MICROENER MC20-X/10-4 User manual

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1

MICROPROCESSOR

OVERCURRENT and EARTH FAULT

RELAY

TYPE

MC20-X/10-4

(I/O Boards)

OPERATION MANUAL

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 2of 35

1. General Utilization and Commissioning Directions ____________________________________________________________________ 3

1.1 - Storage and Transportation_____________________________________________________________________________________ 3

1.2 - Installation __________________________________________________________________________________________________ 3

1.3 - Electrical Connection__________________________________________________________________________________________ 3

1.4 - Measuring Inputs and Power Supply______________________________________________________________________________ 3

1.5 - Outputs Loading _____________________________________________________________________________________________ 3

1.6 - Protection Earthing ___________________________________________________________________________________________ 3

1.7 - Setting and Calibration ________________________________________________________________________________________ 3

1.8 - Safety Protection _____________________________________________________________________________________________ 3

1.9 - Handling ___________________________________________________________________________________________________ 3

1.10 - Maintenance _______________________________________________________________________________________________ 4

1.11 - Waste Disposal of Electrical & Electronic Equipment ________________________________________________________________ 4

1.12 - Fault detection and repair _____________________________________________________________________________________ 4

2. General Characteristics ___________________________________________________________________________________________ 5

2.1 - Power Supply _______________________________________________________________________________________________ 5

2.2 - Operation and Algorithms ______________________________________________________________________________________ 6

2.2.1 - Reference Input Values ____________________________________________________________________________________ 6

2.2.2 - Input quantities___________________________________________________________________________________________ 6

2.2.2.1 - Mains Frequency (Freq) ________________________________________________________________________________ 6

2.2.2.2 - Phase Current inputs (I1) _______________________________________________________________________________ 6

2.2.2.3 - Earth Fault Current Input (Ion) ___________________________________________________________________________ 7

2.2.2.4 - Algorithm of the time current curves _______________________________________________________________________ 7

2.2.3 - Time Current Curves IEC (TU1029 Rev.0) _____________________________________________________________________ 8

2.2.4 - Time Current Curves IEEE (TU1028 Rev.0) ____________________________________________________________________ 9

2.2.5 - Functions and Settings (Function) ___________________________________________________________________________ 10

2.2.5.1 - I> (1F51) - First overcurrent protection level ________________________________________________________________ 10

2.2.5.2 - I>> (2F51) - Second overcurrent protection level ____________________________________________________________ 10

2.2.5.3 - IH (3F51) - Third overcurrent protection level _______________________________________________________________ 11

2.2.5.5 - Io> (1F51N) - First Earth Fault protection level______________________________________________________________ 12

2.2.5.6 - Io>> (2F51N) - Second Earth Fault protection level __________________________________________________________ 12

2.2.5.7 - IoH (3F51N) - Third Earth Fault protection level _____________________________________________________________ 13

2.2.5.8 - BF (F51BF) - Breaker Failure ___________________________________________________________________________ 13

2.2.5.9 - RTD - Remote Trip ___________________________________________________________________________________ 13

2.2.5.10 - I.R.F. - Internal Relay Failure __________________________________________________________________________ 14

2.2.5.11 - Osc - Oscillographic Recording ________________________________________________________________________ 14

2.2.5.12 - Comm – Communication Parameters ___________________________________________________________________ 15

2.2.5.13 - LCD – Display and Buzzer operation ____________________________________________________________________ 15

3. Logic Blocking of Functions ______________________________________________________________________________________ 16

3.1 - Blocking output _____________________________________________________________________________________________ 16

3.2 – Blocking Input ______________________________________________________________________________________________ 16

4. Output Relays__________________________________________________________________________________________________ 16

5. Digital Inputs___________________________________________________________________________________________________ 17

6. Self-diagnostic _________________________________________________________________________________________________ 17

7. Relay Management______________________________________________________________________________________________ 18

8. Signalizations __________________________________________________________________________________________________ 19

9. Keyboard Buttons ______________________________________________________________________________________________ 19

10. Serial Communication Port ______________________________________________________________________________________ 20

10.1 - Main RS485 Serial Communication Port _________________________________________________________________________ 20

10.2 - Communication Port on Front Face Panel _______________________________________________________________________ 21

11. Menu and Variables ____________________________________________________________________________________________ 22

11.1 - Real Time Measurements ____________________________________________________________________________________ 22

11.2 - Meas (Instantaneous Measurements) ___________________________________________________________________________ 22

11.3 - Counter (Operation Counters) _________________________________________________________________________________ 22

11.4 - LastTrip (Event Recording) ___________________________________________________________________________________ 23

11.5 - R/W Set (Programming / Reading the Relay Settings) ______________________________________________________________ 24

11.5.1 - CommAdd (Communication Address) _______________________________________________________________________ 24

11.5.2 - Time/Date (Time/Date)___________________________________________________________________________________ 24

11.5.3 - RatedVal (Rated Input Values) ____________________________________________________________________________ 24

11.5.4 - Function (Functions) ____________________________________________________________________________________ 25

11.6 - RelayCfg (Relay Configuration)________________________________________________________________________________ 27

11.7 - Commands _______________________________________________________________________________________________ 28

11.8 - Info&Ver (Firmware - Info&Version) ____________________________________________________________________________ 28

12. KEYBOARD OPERATIONAL DIAGRAM ____________________________________________________________________________ 29

13. Password ____________________________________________________________________________________________________ 31

13.1 - MS-Com Password _________________________________________________________________________________________ 31

14. Maintenance __________________________________________________________________________________________________ 31

15. Power Frequency Insulation Test_________________________________________________________________________________ 31

16. Connection Diagram ___________________________________________________________________________________________ 32

16.1 – UX10-4 - Expansion Module - Wiring Diagram (10 Digital Inputs + 4 Output Relays) ______________________________________ 32

17. Overall Dimensions ____________________________________________________________________________________________ 33

18. Direction for Pcb's Draw-Out and Plug-In __________________________________________________________________________ 34

18.1 - Draw-Out _________________________________________________________________________________________________ 34

18.2 - Plug-In ___________________________________________________________________________________________________ 34

19. Electrical Characteristics _______________________________________________________________________________________ 35

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 3of 35

1. General Utilization and Commissioning Directions

Always make reference to the specific description of the product and to the Manufacturer's instruction.

Carefully observe the following warnings.

1.1 - Storage and Transportation

must comply with the environmental conditions stated on the product's instruction or by the applicable

IEC standards.

1.2 - Installation

must be properly made and in compliance with the operational ambient conditions stated by the

Manufacturer.

1.3 - Electrical Connection

must be made strictly according to the wiring diagram supplied with the Product, to its electrical

characteristics and in compliance with the applicable standards particularly with reference to human

safety.

1.4 - Measuring Inputs and Power Supply

carefully check that the value of input quantities and power supply voltage are proper and within the

permissible variation limits.

1.5 - Outputs Loading

must be compatible with their declared performance.

1.6 - Protection Earthing

When earthing is required, carefully check its effectiveness.

1.7 - Setting and Calibration

Carefully check the proper setting of the different functions according to the configuration of the

protected system, the safety regulations and the co-ordination with other equipment.

1.8 - Safety Protection

Carefully check that all safety means are correctly mounted, apply proper seals where required and

periodically check their integrity.

1.9 - Handling

Notwithstanding the highest practicable protection means used in designing M.S. electronic circuits, the

electronic components and semiconductor devices mounted on the modules can be seriously damaged

by electrostatic voltage discharge which can be experienced when handling the modules.

The damage caused by electrostatic discharge may not be immediately apparent but the design

reliability and the long life of the product will have been reduced. The electronic circuits reduced by

M.S. are completely safe from electrostatic discharge (8 KV IEC 255.22.2) when housed in their case;

withdrawing the modules without proper cautions expose them to the risk of damage.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 4of 35

a. Before removing a module, ensure that you are at the same electrostatic potential as the equipment

by touching the case.

b. Handle the module by its front-plate, frame, or edges of the printed circuit board. Avoid touching the

electronic components, printed circuit tracks or connectors.

c. Do not pass the module to any person without first ensuring that you are both at the same

electrostatic potential. Shaking hands achieves equipotential.

d. Place the module on an antistatic surface, or on a conducting surface which is at the same potential

as yourself.

e. Store or transport the module in a conductive bag.

More information on safe working procedures for all electronic equipment can be found in

BS5783 and IEC 147-OF.

1.10 - Maintenance

Make reference to the instruction manual of the Manufacturer ; maintenance must be carried-out by

specially trained people and in strict conformity with the safety regulations.

1.11 - Waste Disposal of Electrical & Electronic Equipment

(Applicable throughout the European Union and other European countries with separate collection

program).

This product should not be treated as household waste when you wish dispose of it. Instead, it should be

handed over to an applicable collection point for the recycling of electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help prevent potential negative consequence to

the environment and human health, which could otherwise be caused by inappropriate disposal of this

product. The recycling of materials will help to conserve natural resource.

1.12 - Fault detection and repair

Internal calibrations and components should not be altered or replaced.

For repair please ask the Manufacturer or its authorised Dealers.

Misapplication of the above warnings and instruction relieves the Manufacturer of any liability.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 5of 35

