MICRO-AIR CLEAN AIR BOOTH User manual

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow

as directed. It is impossible to list all of the hazards of dust control equipment. It is important that use of the equipment

be discussed with a Micro-Air Representative. Persons involved with the equipment or systems should be instructed how

to operate in a safe manner.

CLEAN AIR BOOTH (CAB)

Installation and Operation Manual

MICRO AIR

www.microaironline.com

2

CAB MICRO AIR

WARNINGS:

Installation can cause exposure to live components. Disconnect electrical power before

proceeding with installation. Proper Lock Out / Tag Out procedures should be used. All electrical

work must be done by a qualified electrician according to Local, State and National codes.

Avoid mixing combustible materials, such as buffing lint, paper, wood, aluminum, and

magnesium dust with dust generated from grinding ferrous metals due to the potential fire

hazard caused by sparks in the dust collector

Under no conditions should the persons operating the dust collector be allowed to put cigarettes

or any burning object into the inlet grille, hood, or ducting of any dust collector system.

All users of Micro-Air Equipment should comply with all National and Local Fire Codes and/or

other appropriate codes when determining the location and operation of dust control equipment.

Improper installation or operation of this equipment can cause damage to equipment and / or

injury to personnel. The installation / operation manual must be read and followed in its entirety.

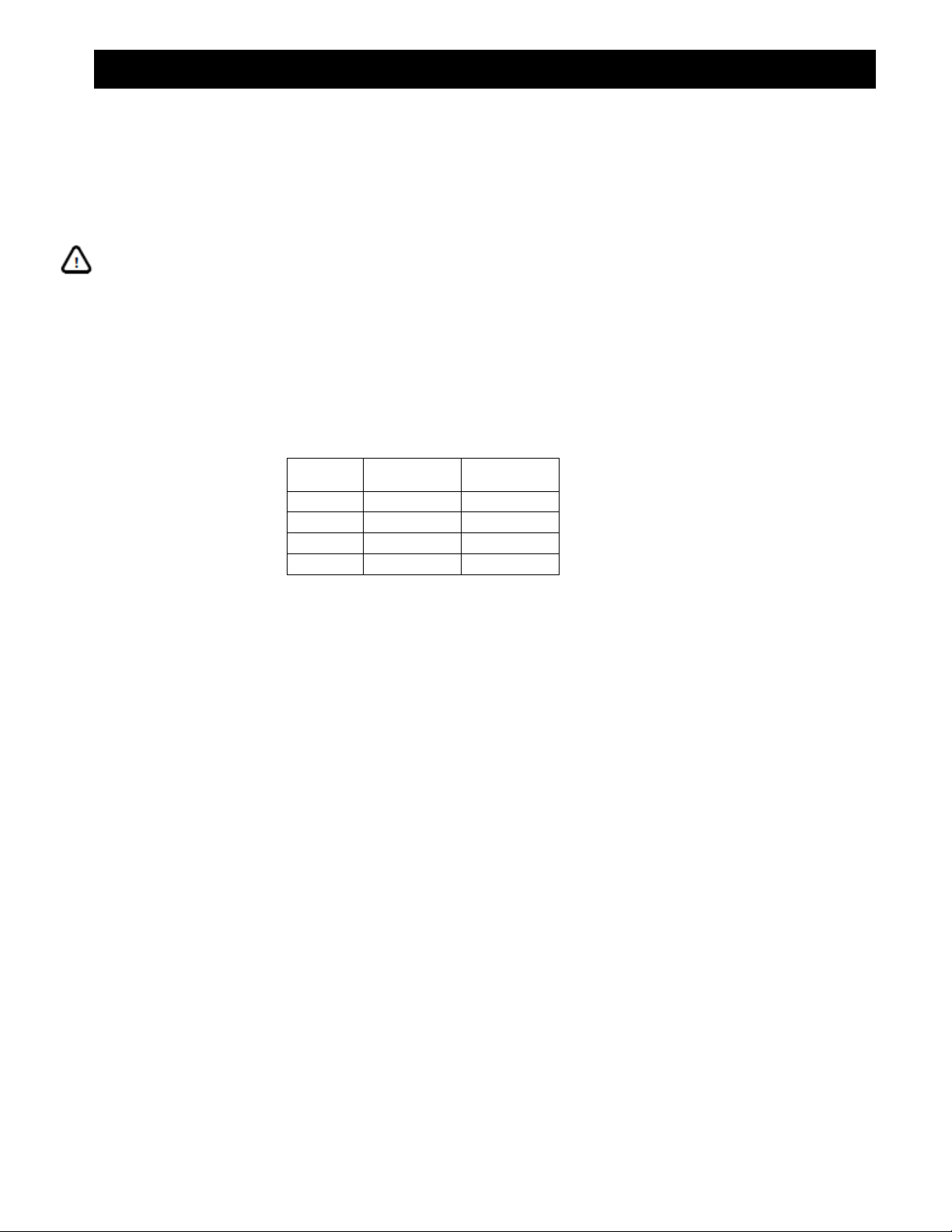

CAB SPECIFICATIONS:

Input Voltage:

230/460V, 60 Hz, 3-Phase

575V, 60 Hz, 3-Phase

Motor Options:

3HP, 3-Phase, TEFC Motor, 3450 RPM

3HP, 3-Phase, TEFC Motor, 3450 RPM, Explosion Rated

5HP, 3-Phase, TEFC Motor, 3450 RPM

5HP, 3-Phase, TEFC Motor, 3450 RPM, Explosion Rated

Maximum Current:

3HP:

230V - 7.4 Amps

460V - 3.7 Amps

575V - 3.2 Amps

5HP:

230V - 14.0 Amps

460V - 7.0 Amps

575V - 5.5 Amps

Cabinet Dimensions

Single:

101" H x 48" W x 36" D, 850 lbs.

and Weights:

Double:

101" H x 96" W x 36" D, 1700 lbs.

Triple:

101" H x 144" W x 36" D, 2550 lbs.

Quad.:

101" H x 192" W x 36" D, 3400 lbs.

Filter Area (80/20 Filter

Single:

1250 Sq. Ft.

Media):

Double:

2500 Sq. Ft.

Triple:

3750 Sq. Ft.

Quad.:

5000 Sq. Ft.

Dust Tray Capacity:

4.75 Cu. Ft.

EQUIPMENT / TOOLS REQUIRED:

Equipment and tools needed for proper installation will include the following:

Crane or Lift Truck

Screw Driver

Lift Straps or Chain

Sockets

Pipe Wrench

3

CAB MICRO AIR

PRE-OPERATING INSTRUCTIONS:

The Micro Air Clean Air Booth is shipped on multiple skids.

1. Inspect every skid for any visible damage that may have occurred during shipment. Report any damage

to the delivery carrier.

2. Remove the shipping crate, shipping straps and plastic wrap from unit. Discard skid and hardware.

3. Additional equipment that may be shipped separately includes:

HEPA After-Filter Kit

Silencer Assembly

Photohelic Kit

Booth Panels & Supports

Magnehelic Kit

Electrical Box

Air Regain Module

Exhaust Panels

ASSEMBLY OF UNIT:

1. Determine the location where the unit is to be installed. Be sure to allow sufficient room to access the

unit for servicing and maintenance on all sides.

