MICRO-AIR MA4210 User manual

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all of the hazards of dust control equipment. It is important that use of the equipment

be discussed with a Micro-Air Representative. Persons involved with the equipment or systems should be instructed how

to operate in a safe manner.

MA4210

Installation and Operation Manual

MICRO AIR

www.microaironline.com

2

MA4210 MICRO AIR

WARNINGS:

CAUTION: Installation can cause exposure to live components. Disconnect electrical power

before proceeding with installation. Proper Lock Out / Tag Out procedures should be used.

All electrical work must be done by a qualified electrician according to local, state and

national codes.

Improper installation or operation of this equipment can cause damage to equipment and /

or injury to personnel. The installation / operation manual must be read and followed in its

entirety.

MA4210 SPECIFICATIONS:

Motor:

1-1/2 HP, 1725 RPM, 1 Phase, TEFC

3 HP, 1760 RPM, 3 Phase, TEFC

Input Voltage:

1-Phase - 120V, 60 Hz

3-Phase - 230/460V, 60 Hz

Max Current:

1-Phase - 16 Amps

3-Phase - 8.4/4.2 Amps

Blower:

12-9 Belt Driven

Dimensions:

86"H x 26"W x 36"L

Shipping Weight:

444 lbs.

Actual Weight:

402 lbs.*

*Add 35 lbs. per charcoal module when selected.

PACKAGE CONTENTS:

1 Ea.

MA4210

16 Ea.

5/16-18 Bolt

1 Ea.

Owner's Manual

16 Ea.

5/16-18 Hex Nut

2 Ea.

Swivel Caster

16 Ea.

5/16" Flat Washer

2 Ea.

Fixed Caster

16 Ea.

5/16" Lock Washer

1 Ea.

Filter Hanger Bar

1 Ea.

Handle

EQUIPMENT / TOOLS REQUIRED:

Forklift or Hoist

Lifting straps or chains

Socket wrenches

Wire nuts

3

MA4210 MICRO AIR

PRE-OPERATING INSTRUCTIONS:

1. Inspect the unit for any visible damage that may have occurred during shipment. Report any

damage to the delivery carrier.

2. Remove the shipping crate, shipping straps and plastic wrap from unit. Discard skid and hardware.

3. Open the filter door and remove the bag filter, pre-filter, hood, handle, and filter hanger bar.

4. Lay the unit down on its back (the side opposite the hose).

5. With the unit still in the horizontal position, secure the casters to the bottom of the unit using bolts,

nuts and washers provided.

6. Slide the pre-filter into the channels provided at the bottom of the unit making sure that the air flow

directional arrows are pointed upward.

7. Making sure that the loops on the filter are towards the door, carefully slide the bag filter back into

the cabinet. Do not snag or rip the delicate media material that is used to make this filter. When

properly inserted, the bag filter will not protrude past the filter slide and will allow the door to close

securely.

8. Insert the filter hanger bar through the loops in the inside the cabinet near the top of the filter door.

9. Close and latch the filter door.

10. Determine the location where the unit is to be installed. Be sure to allow sufficient access to the

unit for servicing and maintenance on all sides.

ELECTRICAL CONNECTIONS:

All electrical work must be done by a qualified electrician according to local, state and

national codes. Be sure that the designated circuit breaker is off until all wiring has been

completed.

NOTE: It is recommended that a properly sized motor starter and overload protector be used in the

supply circuit of the 3 Phase motor. The 120V units have thermally protected motors with on/off

switches.

1. Make electrical connections as shown in the wiring diagram to the wires protruding from the

conduit on the side of the unit.

2. Check blower for proper rotation direction. Blower should rotate clockwise when viewed from the

pulley end. If the blower rotates backwards, interchange two of the motor supply connections.

3. Check current draw of the motor. Do not exceed Amps specified.

PRE-OPERATING CHECKLIST:

Check blower drive belt for proper tension. Belt should deflect ¾” when firm pressure is applied

midway between the pulleys.

Check that motor, blower and drive pulleys are mounted securely.

Make sure that both corners of every pocket in the filter bag is supported by the filter support rods

and that filter support rods are fully engaged in their support brackets.

Air flow direction arrows on the pre-filters must point toward the blower.

Make sure all access panels removed during the installation are re-installed and the filter access

door is closed.

4

MA4210 MICRO AIR

OPERATING INSTRUCTIONS:

1. Choose a suitable, level place near the workstation and position the unit so that the arm assembly

will be placed near the source of pollution being generated.

2. Grasp the hood by the handle ring and position within 18” of the source of pollution.

3. Connect power (stated above in ELECTRICAL CONNECTIONS).

4. Adjust the hood to capture the maximum amount of contaminants. Periodically adjust the position

of the hood to keep it in maximum capture range.

PRESSURE SWITCH ADJUSTMENT:

1. The pressure switch which turns the light on with a differential pressure increase, should be wired

to poles L1 (red) and L2 (blue) at the time of installation with 230/460 volt source (See Wiring

Diagram).

2. The pressure switch is preset at the factory to indicate (light on) dirty filters, but may need

readjustment due to a desire for earlier or later filter changes, a different combination of filters, or

because the set point shifted during shipping. The pressure switch is also orientation sensitive. To

re-adjust the switch, remove the hole plug in the side of the unit for access to the adjustment

screw. Make sure filters and pre-filters are installed in unit. Turn the unit on and place a piece of

cardboard over the intake covering about 80% to 85% of the intake area. With a standard

screwdriver, turn the adjustment screw clockwise until the light goes off, or counterclockwise until

the light comes on.