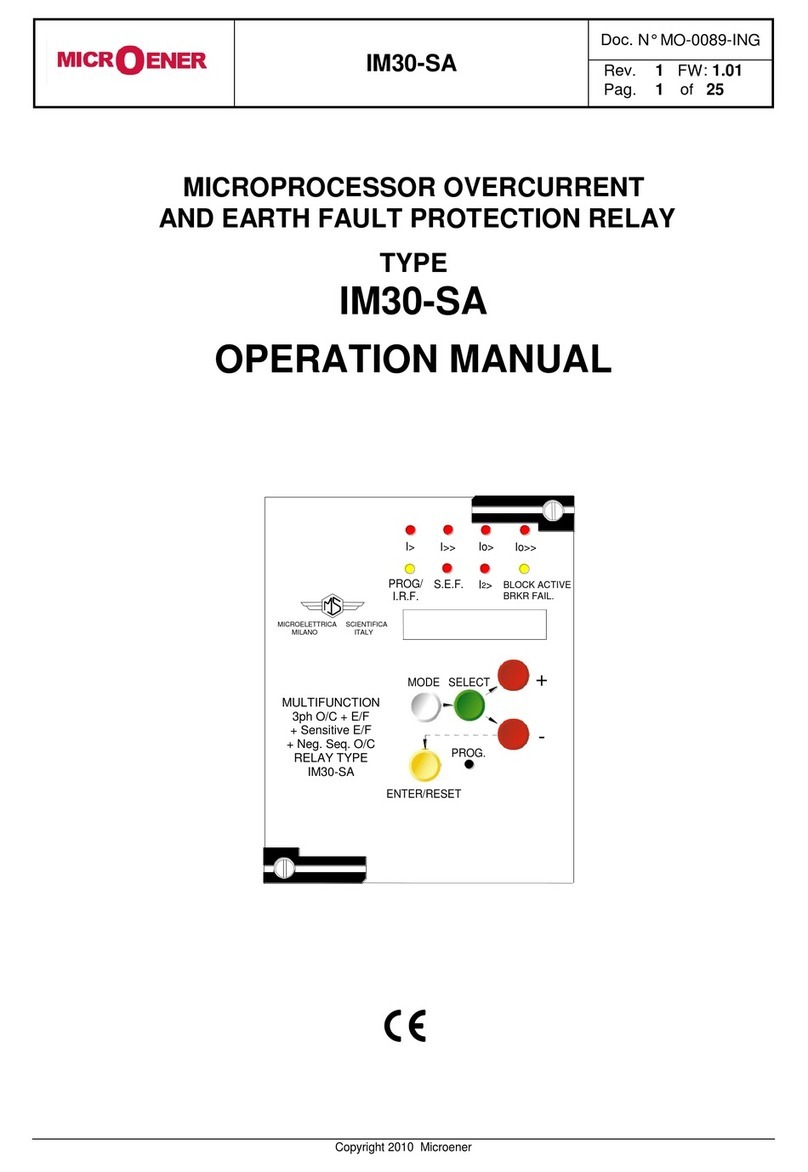

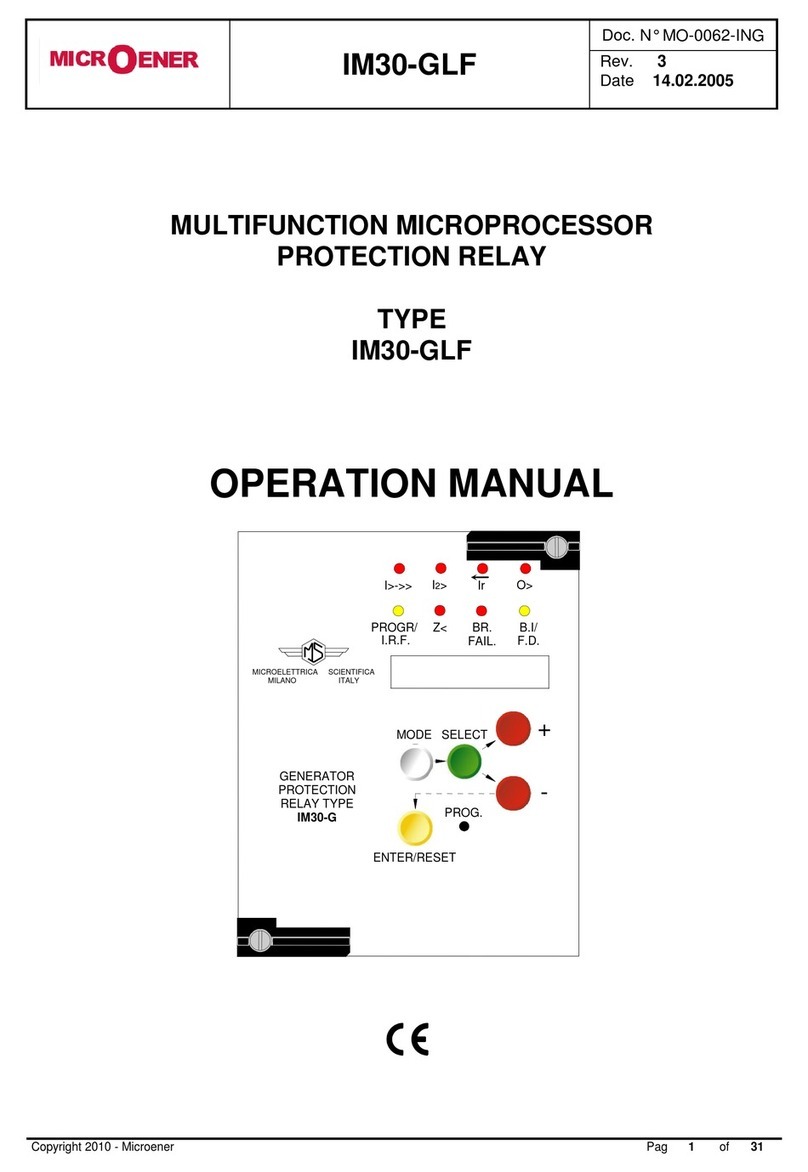

Fig.1

2. General Characteristics

The MC is a very innovative and versatile line of Protective Relays which takes advantage of the long

and successful experience coming from the M-Line.

The main features of the MC-Line relays are:

Compact draw-out execution for Flush Mounting or for assembly in 19” 3U chassis for 19” Rack systems.

User friendly front face with 2x8 characters LCD Display, four signal Leds, four keys for complete local

management and 9-pin socket for local RS232 serial communication.

Four user programmable Output Relays. On request one of the Output Relays can be replaced by a Can

Bus port for control of additional I/O modules.

Three optoisolated, selfpowered Digital Inputs.

RS485 communication port (independent from the RS232 port on front panel)

Totally draw-out execution with automatic C.T. shorting device.

Input currents are supplied to 3 current transformers: - two measuring phase current - one measuring the

earth fault zero-sequence current.

Current inputs can be 1 or 5A, selection between 1A or 5A is made by movable jumpers provided on the

Relay card. (see Fig 1)

The Measuring Ranges of the different inputs

respectively are:

Phase Currents : (0.1-40)In

Neutral Current : (0.01-10)On

Make electric connection in conformity with the

diagram reported on relay's enclosure.

Check that input currents are same as reported

on the diagram and on the test certificate.

2.1 - Power Supply

The auxiliary power is supplied by a built-in module fully isolated an self protected.