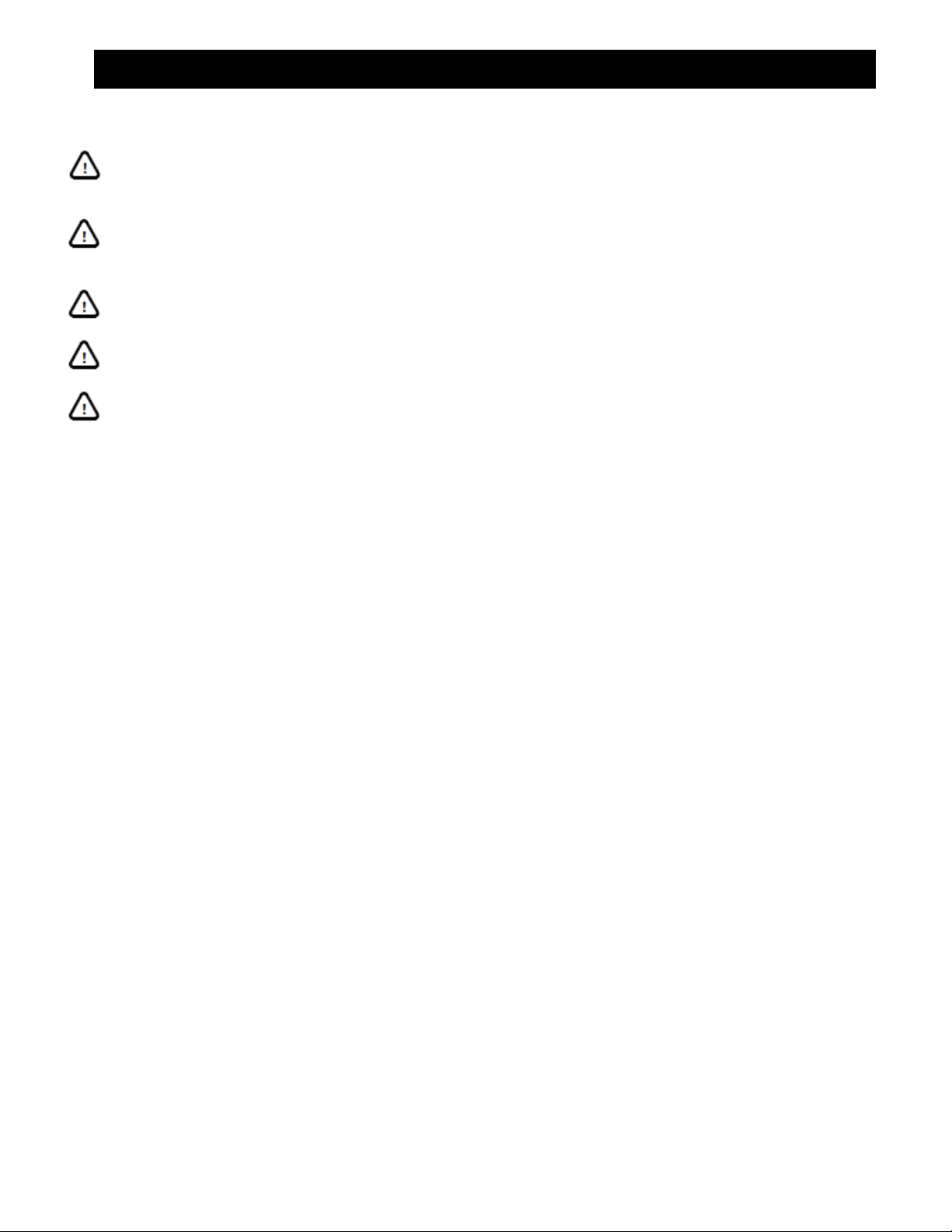

2. Connect chain/lift straps to provided eye-bolts located on top of unit (See FIG.1).

3. Securely attach chain/lift straps to crane. NOTE: Each lifting strap or chain should be rated for a

minimum of 2500 lbs.

4. Slowly lift unit into a standing position. CAUTION: If unit is lifted too quickly or too high it may lose

contact with the ground and swing side to side.

5. Once unit is in standing position readjust chain/lift straps and move unit into its final position.

6. Remove wooden brace used to secure motor (See FIG. 1).

7. If multiple units are to be assembled for a single booth, set each unit side by side.

8. Connect units using Dual Cabinet Plate and provided hardware (See FIG. 2). NOTE: To prevent

vibration noises in multi-cabinet units, silicon can be applied between units.

9. Using holes provided in bottom of cabinet, place four 1/2” anchor bolts for each cabinet.

FIG. 1 FIG. 2

4

CAB MICRO AIR

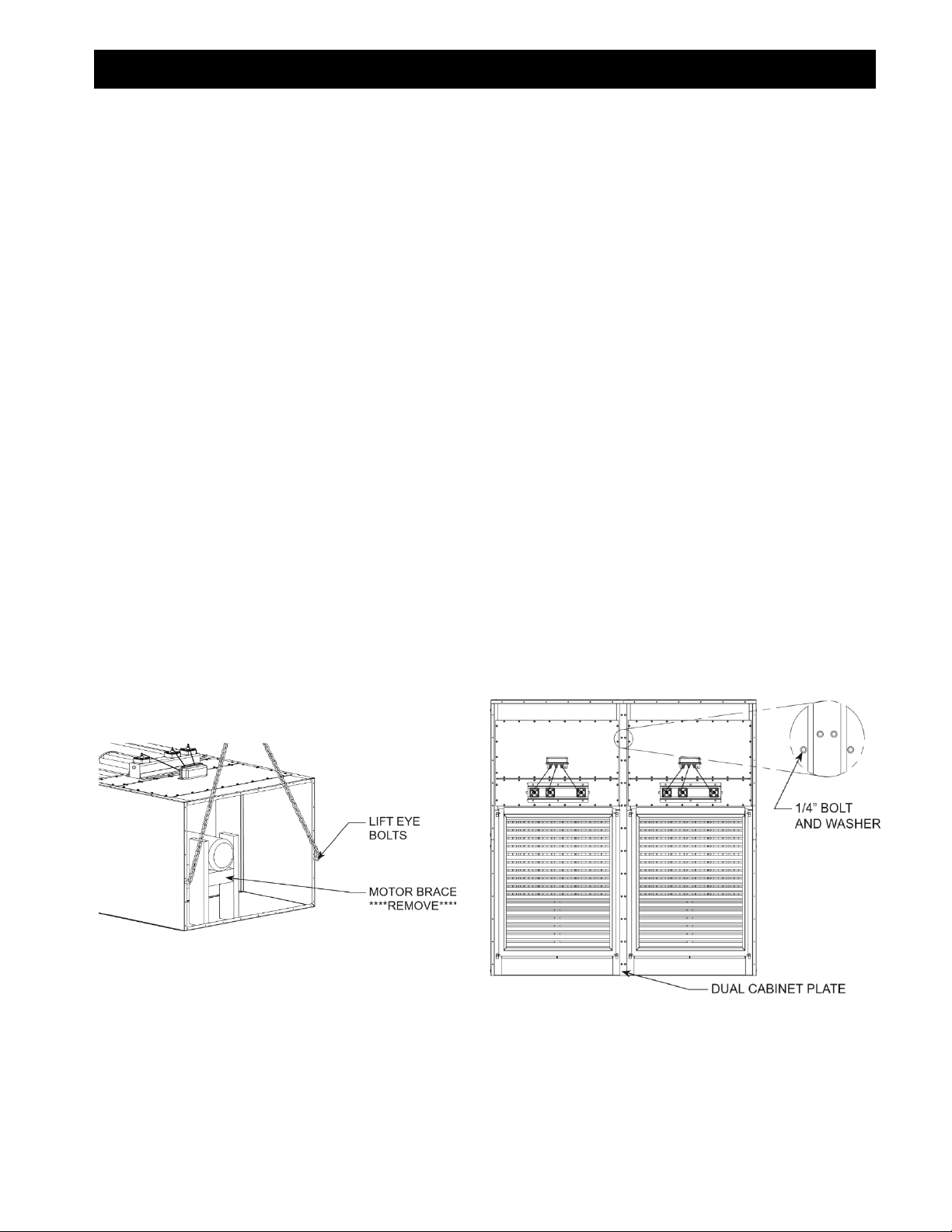

COMPRESSED AIR REQUIREMENTS / INSTALLATION:

NOTE: Clean, dry, compressed air at the specified air pressure is required for the cleaning system to

operate correctly. It is recommended that a pressure regulator and coalescing filter be installed between

the compressed air source and the inlet to the dust collector.

The compressed air inlet for the Roto-Pulse Cleaning System is at the top of the piping assembly located

on the front side of the unit (See FIG. 3). A minimum of a ¾” line and plant air at a pressure of 80 psi is

required, per unit, for proper operation of the Roto-Pulse Cleaning System.

FIG. 3

1. Remove plug from one end of Valve Manifold Assembly.

2. Connect ¾” air line to one end of each Valve Manifold Assembly. NOTE: Up to 2 Valve Manifold

Assemblies may be connected in series to the main trunk line. However additional Valve Manifold

Assemblies must be connected directly to the main air line.

3. The main air line must be sized appropriately for the number of units. The following shows minimum

recommended sizes:

Single Unit:

¾” Main Compressed Air Line (Minimum)

Double Unit:

1” Main Compressed Air Line (Minimum)

Triple Unit:

1-¼” Main Compressed Air Line (Minimum)

Quad. Unit:

1-½” Main Compressed Air Line (Minimum)

ELECTRICAL INSTALLATION:

IMPORTANT: The following installation instructions should be performed by a qualified

electrician. The following installation steps are for general use. Refer to Local and National

electrical codes for installations in your area.

WARNING: Installation can result in exposure to high voltage. Disconnect power source before

performing this installation. Proper lock out / tag out procedures should be used.

1. Unpack electrical box from skid. Inspect for any shipping damages.

2. The CAB unit can be operated with a factory assembled electrical control box, which contains a timer

circuit for automatic filter cleaning, a motor starter circuit for START/STOP operation and overload

protection for motor/blower(s) provided.

3. The electrical box is completely wired from the factory. Prior to making any electrical connections,

VERIFY PROPER INPUT VOLTAGE has been used for wiring the electrical circuit. IMPROPER

VOLTAGE MAY RESULT IN PERMANENT DAMAGE TO ELECTRICAL COMPONENTS.

4. Before making electrical connections, mount the electrical control box to a rigid permanent structure,

such as the unit, booth, or nearby wall.

5

CAB MICRO AIR

5. Electrical connections for motor/blower(s), Roto-Pulse solenoid valves, and incoming power shall be

required upon installation. The electrical box includes a safety interlock switch that disconnects power

to the circuit when the enclosure is opened. To gain access inside the electrical box, simply rotate the

disconnect switch towards the OFF position until a distinct click occurs. Using a Phillips screwdriver,

release the external hardware clamps located around the perimeter of the NEMA enclosure to allow

access to the electrical box.

IMPORTANT: Solid state circuits are sensitive to electrostatic shock. Take measures to ensure

that minimal static charge is discharged before making adjustments or changes to wire

connections on the timer board.

6. Route wire conduit from electrical box enclosure to solenoid valves housed inside NEMA enclosure(s)

located above the air inlet and Roto-Pulse valves of each clean air unit. Conduit should be sized to

allow the appropriate number of wires (16 AWG stranded) for all solenoids used. NOTE: A single wire

can be used for the COM output of the timer board to reduce overall number of wires.

7. Run wire conduit(s) from electrical box enclosure to each motor/blower. Wire size will vary based upon

input voltage and horsepower. A table is shown below for recommended wire size. Consult local

electrical codes.

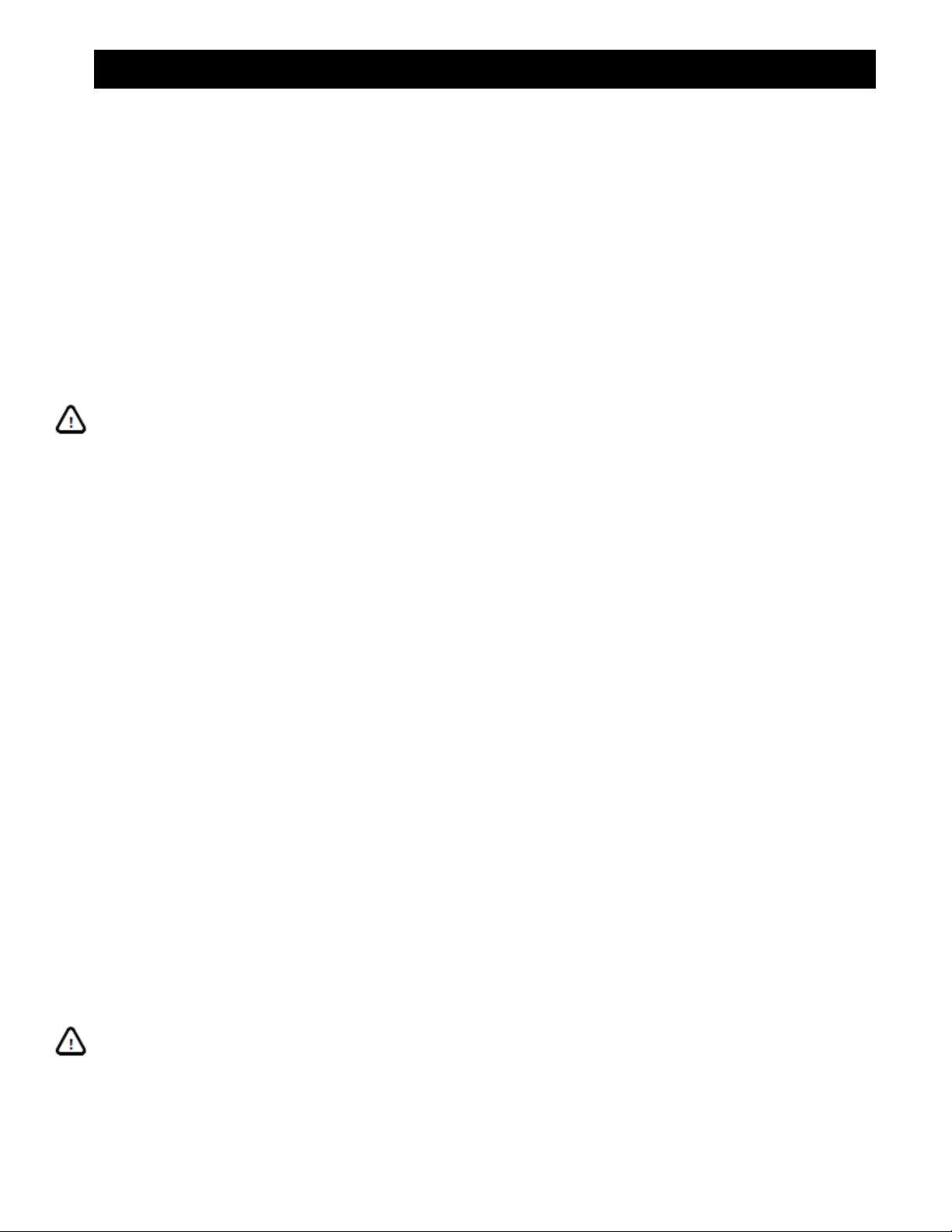

HORSE

POWER

VOLTAGE

WIRE SIZE

(AWG)

3

208 - 230V

14

3

460 - 575V

14

5

208 - 230V

12

5

460 - 575V

14

8. In most instances, three phase motors supplied for the CAB are dual voltage motors. When making

electrical connections to the motor(s) make certain to check motor wiring for correct input voltage.

(Refer to motor wiring label located upon each motor casing.)

9. After completing installation of electrical conduit, run wire and make appropriate electrical connections

as noted on wiring diagram (see PAGES 14-21).

10. After wires have been routed and connected, run conduit and wire connections for input power.

Connect wires to the input side of the interlock disconnect switch located inside the electrical box

enclosure. Use grounding termination located near by the disconnect switch for supply ground.

NOTE: Wire size for supply connections shall be sized according to the maximum horsepower rating of

all motors connected to the electrical box. Total motor load shall not exceed 20HP max.

11. The electrical box enclosure is grounded to the grounding terminal connected to supply ground. When

making electrical connections to each unit motor/blower it is recommended to ground the units. This

can be accomplished by running a ground wire (of equivalent wire gauge) from the motor ground to the

electrical box enclosure.

12. Upon completion of all wiring connections, close the electrical box enclosure, securing each of the

clamps around the enclosure and then turning the disconnect switch to the ON position. The unit is now

electrically ready for operation. Connect power via circuit breaker and/or three-phase disconnect switch.

The unit can now be energized by pushing the START button. Be certain that all other installation steps

have occurred before starting unit.

13. Upon pushing the START button located on the hinged door of the electrical box enclosure, the CAB

unit blower should begin to run and auto cleaning cycle should begin (unless Photohelic switch is used,

See Photohelic Switch). To stop the unit from running, push the STOP button also located on the

electrical box cover. Note that after-pulse cleaning (off-line cleaning) cycle will begin and auto-cleaning

will continue for approximately 1 to 2 minutes.

NOTE: If the enable switch located on the timer board is in the disable position, off-line cleaning will not

occur. If off-line cleaning is desired, simply move the switch to the enable position.

6

CAB MICRO AIR

PHOTOHELIC SWITCH:

For applications that require a Photohelic switch to monitor filter loading and control the operation of

auto-cleaning, additional wiring must be performed.

1. An optional Photohelic switch is made available for the CAB unit. Additional electrical installation is

required for this option in order to allow the switch to control the automatic cleaning system while

monitoring the pressure drop across the cartridge filters. Before wiring may begin, first locate the

Photohelic switch kit and mount it to a suitable location. Run air lines from the Photohelic switch ports to

the CAB unit. (Refer to Photohelic switch installation instructions, Page 13).

2. Once the Photohelic switch has been physically installed, route electrical conduit from the electrical box

enclosure to the Photohelic switch.

3. Next, route 2 wires (16 AWG min.) from the Photohelic switch to the electrical box enclosure. Allow

adequate length of wire to reach the upper left corner of the timer circuit board terminal strip labeled

PRESSURE SWITCH (See PAGES 14-22 for Wiring Diagrams).

IMPORTANT: Solid state circuits are sensitive to electrostatic shock. Take measures to ensure

that minimal static charge is discharged before making adjustments or changes to wire

connections on the timer board.

4. Prior to making connections to the PRESSURE SWITCH terminal, disconnect the two wires connected

to the terminal and also disconnect the other ends of the red wires that are connected to an auxiliary

contact (switch) located on a motor starter relay. Discard wires for this installation.

5. Connect each wire from the Photohelic switch to each terminal on the timer board indicated as

PRESSURE SWITCH. Be certain that only one wire is connected to each terminal.

6. Move the enable/disable switch on the timer board to the DISABLE position. This will inactivate the off-

line cleaning feature of the timer circuit, which is more common when only demanding automatic

cleaning when filters reach a certain static pressure level.

7. After all wiring connections have been completed; close the electrical box enclosure, securing the

enclosure cover with screw clamps provided. By hand, turn the safety switch disconnect to the ON

position.

8. Photohelic settings are to be adjusted for optimized cleaning performance. Typically, a low setting at 2”

w.c. and a high setting at 3” or 4” is a recommended starting point. Once the pressure drop across the

cartridge filters reaches the upper limit of the gauge, the automatic cleaning system will engage and

continue to run until the static pressure drops below the lower setting.

NOTE: If the after-pulse (off-line pulse) switch is enabled, the cleaning system will continue to clean for

the duration of pulses upon reaching the lower limit setting noted above.

TIMER BOARD ONLY:

1. For applications that do not include a factory wired electrical box assembly (which includes timer, motor

starter(s), disconnect, etc.) a multi-channel timer PCB is supplied within a NEMA enclosure. Motor

starters and controls to start and stop the entire system are supplied by other means.

2. Before wiring, locate the timer board and enclosure in an appropriate mounting location that will allow

access for timer adjustments.

3. Run electrical conduit from solenoid valves located on the CAB unit(s) to the timer board enclosure.

4. Run wires from the timer board output channels to the solenoid valves (refer to Wiring Diagram,

PAGES 14-22).

IMPORTANT: Solid state circuits are sensitive to electrostatic shock. Take measures to ensure

that minimal static charge is discharged before making adjustments or changes to wire

connections on the timer board.

7

CAB MICRO AIR

5. Make electrical connects to the input of the timer board. NOTE: Timer board will operate at 108 -

132VAC, 50/60Hz.

CAUTION: Over voltage input (in excess of 132VAC) will damage the timer board and void

warranty. Internal fuse does not protect against over voltage conditions.

6. Make appropriate connections to the PRESSURE SWITCH terminals located on the upper left corner of

the timer board. If the terminal is permanently connected (with a jumper) the timer board will continue to

run as long as input voltage in present. Connecting a SPST pressure switch (or Photohelic Switch) to

this terminal is a recommended method.

CAUTION: Do not allow grounded connection to make contact with the PRESSURE SWITCH

terminal of the timer board. Contact with ground will result in permanent damage to the timer

board and void warranty.

UNIT OPERATION:

1. Turn the unit on via the start switch located on the front side of the electrical box.

NOTE: Some particulate may pass through the cartridge filters and blower upon initial start-up. This will

end once the filters have been seasoned and a powder cake has formed on the filter. If this condition

continues to occur refer to the section ROTO-PULSE CLEANING TIMER ADJUSTMENTS to increase

the period of time between pulses.

2. Once the unit is running, the Roto-Pulse cleaning system will be optional. Operation is detected by

hearing a .07 second air pulse approximately every 5 seconds. If adjustments to timing of pulses is

desired refer to section ROTO-PULSE CLEANING TIMER ADJUSTMENTS.

3. Check the After-Pulse Cleaning cycle by turning off the unit via the stop switch located on the front side

of the electrical box. The unit should continue to pulse every 5 seconds for a period of approximately 17

minutes. If adjustments to the after-pulse time is desired, refer to the section labeled AFTER-PULSE

CLEANING.

