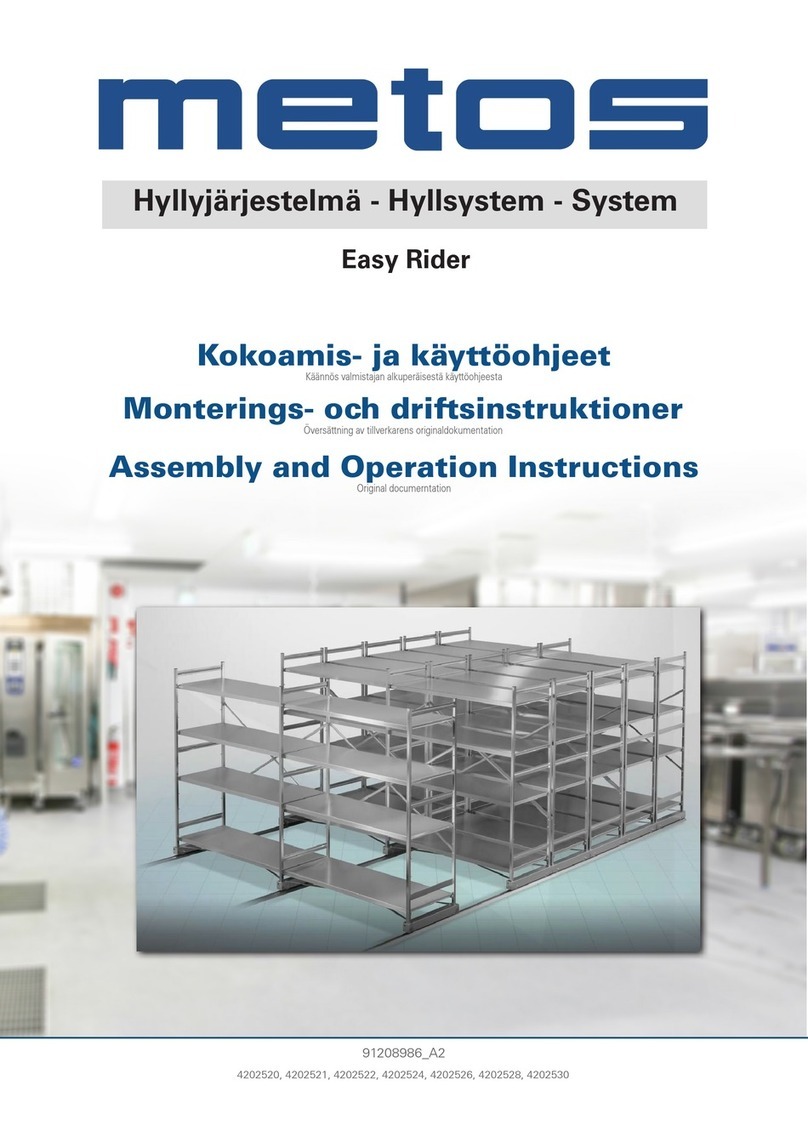

Metos Easy Rider Parts list manual

Metos

Metos BRATT PAN User manual

Metos

Metos 74GFTIST User manual

Metos

Metos Nova CB User manual

Metos

Metos DROP IN CB 450 User manual

Metos

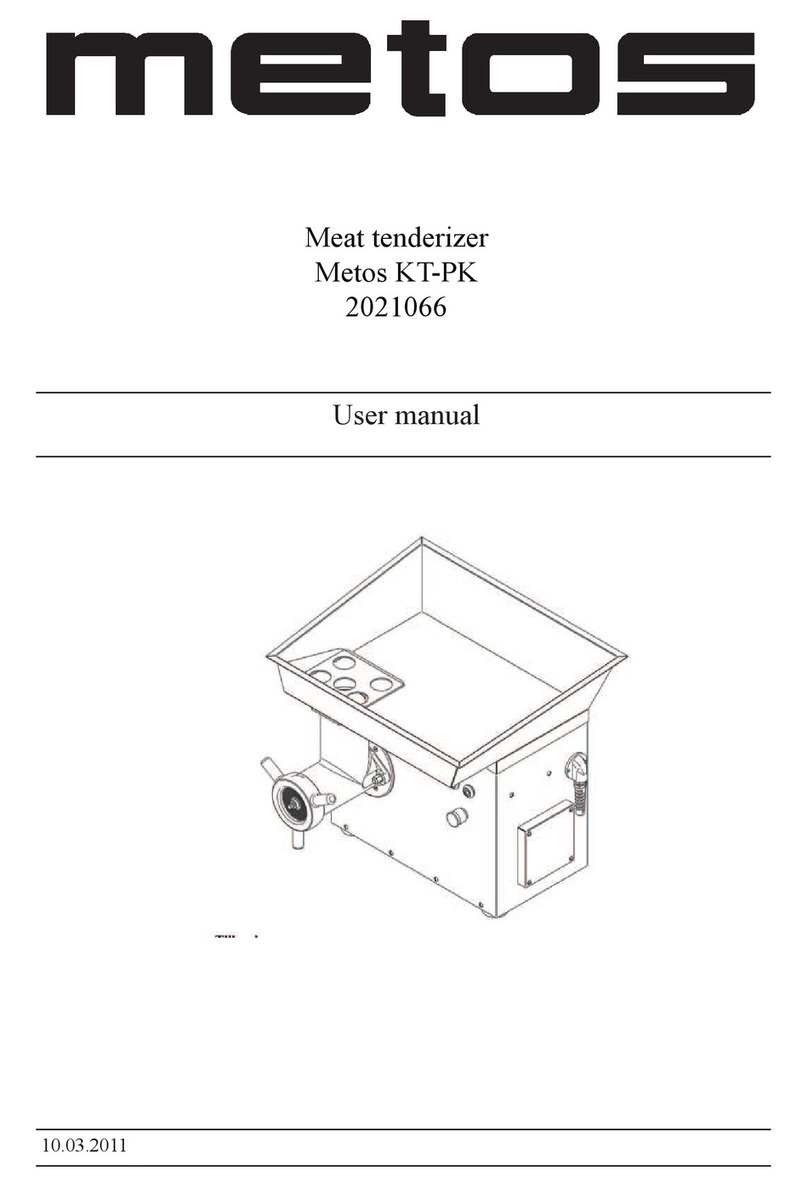

Metos KT-PK User manual

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use