3.9.2004 Rev.

1. General information ..................................................................................... 1

1.1 Symbols used in the manual .......................................................................................... 1

1.2 Symbols used on the appliance ...................................................................................... 2

1.3 Checking correspondence between the appliance and the manual ................................ 2

2. Safety .............................................................................................................. 3

2.1 Using the appliance safely ............................................................................................. 3

2.2 Safety instructions in case of malfunction ..................................................................... 3

2.3 Additional prohibitions (hazardous procedures) ........................................................... 3

2.4 Disposing of the appliance ............................................................................................ 3

3. Functional description .................................................................................. 4

3.1 Application of the appliance .......................................................................................... 4

3.1.1 Unintended usage ................................................................................................... 4

3.2 Construction .................................................................................................................. 4

3.2.1 Construction features ............................................................................................. 4

3.2.2 Cooking tops .......................................................................................................... 5

3.2.3 Gas ovens ............................................................................................................... 6

3.2.4 Electric ovens ......................................................................................................... 6

4. Operating instructions ................................................................................. 7

4.1 Before using the appliance ............................................................................................ 7

4.1.1 Preparing the appliance for use .............................................................................. 7

4.2 Using the appliance ....................................................................................................... 8

4.2.1 Operating controls .................................................................................................. 8

4.2.2 Switching the open fire burners on and off ............................................................ 9

4.2.3 Lighting the gas oven ........................................................................................... 10

4.2.4 Lighting the electrical oven ................................................................................. 11

4.2.5 Safety thermostat ................................................................................................. 12

4.2.6 Preheating ............................................................................................................ 12

4.3 After-use care .............................................................................................................. 12

4.3.1 Cleaning ............................................................................................................... 12

4.3.2 Idle period ............................................................................................................ 13

4.3.3 Periodic maintenance ........................................................................................... 13

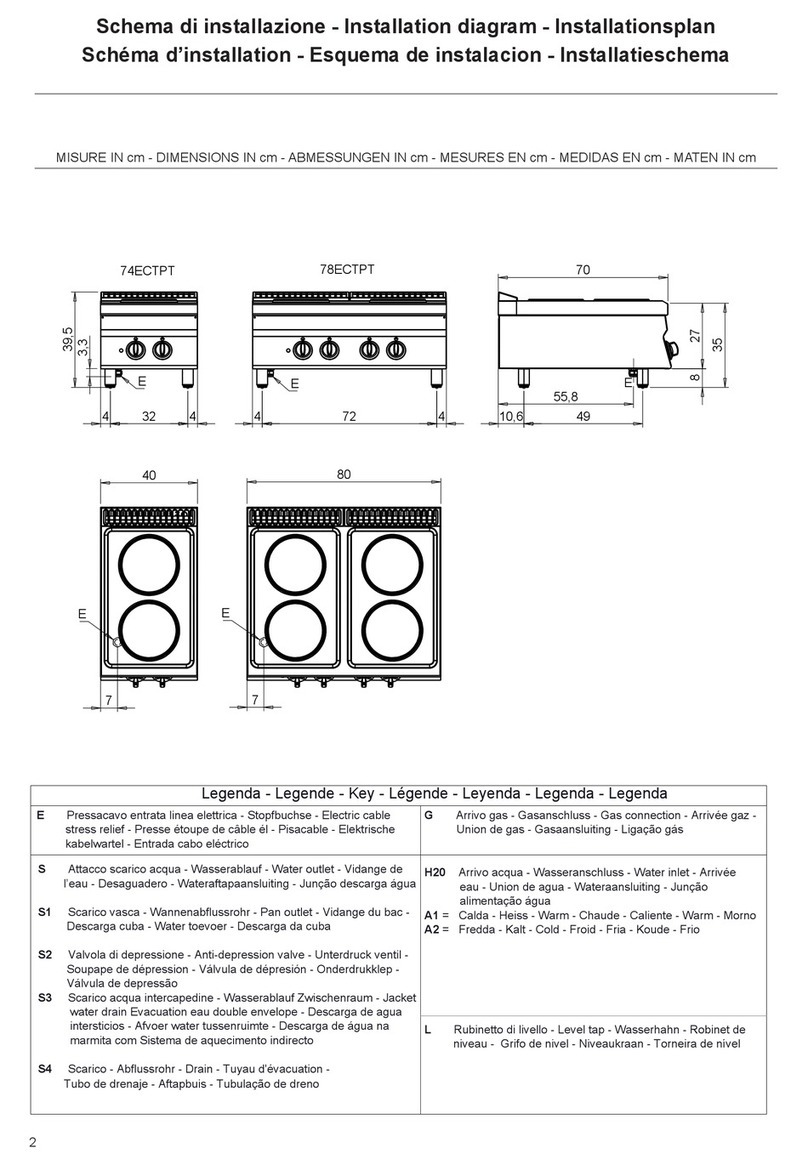

5. Installation ................................................................................................... 14

5.1 General information ..................................................................................................... 14

5.1.1 Regulatory installation conditions ....................................................................... 14

5.2 Exhausting fumes ........................................................................................................ 14

5.3 Possible environmental interference ............................................................................ 15