Michelin Hydraulic-Jack User manual

Maximum

rated load

Maximum

Hight

User Guide

2250 kg

Hydraulic-JAck

51001

04/21

2

FUNCTIONS

1. Carry handle

2. Magnetic tool tray for wheel nuts

3. Lifting arm

4. Soft grip saddle

5. Front wheel

6. Engage release valve with this end

7. Handle

8. Handle grip

9. Rear castor

10. Release valve

11. Handle sleeve

2

4

9

10

11

6

7 8

3

5

1

EN

2 3

2250 kg Hydraulic JAck

User Guide

SAVE THESE INSTRUCTIONS! For your safety, read, understand, and follow the information

provided with and on this jack. Car jack owners and users must be thoroughly familiar with the

safety procedures for car jack use before using it for the first time. The owner and operator

must be aware that use and repair of this product may require special skills and knowledge.

Instructions and safety information shall be conveyed in the operator‘s native language before

use of this jack is authorized. If any doubt exists as to the safe and proper use of this jack,

remove from service immediately.

Inspect before each use. Do not use if broken, bent, cracked, if certain parts are damaged or

rusted (including nameplates) or oil is leaking. Any jack that appears damaged in any way,

operates abnormally or is missing parts, shall be removed from service immediately. If the jack

has been, or suspected to have been, subjected to a shock load (a load dropped suddenly,

unexpectedly upon it), immediately discontinue use and remove from service. If a malfunction

occurs during use (seized lifting rod, plunger stuck), contact a professional or customer service.

In the event of an oil leak, discontinue use. Ensure no further oil leaks and immediately absorb

the oil which has leaked and dispose through designated facilities. It is recommended that an

annual inspection be done by qualified personnel.

PRODUCT DESCRIPTION / SAFETY INSTRUCTIONS

This MICHELIN 2250 kg Hydraulic Jack is designed to lift, but not sustain, rated capacity loads.

It is designed to be used in conjunction with jack stands. The MICHELIN 2250 kg Hydraulic Jack

has a unique feature which provides fast, no load lifts to the jacking point.

Intended use: To lift one axle of a vehicle for the purpose of service and / or repair of vehicle

components. After lifting, loads must be immediately supported by appropriately rated jack

stands. Check with vehicle owner‘s manual for proper jacking points.

BEFORE USE

1. Verify that the product and the application are compatible, if in doubt call the Customer

Support: +49 (0) 7131 27588-44.

2. Before using this product, read the owners manual completely and familiarize yourself

thoroughly with the product, its components and recognize the hazards associated with

its use.

3. Check to ensure that the jack rolls freely and that the pump operates smoothly before

putting into service.

EN

SPECIFICATIONS

Maximum rated load: 2,250 kg

Minimum hight: 150 mm

Maximum hight: 530 mm

Hoisting: 380 mm

Operating temperature: -20 °C to +50 °C

4

WARNING & SAFETY INFORMATION!

Study, understand, and follow all instructions provided with and on this device. Do not

exceed rated capacity. This is a lifting device only. After lifting, immediately transfer the load

to appropriately rated jack stands. Never work on, under, or around a load supported by

this device. Use only on hard, level surfaces capable of supporting the load marked on the

equipment. Do not move or dolly loads with this device. Failure to heed this warning may

result in personal injury and / or property damage.

- Never use the car jack to life persons. Do not use the car jack with people inside or leaning

against the vehicle.

- The user must keep an eye on the jack and the load during all movement.

- The condition of the markings on the car jack must be checked regularly and the markings

must always correspond with the original markings.

Do not use the car jack in the following situations:

- Outdoors in frost / rain.

- In severe conditions (e.g. very cold or very hot weather, when exposed to strong magnetic

radiation and similar situations).

- In potentially explosive environments, mines and similar situations.

- When lifting loads containing the following materials, among others: molten metal, acid,

radioactive material or loose / not firmly connected goods and similar situations.

- In contact with food and similar situations.

- On ships and in similar situations.

To avoid any risk of being crushed or sustaining other injuries: NEVER work on, under or around

a load supported only by a jack. ALWAYS use adequately rated jack stands. If the generated

efforts exceed 400 N (approx. 40 kg), the effort shall be lowered by additional person.

Be sure all tools and personnel are clear before lowering load. Do not alter or modify the car

jack which will adversely affect the car jack’s compliance with standard EN 1494:2000+A1:2008.

Only attachments and / or adaptors supplied by the manufacturer shall be used. Only lift the

vehicle using the jacking points specified by the vehicle manufacturer.

EN

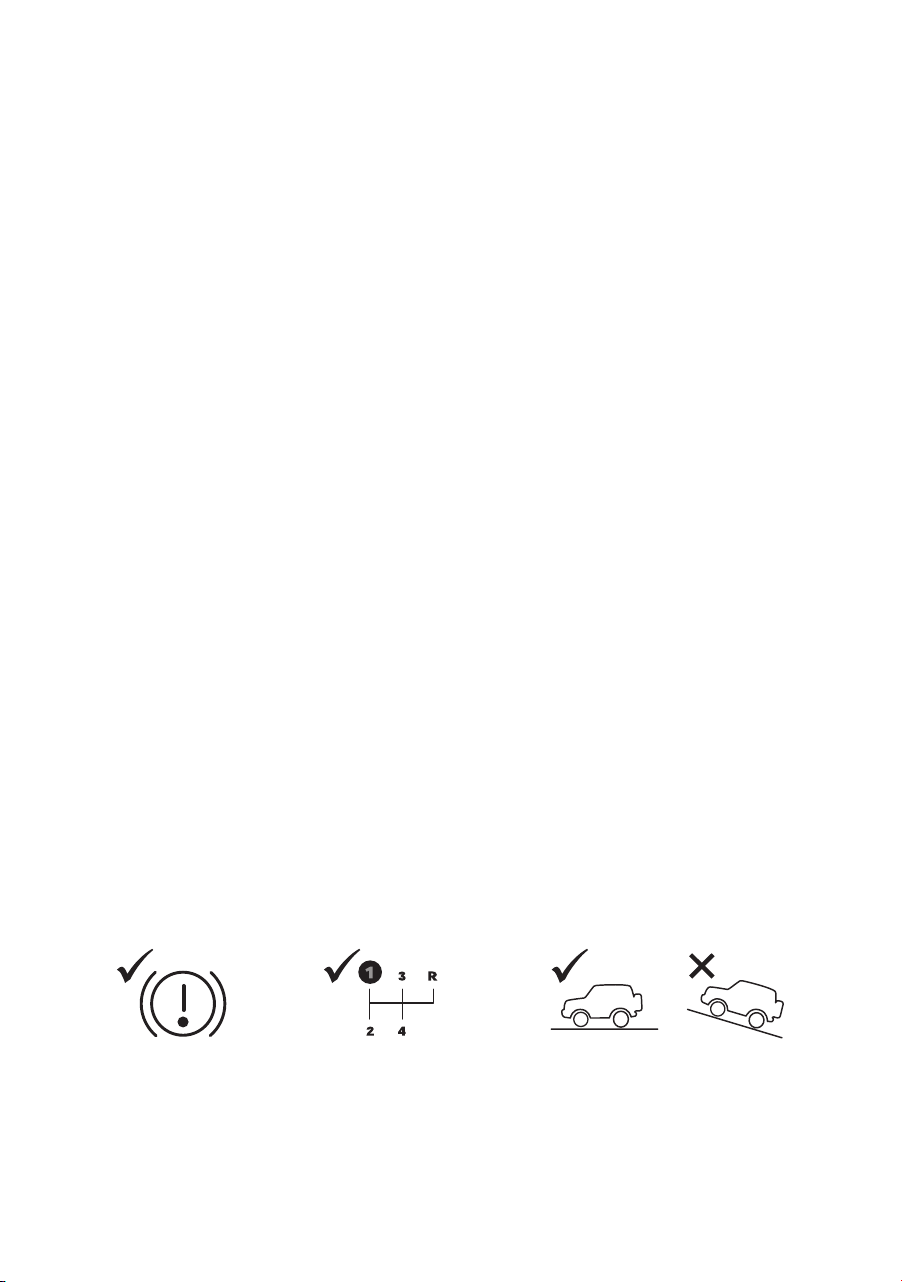

Handbreak on Leave car in

gear

Use on a flat surface

4 5

OPERATION

LIFTING VEHICLE

1. Place vehicle in park, with emergency brake on and wheels securely chocked to prevent

inadvertent vehicle movement.

2. Locate and close release valve by turning handle clockwise until firm resistance is felt to

further thread engagement. Center jack saddle under lift point.

3. Verify lift point, insert handle into handle sleeve and pump to contact lift point. To lift,

pump handle until load reaches desired height.

4. Transfer the load immediately to appropriately rated jack stands.

LOWERING VEHICLE

1. Raise load high enough to clear the jack stands, then carefully remove jack stands (always

used in pairs).

2. Slowly turn the handle anti-clockwise, but no more than a 1/2 full turn.

3. After removing jack from under the load, push soft grip saddle down to lower lifting arm

as much as possible.

EN

MAINTENANCE

- Check the car jack for damage, oil leaks and corrosion before every use. Do not use the

car jack if damaged. Only use original manufacturer parts. Maintenance and repairs must

always be performed by qualified professionals. Have the oil level regularly checked by a

speciality shop.

- Clean the car jack with a dry rag or cloth. Do not use chemical, alkaline, abrasive or other

aggressive cleaners, as these will harm the surfaces.

- Keep the grips free from oil to prevent accidental slipping and the injuries this will cause.

- Regularly lubricate moving car jack parts (e.g. with spray lubricant).

- Check the car jack for signs of corrosion and rust. Clean the affected areas with a cloth

dipped in oil.

- IMPORTANT: Always store the car jack in the lowered position!

DISPOSAL

When disposing of this device, please contact your local retailer or a local recycling centre. Never

dispose of the device in regular household waste! This will greatly contribute to protecting the

environment. Hydraulic oil and objects contaminated with oil (e.g. cleaning cloths) must be

disposed through a hazardous waste collection site.

6

EN

TROUBLE SHOOTING

Symptom Possible Causes Corrective Action

Jack will not lift load • Releasevalvenottightly

closed

• Overloadcondition

• Ensurereleasevalveis

tightly closed

• Remedyoverload

condition

Jack bleeds off after lift • Releasevalvenottightly

closed

• Overloadcondition

• Hydraulicunit

malfunction

• Ensurereleasevalveis

tightly closed

• Remedyoverload

condition

• ContactCustomerSupport

Jack will not lower after

unloading

• Linkagesbinding • Cleanandlubricate

moving parts

Poor lift performance • Fluidlevellow

• Airtrappedinsystem

• Ensureproperuidlevel

to be checked by specialist

Will not lift to full extension • Fluidlevellow • Ensureproperuidlevel

Customer enquiries:

We’re at your service. Let us help

you find a better way forward.

Tel: +49 (0) 7131 27588-44

Michelin@helix-automotive.com

Manufactured and distributed under licence by

Helix Automotive GmbH, Fischeräcker 4, DE-74223 Flein

© 2021 Michelin, www.michelin-lifestyle.com

MICHELIN and/or the Michelin Man Device and/or BIBENDUM

are trademark(s) owned by, and used with the permission of,

the Michelin Group.

Table of contents

Other Michelin Jack manuals