GEK-1

00636

NOTE:

The

pickup

level

of

the

IT

unit

could

be

different

from

the

pickup

level

of

the

BFT

unit.

If

the

IT

unit

is

not

supervised

by

a

timer,

its

pickup

level

will

be

equivalent

to

the

following

equation:

At

60

I-Iz

IT

pickup

=

.535

x

BFT

Pickup

At

50

Hz

iT

pickup

=

.453

x

BFT

Pickup

The

seal-in

contact provided

by

the

IT

function

is

for

those

who

wish

to

use

such

a

feature.

The

seal-in circuit

has

a

slight

time

delay

to

provide

additional

security

against

seal-in

operations

resulting

from

such

causes

as

surges

or

transients. The

purpose

of

the

seal-in

circuit

is

to

ride

over

contact

bounce

in

the

initiating

contacts

(if

such

bounce

exists)

and

to

maintain

the

DC input

of

the

SBC

in

the event

of

a

zero-voltage

fault

that

results

in

resetting

of

the

initiating

protective

relays

before

the

breaker-failure

timer

can

produce

an

output.

The

seal-in

circuit should

be

used

with

caution,

since

it

can

reduce

the security

of

the scheme

during testing

if

the

level

detector

is

set

to

pick up

below

load

current.

Note that

most

static

line-relaying systems

include

a

seal-in

function

SO

that

the

BFI

contacts

remain

closed

until

the

fault

is

cleared.

For the

SBC223A,B,

or

C,

to

implement

the

Seal-In

feature

with

the

IT

contact

at

Stud

II,

the

JI

connector, located

in

the

upper-left-hand

corner

of

the

backplane

(see

Figure

16),

must

have

a

jumper

connecting terminals

I

and

2.

This

will

no

longer

leave the

IT

contact

isolated.

To

implement

the Seal-In

function

with

Stud

9,

the

JI

connector

must have

a

jumper

connecting

terminals

2

and

3.

This

will

flO

longer

leave

Stud

9

and

the

IT

contact

isolated. Both methods

of

Seal-In

can

be

seen

in

the

External Connection

and

Logic

Diagrams

for

each

relay.

To

eliminate

all

Seal-In function, place

the

jumper

on

JI

connected

to

only

one

terminal

(Do

Not

short

together

any

two

terminals).

This

is

the

configuration

with

which

the

original

SBC23

was

shipped.

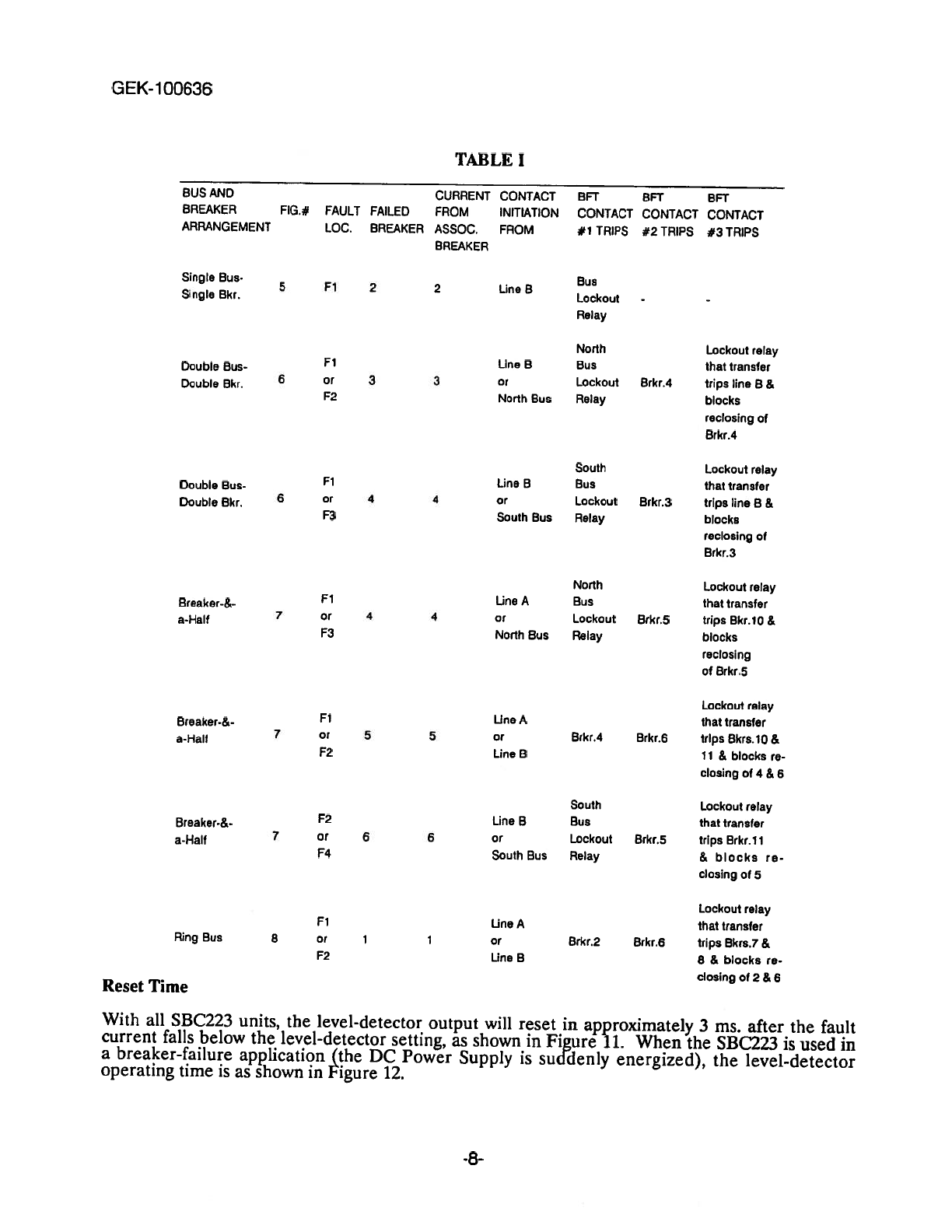

The routing

of

the

contact-initiation

inputs

and

the

BFT

outputs

depend

upon

the

bus and

breaker

arrangement.

The static

breaker-failure

relaying

schemes

described

in

this

book

are

intended

for

application

on

a

per-breaker

basis.

That

is,

there

is

one

breaker-failure

relay

associated

with

each

breaker

in

a

bus array.

On

this

basis

the

current

inputs

to

a

breaker-failure

relay

must

come

from

CT’s

that

measure

the

current

in

the

associated

breaker.

The

trip

outputs

must be

routed

to

initiate

the

tripping (or

transferred

tripping)

of

all

backup

breakers

necessary

to

clear the

fault.

The

listing

in

Table

I

covers

the

bus

arrangements that

are

in

common

use

today.

They are

the

single-bus-single-breaker, double-bus-double-breaker,

breaker-and-a-half,

and ring-bus

arrangements,

and

they

are

shown

in

Figures

6, 7,

8

and

9

respectively.

Each

listing

in

Table

I

indicates

the

assumed

fault

location,

the

breaker

which

is

assumed

to

have

failed,

the

contact

initiation

that

activates

the

relay,

and

which

breakers

or

lockout

relays

should

be

tripped

by

the

BFT

contacts.

For

example,

in

a

single-bus-single-breaker

arrangement

(Figure

6),

if

breaker

#2

is

to

he

protected,

the

level

detector

(LD)

receives

the

currents

associated

with

breaker

#2.

The

contact

initiation

is

from

the

protective

relays

of

line

B.

If

breaker

#2

fails

for

a

fault at

Fl, the

breaker-failure

relay

operates

and the BFT

contact

#1

trips

the

bus

lockout

relay.

For

another

example,

consider

the

ring

bus

arrangement

that

is

shown

in

Figure

9.

If

breaker

1

is

to

he

protected,

the

level

detector

receives

the

currents

associated

with

breaker

1.

The

contact

initiation

is

from the

protective

relays

of

line

A

for

a

fault

at

Fl

or

the

protective

relays

of

line

B

for

a

fault

at

F2.

Assuming

breaker

I

fails

for

a

fault

at

Fl,

the

relay

operates

and

the

BFT

contacts

trip

the

following:

BFT

#1

trips

breaker

2

and

BFT

#2

trips

breaker

6;

BFT

#3

trips

the

lockout

relay

that

transfer

trips

breakers

7

and

8

and

blocks

reclosing

of

2

and

6.

-7-