3. For more time between filter changes (less air flow), cover slightly more of the opening, and for

less time between filter changes (more air flow), cover less of the opening.

GENERAL MAINTENANCE:

Occasionally check the condition of the drive belt for tightness and wear.

Check the bower bearings for unusual wear and the blower wheel for debris and dirt. Clean when

necessary.

Check the wiring for loose connections or for cracked insulation.

No lubrication is required for the motor because it is a permanent pre-lube design. Excessive

dirt/oil should be periodically removed.

Once per month grease the suction arm base assembly with a bearing grease listed to not react

with aluminum.

CHANGING FILTERS:

Always make sure that the unit is turned off before changing filters or servicing the unit.

1. The MA4210 is equipped with a filter change light or optional Magnehelic Gauge. If the differential

pressure has been set properly the light or gauge signals the need for examination for the filters.

2. When the light comes on, or gauge reads high differential pressure, turn the unit off and remove

the pre-filter only. Replace with a new pre-filter, making sure that the air flow directional arrow is

pointed toward the outlet end. Turn the unit back on. If the filter change light is off, or the gauge

reads low differential pressure, then the unit is operating properly.

5

MA4210 MICRO AIR

3. If the filter change light fails to go out, or the gauge continues to read high differential pressure

after replacing the pre-filter, then the media filter also needs to be replaced.

4. To install a new bag filter, turn the unit off. Remove the filter from the channel and insert a new

filter in place.

5. Start the unit. The filter change light should be off or gauge reads low differential pressure and the

unit should be operating properly.

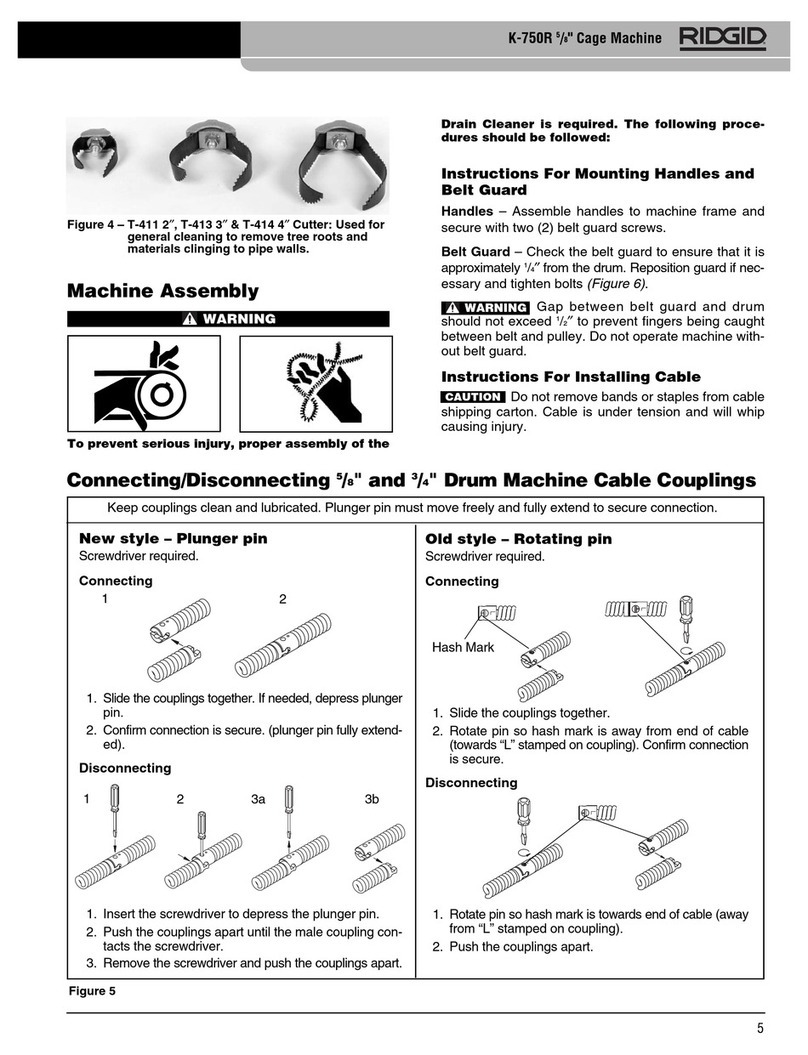

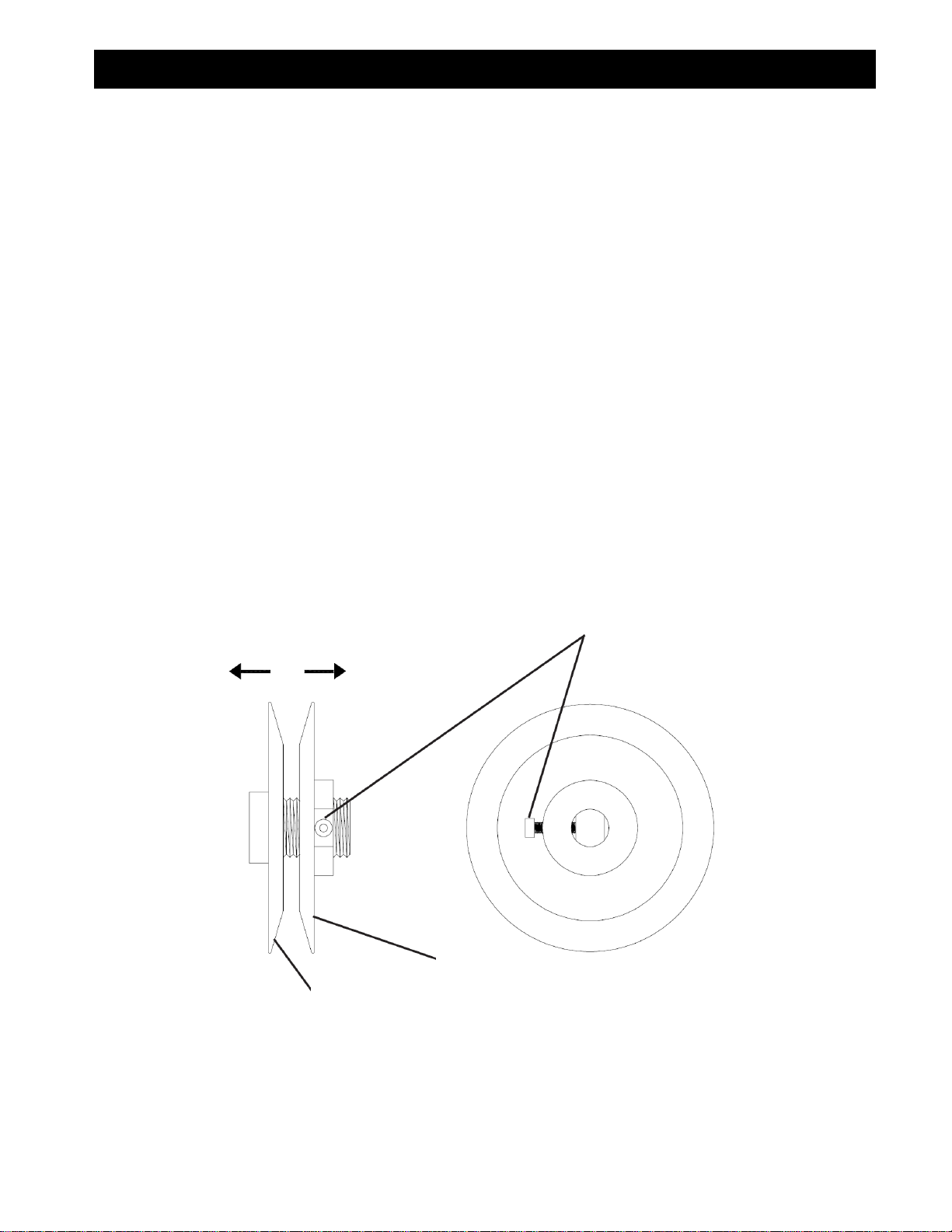

AIR FLOW ADJUSTMENT:

Depending on the configuration, the MA4210 will be equipped with a variable diameter pulley on the

motor to allow the air flow to be adjusted to the installation requirements. The pulley is set for

maximum air flow from the factory. The air flow rate can be adjusted as follows:

1. Remove motor compartment access cover. Be careful to avoid tearing gasket material between

door and cabinet.

2. Remove belt.

3. Loosen pulley adjustment set screw on motor pulley and screw adjustable sheave out away from

fixed sheave. Tighten set screw onto flat of fixed screw (FIG. 1).

4. Adjusting the motor pulley may require a size larger or smaller belt, depending on the application.

5. Replace belt and check belt tension. Proper tension should be between 1/2” and 3/4” deflection

when belt is squeezed with normal pressure between fingers.

6. Replace motor compartment access cover.

7. Recheck for correct draw of motor amperage. NOTE: All filters and panels must be installed on

unit and door must be closed for current measurements of motor.

FIG. 1

Increase

Diameter

Decrease

Diameter

Set Screw

Fixed Sheave

Adjustable Sheave –Rotate by ½ Turn

Increments to Increase Pitch Diameter

6

MA4210 MICRO AIR

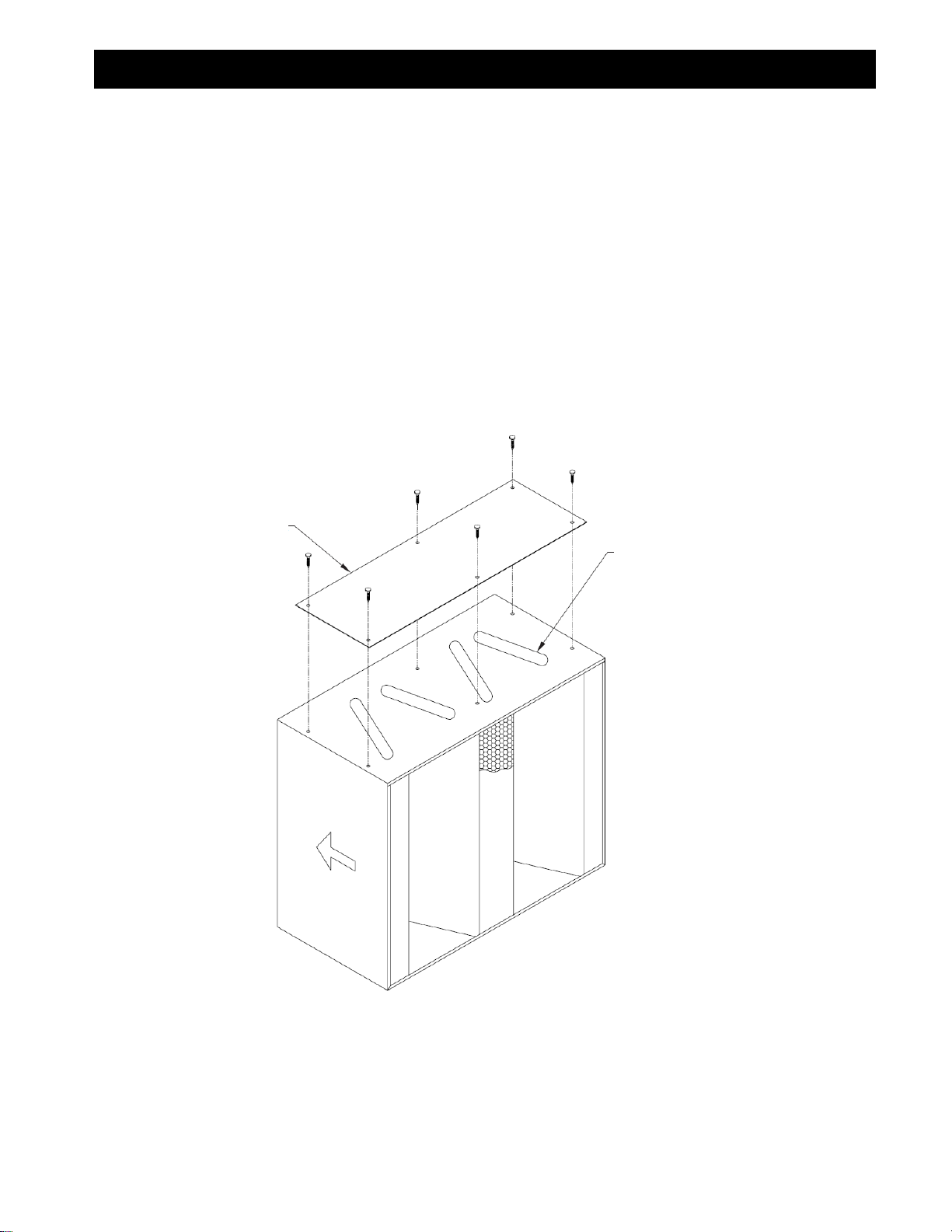

INSTRUCTIONS FOR SIDE DISCHARGE BLOWER EXHAUST:

Read instructions completely before making changes. Due to relocation of internal

components, some wiring may be loose. Be sure to retain wires so they will not become

loose in air stream of blower inlet.

1. The MA4210 motor/blower module can be rotated so that the exhaust air exits from the side of the

unit. Before rotating the motor/blower module be sure that all input power is disconnected and the

unit is turned off.

2. Remove the motor access door and exhaust grille.

3. Remove 5/16” hex bolts and washers that secure the motor/blower module to the filter module.

4. Rotate the motor/blower module 90 deg. (FIG. 2).

5. Using 5/16” hex bolts and washers, re-secure the motor/blower module to the filter module.

6. Re-install motor access door and exhaust grille.

7. Reconnect input power and turn unit on. Check for proper air flow and blower rotation.

FIG. 2

Motor Access Door

Motor / Blower

Module

Filter Module

Filter Door

7

MA4210 MICRO AIR

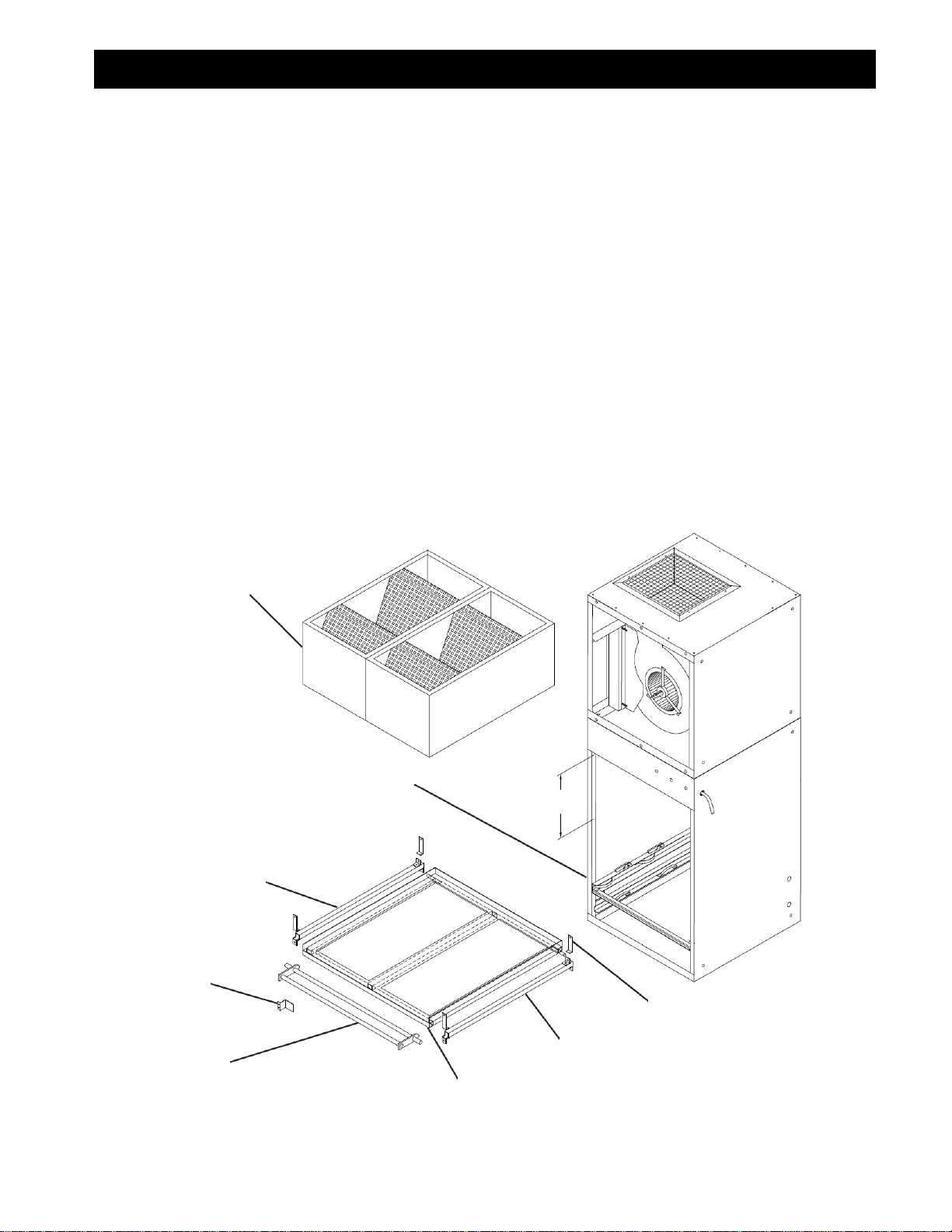

UNITS WITH HEPA OR CHARCOAL AS A SECOND MAIN FILTER:

On units with optional HEPA or charcoal

filters, an adjustable filter track kit is used to

complete the seal of the filters to the filter

stop (FIG. 3 & FIG. 4). If the unit was ordered

with either a HEPA or charcoal filter, the

adjustable filter track kit is included with the

unit. If a HEPA or charcoal filter is ordered as

an after-market item, the adjustable filter track

kit should be ordered as well. Order part

number 38036-01.

Each filter track kit is supplied with:

1 Ea.

Filter Track

2 Ea.

Supports

1 Ea.

Handle

4 Ea.

Retaining Brackets

1 Ea.

Door Stop Bracket

3 Ea.

Horizontal Support

16 Ea.

#8-32 Self Tapping Hex Screws

INSTALLATION:

1. Place supports in cabinet at a dimension of

13-1/4” and secure with self-tapping screws.

2. Place track in cabinet so it rests upon

supports and 1/2” diameter pin is located

behind brackets on supports.

3. Place handle on supports so that it rests in

notches.

4. Lock 1/2” diameter rods on handle and track

in place with brackets and self-tapping

screws.

5. Place handle stop bracket at a dimension of

15-1/2” and secure with self-tapping screws.

This is to keep handle from rotating past 90

degrees and allowing filter to loosen.

6. Horizontal support is not used in this

application.

FIG. 3

13”

RCM or HEPA

Door Removed

for Clarity

Support

Retaining

Brackets

Typ. (4)

Support

Filter Track

Handle

Door Stop

Bracket

8

MA4210 MICRO AIR

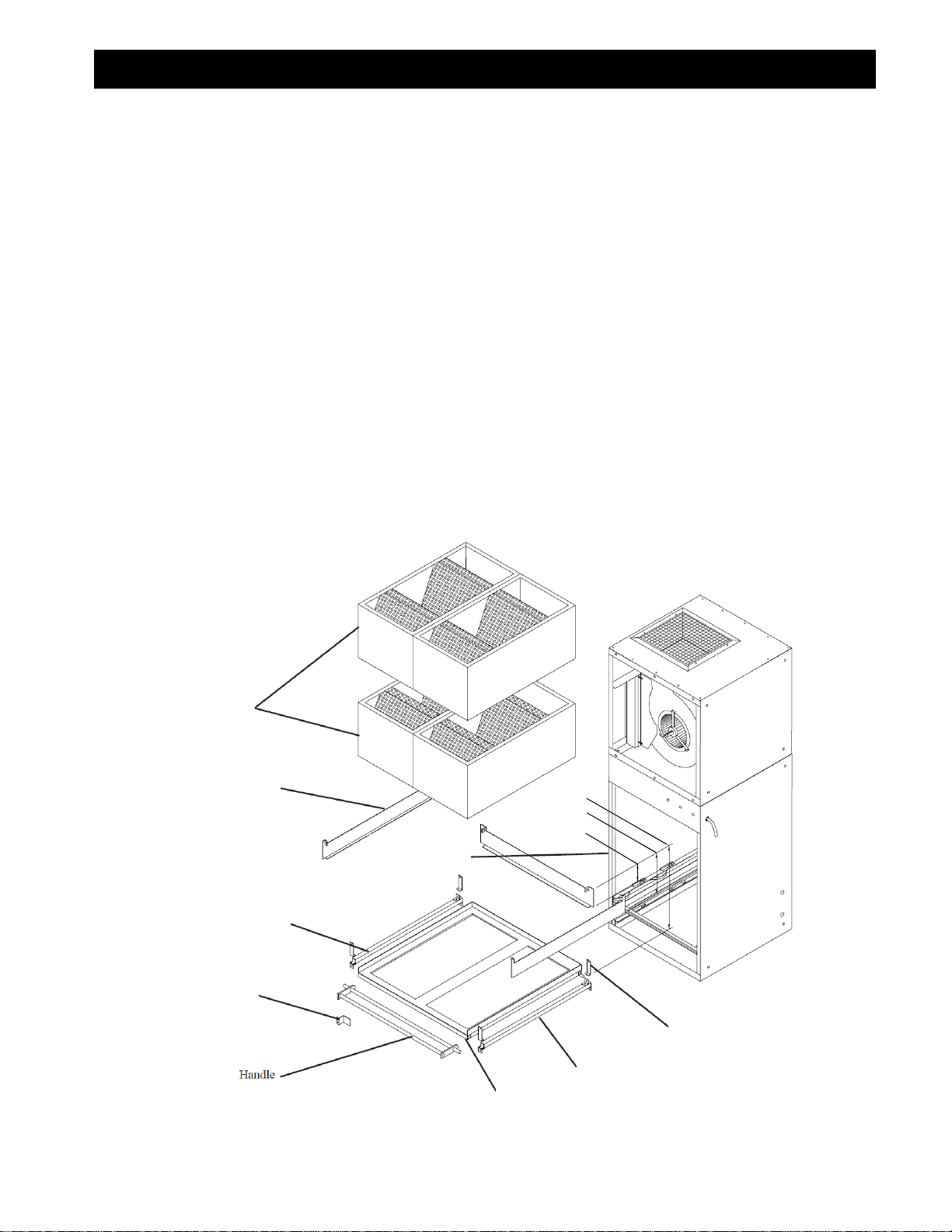

UNITS WITH HEPA OR CHARCOAL AS A FIRST AND SECOND MAIN FILTER:

On units with optional HEPA or charcoal

filters, an adjustable filter track kit is used to

complete the seal of the filters to the filter

stop (FIG. 3 & FIG. 4). If the unit was ordered

with either a HEPA or charcoal filter, the

adjustable filter track kit is included with the

unit. If a HEPA or charcoal filter is ordered as

an after-market item, the adjustable filter track

kit should be ordered as well. Order part

number 38036-01.

Each filter track kit is supplied with:

1 Ea.

Filter Track

2 Ea.

Supports

1 Ea.

Handle

4 Ea.

Retaining Brackets

1 Ea.

Door Stop Bracket

3 Ea.

Horizontal Support

16 Ea.

#8-32 Self Tapping Hex Screws

INSTALLATION:

1. Place supports in cabinet at a dimension of

24-5/8” and secure with self-tapping screws.

2. Place track in cabinet so it rests upon

supports and 1/2” diameter pin is located

behind brackets on supports.

3. Place handle on supports so that it rests in

notches.

4. Lock 1/2” diameter rods on handle and track

in place with brackets and self-tapping

screws.

5. Place handle stop bracket at a dimension of

27” and secure with self-tapping screws.

This is to keep handle from rotating past 90

degrees and allowing filter to loosen.

6. Place horizontal supports (Typ. for two) on

sides of cabinet at a dimension of 10” and

the other horizontal support on rear cabinet

at 5” and secure with self-tapping screws.

FIG. 4

24-5/8”

10”

5”

RCM or HEPA

Horizontal

Support

Support

Door Stop

Bracket

Door Removed

for Clarity

Filter Track

Support

Retaining

Brackets

Typ. (4)

9

MA4210 MICRO AIR

FILLING OF RCM MODULES:

1. Remove bulk charcoal or purasorb from the shipping container.

2. Set module on a level surface. Remove fill cover by removing six #10-32 Phillip head screws that

secure cover. Set cover aside (FIG. 5).

3. Open the lid of the charcoal or purasorb bucket. Pour the material from the plastic bag into the

module through the slots. It may be necessary to slightly shake the module to assure an even fill.

Excess material may be saved by resealing the bucket. Note that slow pouring will minimize dust

that will be present during filling.

4. After filling the module, discard the bucket and reinstall the fill cover removed in step 2.

5. With filter track in place and handle pulled out away from cabinet load RCM modules into track.

6. With filters in place rotate handle 90 deg. and lock filter modules in place.

NOTE: The MA4210 requires two modules when used as a second main filter and four modules

when used as a first and second main filter.

FIG. 5

Fill Cover

Pour Material

into Slots

10

MA4210 MICRO AIR

OPTIONAL SILENCER INSTALLATION:

1. Remove exhaust grille from unit as shown in Fig. 6.

2. Slide silencer over blower assembly.

3. Align holes from silencer with those located on side of the blower assembly.

4. Attach silencer to blower assembly using 3/8” bolt, lock washer and flat washer.

5. Center exhaust grille over hole in silencer and attach using #8-32 self-tapping machine screws.

FIG. 6

#8-32 SMS

Exhaust Grille

Silencer

3/8” Hardware

Blower Assembly

11

MA4210 MICRO AIR

WIRING DIAGRAM:

All electrical work must be done by a qualified electrician according to local, state and

national codes.

FIG. 7

12

MA4210 MICRO AIR

TROUBLESHOOTING:

CAUTION: Before disassembling the unit or doing any inspecting of the parts, make certain

that the power has been cut off and the blower has come to a complete stop. NEVER run the

unit with the access door opened or the panels removed.

TABLE 1 –Troubleshooting Chart

PROBLEM

POSSIBLE CAUSE

REMEDY

Unit fails to start

No incoming power

Check the circuit and switch

Blown breaker or fuse

Replace fuse or throw breaker

Loose wire in terminal box

Reconnect wire

Burned out motor

Replace motor

Primary voltage to motor contactor

Take steps to increase voltage to primary

is below 10% tolerance

Motor thermal trip (1 Phase only)

Reset at motor

Tripped overload (3 Phase only)

Reset overload protector

Unit runs slowly,

Wired for wrong voltage

Check input voltage

Inadequate capture

Check wiring diagram

Improper rotation

Check wiring diagram

Switch L1 & L2 (3 Phase only)

Internal Obstruction

Check if damper is open

Check inlet for blockage

Check hoses for proper connection

Check hoses for holes

Pulleys set for improper static

Adjust or change pulleys

Dirty filters

Service/Replace filters

Vibration

Loose motor mounting bolts

Tighten bolts

Foreign objects in blower/

Remove debris from blower

Build-up on blower wheel

Dirty filters

Service/Replace filters

Mist coming from exhaust

Dirty disposable filters on torn filters

Service/Replace filters

Air bypass around filters

Check for proper seal against picture

frame and seals on door and back wall

Stronger resistance

Lack of grease in the rotating

Lubricate the rotating socket

during rotation of the arm

socket

Arm will not stay in place

Joints are loose

Tighten the joints

13

MA4210 MICRO AIR

ARM ASSEMBLY PARTS LIST:

FIG. 8

ITEM

PART NO.

DESCRIPTION

ITEM

PART NO.

DESCRIPTION

1

P2466

6” Hood Assembly

13

P2479

½-13 Nyloc Hex Nut

P2469

8” Hood Assembly

14

P141

3/8-16 Hex Nut

2

P164

¼-20 x ¾” Hex Head Bolt

15

P142

3/8” Lock Washer

3

P246

¼” Flat Washer

16

P2206

Flat Washer

4

P2482

Hood Disc Pad

17

P2481

3/8-16 x 1-1/4” Carriage Bolt

5

P2485

¼-20 Nyloc Hex Nut

18

P2461

6” Gas Shock

6

37104-01

Damper Handle Stop Plate

P2462

8” Gas Shock

7

P2206

5/16” Flat Washer

19

P2483

¼-20 x 1” Hex Head Bolt

8

P2484

5/16-18 Nyloc Hex Nut

20

P2312

Micro Air Decal

9

37103-01

Damper Handle

21

P2232

Hose Clamp

10

P2478

½-13 X 2.25” Hex Head Bolt

22

P2491

6” Dia. Flex Hose

11

P2468

Cup Washer

P2617

8” Dia. Flex Hose

12

P2467

Friction Pad

14

MA4210 MICRO AIR

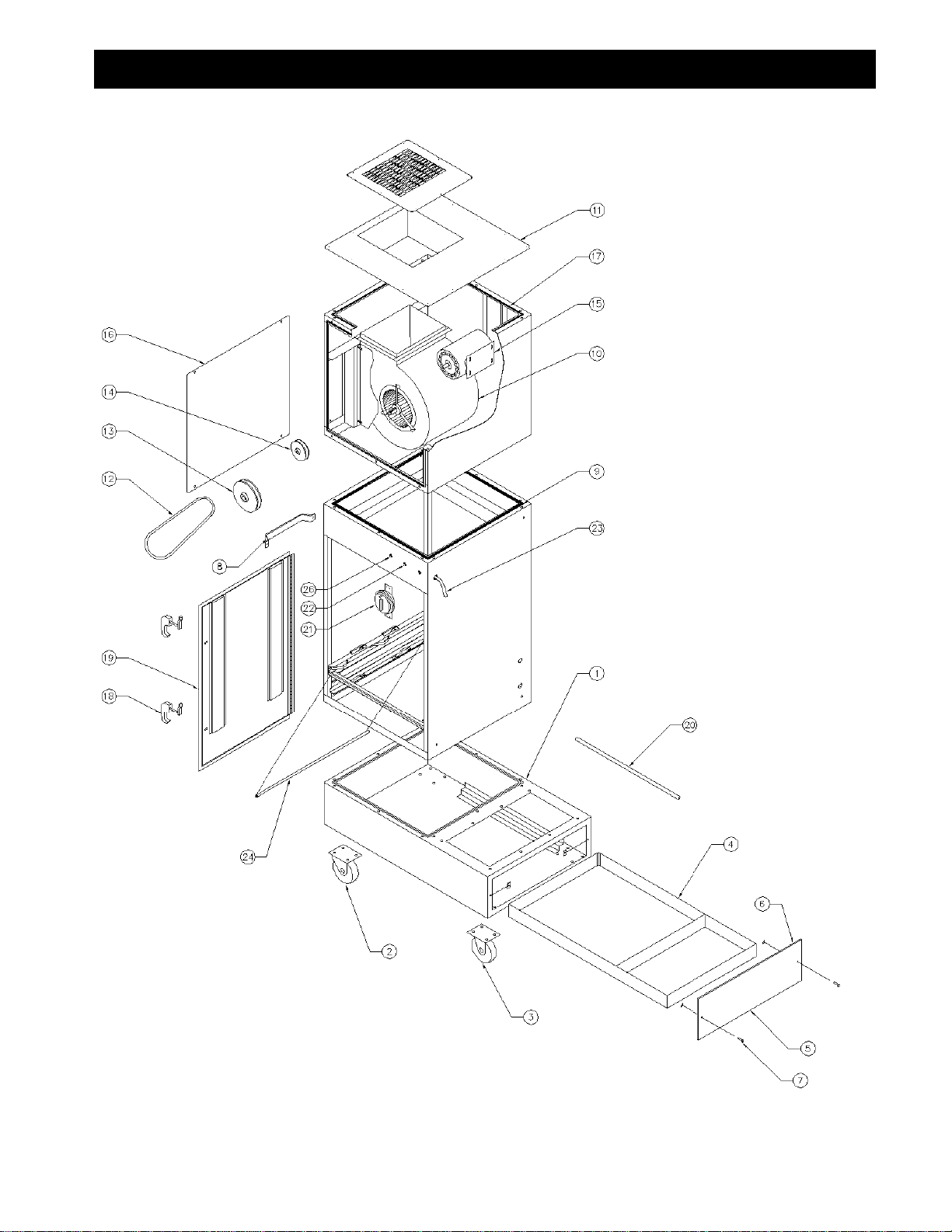

MA4210 ASSEMBLY PARTS LIST:

FIG. 9

15

MA4210 MICRO AIR

MA4210 ASSEMBLY PARTS LIST:

ITEM

PART NO.

DESCRIPTION

ITEM

PART NO.

DESCRIPTION

1

38027-01

Base Assembly

14

P2105

1-1/2HP Var. Pitch Dia. Motor Pulley

2

P3283

Swivel Caster

P3578

3HP, Var. Pitch Dia. Motor Pulley

P2724

Big Wheel

P3986

3HP, 7.75" Motor Pulley

3

P3284

Rigid Caster

15

P3545

1-1/2HP, 120V, 1 Phase Motor

4

38033-01

Spark Tray

P3495

3HP, 230/460V, 3 Phase Motor

5

33299-03

Spark Tray Door

N/S

30251-01

Mounting Bracket for P3495 Motor

6

P1809

Foam Gasket

16

38011-02

Motor Access Door

7

P1856

Spark Tray Door Latches

17

P1032

Access Door Gasket

P1857

18

P1372

Latch

P1858

19

38022-01

Filter Access Door

8

30473-01

Handle

20

33346-02

Filter Rod

9

38070-01

Cabinet Assembly

21

P3505

Pressure Switch

10

P3498

Blower

22

P3206

On/Off Switch (120V Only)

11

38010-01

Blower Access Panel

23

P1363

Cord Set (120V Only)

12

P1495

42" Belt

24

P3214

Seal Gasket

P3207

43" Belt

26

P1429

Light (120V)

P3550

49" Belt

P1481

Light (230V, 460V)

P7135

51" Belt

N/S

P3547

Wiring Diagram

13

P1710

4.95" Blower Pulley

N/S

P2250

Magnehelic Gauge

P1504

5.45" Blower Pulley

N/S

38050-01

Silencer

P1974

6.25" Blower Pulley

N/S

38036-01

Filter Track

P3218

8.00" Blower Pulley

P3270

9.75" Blower Pulley

REPLACEMENT FILTER LIST:

PART NO.

DESCRIPTION

PART NO.

DESCRIPTION

P1411

24" x 24" x 4" Pleated Pre-Filter

P1586*

24" x 24" x 2" 96% Washable Pre-Filter

P1439

24" x 24" x 32" 55% Bag Filter

P1799*

24" x 24" x 2" Baffle Oil Impinger

P1442

24" x 24" x 32" 95% Bag Filter

P2101

24" x 24" x 12" 99.97% DOP HEPA

P1455

24" x 24" x 12" 95% DOP HEPA

P2104

24" x 24" x 32" 95% Duo Cube Bag Filter

P1460

24" x 24" x 15" 95% Short Bag Filter

P2179

24" x 24" x 32" 95% Oil Mist Bag Filter

P1461*

24" x 24" x 2" Pleated Pre-Filter

33740-00

Refillable Module

P1475*

24" x 24" x 2" Mesh Oil Impinger

P1450 - Purasorb Media

P1585*

24" x 24" x 2" 70% Washable Pre-Filter

P1823 - Charcoal Media

*NOTE: 2” Pre-Filters must be used in combination to fill 4” channel.

16

MA4210 MICRO AIR

Notes:

Serial Number:

Supply Voltage:

Date Installed:

Installed By:

L1468

10/23

Table of contents

Other MICRO-AIR Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

unGer

unGer HYDRO POWER ULTRA UHP3C operating instructions

Platinum

Platinum Amazing Foam Instructions for use

Kaivac

Kaivac 1700 Series Operator's & parts manual

HCT

HCT HelioJET C-15 Installation operation & maintenance

POLTI

POLTI CIMEX ERADICATOR Plus instruction manual

Strava

Strava 100.600 Service manual