Two options are available:

24V(-20%) / 110V(+15%) a.c. 80V(-20%) / 220V(+15%) a.c.

a) - b) -

24V(-20%) / 125V(+20%) d.c. 90V(-20%) / 250V(+20%) d.c.

Before energising the unit check that supply voltage is within the allowed limits.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 6of 35

2.2 - Operation and Algorithms

2.2.1 - Reference Input Values

Display Description Setting Range Step Unit

I1 100 A Rated Primary current of phase C.T. 1 - 9999 1 A

I2 1 A Rated Secondary current of phase C.T. 1 - 5 1/5 A

Io1 100 A Rated Primary current of the tore C.T. detecting earth fault

current. 1 - 9999 1 A

Io2 1 A Rated secondary current of the tore C.T. detecting earth fault

current. 1 - 5 1/5 A

In 100 A Reference primary current of the relay 1 - 9999 1 A

Freq 50 Hz System rated frequency 50 - 60 10 Hz

2.2.2 - Input quantities

2.2.2.1 - Mains Frequency (Freq)

The relay can operate either in 50Hz or 60Hz systems.

The rated Mains Frequency “ Freq “ must be set accordingly.

2.2.2.2 - Phase Current inputs (I1)

The relay directly displays the r.m.s. value of the Phase Currents “ IA “, “ IB ”, “ IC ” flowing in the

Primary of the input Current Transformers and refers all its measurements to that value.

To make the relay properly working with any C.T., when programming the relay settings, input the

value “I1“ of the primary current of the phase C.Ts

Only phase A and C currents are measured, whereas the current of the phase B is computed as

vector summation of the currents of the other two phases.

The algorithm is based on the following considerations coming from well-known vector relations

among the three-phase currents and the zero sequence current.

-In any circumstance – currents balanced or not, sinusoidal or not – it is always true that:

0IIII1 0CBA

-When no Earth Fault exists (I0= 0)

CABCBA III0III2

The earth fault protection element is independently supplied by the residual current coming either

from the residual connection of 3 system C.Ts. or from the core balance C.T.

If any Earth Fault is experienced (I0 0) the Earth Fault Protection Element trips independently

from the phase current measuring elements.

If no Earth Fault is present (I0 = 0), the equation (2) is valid, no matter if currents are balanced or

not, sinusoidal or not.

The third phase current is calculated, in real time, as vector summation of the other two-phase

currents.

During Faults:

A) Single phase to earth Fault Trip of the earth fault element directly measuring the Residual

Current.

B) Two Phase Fault

In any case one of the currents directly measured is involved, so

the relay trips correctly.

C) Two Phase to Earth Fault Same as A + B

D) Three Phase Fault All the three currents are correctly measured (in any case two

directly).

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 7of 35

rs

atTKB

1

Is

I

A

t(I)

α

2.2.2.3 - Earth Fault Current Input (Ion)

Same as for the Phase Currents, the relay directly displays the r.m.s. value of the Zero Sequence

Residual Current flowing at the Primary of the Current Transformers.

If the input to the Earth Fault element is supplied by the residual connection of the 3 phase C.Ts.,

we shall set for the variable “ Io1 ” the same value as “ I1 ”.

If the input to the Earth Fault element is supplied by a separated Core Balance C.T., or by another

CT, “ Io1 ” value will be the Rated Primary Current of this C.T., normally different from “ I1 ”.

2.2.2.4 - Algorithm of the time current curves

The Time Current Curves are generally calculated with the following equation :

(1)

where :

t(I) = Actual trip time delay when the input current equals “I”

I = Maximum of the three input currents.

Is = Set minimum pick-up level

K =

Ts= Set time delay : t(I) = Tswhen

tr = Operation time of the output relay on pick-up.

The parameters “A” and “a” have different values for the different Time Current Curves.

Curve Name Curve Identifier A B a

IEC A Inverse A 0.14 0 0.02

IEC B Very Inverse B 13.5 0 1

IEC C Extremely Inverse C 80 0 2

IEEE Moderate Inverse MI 0.0104 0.0226 0.02

IEEE Short Inverse SI 0.00342 0.00262 0.02

IEEE Very Inverse VI 3.88 0.0963 2

IEEE Inverse I 5.95 0.18 2

IEEE Extremely Inverse EI 5.67 0.0352 2

The maximum measuring current is “40xIn” for phase elements and “10xOn” for the neutral

elements.

1

a110

A

10

I

I

s

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 8of 35

2.2.3 - Time Current Curves IEC (TU1029 Rev.0)

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 9of 35

2.2.4 - Time Current Curves IEEE (TU1028 Rev.0)

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 10 of 35

2.2.5 - Functions and Settings (Function)

2.2.5.1 - I> (1F51) - First overcurrent protection level

FuncEnab Enable [Disable / Enable]

Options TCC D [D / A / B / C / MI / VI / I / EI / / SI ]

BI Disable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev I> 0.5 In (0.10 4.00) step 0.01 In

Timers tI> 2.00 s (0.05 60.00) step 0.01 s

FuncEnab : If disable the function is disactivated

TCC : Time current curves

D = Independent Definite Time

A = IEC A Inverse

B = IEC B Very Inverse

C = IEC C Extremely Inverse

MI = IEEE Moderate Inverse Curve

VI = IEEE Very Inverse Curve

I = IEEE Inverse Curve

EI = IEEE Extremely Inverse Curve

SI = IEEE Short Inverse Curve

BI : Operation controlled by Blocking Digital Input

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

I> : Minimum phase current pick-up level (limited to 40 times In)

tI> : Trip time delay

2.2.5.2 - I>> (2F51) - Second overcurrent protection level

FuncEnab Enable [Disable / Enable]

Options BI Disable [Disable / Enable]

2xI Disable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev I>> 2.00 In (0.50 40.00) step 0.01 In

Timers tI>> 1.00 s (0.05 60.00) step 0.01 s

t2xI 0.10 s (0.02 9.99) step 0.01 s

FuncEnab : If disable the function is disactivated

BI : Operation controlled by Blocking Digital Input

2xI : Automatic threshold doubling on inrush

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

I>> : Minimum phase current pick-up level (limited to 40 times In)

tI>> : Trip time delay

t2xI : Trip time delay

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 11 of 35

2.2.5.3 - IH (3F51) - Third overcurrent protection level

FuncEnab Enable [Disable / Enable]

Options BI Disable [Disable / Enable]

2xI Enable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev IH 5.00 In (0.50 40.00) step 0.01 In

Timers tIH 0.05 s (0.05 60.00) step 0.01 s

t2xI 0.10 s (0.02 9.99) step 0.01 s

FuncEnab : If disable the function is disactivated

BI : Operation controlled by Blocking Digital Input

2xI : Automatic threshold doubling on inrush

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

IH : Minimum phase current pick-up level (limited to 40 times In)

t2xI : Trip time delay

tIH : Trip time delay

2.2.5.3.1 – Automatic doubling or Overcurrent thresholds on current inrush

For some of the phase Overcurrent functions it is possible to have the set trip level [Is]

automatically doubled when strong inrush current is detected.

If at circuit Breaker switch-on (i.e. when the input current rises from zero to a minimum

measurable value) the current increases from 0 to 1.5 times the rated value [In] in less than

60ms, the set minimum pick-up level [Is] is dynamically doubled ([Is][2Is]) and keeps this value

until the input current drops below 1.25xIn or the set time [t2xI] has elapsed.

This functionality is very useful to avoid spurious tripping of the instantaneous or short-time

delayed Overcurrent elements that could be experienced at switch-on of reactive loads like

Transformer or Capacitors.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 12 of 35

2.2.5.5 - Io> (1F51N) - First Earth Fault protection level

FuncEnab Enable [Disable / Enable]

Options TCC D [D / A / B / C / I / VI / EI / MI / SI ]

BI Disable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev Io> 0.10 Ion (0.01 4.00) step 0.01 Ion

Timers tIo> 2.00 s (0.05 60.00) step 0.01 s

FuncEnab : If disable the function is disactivated

TCC : Time current curves

D = Independent Definite Time

A = IEC A Inverse

B = IEC B Very Inverse

C = IEC C Extremely Inverse

MI = IEEE Moderate Inverse Curve

VI = IEEE Very Inverse Curve

I = IEEE Inverse Curve

EI = IEEE Extremely Inverse Curve

SI = IEEE Short Inverse Curve

BI : Operation controlled by Blocking Digital Input

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

Io> : Minimum Zero Sequence Residual Current Pick-up level

tIo> : Trip time delay

2.2.5.6 - Io>> (2F51N) - Second Earth Fault protection level

FuncEnab Enable [Disable / Enable]

Options BI Disable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev Io>> 0.50 Ion (0.01 9.99) step 0.01 Ion

Timers tIo>> 1.00 s (0.05 60.00) step 0.01 s

FuncEnab : If disable the function is disactivated

BI : Operation controlled by Blocking Digital Input

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

Io>> : Minimum Zero Sequence Residual Current Pick-up level

tIo>> : Trip time delay

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 13 of 35

2.2.5.7 - IoH (3F51N) - Third Earth Fault protection level

FuncEnab Enable [Disable / Enable]

Options BI Disable [Disable / Enable]

Trg Enable [Disable / Enable]

TripLev IoH 2.00 Ion (0.01 9.99) step 0.01 Ion

Timers tIoH 0.10 s (0.05 60.00) step 0.01 s

FuncEnab : If disable the function is disactivated

BI : Operation controlled by Blocking Digital Input

Trg : Function operation triggers the oscillographic wave form capture

(see § 2.2.3.12)

IoH : Minimum Zero Sequence Residual Current Pick-up level

tIoH : Trip time delay

2.2.5.8 - BF (F51BF) - Breaker Failure

FuncEnab Enable [Disable / Enable]

Options TrR Relay1 Relay1 – Relay2 – Relay3 – Relay4

TripLev No Param No Parameters

Timers tBF 0.20 s (0.05 0.75) step 0.01 s

FuncEnab : If disable the function is disactivated

TrR : Output relay programmed for trip command to the Circuit Breaker

tBF : Trip time delay

Operation: If after the time “tBF” from pick-up of the programmed relay “TrR” the current

measured still exceeds 5%In, the output relay associated to the “BF” function is operated

(relay another than TrR).

2.2.5.9 - RTD - Remote Trip

Remote trip is controlled via the Digital Input D2.

FuncEnab Disable [Disable / Enable]

Options No Param No Parameters

TripLev No Param No Parameters

Timers No Param No Parameters

FuncEnab : If disable the function is disactivated

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 14 of 35

2.2.5.10 - I.R.F. - Internal Relay Failure

FuncEnab No Param No Parameters

Options Opl NoTrip [NoTrip / Trip]

TripLev No Param No Parameters

Timers No Param No Parameters

Opl : The variable “ Opl “ can be programmed to trip the output relays same as

the other protection functions (OpI = TRIP), or to only operate the “ IRF “

signal led without tripping the output relays (OpI = NoTRIP).

2.2.5.11 - Osc - Oscillographic Recording

FuncEnab Enable [Disable / Enable]

Options Trg Trip [Disable / Start / Trip / Ext.Inp.]

TripLev No Param No Parameters

Timers tPre 0.30 s (0.10 0.50) step 0.1 s

tPost 0.30 s (0.10 1.50) step 0.1 s

FuncEnab : If disable the function is disactivated

Trg : Disab = Function Disable (no recording)

Start. = Trigger on time start of protection functions

Trip = Trigger on trip (time delay end) of protection functions

Ext.Inp. = Trigger from the Digital Input D3

tPre : Recording time before Trigger

tPost : Recording time after Trigger

When the option “Start” or “Trip” is selected:

The oscillographic recording is started respectively by the “Time Start” or by the “Time End” of any of

the functions that have been programmed to Trigger the Wave Form Capture (I>, I>>, IH, Io>, Io>>,

IoH).

The “Osc” Function includes the wave Form Capture of the input quantities (IA, IB, IC, Io) and can

totally store a record of 3 seconds.

The number of events recorded depends on the duration of each individual recording (tPre + tPost).

In any case the number of event stored can not exceed ten (10 x 0.3 sec).

Any new event beyond the 3 sec capacity of the memory, cancel and overwrites the former records

(FIFO Memory).

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 15 of 35

2.2.5.12 - Comm – Communication Parameters

FuncEnab No Param No Parameters

Options Com LBd 9600 [9600 / 19200 / 38400 / 57600]

Com RBd 9600 [9600 / 19200]

Com Mod 8,n,1 [8,n,1 / 8,o,1 / 8,e,1]

Com RPd Modbus [Iec103 / Modbus]

TripLev No Param No Parameters

Timers No Param No Parameters

Com LBd : Local Baud Rate (Front panel RS232 communication speed)

Com RBd : Remote Baud Rate

(Rear panel terminal blocks RS485 communication speed)

Com Mod : Remote mode (communication parameters)

Note: Any change of this setting becomes valid at the next power on

Com RPr : Remote Protocol

2.2.5.13 - LCD – Display and Buzzer operation

FuncEnab No Param No Parameters

Options Key BeepON [BeepOFF / BeepON]

LCD Auto [Auto / On]

TripLev No Param No Parameters

Timers No Param No Parameters

Key : Buzzer “Beep” on operation of Keyboard buttons.

LCD : LCD Backlight continuously “ON” or switched-on Automatically on

operation of Keyboard buttons.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 16 of 35

3. Logic Blocking of Functions

3.1 - Blocking output

The instantaneous element of each of the protection functions (1F50, 2F50, 3F50, 1F50N, 2F50N,

3F50N) can be programmed to control one of the Output Relays.

This relay picks-up as soon as the input quantity exceeds the set trip level of the Protection

Function and it automatically resets when the input quantity drops below the function reset level

(95% of the trip level) or, in any case as soon as the time delay (tBF) of the Breaker Failure

function is expired.

This instantaneous output can be used to activate the Blocking Input of another Protection Relay to

implement a logic selectivity systems. As above explained, in case of Breaker Failure, the blocking

output is released and the back-up protection enabled.

3.2 – Blocking Input

The time delayed tripping of any of the Protection functions (1F51, 2F51, 3F51, 1F51N, 2F51N,

3F51N) can be controlled by the activation of the Digital Input D1 (BI=Enable): in this case the set

trip time delay of the function is increased by “2xtBF” so that other Protection Relays (set with the

same trip time delay) that send the activation signal to the blocking Input D2, can trip before open

and the C/B nearest to the Fault.

Also in this case, however, another “2xtBF” seconds from the expiry of the set trip time delay, the

blocking input is disregarded so allowing the protection relay to trip in case of Failure to open of the

upstream Circuit Breaker.

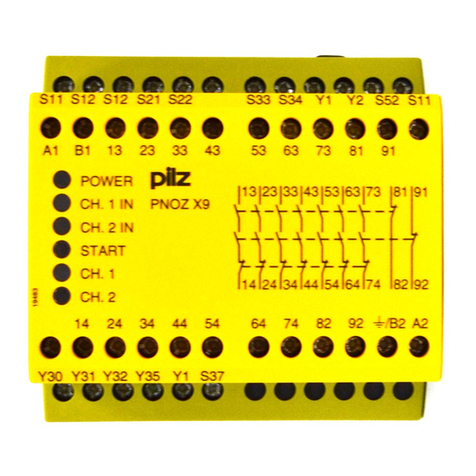

4. Output Relays

Three user programmable Output Relays are normally available on main relay R1, R2, R3, by a Field

Bus output (CANBUS) that controls additional number of user programmable Output Relays 1.R1, 1.R2,

1.R3, 1.R4.

Each of them can be programmed to be controlled by any element (instantaneous or time delayed) of

any of the Relay Functions including Remote trip and Internal Relay Fault.

Moreover, the operation of each of the output relays can be programmed to be either Normally

Deenergized (energized on tripping of the controlling Functional Element) or Normally Energized

(Deenergized on tripping of the controlling Functional Element).

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 17 of 35

5. Digital Inputs

The firmware can manage up to 13 digital inputs and 7 output relays; among these, 3 digital inputs and 3

output relays are available on the relay module, the remaining are available on additional expansion

(UX10-4) modules controlled via the CAN-Bus communication channel.

A Digital Input is activated when its terminals are shorted by a cold contact.

Available in the Main relay

D1 Digital Input “D1” (terminals 22 - 19) It is usable as Function Blocking Input.

D2 Digital Input “D2” (terminals 22 - 21) It is used for Remote Trip.

D3 Digital Input “D3” (terminals 22 - 20) The digital Input indicates the position of the Circuit

Breaker

(Input Closed = C/B closed; Input Open = C/B open).

If the option External Trigger = Enabled any time the DI

passed from closed to open the oscillographic recording is

started.

(UX10-4) Additional Expansion Module

D1 Digital Input “1.D1”

By the interface program “MSCom 2” it is possible view the

status or via RS485 port (Modbus protocol).

D2 Digital Input “1.D2”

D3 Digital Input “1.D3”

D4 Digital Input “1.D4”

D5 Digital Input “1.D5”

D6 Digital Input “1.D6”

D7 Digital Input “1.D7”

D8 Digital Input “1.D8”

D9 Digital Input “1.D9”

D10 Digital Input “1.D10”

6. Self-diagnostic

The relay incorporates a sophisticated self-diagnostic feature that continuously checks the following

elements:

A/D conversion

Checksum of the settings stored into E2Prom.

DSP general operation (Power, Routines, etc.)

Lamp test (only on manual test).

Any time Power is switched on, a complete test is run; then, during normal operation, the test runs

continuously and the checksum is done any time a parameter is stored into E2Prom.

If during the test any Relay Internal Failure (I.R.F) is detected:

If “ I.R.F. “ is programmed to “ Trip “, the programmed output relays are operated same as on

tripping of any protection function operation is stored in the “ Event Records “ and the I.R.F. signal

led is set to flashing.

If “ I.R.F. “ is programmed to “NO Trip”, and only the I.R.F. signal led is set to flashing.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 18 of 35

7. Relay Management

The relay can be totally managed locally, either by the RS232 communication port or by the 4 key

buttons and the LCD display, or remotely via the communication bus RS485 connected to the rear

terminal blocks. The 2 line x 8 characters LCD display shows the available information.

Key buttons operate according to the flow-chart herebelow.

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 19 of 35

8. Signalizations

Four signal leds are available on the Front Face Panel:

a) Green

LED

C/B

OPEN

Illuminated when C/B open status is detected.

(Digital Input D3 Open)

b) Red

LED

C/B

CLOSED

Illuminated when C/B close status is detected.

(Digital Input D3 closed)

Flashing when Breaker Failure is detected.

c) Red

LED

TRIP

(*)

Flashing when a timed function starts to operate.

Illuminated when any function is tripped; reset takes places by pressing the

reset button.

d) Yellow

LED

PWR/

I.R.F.

Illuminated during normal operation when Power Supply is ON.

Flashing when a Relay Internal Fault is detected.

(*) When any protection function is tripped besides the Led which gives the general trip indication.

The display shows the function that caused the tripping:

LastTrip steady

“Cause” blinking

9. Keyboard Buttons

Enter Give access to any menu or convalidate any programming changement.

This button is besides used for the control of Open/Close C/B (see § Command).

Reset Return from the actual selected menu to the former menu.

Select + Scrolls variables available in the different menus or increases/decreases setting

values.

Select -

MC20-X/10-4 Doc. N° MO-0352-ING

Microener - Copyright 2010 FW 720.07.01 Date 09.04.2008 Rev. 1 Pag. 20 of 35

10. Serial Communication Port

10.1 - Main RS485 Serial Communication Port

This port is accessible via the terminals 1-2-3 provided on the relay terminal board.

It is used for connection to a serial bus interfacing up to 31 units with the Central Supervision System

(SCADA, DCS, ecc).

The serial bus is a shielded pair of twisted cables connecting in parallel (Multi Drop) the different units

(slaves) by the relevant terminals.

The physical link is RS485 and the Communication Protocol is MODBUS/RTU / IEC60870-5-103.

The configuration of transmission parameters is selectable.

Baud Rate : 9600/19200 bps 9600/19200 bps 9600/19200 bps

Start bit : 1 1 1

Data bit : 8 8 8

Parity : None Odd Even

Stop bit . 1 1 1

Note: any change of this setting becomes valid at the next power on.

Each relay is identified by its programmable address code (NodeAd) and can be called from the P.C.

A dedicated communication software (MSCom) for windows 95/98/NT4 SP3 (or later) is available.

Please refer to the MSCom instruction manual for more information.

Maximum length of the serial bus can be up to 200m.

For longer distance and for connection of up to 250 Relays, optical interconnection is recommend.

(please ask Microelettrica for accessories)

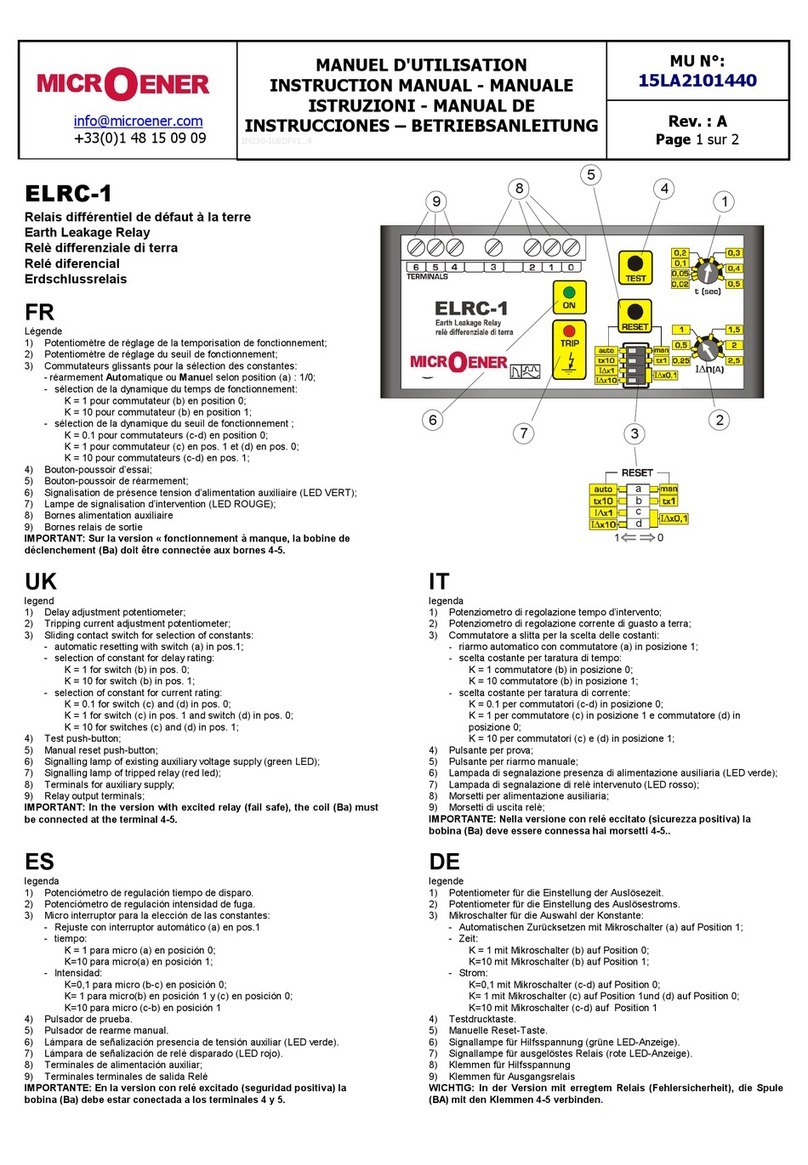

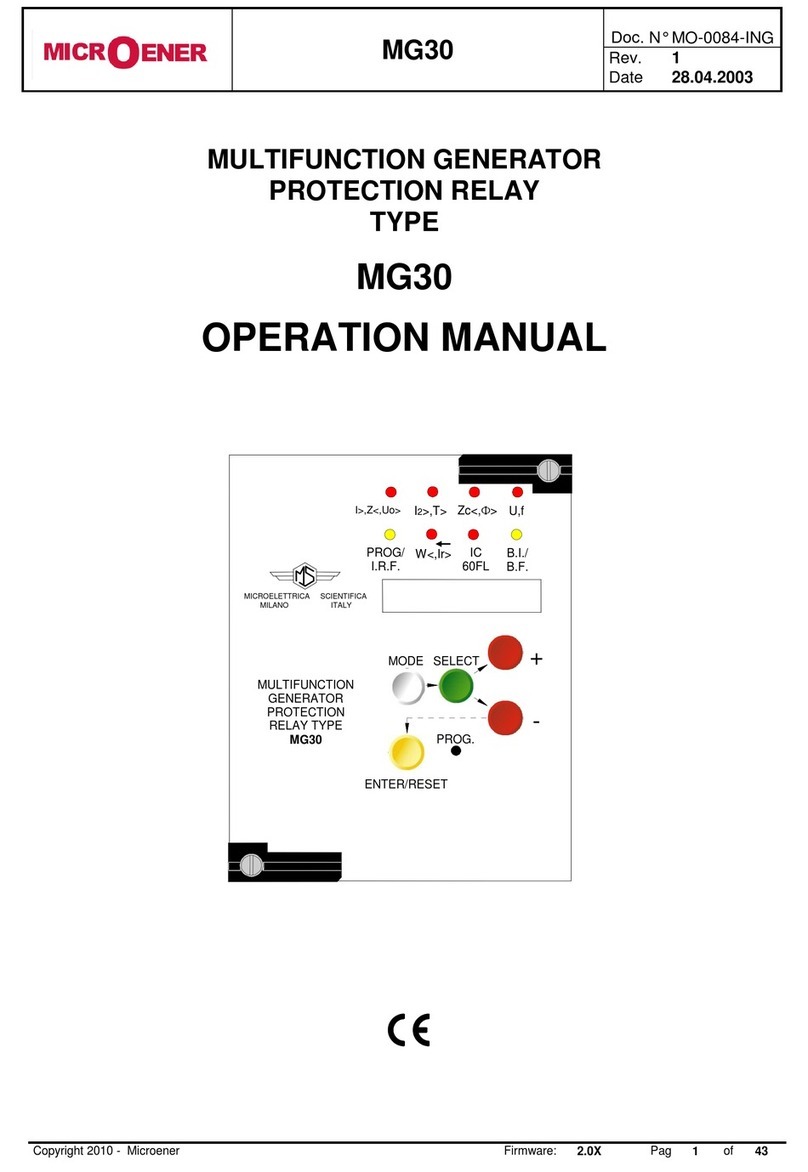

Table of contents

Other MICROENER Relay manuals

MICROENER

MICROENER IM30-DK User manual

MICROENER

MICROENER MM30-W User manual

MICROENER

MICROENER IM30-B00 User manual

MICROENER

MICROENER N-DIN-MSG User manual

MICROENER

MICROENER IM30-GLF User manual

MICROENER

MICROENER ELRC-1 User manual

MICROENER

MICROENER IM3G-VX User manual

MICROENER

MICROENER MG30 User manual

MICROENER

MICROENER MC3V-X/10-4 User manual

MICROENER

MICROENER M-LIB3 User manual