Michell Instruments 4000 Series User manual

SERIES 4000 Precision Dewpointmeters

(Remote, Climatic, RS and TRS)

Users

Guide

Issue 21, August 2009 Manual No. 97051 43 Pages

1999 Michell Instruments Ltd

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

TABLE OF CONTENTS

1 INTRODUCTION 4

1.1 General ..................................................................................................4

1.2 Operating Principle.................................................................................5

1.3 Calibration..............................................................................................5

1.4 Manufacturing Quality.............................................................................5

2 INSTRUMENT DESCRIPTION 6

2.1 Monitor Front Panel................................................................................6

2.2 Monitor Rear Panel.................................................................................6

2.3 Sensor Unit.............................................................................................6

2.4 Monitor Front Panel Controls..................................................................7

2.5 Monitor Rear Panel Controls / Connections............................................8

2.6 Operation / Standby Modes....................................................................8

2.6.1 Operation Mode 8

2.6.2 Standby Mode 8

2.7 Manual / Auto Modes..............................................................................9

2.8 Automatic Balance Compensation (ABC)...............................................9

2.9 Manual Balance Compensation............................................................10

2.10 Data Hold .............................................................................................11

2.11 Clean Optics Warning ..........................................................................11

2.12 Max Cool..............................................................................................11

2.13 Display Operation.................................................................................12

2.13.1

Upper Display 12

2.13.2

Lower Display 13

2.14 Pressure Measurement ........................................................................14

3 INSTALLATION 15

3.1 General ................................................................................................15

3.2 Installing the Monitor ............................................................................15

3.3 Installing the Sensor.............................................................................16

3.4 Electrical Connections..........................................................................16

3.5 S4000 TRS Enclosure..........................................................................17

3.5.1 General 17

3.5.2 Gas Connections 17

3.5.3 Electrical Connections 17

4 OPERATION 18

4.1 General ................................................................................................18

4.2 Sampling Hints .....................................................................................18

Page 2

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

4.3 Which Gases to Measure? ...................................................................19

4.4 Operating the Hygrometer....................................................................19

4.4.1 General 19

4.4.2 Adjusting the Sensor Body Temperature (RS and TRS Models)

20

4.4.3 Adjusting the Balance Compensation System 21

4.4.4 Automatic Operation 22

4.4.5 Manual Operation 22

4.4.6 Effectiveness of the ABC Operation 23

4.5 Additional Operating Guidelines for S4000 TRS...................................24

4.5.1 Analogue Inputs / Outputs 25

4.5.2 Digital Interface 25

4.6 Direct Measurement of Mirror Temperature..........................................27

4.7 Microscope...........................................................................................27

5 TECHNICAL SPECIFICATIONS 30

5.1 General ................................................................................................30

5.2 Sensor Unit...........................................................................................30

5.3 Monitor Unit..........................................................................................31

5.4 S4000 TRS Enclosure..........................................................................32

6 MAINTENANCE 33

6.1 Cleaning the Optical System ................................................................33

6.1.1 Cleaning Procedure 33

6.2 Refrigeration Unit .................................................................................34

7 OPTIONS 35

7.1 RS485 Output - Option.........................................................................35

7.2 Microscope...........................................................................................35

7.3 Remote Pressure Transducer...............................................................35

APPENDIX 1

S4000 Remote Outline Drawings

36

APPENDIX 2

System Schematic

40

APPENDIX 3

S4000 Remote Depression Range

40

APPENDIX 3

S4000 Remote Depression Range

41

APPENDIX 4

Hazardous Products

42

APPENDIX 5

Recycling

42

APPENDIX 6

WEEE & RoHS

42

APPENDIX 7

Liability

42

APPENDIX 8

Customer Service Contact Details

43

Page 3

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

1 INTRODUCTION

1.1 General

Michell Instruments manufacture a wide range of on-line and portable instruments for

the determination of moisture content in air and gases. In addition, the company

manufactures Humidity Calibration Systems for Industrial and Scientific users and

undertakes custom design-and-build contracts for large scale humidity monitoring

and control applications.

The Series 4000 Precision Dewpointmeter is a precision instrument which may be

used in Calibration and Standards Laboratories and in exacting process monitoring

and control applications where wide humidity range and high accuracy is a prime

requirement.

A direct indication of dew point to a resolution of 0.01 °Celsius (°C) is provided by the

instrument display, the dew point may also be displayed in a number of other

engineering units including °Farenheit (°F), Parts Per Million by Volume (ppm(v)),

Parts Per Million by Weight in SF6 (ppm(w) in SF6), grams per cubic metre (g/m3)

and grams per kilogramme (g/kg). Additionally, the instrument can measure and

display the gas temperature using an external remote P.R.T. probe (supplied as

standard). This temperature may be displayed in °C or °F. Relative Humidity (% rh)

may then be calculated from the fundamental gas dew point and temperature at

atmospheric pressure. The instrument may also be configured to display measured

gas pressure (kPa) using an external pressure transducer, and use this measured

pressure to calculate pressure compensated (ppm(v), (ppm(w))SF6, g/m3 and g/kg.

Experiments conducted by the National Physical Laboratory (NPL) have indicated

that, by reference directly to the instrument's resistance thermometer, accuracies of

thousandths of a °C. dew point can be observed and repeated.

NPL (Teddington, UK) use a Series 4000 as a Transfer Standard instrument. Also,

the National Measurement Accreditation Service (UKAS) use one as a portable

Transfer Standard to audit the performance of Humidity Calibration Laboratories.