FIG. 4

8

CAB MICRO AIR

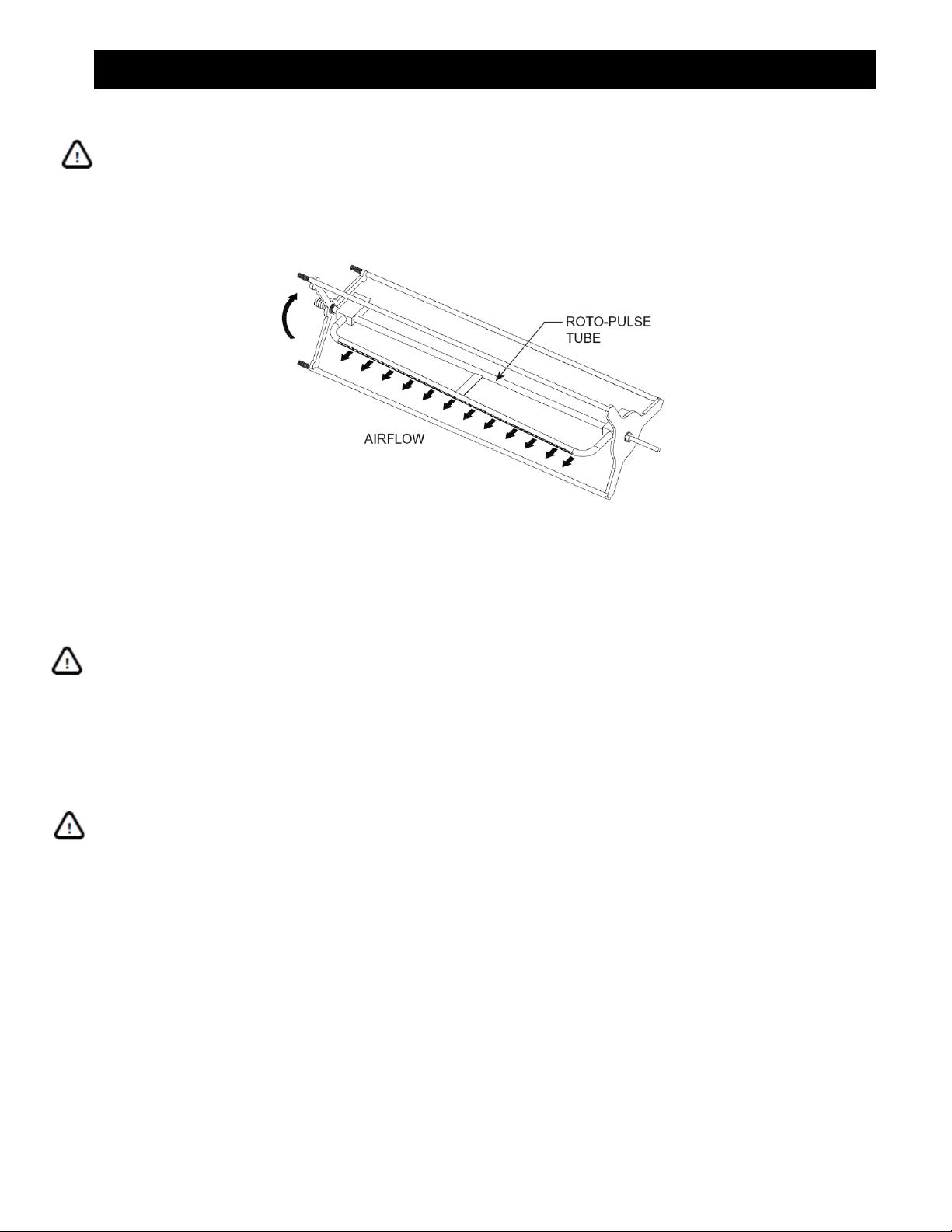

CARTRIDGE CLEANING OPERATION:

CAUTION: When servicing the collection system, be sure to turn the unit off.

The Micro-Air Dust Collector is designed with the Roto-Pulse Cleaning System to clean the cartridge

filters. This system provides superior cleaning performance using a rotating tube with pre-drilled holes

(See FIG. 5). As the diaphragm valve opens, the Roto-Pulse tube rotates while air exits the holes, thus

providing the cleaning of the cartridge.

FIG. 5

1. For proper cleaning, the compressed air pressure should be regulated at 80 psi maximum.

2. During normal operation the Roto-Pulse cleaning system is factory set to clean 2 cartridge filters for a

period of .07 seconds every 5 seconds

3. Once the unit is turned off, the cleaning cycle will continue for a period of 2 minutes. Do not service the

filters until cleaning is completed.

CAUTION: Allow 20 minutes downtime before accessing filters. After-pulse system is

momentarily operational after unit is turned off.

4. The Roto-Pulse cleaning operation dislodges particles from the cartridges. Particles then fall down into

the collection tray.

ROTO-PULSE CLEANING TIMER ADJUSTMENTS:

CAUTION: Installation can cause exposure to live components. Disconnect electrical power

before proceeding with timer adjustments. Proper lockout / tag out procedures should be used.

1. Turn unit off via the stop switch and disconnect power.

2. Open the electrical box cover.

3. The timer control board is present at the factory to clean 2 cartridge filters every 5 seconds. This time

can be adjusted from 1 second to 999 seconds. To adjust this time press the select button on the timer

board until the off time LED is lit. Press the up/down buttons until the desired value is displayed and

press select to set the new value.

NOTE: Cleaning of the filters too often will decrease your level of performance. A certain level of dust

cake on the filters will improve the efficiency of the filter cartridges. You should try to maintain 1” W.C. of

pressure differential across the filters the time between cleaning pulses should be increased until this

can be achieved.

4. The timer control board is preset at the factory to have a cleaning pulse duration of .07 seconds. This

can be adjusted from .05 seconds to 600 seconds. To adjust this time press the select button on the

9

CAB MICRO AIR

timer board until the on time LED is lit. Press the up/down buttons until the desired value is displayed;

press select to set the new value.

NOTE: While this time can be adjusted we recommend you leave the “ON TIME” at the factory setting. If

less cleaning is needed you should increase the time between pulses as this means of reducing the

amount of cleaning. If more cleaning is needed you should decrease the amount of time between pulses.

Be aware, as the time between pulses is decreased for additional cleaning, this will increase your

compressed air consumption and create an additional load on your compressed air system.

5. Once adjustments have been made replace the electrical box cover and reconnect the power.

6. Start the unit and observe the new pulse settings and determine if additional adjustments are

necessary. If more adjustments are needed repeat the previous steps.

AFTER-PULSE CLEANING TIMER ADJUSTMENTS:

CAUTION: Installation can cause exposure to live components. Disconnect electrical power

before proceeding with timer adjustments. Proper lockout / tag out procedures should be used.

1. The unit is equipped with an After-Pulse Cleaning cycle. This cycle will continue to clean the cartridge

filters for a period of time after the unit is turned off.

2. The length of the After-Pulse operation is present at the factory for 100 seconds. This time can be

adjusted from 0 seconds to 999 seconds. To adjust this time press the select button until the off-time

LED is lit. Press and hold the select button for 3 seconds. Press the up/down buttons until the desired

value is displayed; press select to set the new value. The after-pulse operation can be disabled by

setting the time value to zero (0) seconds.

10

CAB MICRO AIR

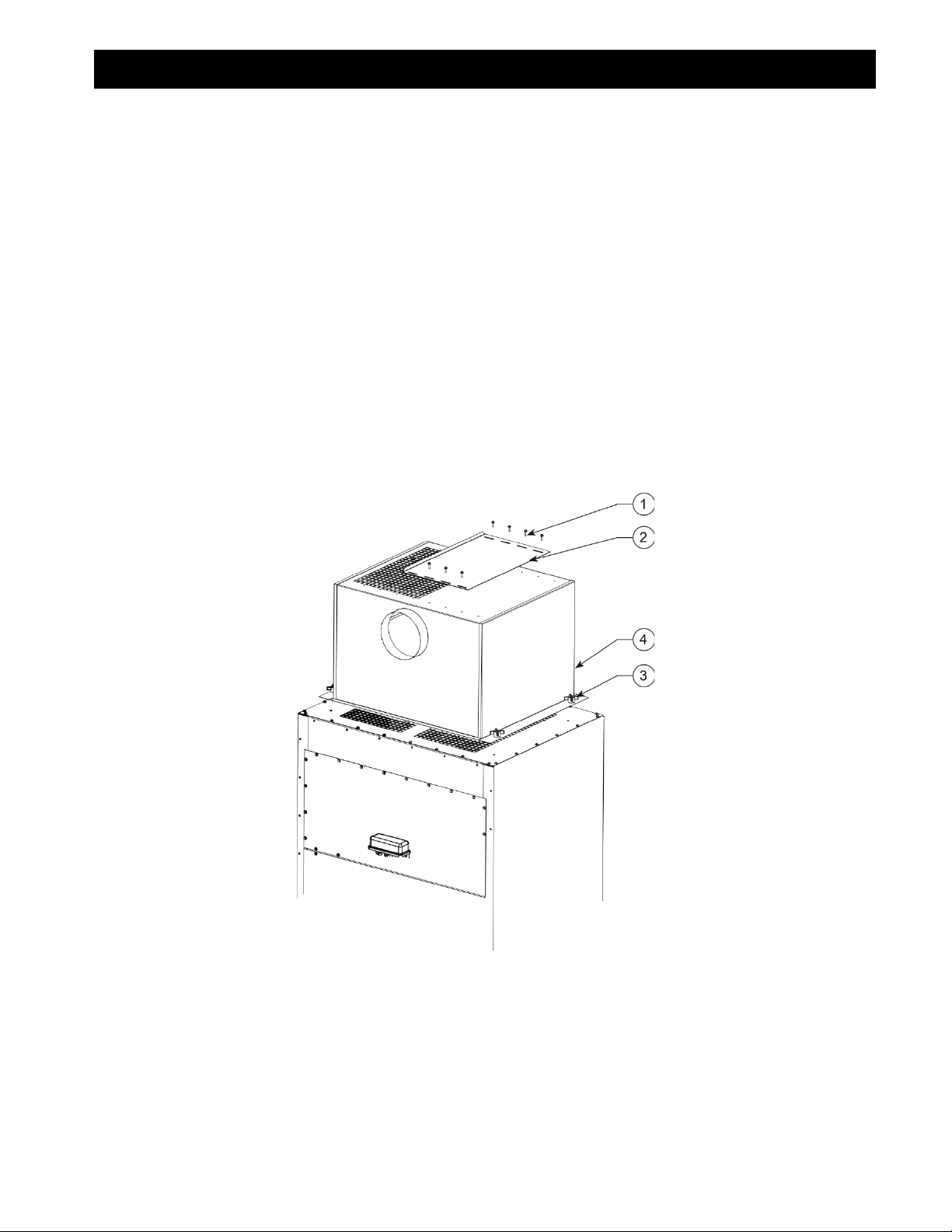

HEPA/REGAIN PLENUM INSTALLATION PROCEDURE

This kit includes:

ITEM

PART NO.

DESCRIPTION

QTY.

1

P2543

¼” x 1 Self-Tapping Screw

8 ea.

2

37527-01

Exhaust Plate

1 ea.

3

P3649

4-Prong Knob

4 ea.

4

37580-01

HEPA/Regain Plenum Assembly

1 ea.

5

P2692

95% HEPA Filter

2 ea.

INSTALLATION:

1. Remove HEPA/Regain plenum from skid and inspect for any possible damage incurred during shipping.

2. Place HEPA Filters (foam side down) on top of cabinet. NOTE: Center filters over grille on cabinet.

3. Place the HEPA/Regain Assembly over the filters. The duct opening should point towards the front of

the cabinet (See FIG. 6).

4. Use the four 4-Prong Knobs to fasten the HEPA/Regain assembly to the cabinet.

5. Connect duct work for Regain.

6. Adjust Exhaust Grille Plate to set Regain at the desired amount.

NOTE: Blocking more of the exhaust increases the amount of Regain Air.

FIG. 6

11

CAB MICRO AIR

SILENCER INSTALLATION PROCEDURE

This kit includes:

ITEM

PART NO.

DESCRIPTION

QTY.

1

P2543

¼” x 1 Self-Tapping Screw

8 ea.

2

37527-01

Exhaust Plate

1 ea.

3

P3649

4-Prong Knob

4 ea.

4

37590-01

Silencer Plenum Assembly

1 ea.

INSTALLATION:

1. Remove Silencer plenum from skid and inspect for any possible damage incurred during shipping.

2. Place the Silencer assembly over the exhaust plate. The duct opening should point towards the front of

the cabinet (See FIG. 7).

3. Use the four 4-Prong Knobs to fasten the Silencer assembly to the cabinet.

4. Connect duct work for Regain.

5. Adjust Exhaust Grille Plate to set Regain at the desired amount.

NOTE: Blocking more of the exhaust increases the amount of Regain Air.

FIG.7

12

CAB MICRO AIR

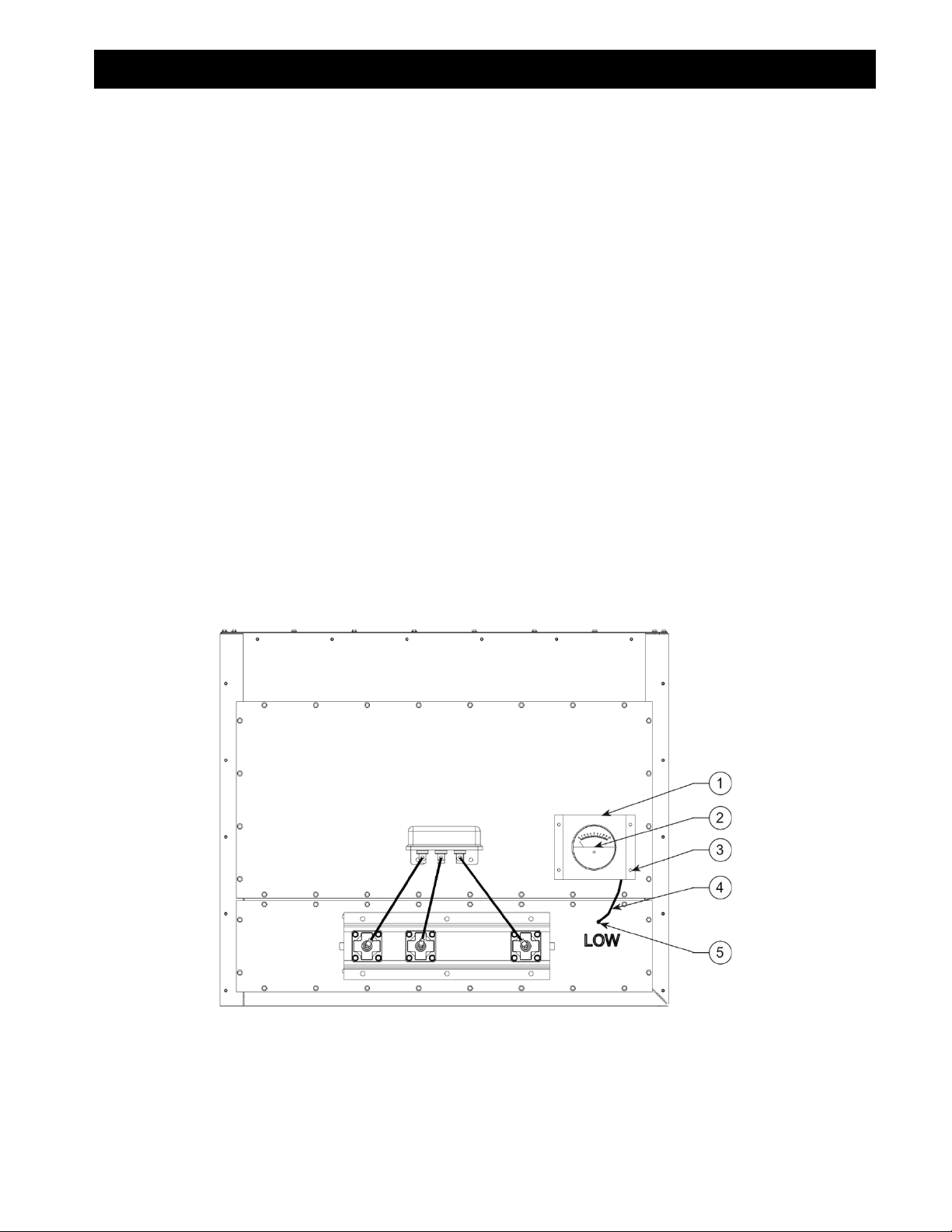

MAGNEHELIC KIT INSTALLATION PROCEDURE

This kit includes:

ITEM

PART NO.

DESCRIPTION

QTY.

1

38294-01

Magnehelic Mounting Bracket

1 ea.

2

P3755

0-10” W.C. Magnehelic Gauge

1 ea.

3

P3543

¼”-14 x 1” Self-Tapping Screw

4 ea.

4

P1848

¼” Clear Tubing

10 ft.

5

P2098

⅛” Male x ¼” Barb Fitting

1 ea.

INSTALLATION:

1. Remove parts from package and inspect for any possible damage incurred during shipping.

2. Turn off Clean Air Booth and disconnect power to the unit.

3. Mount the Magnehelic Gauge into the Magnehelic Mounting Bracket and place the 2 male barb fittings

in the pressure ports located on the side of the Magnehelic Gauge.

4. Place the two pressure port plugs supplied with the Magnehelic Gauge on the 2 ports located on the

backside of the gauge.

5. Mount the bracket using the ¼” self-taping screws. The Magnahelic gauge may be mounted on any

surface within 10 ft. of the unit.

6. Using ¼” Clear Tubbing (Additional length can be purchased) connect the “LOW” pressure port on the

gauge to the clean air plenum. If the unit has multiple cabinets the gauge can be connected to any

cabinet.

7. Reconnect the power to the unit and start the Clean Air Booth.

8. Upon start up, the gauge should measure some amount of pressure drop (typically ½” W.C.). If no

pressure is measured, check connections for proper installation.

FIG. 8

13

CAB MICRO AIR

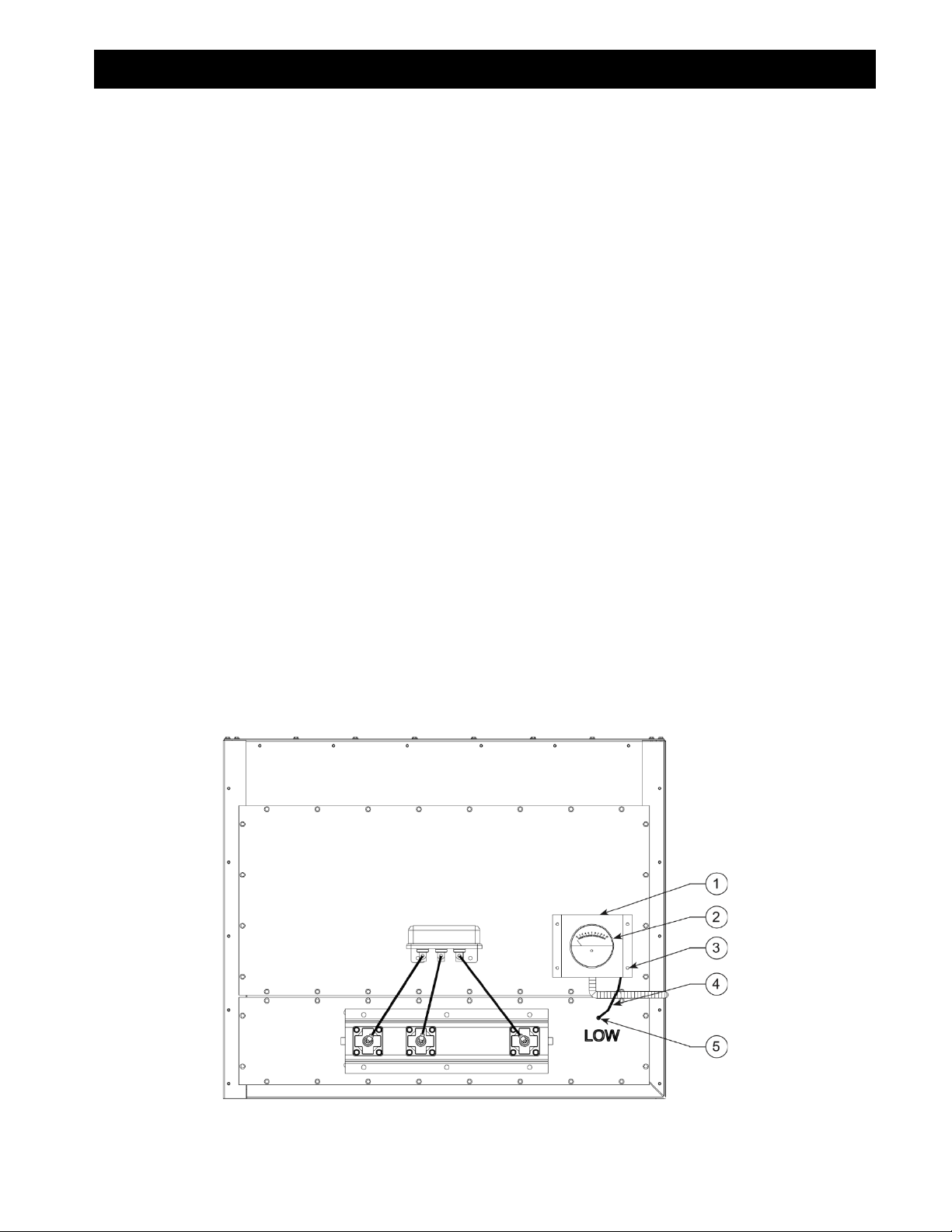

PHOTOHELIC KIT INSTALLATION PROCEDURE

This kit includes:

ITEM

PART NO.

DESCRIPTION

QTY.

1

38293-01

Photohelic Mounting Bracket

1 ea.

2

P3643

0-10” W.C. Photohelic Gauge

1 ea.

3

P3543

¼-14 x 1” Self-Tapping Screw

4 ea.

4

P1848

¼” Clear Tubing

10 ft.

5

P2098

⅛” Male x ¼” Barb Fitting

2 ea.

INSTALLATION:

1. Remove parts from package and inspect for any possible damage incurred during shipping.

2. Turn off Clean Air Booth and disconnect power to the unit.

3. Remove the plastic cover on the back of the Photohelic Gauge.

4. Mount the Photohelic Gauge into the Photohelic Mounting Bracket and place the 2 male barb fittings in

the pressure ports located on the side of the Photohelic Gauge.

5. Remove the cover from electrical box so that wiring diagram on back of cover can be used.

6. Remove two red wires that are connected to the Timer Board Pressure Switch Input and Auxilary

Contact.

7. Wire the Photohelic Guage as the electrical diagram shows in FIG. 18 (See PAGE 22) using the ¾”

conduit opening on the Photohelic (Wire and conduit supplied by others).

8. Replace the cover back onto the Photohelic Gauge and mount the bracket using the four ¼” self-

tapping screws.

9. Using ¼” clear tubing (Additional length can be purchased) connect the “LOW” pressure port on the

gauge to the clean air plenum.

10. You must replace the enable / disable switch located on the timer board to the “DISABLE” position. This

will disable the after-pulse mode of the timer board.

11. Replace the cover on the electrical box and reconnect the power to the unit.

12. The right set point dial of the gauge should be positioned at the filter differential set point you want the

Roto-Pulse system to be enabled. The left set point dial should be positioned at the filter differential set

point you want the Roto-Pulse system to be disabled.

FIG. 9

14

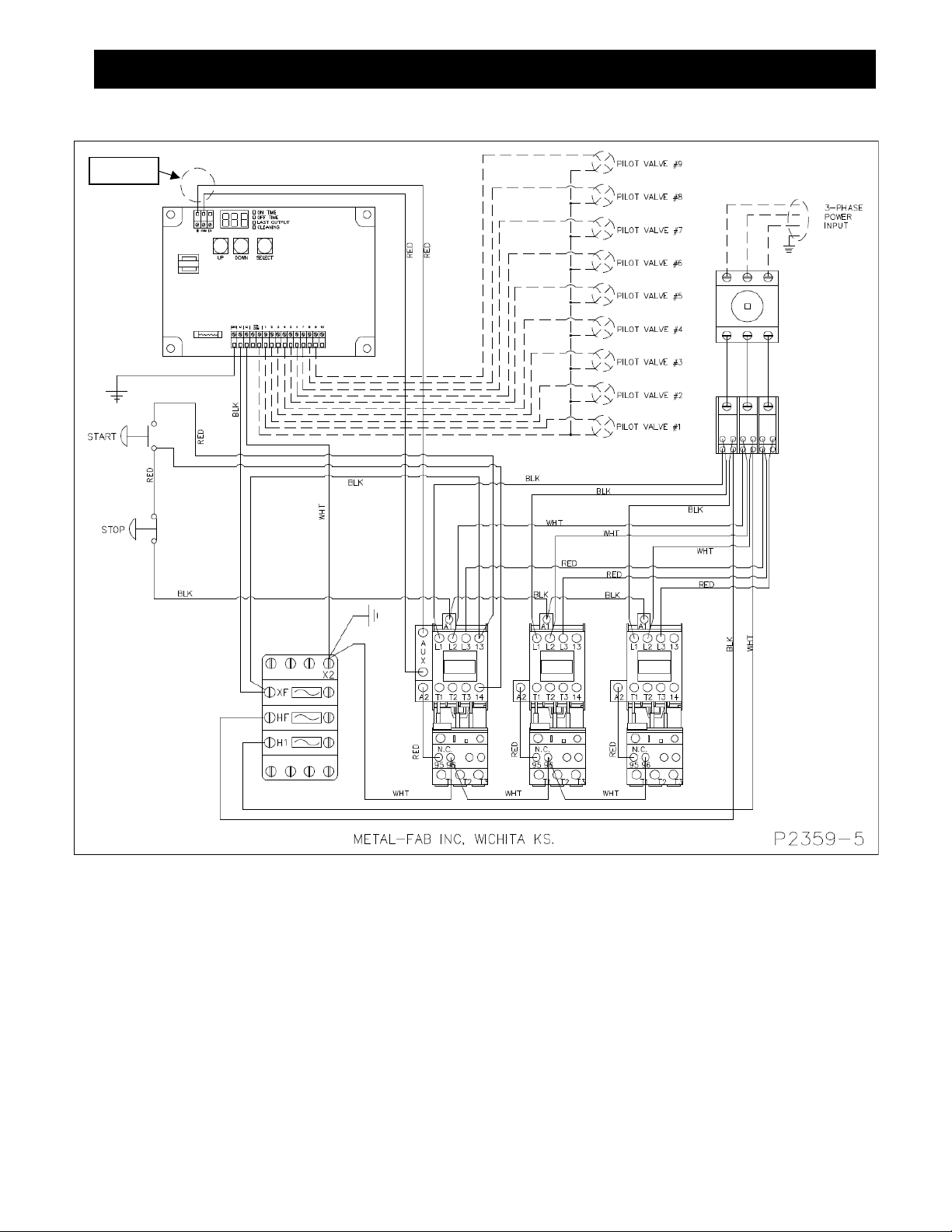

CAB MICRO AIR

SINGLE POWER PACK 230/460V MOTOR/BLOWER

FIG. 10

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

15

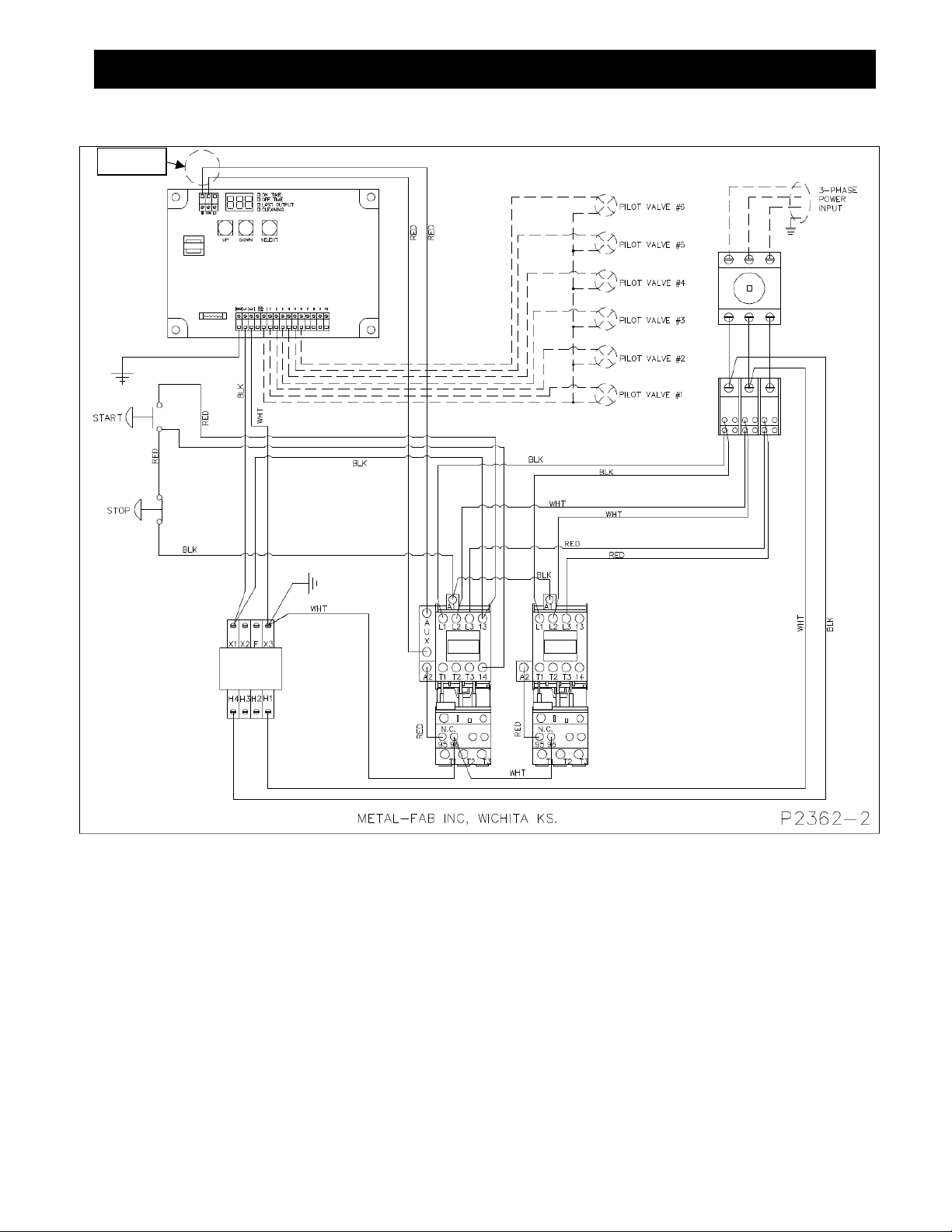

CAB MICRO AIR

DUAL POWER PACK 230/460V MOTOR/BLOWER

FIG. 11

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

16

CAB MICRO AIR

TRIPLE POWER PACK 230/460V MOTOR/BLOWER

FIG. 12

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

17

CAB MICRO AIR

QUADRUPLE POWER PACK 230/460V MOTOR/BLOWER

FIG. 13

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

18

CAB MICRO AIR

SINGLE POWER PACK 575V MOTOR/BLOWER

FIG. 14

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

19

CAB MICRO AIR

DOUBLE POWER PACK 575V MOTOR/BLOWER

FIG. 15

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

20

CAB MICRO AIR

TRIPLE POWER PACK 575V MOTOR/BLOWER

FIG. 16

*NOTE: Units supplied with Photohelic option see FIG. 18 (Page 22). Refer to page 6 for installation

information.

*NOTE

Other manuals for CLEAN AIR BOOTH

1

Table of contents

Other MICRO-AIR Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual