MICROENER ULTRA Series User manual

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

1

of

87

DIGITAL-MULTIFUNCTION

TRANSFORMER DIFFERENTIAL

PROTECTION RELAY

TYPE

DTMR33-TX

(Multiple I/O Boards)

ULTRA Line

OPERATION MANUAL

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

2

of

87

1. General Utilization and Commissioning Directions ________________________________________4

1.1 - Storage and Transportation _______________________________________________________________________ 4

1.2 - Installation ____________________________________________________________________________________ 4

1.3 - Electrical Connection ____________________________________________________________________________ 4

1.4 - Measuring Inputs and Power Supply ________________________________________________________________ 4

1.5 - Outputs Loading________________________________________________________________________________ 4

1.6 - Protection Earthing _____________________________________________________________________________ 4

1.7 - Setting and Calibration___________________________________________________________________________ 4

1.8 - Safety Protection _______________________________________________________________________________ 4

1.9 - Handling______________________________________________________________________________________ 4

1.10 - Maintenance__________________________________________________________________________________ 4

1.11 - Waste Disposal of Electrical & Electronic Equipment __________________________________________________ 4

1.12 - Fault Detection and Repair ______________________________________________________________________ 5

2. General _________________________________________________________________________5

2.1 - Power Supply__________________________________________________________________________________ 5

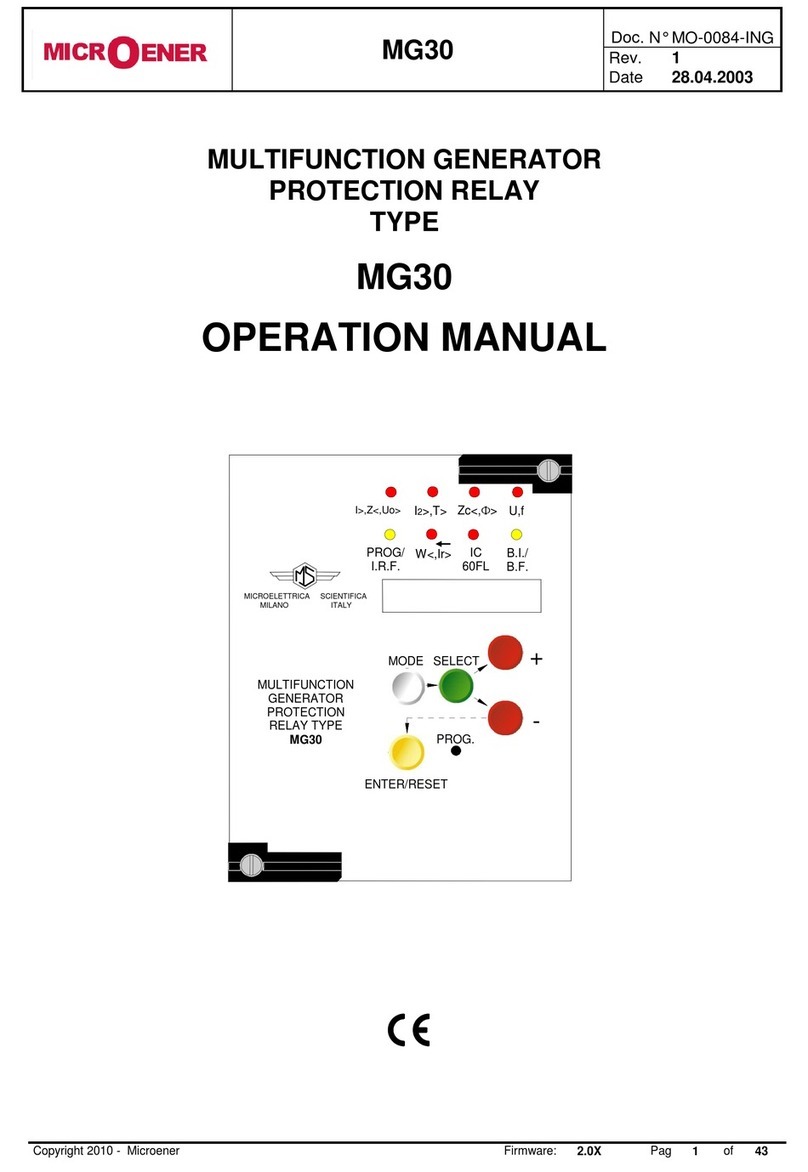

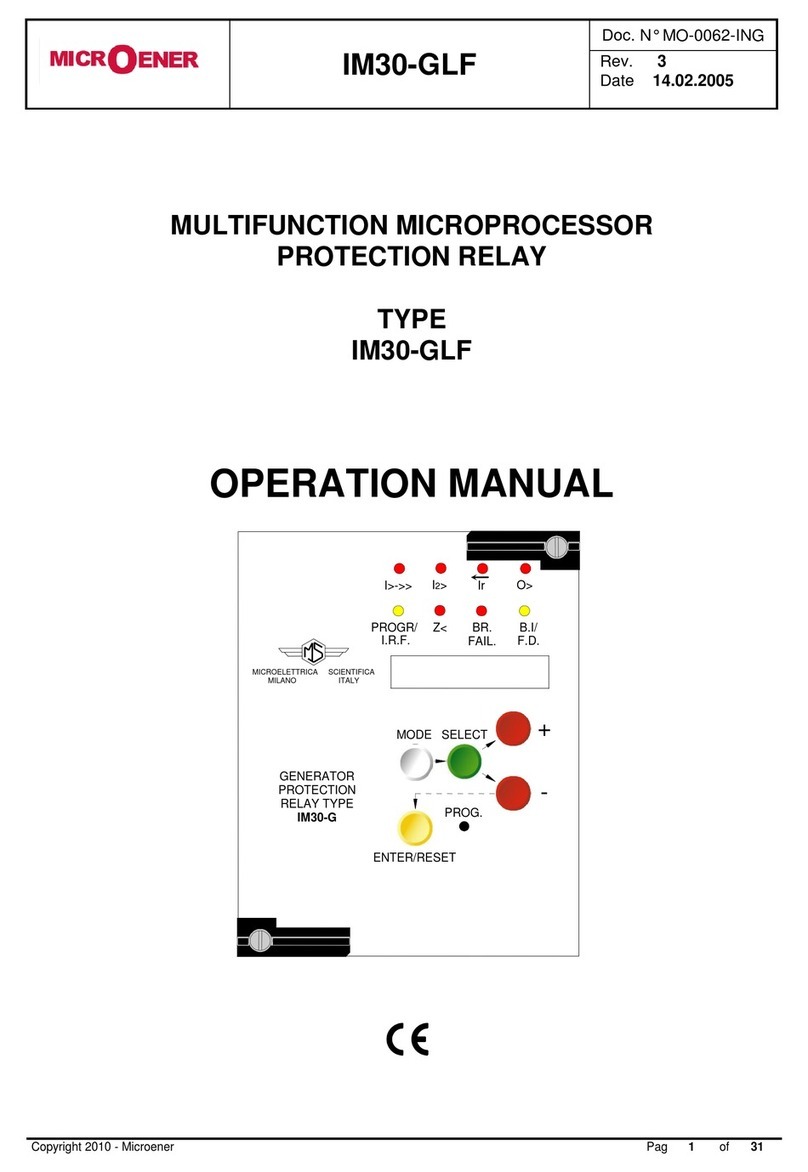

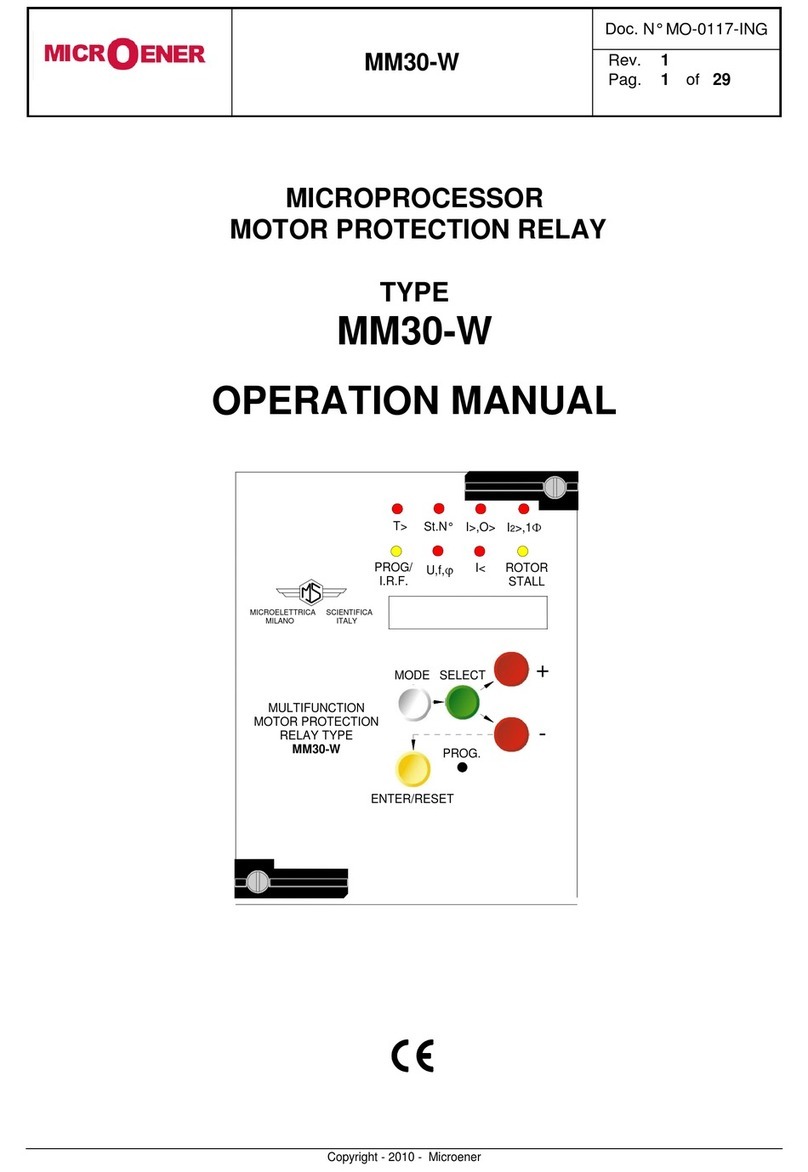

3. Front Panel ______________________________________________________________________5

4. Keyboard and Display ______________________________________________________________6

4.1 - Display_______________________________________________________________________________________ 6

5. Icons of Display___________________________________________________________________7

6. Signalization _____________________________________________________________________8

6.1 - Leds Manual Reset _____________________________________________________________________________ 8

6.2 –Display of the last trip ___________________________________________________________________________ 8

7. Cmd (Local Commands) _______________________________________________________9

8. Measure___________________________________________________________________10

9. Max.Val. (Inrush maximum measure values) ______________________________________11

10. Trip Recording (LTrip) _______________________________________________________12

11. Cnt (Counters)_____________________________________________________________14

12. RCE (Recorder Chronological Events) __________________________________________15

12.1 –Events on display ____________________________________________________________________________ 16

13. Sys (System parameters) ____________________________________________________18

14. Settings __________________________________________________________________21

14.1 Modifying the setting of variables__________________________________________________________________ 22

14.2. Password ___________________________________________________________________________________ 23

14.3 –Menu: Communic. (Communication) ____________________________________________________________ 24

14.3.1 –Description of variables ____________________________________________________________________ 24

14.3.2 –Front Panel serial communication port (RS232) _________________________________________________ 24

14.3.3 –Cable for direct connection of Relay to Personal Computer ________________________________________ 24

14.3.4 –Main serial communication port (RS485)_______________________________________________________ 24

14.4 - Menu: LCD__________________________________________________________________________________ 25

14.4.1 –Description of variables ____________________________________________________________________ 25

14.5 - Function: 1d> (First differential element) ___________________________________________________________ 27

14.5.1 - Description of variables ____________________________________________________________________ 27

14.6 - Function: 2d> (Second differential element) ________________________________________________________ 28

14.6.1 - Description of variables ____________________________________________________________________ 28

14.7 - Function: HLock (2nd –5th HarmonicLock)__________________________________________________________ 29

14.7.1 - Description of variables ____________________________________________________________________ 29

14.8 - Function: 1I> (First Overcurrent Element side 1)_____________________________________________________ 30

14.8.1 - Description of variables ____________________________________________________________________ 30

14.8.2 - Algorithm of the time current curves___________________________________________________________ 31

14.8.3 - IEC Curves ______________________________________________________________________________ 32

14.8.4 –IEEE Curves ____________________________________________________________________________ 33

14.8.5 –Blocking Logic (BO-BI)_____________________________________________________________________ 34

14.8.6 - Automatic doubling of Overcurrent thresholds on current inrush _____________________________________ 34

14.9 –Function: 1I>> (Second Overcurrent Element side 1)_________________________________________________ 35

14.9.1 –Description of variables ____________________________________________________________________ 35

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

3

of

87

14.10 - Function: 2I> (First Overcurrent Element side 2)____________________________________________________ 36

14.10.1 - Description of variables ___________________________________________________________________ 36

14.11 –Function: 2I>> (Second Overcurrent Element side 2)________________________________________________ 37

14.11.1 –Description of variables ___________________________________________________________________ 37

14.12 –Function: do2> (Earth fault element side 2) _______________________________________________________ 38

14.12.1 –Description of variables ___________________________________________________________________ 38

14.13 - Function: Wi (Circuit Breaker maintenance level) ___________________________________________________ 39

14.13.1 - Description of variables ___________________________________________________________________ 39

14.13.2 - Operation (Accumulation of the interruption Energy) _____________________________________________ 39

14.14 - Function: TCS (Trip Circuit Supervision) __________________________________________________________ 40

14.14.1 - Description of variables ___________________________________________________________________ 40

14.14.2 - Operation ______________________________________________________________________________ 40

14.15 - Function: IRF (Internal Relay Fault)______________________________________________________________ 41

14.15.1 - Description of variables ___________________________________________________________________ 41

14.15.2 - Operation ______________________________________________________________________________ 41

14.16 - Function: CB Mngn (Control C/B) _______________________________________________________________ 42

14.16.1 - Description of variables ___________________________________________________________________ 42

14.16.2 - Display Message ________________________________________________________________________ 43

14.17 - Function: Oscillo (Oscillographic Recording) ______________________________________________________ 44

16.17.1 - Description of variables ___________________________________________________________________ 44

14.17.2 - Operation ______________________________________________________________________________ 44

14.17.3 –Available on MSCom2 ____________________________________________________________________ 45

14.17.4 –Setting “User Trigger Oscillo”_______________________________________________________________ 47

14.18 - Function: BrkFail (Breaker Failure)______________________________________________________________ 52

16.18.1 - Description of variables ___________________________________________________________________ 52

14.18.2 - Operation ______________________________________________________________________________ 52

14.19 - Function: ExtReset (External Reset Configuration)__________________________________________________ 53

14.19.1 - Description of variables ___________________________________________________________________ 53

15. User Variables__________________________________________________________________54

16. Input –Output (via software MSCom2)__________________________________________60

16.1 –Digital Inputs ________________________________________________________________________________ 60

16.2 –“DI” Configuration (via MSCom2 software) _________________________________________________________ 61

16.3 –Outputs Relay _______________________________________________________________________________ 64

16.4 - “DO” Configuration ____________________________________________________________________________ 64

17. Date and Time_____________________________________________________________71

17.1 –Clock synchronization _________________________________________________________________________ 72

18. Healthy (Diagnostic Information)_______________________________________________73

19. Dev.Info (Relay Version) _____________________________________________________73

20. Battery________________________________________________________________________74

21. Maintenance ___________________________________________________________________74

22. Power Frequency Insulation Test ___________________________________________________74

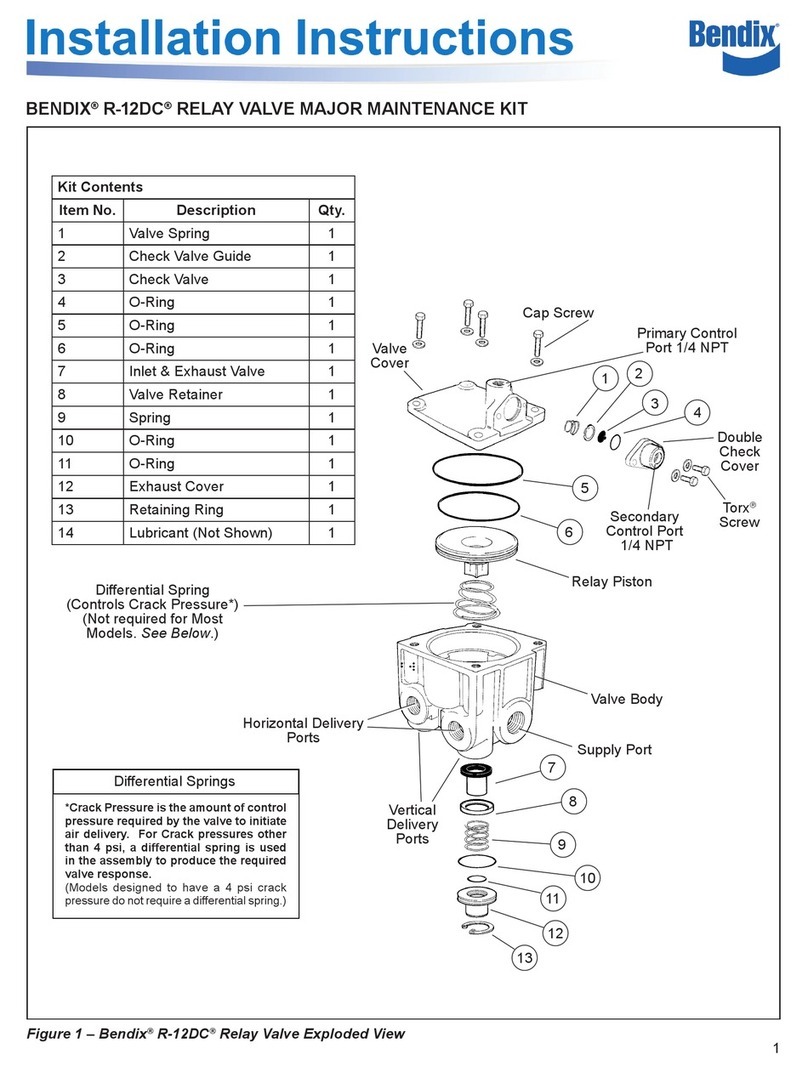

23. Basic Relay - Wiring Diagram ______________________________________________________75

23.1 –UX10-4 - Expansion Module - Wiring Diagram (10 Digital Inputs + 4 Output Relays) ________________________ 75

23.2 –14DI - Expansion Module - Wiring Diagram (14 Digital Inputs) __________________________________________ 76

23.3 –14DO - Expansion Module - Wiring Diagram (14 Output Relays) ________________________________________ 76

23.4 –14DO-S - Expansion Module - Wiring Diagram (14 Output Relays)_______________________________________ 77

23.5 –TX3 - Adapter - Wiring Diagram _________________________________________________________________ 77

24. Wiring The Serial Communication Bus _______________________________________________78

25. Basic Relay - Overall Dimensions __________________________________________________79

25.1 –(1 Expansion Module) & (2 Expansion Module) - Overall Dimensions ___________________________________ 80

25.2 –Rack 3U –Overall Dimensions __________________________________________________________________ 81

25.3 –TX3–Overall Dimensions ______________________________________________________________________ 81

26. Direction For Pcb's Draw-Out And Plug-In ____________________________________________82

26.1 - Draw-out____________________________________________________________________________________ 82

26.2 –Plug-in_____________________________________________________________________________________ 82

27. Electrical Characteristics__________________________________________________________83

28. Software & Firmware Version ______________________________________________________84

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

4

of

87

1. General Utilization and Commissioning Directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - Storage and Transportation

Must comply with the environmental conditions stated in the product's specification or by the applicable

IEC standards.

1.2 - Installation

Must be properly made and in compliance with the operational ambient conditions stated by the

Manufacturer.

1.3 - Electrical Connection

Must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human

safety.

1.4 - Measuring Inputs and Power Supply

Carefully check that the value of input quantities and power supply voltage are proper and within the

permissible variation limits.

1.5 - Outputs Loading

Must be compatible with their declared performance.

1.6 - Protection Earthing

When earthing is required, carefully check its effectiveness.

1.7 - Setting and Calibration

Carefully check the proper setting of the different functions according to the configuration of the

protected system, the safety regulations and the co-ordination with other equipment.

1.8 - Safety Protection

Carefully check that all safety means are correctly mounted, apply proper seals where required and

periodically check their integrity.

1.9 - Handling

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits,

the electronic components and semiconductor devices mounted on the modules can be seriously

damaged by electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent but the design

reliability and the long life of the product will have been reduced. The electronic circuits produced by

M.S. are completely safe from electrostatic discharge (8 kV IEC 255.22.2) when housed in their case;

withdrawing the modules without proper cautions expose them to the risk of damage.

1.10 - Maintenance

Make reference to the instruction manual of the Manufacturer; maintenance must be carried-out by

specially trained people and in strict conformity with the safety regulations.

1.11 - Waste Disposal of Electrical & Electronic Equipment

(Applicable throughout the European Union and other European countries with separate collection

program). This product should not be treated as household waste when you wish dispose of it. Instead,

it should be handed over to an applicable collection point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help prevent potential negative

consequence to the environment and human health, which could otherwise be caused by inappropriate

disposal of this product. The recycling of materials will help to conserve natural resource.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

5

of

87

1.12 - Fault Detection and Repair

Internal calibrations and components should not be altered or replaced.

For repair please ask the Manufacturer or its authorized Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

2. General

Input currents are supplied to 8 current transformers: - three measuring phase current side 1 –

three measuring phase current side 2 - one measuring the earth fault zero-sequence current side 1 -

one measuring the earth fault zero-sequence current side 2.

Current input can be selected 1A or 5A by movable jumpers available on relay cards.

The Measuring Ranges of the different inputs are respectively:

Phase Currents

:

(0.02-25)In

Neutral Current

:

(0.005-4)On

Make electric connection in conformity with the diagram reported on relay's enclosure.

Check that input currents and voltages are the same as reported on the diagram and on the test

certificate.

The auxiliary power is supplied by a built-in interchangeable module fully isolated and self protected.

2.1 - Power Supply

The relay can be fitted with two different types of power supply:

24V(-20%) / 110V(+15%) a.c.

80V(-20%) / 220V(+15%) a.c.

Type

1)

-

Type

2)

-

24V(-20%) / 125V(+20%) d.c.

90V(-20%) / 250V(+20%) d.c.

Before energizing the unit check that supply voltage is within the allowed limits.

3. Front Panel

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

6

of

87

4. Keyboard and Display

Navigation

menu

By these buttons the options showed in

correspondence on the display are

selected.

Increase

These buttons are used to scroll the items

of the different menus (Local Control,

Measurements, etc).

Decrease

Open

these buttons (when enabled) operate

Circuit Breaker Open/Close control

(see § C/B Mngn)

Close

By the key select the windows showing the ICONS of the available menus.

By the key , select the desired icon and enter by key

The different elements can be selected by the key and .

The details of the individual menus are given in the following paragraphs.

4.1 - Display

The 128x64 pixel LCD display the available information (menu, etc.).

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

7

of

87

5. Icons of Display

Cmd

Local Commands

Measure

Actual Measurements

MaxVal

Inrush maximum measure values

LTrip

Trips Recorded

Cnt

Overall Counters

RCE

Recorder Chronological Events

Setting

Function Settings

Sys

System Parameters

InfoStatus

Functional Status

Osc

Oscillographic Recorder

TimeDate

Time and Date

Healthy

Diagnostic Information

Info

Info Device

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

8

of

87

6. Signalization

Four signal leds are provided:

Green Led

Illuminated

-

Relay working properly.

Flashing

-

Internal Relay Fault

Yellow Led

Off

-

No Trip

Illuminated

-

Trip occurred

Flashing

-

Function Timing

Reset from Illuminated status is manual

Red Led

Off

-

C/B Open

Both Flashing

Operation of Trip Circuit

Supervision element.

Illuminated

-

C/B Close

Green Led

Off

-

C/B Close

Illuminated

-

C/B Open

In case of auxiliary power supply failure the status of the leds is recorded and reproduced when

power supply is restored.

6.1 - Leds Manual Reset

For Leds’ manual reset operate as follows:

1

Press “Menu” for

access to the main

menu with icons.

3

Select

“LedClear”

Press “Select” to

execute the

command.

(See § Password).

2

Select icon “Cmd”.

4

When command

has been executed

the display shows

“! Command

Done”;

Press “Select”,

6.2 –Display of the last trip

Beside the signalization of the yellow led “Trip”, indicating a generic function trip, the display shows a

window indicating the last function that was tripped and the number of events that are stored in the

memory. The display will show this window until the reset button or external reset are operated.

1

Press “Menu” to access to the main menu with icons.

Press “Res.” to erase visualization.

Ex. “t1I>” (flashing) is the last trip.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

9

of

87

7. Cmd (Local Commands)

“Cmd” allow to operate from relay front face controls like Leds reset, Event clear, etc.

Menu

Description

Password

Led

Clear

Reset of signal Leds

No

Relays

Clear

Manual reset of output relays

No

Breaker

Close

Manual C/B closing

Yes

Breaker

Open

Manual C/B opening

Yes

Breaker2

Close

Manual C/B 2 closing

Yes

Breaker2

Open

Manual C/B 2 opening

Yes

Breaker3

Close

Manual C/B 3 closing

Yes

Breaker3

Open

Manual C/B 3 opening

Yes

Breaker4

Close

Manual C/B 4 closing

Yes

Breaker4

Open

Manual C/B 4 opening

Yes

Event

Clear

Reset of all Events recorded

Yes

HistFail

Clear

Reset of Internal Failure Historic records

Yes

Reset

Wi

Reset Circuit breaker maintenance level

No

Leds

Test

Signal Leds test

No

Force

Osc

Issue a trigger on oschillographic recording

Yes

To operate one command by the Front Face Keyboard, proceed as follows (Led Reset in the present

example).

1

Press “Menu” for access to the main menu with icons.

2

Select “Cmd” icon with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

3

Select with pushbutton “Increase” or “Decrease” the menu “LedClear”.

Press “Select” to execute the command.

(if Password is request, see § Password).

4

When command has been executed the display shows

“! Command Done”; go to “3”.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

10

of

87

8. Measure

Real time values as measured during the normal operation.

1

Press “Menu” for access to the main menu with icons.

2

Select “Measure” icon with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

3

Scroll the menu “Measure”with pushbutton “Increase” or “Decrease” to display

the measurement.

Press “Exit” to go to the main menu.

dA

(0 99.99)

In

RMS phase A differential value

dB

(0 99.99)

In

RMS phase B differential value

dC

(0 99.99)

In

RMS phase C differential value

Io2

(0 9999)

A

Earth fault current side 2

1A

(0 9999)

A

RMS value of phase A side 1

1B

(0 9999)

A

RMS value of phase B side 1

1C

(0 9999)

A

RMS value of phase C side 1

2A

(0 9999)

A

RMS value of phase A side 2

2B

(0 9999)

A

RMS value of phase B side 2

2C

(0 9999)

A

RMS value of phase C side 2

d2A

(0 999)

%

2nd harmonic phase A

d5A

(0 999)

%

5th harmonic phase A

d2B

(0 999)

%

2nd harmonic phase B

d5B

(0 999)

%

5th harmonic phase B

d2C

(0 999)

%

2nd harmonic phase C

d5C

(0 999)

%

5th harmonic phase C

IR

(0 99.99)

In

Selected bias through current

Wir

(100 0)

%W

Amount still remaining of permissible interruption energy before Circuit

Breaker maintenance is requested.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

11

of

87

9. Max.Val. (Inrush maximum measure values)

Maximum demand values recorded starting from 100ms after closing of main Circuit Breaker

(updated any time the breaker closes).

1

Press “Menu” for access to the main menu with icons.

2

Select “MaxVal” icon with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

3

Scroll the menu “MaxVal”with pushbutton “Increase” or “Decrease” to display

the measure

Press “Exit” to go back to the main menu.

dA

(0 99.99)

In

RMS phase A differential value

dB

(0 99.99)

In

RMS phase B differential value

dC

(0 99.99)

In

RMS phase C differential value

Io2

(0 9999)

A

Earth fault current side 2

1A

(0 9999)

A

RMS value of phase A side 1

1B

(0 9999)

A

RMS value of phase B side 1

1C

(0 9999)

A

RMS value of phase C side 1

2A

(0 9999)

A

RMS value of phase A side 2

2B

(0 9999)

A

RMS value of phase B side 2

2C

(0 9999)

A

RMS value of phase C side 2

d2A

(0 999)

%

2nd harmonic phase A

d5A

(0 999)

%

5th harmonic phase A

d2B

(0 999)

%

2nd harmonic phase B

d5B

(0 999)

%

5th harmonic phase B

d2C

(0 999)

%

2nd harmonic phase C

d5C

(0 999)

%

5th harmonic phase C

IR

(0 99.99)

In

Selected bias through current

Wir

(100 0)

%W

Amount still remaining of permissible interruption energy before Circuit

Breaker maintenance is requested.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

12

of

87

10. Trip Recording (LTrip)

Display of the function which caused the tripping of the relay and values of the measurement at the

moment of tripping. The last 10 events are recorded.

The memory buffer is refreshed at each new relay tripping (FIFO logic).

Display

Reading of recorded Trips.

Erase

Clear all Trip recorded.

1

Press “Menu” for access to the main menu with icons.

2

Select “TripRec.” icon with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

3

Select “Display” with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

For “Erase” go to “8”

4

If no trip is recorded the display shows “! No Trips”.

5

If any trip was recorded, select “View” to display the chronological list of the

records.

By the keys “Increase” or “Decrease” select the date of the record to be

checked.

6

Will be shown:

“Descr” the function that caused the event (Example: t1I> = Trip)

“Edge” if the function was tripped (Rise) or reset (Fall)

“Date”, date of trip, year/month/day, hour:minutes:seconds:milliseconds

Press “Value”, for reading the value of input quantities on tripping.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

13

of

87

7

Scroll with pushbuttons “Increase” or “Decrease” the available measurements.

Select “Exit” to go back to “5” for another selection, or “2” go back to the main

menu.

8

Select “Erase” with button “Decrease”.

Press “Select” to execute the commands; All Trips recorded are erased.

(if Password is request, see § Password).

9

When command has been executed the display shows “! Command Done”;

Press “Exit” to go back to the main menu.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

14

of

87

11. Cnt (Counters)

Counters of the number of operations for each of the relay functions.

By the interface program “MSCom 2” it is possible to individually reset the counters and set an initial

starting value.

Display

1dA>

0

Operations counters

Low set differential first element phase A

1dB>

0

Operations counters

Low set differential first element phase B

1dC>

0

Operations counters

Low set differential first element phase C

2dA>

0

Operations counters

High set differential first element phase A

2dB>

0

Operations counters

High set differential first element phase B

2dC>

0

Operations counters

High set differential first element phase C

1I>

0

Operations counters

First overcurrent element side 1

1I>>

0

Operations counters

Second overcurrent element side 1

2I>

0

Operations counters

First overcurrent element side 2

2I>>

0

Operations counters

Second overcurrent element side 2

do2>

0

Operations counters

Earth fault element side 2

IRF

0

Operations counters

Internal Relay Fault

TCS

0

Operations counters

Trip Circuit Supervision

BrkF

0

Operations counters

Breaker failure to open

Wi

0

Operations counters

Circuit Breaker maintenance alarm

Aut Op

0

Operations counters

Automatic C/B Openings

Aut CL

0

Operations counters

Automatic C/B Closings

Man Op

0

Operations counters

Manual C/B Openings

Man CL

0

Operations counters

Manual C/B Closings

OvrOp

0

Operations counters

Overall C/B Openings total (Man+Aut)

OvrCL

0

Operations counters

Overall C/B Closings total (Man+Aut)

1

Press “Menu” for access to the main menu with icons.

2

Press “Counter” for access.

3

Press “Display” for access.

4

Display of the number of operations of each individual function.

With pushbuttons “Increase” or “Decrease” scroll the parameters

Press “Exit” go back to “3”.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

15

of

87

12. RCE (Recorder Chronological Events)

Display of the function which caused any of the following events: - Status change of digital

Inputs/Outputs. - Start of protection functions –Trip of protection function –Function reset.

The last 100 events are recorded.

The memory buffer is updated at each new event.

Display

Reading events recorded.

Erase

Clear all events recorded.

1

Press “Menu” for access to the main menu with icons.

2

Select “Events” icon with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

3

Select “Display”with pushbutton “Increase” or “Decrease”.

Press “Select” for access.

For “Erase” go to “7”

4

If no event is recorded the display shows message “! No Events”.

5

If any event was recorded, select “View” to display the chronological list of the

records.

By the keys “Increase” or “Decrease” select the date of the record to be

checked.

6

Will be shown:

“Descr” the function that caused the event

(Example: 1I> = Start, t1I> = Trip)

“Edge” if the function was tripped (Rise) or reset (Fall)

“Date”, date of trip, year/month/day, hour:minutes:seconds:milliseconds

7

Select “Erase” with button “Decrease”.

Press “Select” to execute the commands; All Events recorded are erased.

(if Password is request, see § Password).

8

When command has been execute the display shows “! Command Done”;

Press “Exit” to go back to the main menu.

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

16

of

87

12.1 –Events on display

Functions

Events

Displayed

Events Description MScom2

Status

1d>

R1d>

Start

first differential elelement phase R

Rise

Fall

tR1d>

Trip

first differential element phase R

Rise

Fall

S1d>

Start

first differential element phase S

Rise

Fall

tS1d>

Trip

first differential element phase S

Rise

Fall

T1d>

Start

first differential element phase T

Rise

Fall

tT1d>

Trip

first differential element phase T

Rise

Fall

2d>

R2d>

Start

second differenti alelement phase R

Rise

Fall

tR2d>

Trip

second differential element phase R

Rise

Fall

S2d>

Start

second differential element phase S

Rise

Fall

tS2d>

Trip

second differential element phase S

Rise

Fall

T2d>

Start

second differential element phase T

Rise

Fall

tT2d>

Trip

second differential element phase T

Rise

Fall

HLock

2HRL

Phase R

second harmonic lock

Rise

Fall

5HRL

Phase R

fifth harmonic lock

Rise

Fall

2HSL

Phase S

second harmonic lock

Rise

Fall

5HSL

Phase S

fifth harmonic lock

Rise

Fall

2HTL

Phase T

second harmonic lock

Rise

Fall

5HTL

Phase T

fifth harmonic lock

Rise

Fall

2HReduct

Second harmonic reduction level

Rise

Fall

5HReduct

Fifth harmonic reduction level

Rise

Fall

1I>

1I>

Start

First overcurrent element

Side 1

Rise

t1I>

Trip

First overcurrent element

Side 1

Rise

Fall

1I>>

1I>>

Start

Second overcurrent element

Side 1

Rise

t1I>>

Trip

Second overcurrent element

Side 1

Rise

Fall

2I>

2I>

Start

First overcurrent element

Side 2

Rise

t2I>

Trip

First overcurrent element

Side 2

Rise

Fall

2I>>

2I>>

Start

Second overcurrent element

Side 2

Rise

t2I>>

Trip

Second overcurrent element

Side 2

Rise

Fall

do2>

do2>

Start

Earth Fault element

Side 2

Rise

tdo2>

Trip

Earth Fault element

Side 2

Rise

Fall

Wi

tWi>

Circuit breaker maintenance level

Rise

TCS

TCS

Start

trip coil supervision

Rise

tTCS

Trip

trip coil supervision

Rise

Fall

IRF

IRF

Start

Internal Relay Failure

Rise

tIRF

Trip

Internal Relay Failure

Rise

BF

tBF

Trip

Breaker Failure

Rise

Fall

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

17

of

87

Functions

Events

Displayed

Events Description MScom2

Status

L/Rdisc.

Local/Remote signal Discrepancy

Rise

manOpKey

Circuit Breaker intentional open by Key

Rise

manOpLocC

Circuit Breaker intentional open by local command

Rise

manOpRemC

Circuit Breaker intentional open by remote command

Rise

manOpExtIn

Circuit Breaker intentional open by external input

Rise

ManOpExternal

Circuit Breaker intentional external open

Rise

manClKey

Circuit Breaker intentional close by Key

Rise

manClLocC

Circuit Breaker intentional close by local command

Rise

manClRemC

Circuit Breaker intentional close by remote command

Rise

manClExtInp

Circuit Breaker intentional close by external input

Rise

ExterManCh

Circuit Breaker intentional external close

Rise

CB-Fail

Circuit Breaker failure

Rise

Fall

0.D0

Digital Input on Main Relay

Rise

Fall

----

0.D4

1.D1

Digital input on Expansion Board 1

Rise

Fall

----

1.D15

2.D1

Digital input on Expansion Board 2

Rise

Fall

----

2.D15

0.R1

Output relay on Main Relay

Rise

Fall

----

0.R6

1.R1

Output relay on Expansion Board 1

Rise

Fall

----

1.R14

2.R1

Output relay on Expansion Board 2

Rise

Fall

----

2.R14

UpDateMon

Monitor Update

Rise

Fall

IPU boot

IPU boot

Rise

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

18

of

87

13. Sys (System parameters)

Setting of system parameters.

CT&PTs

Phase CT

Side 1

Prim.

1000

A

(1 9999)

step

1

A

Sec.

1

A

(1 / 5)

(1)

Phase CT

Side 2

Prim.

1000

A

(1 9999)

step

1

A

Sec.

1

A

(1 / 5)

(1)

Neut.CT

Side 1

Prim.

1000

A

(1 9999)

step

1

A

Sec.

1

A

(1 / 5)

step

(1)

Neut. CT

Side 2

Prim.

1000

A

(1 9999)

step

1

A

Sec.

1

A

(1 / 5)

step

(1)

Nom.Val.

fn

50

Hz

(50 / 60)

(System Rated Values)

It2

1000

A

(1 9999)

1

A

1V

10.00

kV

(0.10 655.00)

0.01

kV

2V

10.00

kV

(0.10 655.00)

0.01

kV

Sys Options

Alfa

Yy6

[Yy0 / Yy6 / Yd1 / Yd5 / Yd7 / Yd11 / Ddo

/ Dd2 / Dd4 / Dd6 / Dd8 / Dd10 / Dy1 /

Dy5 / Dy7 / Dy11 / Yz1 / Yz5 / Yz7 /

Yz11]

(Vector Goup)

Setup Group

Group

1

(1 / 2)

13.1 –Description of variables

fn

:

Nominal Frequency

It2

:

Primary nominal current side 2

1V

:

Nominal Voltage Side 1

2V

:

Nominal Voltage Side 2

Alfa

:

Vector Group

Group

:

Group settings

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

19

of

87

(1) Move the switch in the corresponding founding to the required input current as herebelow shorted.

1

Press “Menu” for access to the main menu with icons.

2

Select “Sys” icon with pushbuttons “Increase” or “Decrease”.

Press “Select” for access.

3

Select “CT&PTs”.

Press “Select”for access.

4

Select “Phase CT site 1”.

Press “Select” for access.

5

Select “Prim.” to modify the primary value of Phase CT, or press “Decrease”

and select “Sec.” to modify the secondary value of Phase CT.

Press “Modify” to modify the parameter.

(if Password is request, see § Password).

6

The value appear as bold figure.

Use pushbuttons “Increase” or “Decrease”to set the value.

Press “Write” to confirm the value

DTMR3-TX

Doc. N° MO-0377-ING

Copyright 2010

Data

01.04.2009

Rev.

0

Pag.

20

of

87

7

The value is now set.

To set a new value return to the point “5”.

Press “Exit”.

8

The display show “Confirm the change?”.

Choose “Yes ” to convalidate the changes.

Choose “No ” to don’t confirm the changes.

After set confirmation (or non confirmation) the display goes back to point “4”.

9

To modify the input quantities, select with pushbutton “Decrease”,

“Nom.Val.”.

Press “Select” for access.

10

To set the input quantities see points “5-6-7-8” .

11

To select the Vector Group press “Sys.Options”.

Press “Select” for access.

12

To set Vector Group see points “5-6-7-8” .

13

To select the Active Bank of setting press “SetUp Group”.

14

To set the Group active see points “5-6-7-8” .

This manual suits for next models

1

Table of contents

Other MICROENER Relay manuals

MICROENER

MICROENER MG30 User manual

MICROENER

MICROENER MC20-X/10-4 User manual

MICROENER

MICROENER ELRC-1 User manual

MICROENER

MICROENER IM30-GLF User manual

MICROENER

MICROENER N-DIN-MSG User manual

MICROENER

MICROENER MC3V-X/10-4 User manual

MICROENER

MICROENER MM30-W User manual

MICROENER

MICROENER M-LIB3 User manual

MICROENER

MICROENER IM30-SA User manual

MICROENER

MICROENER IM30-DK User manual