The Series 4000 is based on the cooled mirror principle and is derived from Michell

Instruments' highly successful Transfer Standard Dew-point Hygrometer. This

Transfer Standard was developed during the early 1980's in collaboration with the

EEC Bureau of Reference as a European link to the National Institute of Standards

and Technology (NIST) humidity standard in Washington, USA.

Dew points over the range -100 °C to +80 °C may be measured with the Series 4000

Remote instrument with the relevant auxilliary heating / cooling system, this is

equivalent in terms of absolute humidity at atmospheric pressure to a range of 10

ppb(V) to almost 50% V/V (percentage moisture by volume).

In order to measure very low humidities a cooling system may be required,

depending on the model this may be a single (RS) or twin (TRS) refrigeration system.

In order to measure high humidities the sensor needs to be heated above the dew-

point temperature, this is usually achieved by placing the sensor in a heated

chamber (climatic sensor).

The use of the single or twin refrigeration systems on the S4000 RS and S4000 TRS

models, together with the use of electronic PID temperature control, enables sensor

unit operating temperatures as low as -80 °C to be maintained. The low ambient

operating temperatures of these refrigerated sensors minimises the uncertainties of

Page 4

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

measurement associated with the thermal gradient between sample gas and dew-

point temperature. The unique double detection system utilised on the Series 4000

range of instruments, sensing both reflected and scattered light from the cooled

mirror surface, ensures the highest precision and repeatability of measurement

possible at trace moisture levels.

The Series 4000 Precision Dewpointmeter is also available in an “Integrale”

configuration, where the dew-point sensor is located in the same unit as the monitor,

providing a portable self-contained instrument. The Series 4000 Integrale Precision

Dewpointmeter uses the same principle of operation as the Remote instrument,

except that the measurement range is limited, due to it‟s self-contained design. The

Series 4000 Integrale instrument can be used to measure dew points in the range

-60 °C to +35 °C (equivalent to 10.7 ppm(v) (parts per million by volume) to 140,000

ppm(v).

1.2 Operating Principle

Within the sensor a Peltier thermoelectric device cools the plated copper mirror. At a

temperature, determined by the moisture content of the sample gas, dew will form on

the mirror surface. This formation of dew causes a reduction in reflected light

intensity from the red L.E.D. light source and, at the same time, causes an increase

in scattered light from the mirror surface. This signal change is perceived by a

differential optical detection system which in turn regulates power to the Peltier via a

control circuit. The control loop maintains the mirror surface exactly at the dew-point

temperature which is then accurately measured by an embedded 4-wire platinum

resistance thermometer.

The monitoring electronics performs all the control functions for the sensor as well as

measuring and displaying the dew-point temperature. An automatic balance

compensation (ABC) system is incorporated in the monitor to eliminate the effects of

mirror contamination build-up ensuring continuous accurate operation. If automatic

balance is not required on a specific application the ABC system can be switched off

and the monitor balanced manually when required.

1.3 Calibration

Michell Instruments‟ calibration facilities are amongst the most sophisticated in the

world and have been recognised for their excellence by the National Physical

Laboratory (NPL) UK. Our humidity calibration laboratory is accredited by UKAS for

dew-point measurements in the range -90 to +82 C dew point (calibration

accreditation number 0179). It is also traceable directly to the National Institute of

Standards & Technologies (NIST) USA over the range -75 to +20 C dew point. Our

full range calibration facility extends from -100 to +90 C dew point.

1.4 Manufacturing Quality

Your S4000 Hygrometer should reach you in perfect working condition. Michell

Instruments are registered with the British Standards Institute for Quality Assurance

to BS EN ISO 9001 : 2000. We have rigorous procedures at every stage of

production to ensure that the materials of construction, manufacturing, calibration

and final test procedures meet the requirements laid down by our Quality System

which is approved by BSI.

Page 5

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

2 INSTRUMENT DESCRIPTION

The Series 4000 Remote Precision Dewpointmeter comprises of two individual units,

a sensor and a monitor, interconnected by three cables carrying the control, optical

and measurement signals. The Remote monitor unit is constructed in a 19" 3U sub-

rack enclosure, and requires only a mains power supply for operation. The standard

sensor unit is housed in a half width 19" 3U sub-rack enclosure and requires only

sample gas connections for operation. Other versions of the sensor vary in size, the

refrigeration units (RS and TRS models) also require a mains power supply for

operation. Refer to Appendix 1.0 for Dimensional Drawings and Section 5.0 for

Technical Specification.

2.1 Monitor Front Panel

On the far right of the monitor is the mains POWER switch. The L.E.D. displays and

display selection push-buttons are located in the centre of the facia. The MAX COOL

pushbutton, DATA HOLD L.E.D. indicator, and the OPERATION / STANDBY switch

are located vertically down the centre of the monitor. The ABC INITIATE push

button, MANUAL / AUTO switch, and ABC STATUS L.E.D. indicator are located

along the bottom left of the panel. The OPTICAL BALANCE control and meter are

located along the top left of the monitor.

2.2 Monitor Rear Panel

It is important that air flow to the vent, located on the rear panel of the monitor, is not

obstructed. The operation of the instrument will be adversely affected by preventing

sufficient cooling flow.

The three connections to the S4000 Sensor are located on the rear of the monitor,

these are labelled SENSOR TEMPERATURE, CONTROL ELECTRONICS, HEAT

PUMP. With the exception of a mains power supply and connection of the remote

temperature probe if required, these are the only connections required for operation

of the instrument.

All user input and output connectors are available on the rear panel of the monitor.

These include the RS232 interface, User I/O, and remote pressure input. In addition,

the sensor heat pump overload fuse, DIP switches SW2, SW3, and SW4 and the

mains power inlet are located on the rear panel.

Sensor Unit

The Sensor Unit contains the dew-point sensing assembly, pipework, and

refrigeration system (if applicable).

The mirror and optics, within the sensor, may be accessed from the front of the

sensor, for cleaning and maintenance purposes, by un-screwing and removing the

microscope housing.

The black blanking plug may be removed from the sensor and a microscope

attached to the sensor assembly to allow the formation of ice crystals to be observed

by the operator. Refer to Section 4.8.

The dew-point sensing assembly comprises a measurement sample flow-through

housing which contains optical signal emission and detection components. These

components are accurately positioned around a plated mirror which is mounted on

Page 6

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

the Peltier cooling device. If the sensor is a refrigerated model, then the complete

sensor assembly is mounted directly to a single or dual refrigeration system.

Sample gas is transmitted into the measurement chamber through stainless steel

pipe-work and fittings to ensure negligible contamination of the sample gas.

Both the air inlet and outlet vents are located on the rear of the unit, this allows the

instrument to be located in a rack unit above and below other instrumentation whilst

maintaining the air cooling flow required for continuous operation.

The sensor mirror is cooled by the Peltier cooling device to below the dew-point

temperature until sufficient dew or ice forms on the mirror surface for the optical

system to detect. When this point is reached the electronic control circuit adjusts the

Peltier device power until the mirror temperature is controlled at the equilibrium value

where rate of condensation equals the rate of evaporation - dew point.

2.3 Monitor Front Panel Controls

The following is a basic description of the function of each of the front panel user

controls and connections. For further information refer to the relevant Section or

Section 4.0.

a) Mains Power Switch - isolates all power to the instrument and sensor, and

includes a visual indication (neon).

b) MAX COOL Pushbutton - refer to Section 2.12.

c) DATA HOLD L.E.D. - illuminates red when dew-point display and outputs are

held. Refer to Section 2.10.

d) OPERATE/STANDBY-refer to Section 2.6.

e) ABC STATUS L.E.D. - indicates current status of Balance cycle.

Refer to Section 2.8. and 2.9.

f) MANUAL/AUTO Switch - refer to Section 2.7.

f) INITIATE Pushbutton - manually starts a Balance cycle. Refer to Section 2.9.

g) Unit Select Pushbuttons

h) Upper and Lower display annunciators refer to Section 2.13.

i) Upper and Lower six digit displays

j) OPTICAL BALANCE CONTROL –refer to Section 2.9.

k) OPTICAL BALANCE METER –refer to Section 2.9.

Page 7

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

2.4 Monitor Rear Panel Controls / Connections

The following is a basic description of the function of each of the rear panel user

controls and connections. For further information refer to the relevant Section or

Section 4.0.

a) RS232 - 9 way “D” type connector for serial communication

interface. Refer to Section 4.6.2.

b) User I/O - 12 way analogue / digital. Refer to Section 4.6.1

c) SW4 ABC Duration - Pre-sets duration of ABC Cycle. Refer to Section 2.9.

d) SW3 ABC Frequency - Pre-sets frequency of ABC Cycle. Refer to Section 2.8.

e) SW2 Data Hold Duration - Pre-sets duration of dew-point data hold function.

Refer to Section 2.10.

f) Remote Temperature - Provides input for remote temperature probe (if required).

3-way circular fixed plug connection.

g) Remote Pressure - Provides input for Pressure transducer, if required.

Refer to Section 2.14.

h) Heat Pump Supply Fuse - Overload protection fuse for

sensor‟s

Peltier heat

pump. Fuse rating T 3.15 A 250V.

i) Mains Power Input - I.E.C. Socket for mains supply. Fused at T3.15A 250V.

j) Sensor Temperature -

k) Control Electronics - Connections to Sensor Unit. Refer to Section 3.4.

l) Heat Pump -

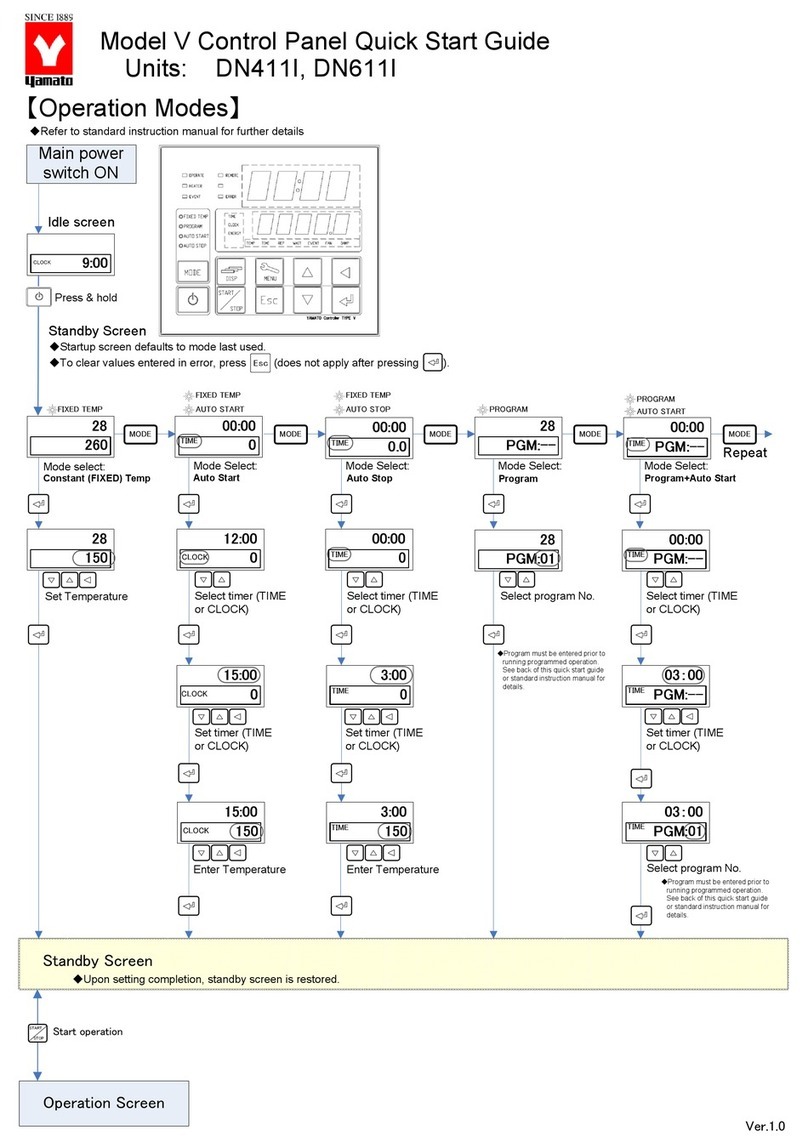

2.5 Operation / Standby Modes

2.5.1 Operation Mode

Operation mode is the normal setting of the instrument for dew point

measurement.

2.5.2 Standby Mode

This function should only be used for applications where the sample gas dew

point changes very quickly from “dry”to “wet” with the possibility of sensor

saturation, or in circumstances where a manual measurement is only taken

very infrequently and it is preferential to have the sensor disabled between

measurements. In this mode the power to the sensor is disabled to allow the

sensor to naturally settle at the ambient temperature and so eliminate the

possibility sensor saturation.

Page 8

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

2.6 Manual / Auto Modes

The instrument may be operated in an automatic or manual mode of operation. The

switch on the front panel MANUAL / AUTO sets the mode of operation. The mode

may be changed at any time, but the front panel INITIATE push-button is only active

when the switch is in the MANUAL position.

In the automatic mode, the instrument initiates an ABC cycle automatically at pre-

determined user-definable intervals (refer to Section 2.8.).

In the manual mode, it is the responsibility of the user to manually initiate an ABC

cycle periodically.

The front panel OPTICAL BALANCE CONTROL is only active when the AUTO /

MANUAL switch is in the MANUAL position. The OPTICAL BALANCE METER is

always active.

Important Note: Automatic operation of the Balance Compensation System must

not be used if the dew point to be measured is lower than -60ºC,

or if the sensor temperature is lower than -30ºC.

2.7 Automatic Balance Compensation (ABC)

In Operation Mode, the optical components of the sensor (i.e. mirror, light guides

etc.) become progressively contaminated which results in a gradual loss of

sensitivity. To compensate for this, a compensation system is provided that heats the

sensor‟s

mirror to evaporate the condensate and allow the system to measure the

mirror‟scontamination. This provides a new baseline for the dew point measurement

until the next ABC is initiated. The duration of the ABC is user definable from 1 to 8

minutes and is set using SW4 –refer to Section 2.9.

The AUTO/MANUAL switch enables automatic or manual initiation of the ABC. In

MANUAL an ABC is only initiated by pressing the ABC button, whereas it is initiated

periodically in AUTO.

The duration of the ABC is set as follows :

ABC Duration

SW3-1

30 minutes

SW3-2

1 Hour

SW3-3

2 Hours

SW3-4

4 Hours

SW3-5

8 Hours

SW3-6

16 Hours

SW3-7

32 Hours

SW3-8

N/A

Note that only one switch may be in the ON position at any time.

If the Data Hold facility (see section 2.10) is not used to maintain the measured dew

point during an ABC, it is important that the instrument is allowed sufficient time to

settle before a dew point reading can be taken. This settling time is dependent on

the dew point of the sample gas and the particular application.

Page 9

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

2.8 Manual Balance Compensation

If the instrument is being used for calibration applications, or to measure dew points

below -60 °C, or in system configurations where the dew-point measurement cannot

be interrupted, it is recommended that the automatic balance compensation is

disabled to avoid a potential interruption of measurement. It is then the responsibility

of the user to periodically initiate a Balance Cycle.

The Balancing Cycle can be initiated, manually, in any of three ways :

a) manually by pressing the front panel switch INITIATE provided the AUTO /

MANUAL switch is in the MANUAL position,

b) by means of the remote input on the rear of the monitor,

c) by means of the RS-232 interface.

Once initiated the ABC mode is dependent on the position of the front panel AUTO /

MANUAL switch. If it is in the AUTO position the instrument will conduct an

automatic balancing cycle, no further adjustment is necessary. If the “AUTO /

MANUAL”switch is in the “MANUAL”position then the Optical Balance Control must

be adjusted such that the Optical Balance meter indicates centre scale i.e. Balanced.

A Balance Cycle can also be initiated automatically, at pre-determined user definable

intervals (refer to Section 2.8.).

The duration of the Balance cycle (manual and auto) is set as follows :

Balance Cycle Duration

SW4-1

1 minute

SW4-2

2 minute

SW4-3

4 minute

SW4-4

8 minute

Notes: 1. Only one switch may be in the ON position at any time.

2. One switch must be in the ON position, otherwise, if an ABC is

initiated it will continue indefinitely.

After an ABC cycle is initiated with the AUTO / MANUAL switch in the MANUAL

position the Optics need to be balanced manually by the user. This is carried out by

observing the OPTICAL BALANCE METER and adjusting the OPTICAL BALANCE

CONTROL until the meter indicates centre scale i.e. “BAL”.

NOTE

If the instrument is operated in the MANUAL mode, it is important that the OPTICAL

BALANCE CONTROL is not re-adjusted during operation. This will cause the

instrument to no longer be balanced and may no longer measure the dew point

accurately.

Page 10

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

2.9 Data Hold

The data-hold facility allows the measured dew-point temperature to be temporarily

held during and after an ABC cycle. The measured dew point at the moment the

balance cycle starts is maintained for a time period, defined by the user. This time

period allows the balance cycle to be completed and the measured dew point to

settle before returning to normal measurement mode. This function holds the display,

analogue output and digital output for the defined time period, and is activated

whenever a Balance cycle is initiated i.e. whether manually or automatically.

Note that the Data Hold time period starts when the ABC cycle starts. Therefore the

Data Hold duration time should be set to last longer than this period to allow the

instrument to settle on a new measurement, before the data hold function is switched

off. This “settling period”will be different for each application, but generally the drier

the gas the longer this period will be. For example at -50 °C dew point this settling

period may be in the order of 30 minutes, whilst at +30 °C dew point the settling

period may only be 1 minute.

The time period of the Data Hold Function is set as follows :

Data Hold Duration

SW2-1

1 minute

SW2-2

2 minutes

SW2-3

4 minutes

SW2-4

8 minutes

SW2-5

16 minutes

SW2-6

N/A

SW2-7

N/A

SW2-8

N/A

Note that only one switch may be in the ON position at any time.

Note that to disable the Data Hold, all switches SW2-1 to SW2-5 should be in the

OFF position.

2.10 Clean Optics Warning

After some time in use, when the optics have collected a considerable degree of

contamination, the balance system produces a warning signal demanding that the

optics be cleaned. This warning is given by the dual coloured ABC STATUS (L.E.D.)

on the Series 4000 Monitor front panel, which will glow red. If this warning is ignored

the instrument cannot accurately measure dew point.

2.11 Max Cool

This control is a non-latching push button switch, which over-rides the dew-point

control loop system and applies maximum cooling current to the Peltier. The purpose

of this control is two fold:

a) As a functional test. By pressing and holding in the MAX COOL button it is

possible to determine what temperature the mirror can be driven down to with

reference to sensor body temperature. This temperature will be indicated on

the Monitor Unit digital display.

b) The button may also be used to determine whether or not the instrument is

controlling at a dew point or is not able to reach it. This situation could arise

when attempting to measure very low dew points without using suitable

sensor cooling.

Page 11

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

Momentary pressing of the MAX COOL button should cause a dip in the

mirror temperature, which, upon release of the button, will provoke the mirror

temperature into oscillation around the dew-point value. After a few minutes

the mirror should return to its original stable temperature. If this does not

happen it may be necessary to consider improving the method of sensor

cooling.

2.12 Display Operation

There are two six digit 7-segment L.E.D. displays on the front panel of the monitor

unit. These can be configured to display a number of measured and calculated

parameters.

Note that all parameters listed in Section 4.6.1. and 4.6.2. are available on the

analogue and RS232 outputs, regardless of which are displayed at any time.

During operation, if % rh is selected, the lower display will automatically display the

sample gas temperature. The display is configured such that two “calculated”

parameters cannot be displayed at any time.

Note that the operation of the display depends on whether the remote temperature

probe is connected. If the probe is not fitted, remote temperature and % rh is not

displayed and °C/°F mode is selected by the upper “UNIT SELECT” push button.

2.12.1 Upper Display

When the instrument is initially switched ON, the measured dew point in degrees

Celsius (°C) is displayed on the upper display. The two-digit annunciator, between

the upper “UNIT SELECT”push button and the upper display will display “C”

indicating °Cdp.

If the remote temperature probe is fitted, by pressing the upper “UNIT SELECT”

push button the upper display may be toggled between measured dew point (°C) and

Relative Humidity (% rh). The two-digit annunciator, between the upper “UNIT

SELECT” push button and the upper display will display “rh” indicating % rh.

If the remote temperature probe is not fitted, by pressing the upper “UNIT SELECT”

push button, the upper display may be toggled between measured dew point in °C

and °F. The two digit annunciator will display “F” indicating degrees Fahrenheit.

The “UNIT SELECT” switch will scroll through the functions as follows:

Upper Display : % rh Mode Dew point only Mode

C - °Cdp C - °Cdp

or

rh - % rh F - °Fdp

Notes:

1. If the display is configured to °F mode (by means of the lower display),

then the upper display will toggle between % rh and °Fdp.

2. When % rh is selected on the upper display, the lower display

automatically displays Sample Gas Temperature either in °C or °F.

Page 12

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

or

2.12.2 Lower Display

When the instrument is initially switched ON, the water content in ppm(v) (Parts Per

Million by Volume) is displayed on the lower display. By pressing the lower “UNIT

SELECT”push button the function of the lower display will change to display one of

the following : Parts Per Million by Weight in SF6 (ppm(w))

Parts Per Million by Volume (ppm(v))

Grams per cubic metre (g/m3)

Grams per kilogramme (g/kg)

Pressure (kPa)

Sample Gas Temperature (°C)

Sample Gas Temperature (°F)

The “UNIT SELECT” switch will scroll through the above functions as follows :

Lower Display : % rh Mode Dew point only Mode

°C Display

mode selected

at switch ON.

Selects °F

Display mode.

Selects °C

Display mode.

P - ppm(v)

SF - ppm(w)

in

SF

6

G1 - (g/m3)

G2 - (g/Kg)

Pr - (kPa)

F - (°F)

P - ppm(v)

SF - ppm(w)

in

SF

6

G1 - (g/m3)

G2 - (g/Kg)

Pr - (kPa)

C - (°C)

P -

ppm(v)

SF -

ppm(w)

in

SF

6

G1 - (g/m3)

G2 - (g/Kg)

Pr -

(kPa)

°C/°F Mode selected by

Upper “UNIT SELECT”

push button.

Page 13

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

Notes

1. If a pressure transducer is not connected to the instrument, then by

default, atmospheric pressure (101.3 kPa) is selected and displayed.

2. During a data hold cycle the measured dew-point reading is held and

therefore the ppm(v), ppm(w), g/m3, and g/kg parameters will also be

temporarily held. The sample gas temperature and pressure parameters

are not held.

3. If the upper display is indicating % rh, and the lower “UNIT SELECT” push

button is pressed, then ppm will be displayed, and the upper display

reverts to dew point in either °C or °F.

2.13 Pressure Measurement

A remote pressure transducer may be connected to the S4000 Remote Monitor. This

allows on-line mea surement and display of the sample gas pressure, as well as

calculation of pressure compensated ppm(v), ppm(w), g/m3, and g/kg.

If a pressure transducer is not connected to the instrument, a default pressure of

101.3 kPa (atmospheric pressure) is assumed, and all pressure dependent

parameters are calculated using this pressure.

The pressure is displayed in kPa, and is available as a digital output on the RS232

interface. Refer to Section 4.6.2.

The standard pressure range is 0 to 50 p.s.i. absolute, but particular pressure ranges

may be supplied to order. Contact Michell Instruments‟ Technical Sales Department

for further information.

Remote Pressure Connection

A 6 pin circular socket (type Hirose RM12B Series Bayonet) on the monitor unit rear

panel marked „REMOTE PRESSURE

‟

provides the supply voltage (+15V) and signal

input voltage (1-6V) scaled over the range 0-50psia required for the pressure

measurement circuit .

Pin connections are as follows:

Pin Number Function

1 N/C

2 N/C

3 N/C

4 Signal I/P

5 0V

6

+V

Page 14

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

3 INSTALLATION

3.1 General

The Series 4000 Precision Hygrometer is supplied with a full accessory package.

Please check that you have received all the items listed on the Packing Check List.

Both the Monitor and Sensor Units (if applicable) have single 3 pin I.E.C. plug

connections for the mains supply.

Note that the S4000 TRS model is supplied in a self-contained enclosure. The

connections and dimensions are different for this model, refer to Section 3.5.

The monitor unit has a universal power supply, capable of operating from any mains

supply between 90 to 260 Volts A.C.

The Sensor Unit, if fitted with a refrigeration system, will require a mains power

supply. Due to the nature of the refrigeration system the power supply voltage is

factory set. The power supply voltage setting cannot be changed by the user.

Contact Michell Instrument‟s Technical Sales Department for advice.

The factory set power supply voltage is indicated on the yellow label located on the

rear of the unit.

Two power leads are supplied, fitted with 3 pin IEC socket for connecting onto the

monitor and sensor units. Suitable fused power plugs, conforming to local electrical

safety regulations, must be fitted to the free end of the cables. The power leads are

approximately 2 metres long with 3 cores colour coded as follows:

Brown - Live

Blue - Neutral

Green/Yellow - Earth

WARNING!: This instrument must be connected to electrical earth for safety.

3.2 Installing the Monitor

The Series 4000 Precision Hygrometer monitor requires an operating environment of

0 to 40 ˚C, 0 to 90 % rh.

The monitor case is designed for 19" 3U rack mounting. However, it can be used as

a bench mounted device without any special preparation.

For rack mounting, simply screw the monitor front panel to the front of the rack using

4 of M6 x 15mm screws and plastic inserts. The unit should be supported by suitable

horizontal runners, the front panel fixings alone are not sufficient to suspend the

weight of the entire unit.

NOTE: A minimum depth behind the S4000 front panel of 511 mm is required

for the monitor, its connectors and wiring. Also, it is important that a

sufficient flow of ambient air is allowed at the rear of the unit.

Page 15

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

3.3 Installing the Sensor

Sample gas connections are made through pipe couplings marked "GAS IN" and

"GAS OUT". These couplings are suitable for use with 6mm O.D. stainless steel or

P.T.F.E. tubing. If the vent gas is not routed to another test set or measuring

instrument then lower quality tubing may be used on the "GAS OUT" port.

Before operation, the sensor mirror and optical surfaces should be cleaned as

described in Section 6.1.

3.4 Electrical Connections

Refer to the rear panels of the Series 4000 Remote Monitor and Sensor Units in

Appendix 1.0.

For operation, the only connections required are :

a) Sensor Temperature inter-connection from Sensor Unit to Monitor Unit.

b) Control Electronics inter-connection from Sensor Unit to Monitor Unit.

c) Heat Pump inter-connection from Sensor Unit to Monitor Unit.

d) Mains supply to Monitor.

e) Mains supply to Sensor Unit (if applicable).

The three interconnection cables from the Sensor Unit to the Monitor Unit are

supplies (standard length 2 metres).

A 2 metre power cable is supplied, as standard, for each unit requiring a mains

supply. A suitable fused power connecting plug, conforming to local electrical safety

regulations, must be fitted to the free end of each cable.

IMPORTANT: Before connecting the monitor and sensor units to an A.C.

power source ensure that the mains supply is within the limits of

the operating voltage specified on the rear of the unit.

Once the power cable and three inter-connection cables are connected, and the

sample gas connections are made and checked, the instrument is ready for

operation.

If indication of % rh relative humidity and remote gas temperature are required, the

remote P.R.T. probe should be placed in the gas flow, and the probe connected to

the connector on the rear of the unit.

Further electrical connections for analogue or digital I/O may be required, refer to

Section 4.6.

Page 16

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

3.5 S4000 TRS Enclosure

The S4000 TRS model is supplied, as standard, in a 19”enclosure. The instrument

is completely housed within an equipment cabinet, fitted with castors for ease of

movement. The S4000 Sensor and Monitor are connected together internally. The

only connections needed in order to operate the system is a sample gas and mains

power supply.

Note: A minimum depth behind the equipment cabinet of 100mm must be

maintained to allow sufficient airflow over the refrigeration system.

3.5.1 General

The sample handling system of the S4000 TRS is optimised to maintain the integrity

of the gas flow being measured through the use of the highest grade materials and

fittings. Whilst perfected for trace moisture analysis, the TRS retains the capability

for measurements of any dew-point temperature up to +20ºC.

The S4000 TRS Monitor is identical to the standard S4000 Monitor in all respects.

3.5.2 Gas Connections

The sample gas connections are made through stainless steel tube fittings located

on the front panel of the enclosure marked "GAS IN" and "GAS OUT".

The GAS IN connection is a Cajon type VCR metal gasket face seal fitting suitable

for 1/4” OD stainless steel tubing.

The GAS OUT connection is a Swagelok type twin ferrule compression tube fitting

suitable for 1/4” OD stainless steel tubing.

3.5.3 Electrical Connections

The factory set power supply voltage is indicated on the yellow label located on the

rear panel of the unit. The power supply voltage setting cannot be changed by the

user. Contact Michell Instruments' Technical Sales Department for advice.

A single 3 pin IEC plug is available on the rear panel of the instrument for connecting

to the appropriate power supply.

A power lead is supplied fitted with a 3 pin IEC socket for connecting onto the

instrument. A suitable fused power plug, conforming to local electrical safety

regulations, must be fitted to the free end of the cable. The power lead is

approximately 2 metres long with 3 cores colour coded as follows:

Brown - Live

Blue - Neutral

Green/Yellow - Earth

WARNING!: This instrument must be connected to electrical earth for safety.

For 100 V to 115 V 60 Hz Working Voltage Only

An additional 3 pin IEC fused plug is available on the rear panel of the instrument for

connecting to the appropriate power supply. This is due to the high current loading

from the in-built refrigeration system. An additional 2 metre long power lead is

supplied.

Page 17

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

4 OPERATION

4.1 General

Operation of the Series 4000 Remote Precision Hygrometer is very simple as long as

necessary precautions are taken to provide an accurate sample of the gas to be

measured. Statistical information indicates that the vast majority of failures are

caused either by incorrect sampling methods, sampling positions or inadequate

protection against dangerous substances.

4.2 Sampling Hints

The Series 4000 Precision Hygrometer sensor is designed to operate in a flowing

gas stream. It is provided with a sampling chamber which enables a small sample of

gas to be passed over a Peltier cooled, plated copper mirror. The sample gas is bled

off to atmosphere through the Sensor Unit front panel coupling marked "GAS OUT".

Although the correct operation of the sensor is not flow-rate dependent it is important

to ensure that the flow velocity through the sample line, connecting the sample

source to the Sensor Unit, is high enough to avoid long time lags in response to

changes in humidity at the sample source. We therefore recommend a flow rate of

between 0.3 to 0.7 Litre / minute be set, the ideal figure being 0.5 Litre / minute.

Flow regulation is not provided within the Sensor Unit. If gas flow must be regulated,

add a precision needle valve or similar device at a suitable location in the sample

gas stream before the "GAS IN" coupling on the unit. Take care not to introduce

errors into the system by using inferior quality valves or making poor connections.

Avoid pressure gradients in the system by excess flow restriction after the sensor. If

the test gas has a very high flow rate then a by-pass arrangement is preferable to a

flow restriction after the sensor.

The general rules to be adhered to when arranging a sampling system are as

follows:

a) Ensure the sample is representative of the gas under test.

The sample point should be as close to the critical measurement point as

possible. For example, in a glove box application connect the sensor at the

exit of the glove box not at the gas entry point.

b) Minimise dead space in sample lines.

Try to avoid too many "T" pieces or unnecessary pipe-work. Where possible,

build up the sampling pipe specifically for the job and do not use pipe-work

previously installed for another application. Dead space in sample lines

increases response time by holding water molecules which are more slowly

released to the passing gas sample.

c) Remove any particulate matter or oil from the gas sample.

Particulates entering the sensor measurement chamber will cause

contamination of the sensitive optical components, this will result in the need

for more frequent cleaning of the sensor optics. If particulates such as

degraded desiccant or pipe swarf and rust are possible, use a particulate in-

line filter. Michell instruments' technical sales staff will be pleased to give

advice.

Page 18

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

d) Use high quality sample pipe fittings.

We would recommend that, wherever possible, stainless steel pipe-work and

fittings are used. This is particularly important at low dew points since other

materials have hygroscopic characteristics and absorb moisture in the pipe

walls. Absorbed moisture will slow down measurement response and, in

extreme circumstances, giving false dew-point readings.

For temporary applications, or where stainless steel pipe-work is not feasible,

use high quality thick-walled p.t.f.e. pipe which exhibits similar characteristics

to stainless steel.

Always use the shortest run of pipe-work possible between two points. Use

the smallest diameter pipe-work possible to reduce response time. But, take

care not to induce pressure differentials by aiming for too high a flow-rate

through small bore pipe-work. A sample flow-rate between 0.3 and 0.7 litres

per minute will be satisfactory for the Series 4000 Remote Dew-point

Hygrometer to operate correctly.

4.3 Which Gases to Measure?

The Series 4000 Remote Precision Hygrometer, by nature of its design, is suitable

for measurement of the moisture content of a wide variety of gases. In general, if the

gas (in conjunction with water vapour) is not corrosive to base metals then it will be

suitable for measurement by the Series 4000 Remote Precision Hygrometer.

However, gases containing entrained solids should be filtered before presentation to

the Series 4000 Sensor.

Care should be taken with gas mixtures containing other potentially condensable

components in addition to water vapour to ensure that only water can condense onto

the cooled mirror surface.

High purity gases will not be contaminated by the Series 4000 Sensor Unit.

Components which are likely to out-gas (epoxy, most plastics etc.) are not used in

the manufacture of the sensor. Therefore, the instrument is safe for use in critical

semiconductor and fibre optic applications.

While the Series 4000 Sensor is designed to be operated at atmospheric pressure

each sensor is factory tested to a sample gas pressure of 10 p.s.i.g before any

calibration work is undertaken. In its standard form, the sensor unit is not suitable for

measuring samples below atmospheric pressure.

4.4 Operating the Hygrometer

4.4.1 General

Use the following instructions with reference to the front panel of the Series 4000

Remote Monitor Unit, and the functional descriptions provided in Section 2.0.

Check that the sensor optics are clean as described in Section 6.0. If the optional

microscope is not being used ensure that the black blanking plug is screwed into the

microscope fitting on the front of the Sensor Unit to prevent stray light from

interfering with the optical detection system. Set the sample gas flow-rate to between

0.3 and 0.7 litres per minute.

The temperature measurement and % rh calculations within the instrument are fully

automatic and do not require any user adjustment or maintenance.

When the Monitor Unit is switched ON a red neon illuminates in the power switch

and the digital display should illuminate. Page 19

SERIES 4000 Precision Dewpointmeter (Remote, Climatic, RS and TRS)Users Guide

www.michell.com

If the instrument is an RS or TRS model, when the Sensor Unit is switched ON the

temperature controllers‟ digital display should illuminate. The Sensor Unit is fitted

with a two or three position power switch, depending on the model :

S4000 RS :

i) Up position is off.

ii) Down position switches on the temperature controlled refrigeration system.

S4000 TRS :

i) Centre position is off.

ii) Down position switches on the temperature controlled refrigeration system.

iii) Up position switches off the refrigeration system but still operates the

temperature control circuit. This facility is provided to enable the sensor body

temperature to be warmed-up in order to measure dew-point temperatures in

the region 0 to +20 ºC and also for maintenance purposes.

NOTE: The refrigeration system may be set for operation above 0 °C, up to

20 °C, for short periods only (up to 30 minutes). This allows dew points

in the region 0 to +20 ºC to be measured and also for the sensor to be

warmed-up for maintenance purposes.

WARNING: Do not switch the refrigeration system on until at least 4 hours after

final installation. This time is required to allow the compressors’ fluid to

drain. If the compressors’ have been exposed to very cold conditions

prior to installation this time must be extended to about 12 hours.

Failure to observe this precaution may result in permanent damage to

the refrigeration systems’ compressors.

4.4.2 Adjusting the Sensor Body Temperature (RS and TRS Models)

A CAL 3200 Autotune PID Temperature Controller is included which enables the

user to set the sensor body temperature above the dew-point temperature to be

measured.

To adjust the sensor body temperature press and hold down the "" button on the

temperature controller and then press either " " or " " buttons to change the

temperature set-point. Control functions are as follows:

View set-point

Increase set-point

Decrease set-point

The sensor body temperature must always be above the dew-point temperature, if

not condensation will occur in the sensor measurement chamber and internal sample

system pipes. This means that before changing to wetter dew points the sensor body

temperature must be raised and allowed to stabilise at the new temperature.

Page 20

This manual suits for next models

1

Table of contents

Other Michell Instruments Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

IKA

IKA Lab Disc IKAMAG operating instructions

Ivoclar Vivadent

Ivoclar Vivadent IvoBase Series operating instructions

SIGNALCORE

SIGNALCORE SC5511A Operating & programming manual

HP

HP 7683 installation guide

Terragene

Terragene Bionova IC10FR Operator's manual

Elster Instromet

Elster Instromet enCore FC1 manual