Micron Wings Balsa Craft Kits LiteStick Manual

Other Micron Wings Toy manuals

Micron Wings

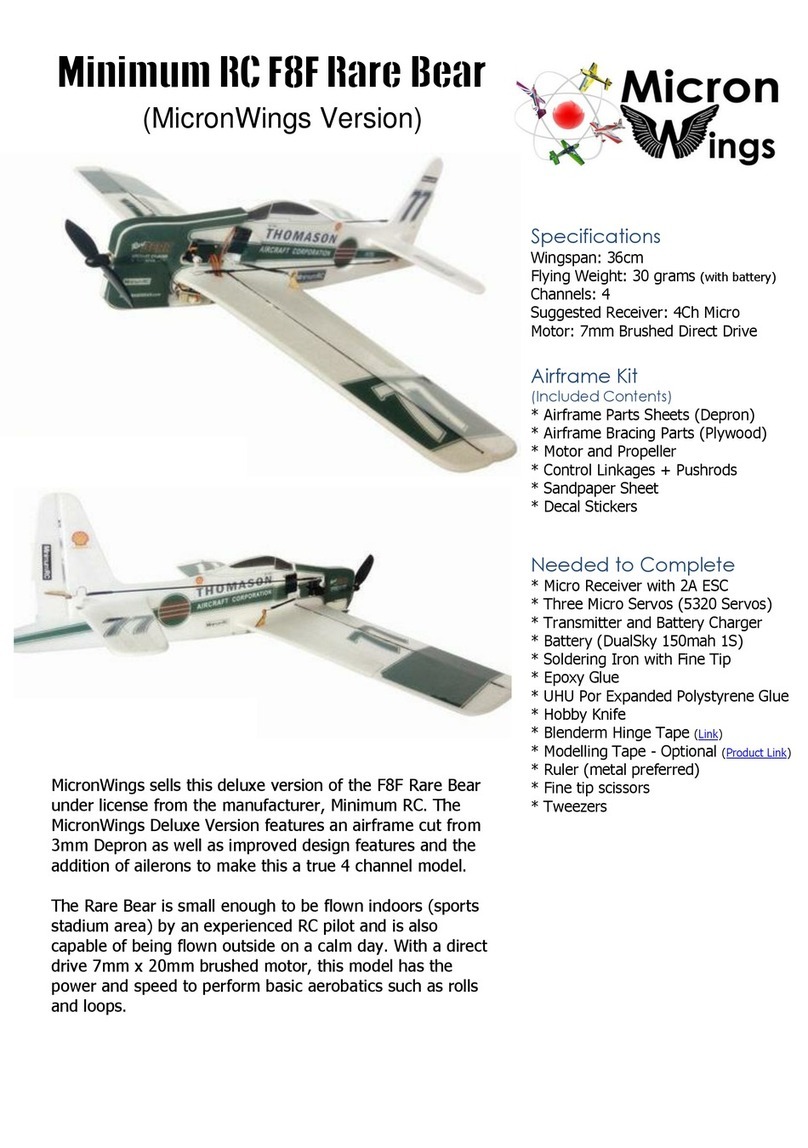

Micron Wings Minimum RC F8F Rare Bear User manual

Micron Wings

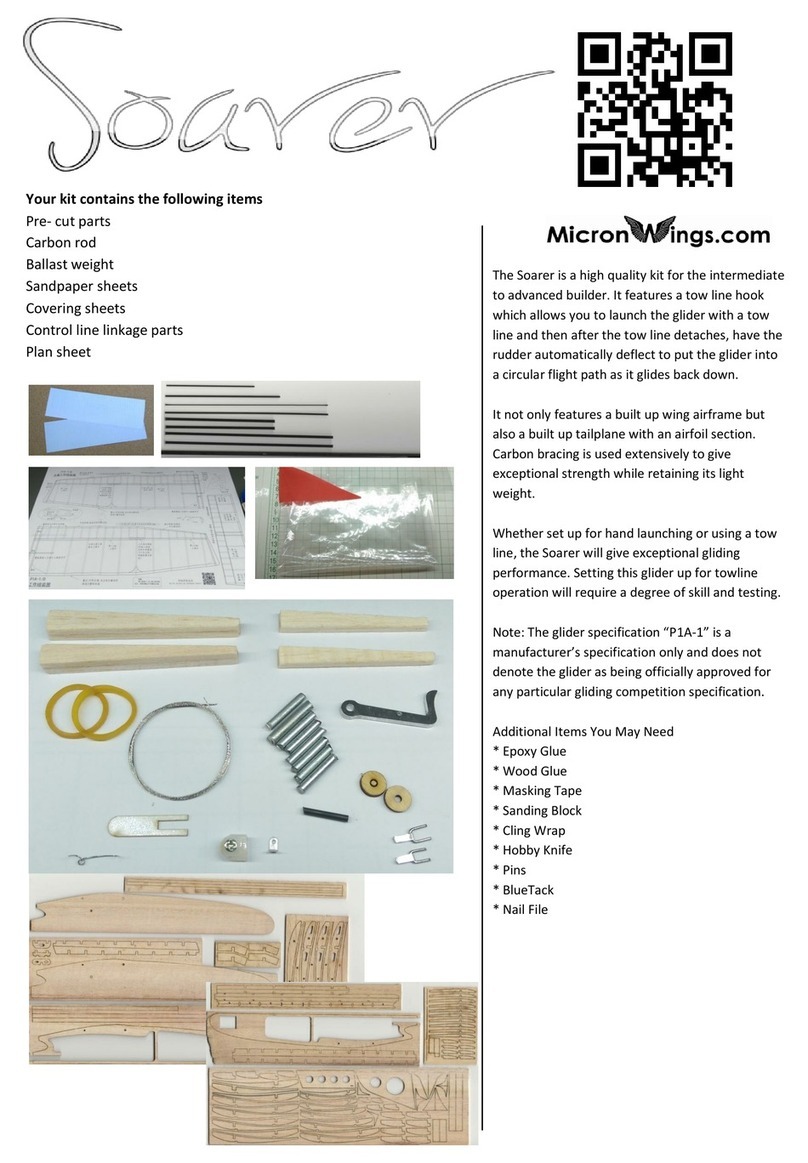

Micron Wings Soarer User manual

Micron Wings

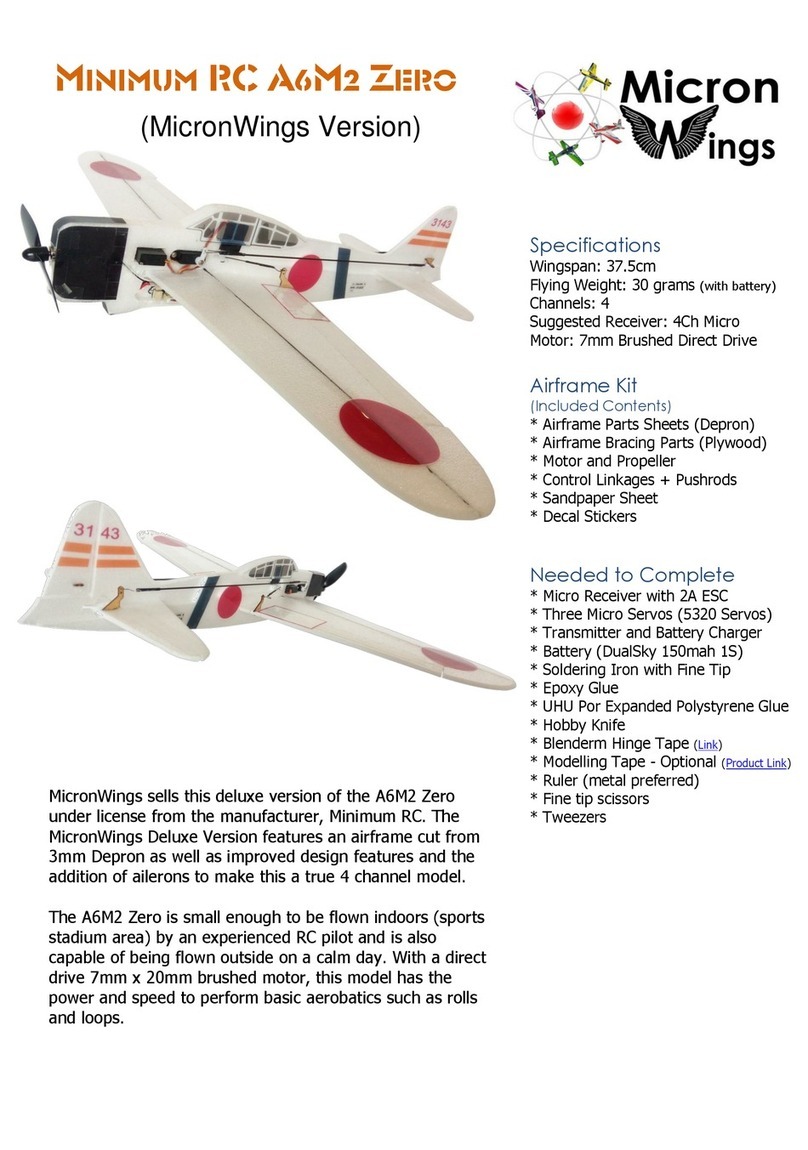

Micron Wings Minimum RC A6M2 Zero User manual

Micron Wings

Micron Wings Depron Bug Airframe Kit V2 Manual

Micron Wings

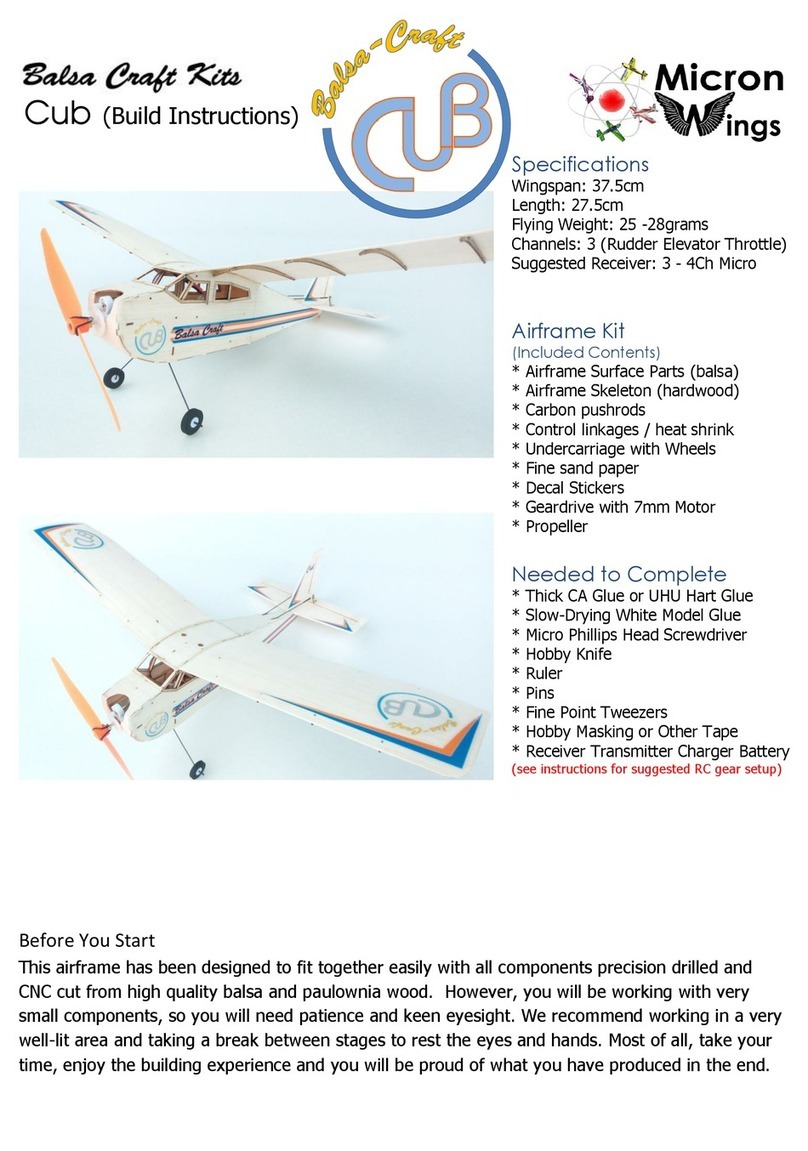

Micron Wings Balsa Craft Cub Manual

Micron Wings

Micron Wings Ezee Flyer User manual

Micron Wings

Micron Wings Student Flyer User manual

Micron Wings

Micron Wings Falcon User manual

Micron Wings

Micron Wings Sopwith Pup Manual

Micron Wings

Micron Wings Balsa Craft S.E.5a Manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions