Michell Instruments XTP601 User manual

XTP601

Process Oxygen Analyzer

User’s Manual

97313 Issue 8.1

November 2020

(For use with firmware V1.11)

Please ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

© 2020 Michell Instruments

This document is the property of Michell Instruments Ltd and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

XTP601

For Michell Instruments' contact information please go to

www.michell.com

XTP601 User’s Manual

iv 97313 Issue 8.1, November 2020

Contents

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Pressure Safety...........................................................................................................vii

Temperature Safety.....................................................................................................vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration..................................................................................................................vii

Safety Conformity .......................................................................................................vii

Equipment Ratings ......................................................................................................vii

Abbreviations.................................................................................................................... viii

Warnings .......................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 2

1.2 Applications ....................................................................................................... 3

1.3 O-Ring Selection................................................................................................. 3

2 OPERATION ......................................................................................................4

2.1 Preparation ........................................................................................................ 4

2.2 Powering up the Analyzer.................................................................................... 5

2.3 User Interface .................................................................................................... 6

2.3.1 Interface Controls ......................................................................................... 6

2.3.2 ‘ESC’ Button.................................................................................................. 7

2.3.3 ‘Up/Down Arrow’ Buttons............................................................................... 7

2.3.4 ‘ENTER’ Button ............................................................................................. 7

2.4 Menu Structure .................................................................................................. 8

2.4.1 Changing the Passcode.................................................................................. 8

2.4.2 Menu Map .................................................................................................... 9

2.5 Front Pages (No passcode Required).................................................................... 9

2.5.1 Front Page.................................................................................................. 10

2.5.2 Chart Page ................................................................................................ 11

2.5.3 Secondary Parameters Page......................................................................... 12

2.5.4 O2 Min/Max Page ....................................................................................... 12

2.5.5 Alarms Log Pages ....................................................................................... 13

2.6 Info Page ........................................................................................................ 13

2.7 Main Menu (Passcode Required) ........................................................................ 14

2.7.1 Settings Page.............................................................................................. 15

2.7.2 Human Machine Interface (HMI) Page .......................................................... 16

2.7.3 Reset Page ................................................................................................. 17

2.7.4 Alarms Page ............................................................................................... 18

2.7.5 External Compensation Page........................................................................ 19

2.7.6 External Sensor Page .................................................................................. 20

2.7.7 Outputs Page.............................................................................................. 21

2.7.8 Field Cal Page ............................................................................................. 22

2.7.9 Light Guide Option ...................................................................................... 22

3 CALIBRATION..................................................................................................23

3.1 1-Point Calibration ............................................................................................ 24

3.2 2-Point Calibration ........................................................................................... 25

3.3 Field Calibration Reset ...................................................................................... 26

4 INSTALLATION ................................................................................................27

4.1 Unpacking........................................................................................................ 28

4.2 System Components ......................................................................................... 29

XTP601 User’s Manual

Michell Instruments v

Figures

Figure 1 XTP601 Oxygen Analyzer Versions ...............................................................1

Figure 2 Initializing Screen .......................................................................................5

Figure 3 Main Page..................................................................................................5

Figure 4 User Interface ............................................................................................6

Figure 5 XTP600 Series Application Software .............................................................6

Figure 6 ESC Button ................................................................................................7

Figure 7 Up/Down Arrow Buttons .............................................................................7

Figure 8 ENTER Button ............................................................................................7

Figure 9 Menu Map..................................................................................................9

Figure 10 Front Page ...............................................................................................10

Figure 11 Chart Page...............................................................................................11

Figure 12 Secondary Parameters Page ......................................................................12

Figure 13 O2

Min/Max Page ......................................................................................12

Figure 14 Alarms Log Page ......................................................................................13

Figure 15 Info Page.................................................................................................13

Figure 16 User Set-Up Variables Page .......................................................................14

Figure 17 Settings Page ...........................................................................................15

Figure 18 HMI Page.................................................................................................16

Figure 19 Date and Time Page .................................................................................16

Figure 20 Reset Page...............................................................................................17

Figure 21 Alarms Page.............................................................................................18

Figure 22 External Compensation Page .....................................................................19

Figure 23 External Sensor Page................................................................................20

Figure 24 OUTPUTS Page ........................................................................................21

Figure 25 NAMUR ERR Page.....................................................................................21

Figure 26 Field Cal Page ..........................................................................................22

Figure 27 1-Point Calibration Page............................................................................24

Figure 28 2-Point Calibration Page............................................................................25

Figure 29 Field Calibration Reset Page ......................................................................26

Figure 30 XTP601 Cutaway Showing Major Components ............................................29

Figure 31 XTP601 Lid Removal.................................................................................30

Figure 32 XTP601 Cable Entries................................................................................31

Figure 33 Terminal Block Locations ...........................................................................32

Figure 34 XTP601 Dimensional Drawings ..................................................................39

4.3 Set-Up............................................................................................................. 30

4.4 Mechanical Installation...................................................................................... 31

4.4.1 Gas Connection........................................................................................... 31

4.4.2 Sample Gas Requirements ........................................................................... 31

4.4.3 Calibration Gases ........................................................................................ 32

4.5 Electrical Installation......................................................................................... 32

4.5.1 Power Supply and Input/Output Signal ......................................................... 32

4.5.2 Power Supply (PL9 - Green) ........................................................................ 33

4.5.3 Signal Output ............................................................................................. 33

4.5.4 Serial Output .............................................................................................. 33

4.5.5 Analog (4-20 mA) Outputs and Communications (PL5 - Green)....................... 34

4.5.6 Alarm Relay Contacts (PL1- Black)................................................................ 34

4.5.7 Analog (4-20 mA) Inputs and Sensor Excitation Voltage (PL4 - Green) ............ 35

4.5.8 Light Guide................................................................................................. 35

XTP601 User’s Manual

vi 97313 Issue 8.1, November 2020

Appendices

Appendix A Technical Specifications.............................................................................37

A.1 Dimensions Ex version ................................................................ 39

Appendix B Modbus Register Map ...............................................................................41

Appendix C Hazardous Area Certification .....................................................................47

C.1 Product Standards ...................................................................... 47

C.2 Product Standards ...................................................................... 47

C.3 Global Certicates/Approvals ....................................................... 47

C.4 Special Conditions....................................................................... 48

C.5 Maintenance and Installation....................................................... 48

Appendix D Quality, Recycling, Compliance & Warranty Information...............................50

Appendix E Analyzer Return Document & Decontamination Declaration .........................52

XTP601 User’s Manual

Michell Instruments vii

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualified personnel and good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument. The input power supply voltage is 24 V DC, 1.5 A

(max). Refer to labels on the instrument or calibration certificate.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specified safe working pressure for this instrument is 3 barg (43 psig) max.

Temperature Safety

During operation some parts of the instrument may be at high temperature.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Long exposure to, or breathing of the calibration gases, may be dangerous.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. For

Michell Instruments’ worldwide offices contact information go to www.michell.com.

Calibration

The recommended calibration interval for the analyzer is 3 months. Depending on the application in

which the instrument is used, the calibration interval may be reduced. Please consult the factory for

the specific calibration interval.

Safety Conformity

This product carries the CE mark and meets the requirements of relevant European safety directives.

Equipment Ratings

This equipment must be supplied with a voltage of 24 V DC, 1.5 A (36 W).

The power is connected via PL9 on the mother board (see Section 4.5).

All input and output connectors are 2-part pcb mounted type.

The detachable, screw terminal half of each connector is designed to accept 24 -12 AWG stranded

or solid conductors.

XTP601 User’s Manual

viii 97313 Issue 8.1, November 2020

Abbreviations

The following abbreviations are used in this manual:

A Ampere

AC alternating current

bara pressure in bar (absolute)

barg pressure in bar (gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

kg kilogram

kPa Kilopascal

lb pound

max maximum

mA milliampere

ml/min milliliters per minute

mm millimeters

ppm parts per million

psig pounds per square inch

scfh standard cubic feet per hour

V Volt

" inches

Ω ohm

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

Where this symbol appears in the following sections it

is used to indicate areas where potentially hazardous

operations need to be carried out.

THESE TASKS SHOULD BE UNDERTAKEN BY QUALIFIED

PERSONNEL ONLY.

Where this symbol appears in the following sections it is

used to indicate areas of potential risk of electric shock.

NOTE: Warnings and important notifications are marked with bold text.

XTP601 User’s Manual

Michell Instruments 1

INTRODUCTION

1 INTRODUCTION

This manual will show how to measure oxygen easily using the XTP601 Oxygen Analyzer.

The following sections contain information about:

• Analyzer components

• Operating instructions

• Calibration and maintenance of the Analyzer

• Installation

Please read this manual carefully and pay special attention to the safety warnings and

notifications.

NOTE: Warnings and important notifications are marked with bold text.

The 3 versions of the XTP601 available are shown below:

XTP601-EX1 XTP601-GP1 XTP601-GP2

(Hazardous Area) (Safe Area) (with flame arrestors)

Figure 1

XTP601 Oxygen Analyzer Versions

The XTP601 Oxygen Analyzer is based on Michell Instruments’ advanced proprietary

Thermo-Paramagnetic technology. It measures the percentage of oxygen in a wide

range of gases, including nitrogen, hydrogen, carbon dioxide methane and biogas.

The sensor is housed in a weather-proof (GP version) or explosion-proof (EX version)

casing - both IP66 & NEMA 4X rated. It is suitable for a range of applications in safe or

hazardous areas.

EX1 and GP2 models are supplied with flame arrestors for use with flammable gases or

in hazardous areas.

NOTE: this manual relates to products with firmware version V1.11

XTP601 User’s Manual

297313 Issue 8.1, November 2020

INTRODUCTION

1.1 Features

• The XTP601 can be supplied meeting the requirements of IEC 61508

SIL2, allowing the user to integrate the analyzer into their functional

safety system.

• There are 2 versions of the XTP601 available:

General Purpose Analyzer with touch screen (capacitive buttons)

Hazardous Area version of above with ame arrestors

• The XTP601 is calibrated in a specific background gas to match

customer's requirements. This is displayed on the front screen of the

analyzer or via the Application Software.

• The XTP601 provides 2 off 4-20 mA analog output signals that are

proportional to the oxygen concentration. The primary 4-20 mA output

is locked on the calibrated range of the instrument. The secondary

output is user-selectable within the calibrated range.

• Modbus RTU over RS485 protocol serial communications are provided

as standard.

• Accuracy of 1% of reading or 0.02% O2, whichever is greater. (Zero

suppressed ranges ±0.2% O2).

• Zero and span stability of 0.25% of span per month.

• The innovative Thermo-Paramagnetic sensor design used in the XTP601

Oxygen Analyzer has no moving parts. This makes it less sensitive

to vibration and movement and highly resistant to drift over a long

period of time, compared to other sensing technologies, and it offers

increased protection against contamination.

• The robust and weather-proof enclosure (IP66 rated) allows the XTP601

to be installed on-site, at the point of measurement. It is also available

with an explosion-proof casing.

• Low cost of ownership due to minimal maintenance. For installation

and commissioning, the casing unscrews to allow for easy access to the

electrical connections.

• The XTP601 is certified to ATEX, IECEX, cQPSus, INMETRO & TC TR Ex

for use in hazardous areas.

• 2 x single pole change-over relay alarms for oxygen concentration,

supplied as standard. Can be configured as OFF, LOW or HIGH.

XTP601 User’s Manual

Michell Instruments 3

INTRODUCTION

1.2 Applications

The XTP601 has a robust sensor with high sensitivity and stability. It can be factory-

calibrated in varying backgrounds to match the customer’s process gas.

Together with the purpose-designed sampling system, the XTP601 is able to work under

various process and environmental conditions. Examples of applications include:

• Oxygen generator monitoring inert blanketing gases

• Oxygen measurement at inlet of compressors in steel or gas industries

for safety

• Biogas, waste, landfill and digester plants

• Inert gas monitoring for pharmaceutical industry

1.3 O-Ring Selection

The XTP601 is available with 3 types of O-rings to offer greater flexibility with material

compatibility. The Viton O-ring is fitted as standard. The EKRAZ O-ring is available for

solvent resistance. For extremely low temperatures there is a closed cell Silicone O-ring.

To comply with Hazardous Area certification, the material used in the EX1 version is

dependent on the lowest ambient temperature of the area the units are to be transported,

stored or installed in:

Ambient operating range:

+5°C to +60°C (41°F to +140°F)

Ambient range for storage and transportation:

-40°C to +60°C (-40°F to +140°F) (for Silicone version)

-15°C to +60°C (5°F to +140°F) (for Viton version) – Standard

-10°C to +60°C (14°F to +140°F) (for Ekraz version)

NOTE: Silicone O-ring is not suitable for oxygen-enriched samples, i.e. O2> 21%.

XTP601 User’s Manual

497313 Issue 8.1, November 2020

OPERATION

2 OPERATION

The XTP601 is not certied for use with ambient oxygen

levels that are enriched (i.e. over 21% O2)

This analyzer has been manufactured within our quality procedures and is configured

according to the purchase order. When it is installed and used as per the manufacturer’s

guidelines, it will operate within the stated specification.

Before starting operation it is recommended that the user becomes familiar with this

manual in which all the equipment controls, indicators, the elements of the display and

the overall menu structure are described.

2.1 Preparation

Before applying power and beginning the ow of gas,

please ensure that the system has been properly installed

following the instructions in Section 4.

Check that the wiring has been completed correctly.

Zero and Span gas cylinders with correct regulation and flow control should be in place

before installing and powering up the analyzer. Commissioning should include a check

with both gases and, if necessary, a field calibration performed.

The factory calibration is performed at nominally 300 ml/min with an atmospheric vent

(50-100 mbarg back-pressure). The calibration gas applied to the analyzer should be at

the same temperature, pressure and flow rate as the process gas being sampled.

Sample Pressure:

0.75 to 2 BarA (11 to 29 psiA)

Sample Flow Rate:

GP1 models: 100 to 500 ml/min (0.25 to 1.0 scfh)

EX1 & GP2 Models: 270 to 330ml/min (0.57 to 0.7 scfh)

XTP601 User’s Manual

Michell Instruments 5

OPERATION

2.2 Powering up the Analyzer

After all the preparation work is done and the installation

and wiring have been checked, turn on the analyzer and

wait for at least 30 minutes (or until Cell T Not StableCell T Not Stable

message disappears). This will allow the analyzer to reach

its operating temperature.

There is no power switch on the XTP601 Oxygen Analyzer. It is turned on automatically

once a 24 V DC power source is applied. After the analyzer is powered up, the display

will be illuminated. The analyzer takes up to 5 seconds to initialize, and during this

period will display the product type and firmware version number.

Figure 2

Initializing Screen

5.23 % 02

Cell T Not Stable

Back. Gas: N2

Cell Temperature

Indication

Cell Heating

Symbol

Oxygen

Concentration

Status Bar

Figure 3

Main Page

Once initialized, the analyzer will show the Main Page which displays the O2 concentration.

During warm-up (less than 25 minutes) a heating symbol will flash in the top right

hand corner of the page. This symbol will remain until the temperature has stabilized

for a minimum of 5 minutes. The analyzer will be ready for use within 30 minutes from

power-up.

XTP601 User’s Manual

697313 Issue 8.1, November 2020

OPERATION

2.3 User Interface

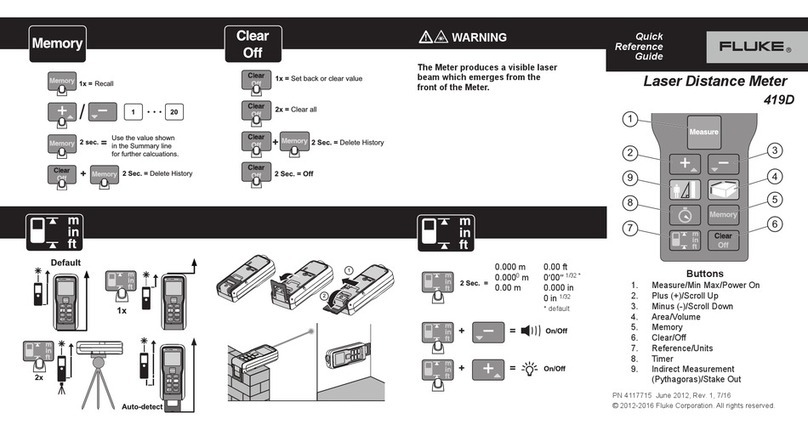

2.3.1 Interface Controls

XTP601-EX1

Oxygen Analyzer

ENTER

ESC

Up/Down

Arrow

Buttons

ESC

Button

ENTER

Button

Blue LEDs

Backlit LCD

Figure 4

User Interface

The diagram above illustrates the user interface, which consists of a backlit Liquid

Crystal Display and 4 touch-sensitive pads that facilitate user interaction through the

glass of the enclosure.

All versions have Application Software to monitor or adjust parameters. Application

software will require a PC or laptop with comm port connection. If using RS232 serial

port ensure that an isolated RS232 to RS485 converter is used.

Figure 5

XTP600 Series Application Software

XTP601 User’s Manual

Michell Instruments 7

OPERATION

2.3.2 ‘ESC’ Button

Figure 6

ESC Button

The ESCESC button is used to exit the current menu and to return to the previous menu.

From the Main Page, pressing ESCESC will access the Info Page.

2.3.3 ‘Up/Down Arrow’ Buttons

Figure 7

Up/Down Arrow Buttons

The UpUp () and Down (Down () buttons are used to change pages, scroll through lists and

adjust values. In the Reset and Field Calibration Menus, pressing the UpUp () button

3 times will confirm a selection.

2.3.4 ‘ENTER’ Button

Figure 8

ENTER Button

The ENTERENTER button is used to select or de-select the highlighted item in a menu and to

confirm a value. From the Main Page, pressing ENTERENTER will access the Passcode Page.

XTP601 User’s Manual

897313 Issue 8.1, November 2020

OPERATION

2.4 Menu Structure

The XTP601 has a front page that does not require a passcode but allows the user

to scroll through and view oxygen concentration, recent trend, internal parameters,

minimum & maximum oxygen concentration and alarm history.

In order to change any settings on the User Menu pages, the user must enter a passcode.

There is also a separate passcode for service engineers to allow factory setting changes.

To access the User Menu press the ENTERENTER button from the Main Page to call up a

passcode prompt. Use the UpUp () and Down (Down () buttons and press ENTERENTER after each

value.

The User Passcode is: 19191919

From the Main Page the user can press the ESCESC button to view the Info Page. This page

shows the firmware version, hours used, last calibration date, calibration pressure and

the received Modbus code.

The passcode is stored for one minute to allow access back into the User Menu, if

necessary.

2.4.1 Changing the Passcode

As part of the SIL compliance the user must change the passcode after the unit is set

up and before bringing it on-line in a functional safety system. This new passcode must

be kept secure and must only be made available to authorized personnel.

Press EnterEnter from the Front Page and arrive at the Passcode Screen.

Enter the activation code: 6182 and the unit will be ready to accept the new passcode.

Warning: The passcode can only be changed once, so care must be taken from this

point onwards.

Now enter the new passcode and once activated the analyzer will bring you straight into

the user menu. If you want to change your mind or you make a mistake at any point

before you hit the enter button the final time, just press and hold the ESCESC button to

return to the front screen and start again.

The passcode will be active for 5 minutes, so make a note of what was actually entered

by going back to the passcode screen. Store this new passcode in a secure place.

If you forget/lose the passcode, contact Michell Instruments for help.

XTP601 User’s Manual

Michell Instruments 9

OPERATION

2.4.2 Menu Map

Figure 9

Menu Map

2.5 Front Pages (No passcode Required)

The EX1 and GP1 versions of the XTP601 have 5 front pages that the user can display

without t he need for a passcode. NOTE: These are for display of information only

and there is no way of adjusting any settings on these pages.

From the Main Page (O2 concentration) the rest of the front pages can be accessed

using the Down (Down () button. To return to the Main Page, either press the UpUp () button

the required amount of times or press the ESCESC button.

XTP601 User’s Manual

10 97313 Issue 8.1, November 2020

OPERATION

2.5.1 Front Page

Figure 10

Front Page

Parameter Description

Background GasBackground Gas Displays the background gas that the unit was calibrated in

% O% O22

(if HSR=OFF)

Real oxygen reading in %

Display resolution = 0.01

(Display resolution 0.1% when min value is >=20%)

% O% O22pp

(if HSR = ON)

HSR oxygen reading (extrapolated quick response value of real

oxygen reading) Real oxygen value is displayed in status bar

Flashing “Heating”

Symbol

This flashes until cell temperature is stable at set point ±0.5°C

for minimum of 5 minutes

Pressure Compensation If 'P' is visible this indicates that the pressure compensation is

turned on

Status Bar Flashes any system warnings and error messages (see below)

Status Message Table

Message

(Trigger Condition)

Light Guide

(if fitted)

% O% Oout of rangeout of range

(beyond calibration range, e.g. 0-25%) N/A

AL1 ONAL1 ON ORANGE1 ON (app s/w only)

AL2 ONAL2 ON ORANGE2 ON (app s/w only)

Comp i/p signal errorComp i/p signal error

(input < 3.6 mA or > 21 mA)

RED FLASH

(priority2)

Ext sens signal errorExt sens signal error

(input < 3.6 mA or > 21 mA)

RED FLASH

(priority2)

Cell T not stableCell T not stable

(not within ±0.5ºC of set point for continuous period

of 5 minutes)

RED ON

(priority1)

Cell T sensor errorCell T sensor error (cell temp measures <-50 or

>+80ºC)

RED ON

(priority1)

Press sensor errorPress sensor error

(pressure sensor < 850 or >1100 mbar)

RED ON

(priority1)

OOsensor errorsensor error

(Vcomp <1 or >8191)

RED ON

(priority1)

PCB temp too highPCB temp too high

(PCB temp > cell temp set point)

RED ON

(priority1)

XTP601 User’s Manual

Michell Instruments 11

OPERATION

2.5.2 Chart Page

Figure 11

Chart Page

NOTE: This data is not available via the Modbus

• This indicative chart is continuously running at the set chart interval (2

to 60 seconds).

• Chart duration in seconds = (chart interval * 60).

• It is auto ranging with an auto range resolution of 1% O2.

• It is reset if the chart interval is changed, the Display is changed between

% O% O22 and % O% O22HSRHSR or the instrument power is cycled.

• The chart will record either % O2 (Non HSR) or % O2 HSR if this is set to

ONON in the setup pages.

• Chart buffer size is 60 values and therefore the chart duration changes

according to interval chosen.

• Chart data is only stored in volatile memory and therefore is not saved.

Chart interval is saved and available in a Modbus register.

• Chart data is not available via serial comms as the Application Software is

able to perform more sophisticated charting functions.

XTP601 User’s Manual

12 97313 Issue 8.1, November 2020

OPERATION

2.5.3 Secondary Parameters Page

Figure 12

Secondary Parameters Page

Parameter Description

CELL TCELL T Sensor cell temperature display in set unit (°C, °F or Kelvin)

Display Resolution = 0.1

PCB TEMPPCB TEMP

Temperature display of Microcontroller in selected temperature unit

This gives an indication of the internal GUB temperature

Display Resolution = 1 unit

Accuracy = ±2ºC

COMP I/PCOMP I/P

The value of compensation input (mA i/p channel 1) as a %

(4 mA=0% and 20 mA=100%)

OFFOFF displayed instead of value if external compensation is turned off

EXT I/PEXT I/P

Value of the external input in the selected parameter and unit

(DEWP, TEMPR, PRESS or NONE)

OFFOFF displayed instead of value if external compensation parameter is set

to NONENONE

2.5.4 O2Min/Max Page

Figure 13

O2

Min/Max Page

This indicates the minimum and maximum O2 values measured, along with date/

time of occurrence. The value is reset manually via the Reset Page in the User Menu.

NOTE: This data is not saved in NV memory and is not available via serial

communications or in the blind unit.

Other manuals for XTP601

2

This manual suits for next models

3

Table of contents

Other Michell Instruments Analytical Instrument manuals

Michell Instruments

Michell Instruments Liquidew I.S. User manual

Michell Instruments

Michell Instruments XTP601 User manual

Michell Instruments

Michell Instruments Condumax II User manual

Michell Instruments

Michell Instruments XZR200 User manual

Michell Instruments

Michell Instruments XZR500ST User manual

Michell Instruments

Michell Instruments XTC601 User manual