IO-Link mode

IO-Link mode

The pico+ sensors are IO-Link capable

in accordance with IO-Link specifica-

tion V1.0.

Notes

ԎIn IO-Link mode Teach-in, LinkCon-

trol and synchronisation via pin 5

are not available.

ԎIn IO-Link mode, pin 5 must not be

connected to any potential.

Î

For current information about IO-

Link please contact the microsonic

sales department.

Synchronisation in IO-Link mode

In IO-Link mode each sensor is syn-

chronised on the protocol of the IO-

Link master. In multiple sensor opera-

tion the sensors are synchronous if the

master protocols are synchronous.

Process data

The pico+ cyclically transmits the mea-

sured distance value with a resolution

of 0,1 mm and the state of the swit-

ching output.

Service data

The following sensor parameters may

be set via IO-Link interface using the

IO-Link device description (IODD).

Detect point 1

The switching output is activated

when the distance to an object is un-

der that of the present detect point.

Return detect point 1

The switching output is reactivated

when the distance to an object is gre-

ater than the present return detect

point (detect point + hysteresis).

Note

The return detect point 1 must always

be greater than the detect point 1.

Detect point 2, return detect

point 2

By programming these two detect di-

stances the window mode is activated.

Note

The return detect point 2 must always

be smaller than the detect point 2.

ԎF02:

Average value filter, forms the arith-

metic mean across a number of

measurements. The output is acti-

vated in keeping with the average

value. The number of measure-

ments, from which the average va-

lue is formed, depends on the selec-

ted filter strength.

Filter strength

A filter strength between 0 (weak filter

effect) and 9 (pronounced filter effect)

can be selected for each measurement

filter.

Foreground suppression

Spurious reflections, caused by objects

in the foreground of the sensor, may

be blocked out by the foreground sup-

pression.

Notes

Î

Check that the object in the fore-

ground does not cause multiple

reflections.

NOC/NCC operation

The NCC or NOC output function can

be present for the switching output.

Measurement filter

pico+ ultrasonic sensors provide for a

choice of 3 filter settings:

ԎF00:

No filter, each ultrasonic measure-

ment acts in an unfiltered manner

on the output.

ԎF01:

Standard filter, on the object conti-

nuously approaching the sensor, the

ongoing interval is immediately ta-

ken on and the output correspon-

dingly activated. The effect of the

object abruptly moving away from

the sensor is for the existing dis-

tance to be saved for a retaining

time dependent on the filter

strength and for the switching out-

put state to be maintained.

Î

Make sure that the sensor is not

covered by the interfering object to

such an extent that the detection

range is influenced.

System commands

With 4 system commands the fol-

lowing settings may be carried out:

ԎTeach-in detect point – method A

ԎTeach-in detect point – method B

ԎTeach-in two way reflective barrier

ԎReset sensor to factory settings

Notes

To achieve the maximum resolution

the Master Cycle Time has to comply

with the following requirements:

Ԏ

Min Cycle Time ≤Master Cycle

Time ≤Min Cycle Time + 1.2 ms.

Ԏ

If this condition can not be fullfilled,

sporadic discontinuities of the mea-

surement value can occur. In this

case the Master Cycle Time has to

be increased in 400 µs steps until

the discontinuities of the measure-

ment disappear.

Note

If the pico+ sensor was set using

Teach-in or LinkControl it is recom-

mended to reset the sensor to the

factory setting prior to using it in IO-

Link mode (see »Further settings«).

IODD file

ԎThe latest IODD file you will find on

the internet under

www.microsonic.de/en/IODD.

ԎFor further informations on IO-Link

see www.io-link.com.

microsonic

GmbH

/

Phoenixseestraße

7

/

44263

Dortmund

/

Germany

/

T+49 231 975151-0 / F+49 231 975151-51 / E[email protected] / Wmicrosonic.deThe content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

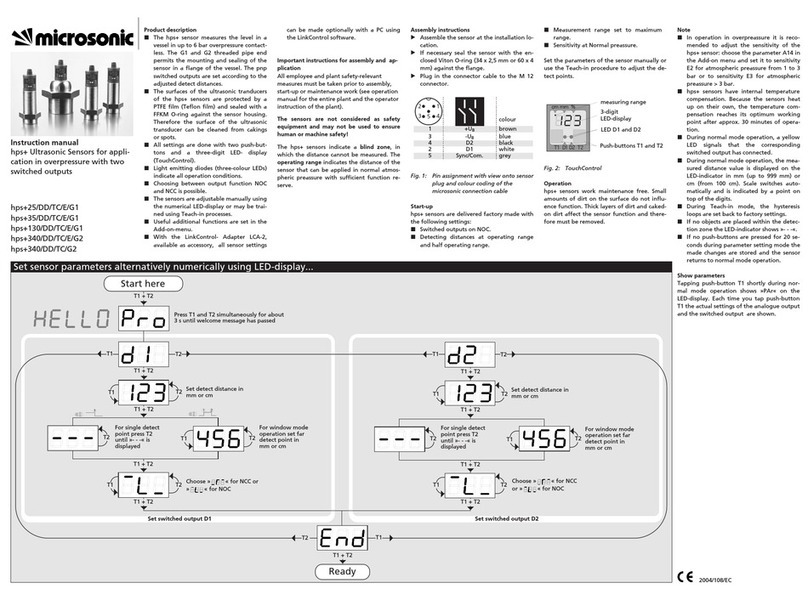

IO-Link data

pico+15... pico+25... pico+35...

pico+100...

physical layer

SIO mode support yes yes yes yes

min cycle time 8.4 ms 8.4 ms 16 ms 20.4 ms

baud rate COM 2 (38.400 Bd) COM 2 (38.400 Bd) COM 2 (38.400 Bd) COM 2 (38.400 Bd)

format of process data 16 Bit, R, UNI16 16 Bit, R, UNI16 16 Bit, R, UNI16 16 Bit, R, UNI16

content of process data Bit 0: state of switching output; Bit 0: state of switching output; Bit 0: state of switching output; Bit 0: state of switching output;

Bit 1-15: distance value with 0.1 mm resolution Bit 1-15: distance value with 0.1 mm resolution Bit 1-15: distance value with 0.1 mm resolution Bit 1-15: distance value with 0.1 mm resolution

service data IO-Link specific index access value index access value index access value index access value

Vendor name 0x10 R microsonic GmbH 0x10 R microsonic GmbH 0x10 R microsonic GmbH 0x10 R microsonic GmbH

Vendor text 0x11 R www.microsonic.de 0x11 R www.microsonic.de 0x11 R www.microsonic.de 0x11 R www.microsonic.de

Product name 0x12 R pico+ 0x12 R pico+ 0x12 R pico+ 0x12 R pico+

Product ID 0x13 R 15/F;15/WK/F 0X13 R 25/F;25/WK/F 0X13 R 35/F;35/WK/F 0X13 R 100/F;100/WK/F

Product text 0x14 R Ultraschall-Sensor 0x14 R Ultraschall-Sensor 0x14 R Ultraschall-Sensor 0x14 R Ultraschall-Sensor

service data sensor specific index format access range (dez) index format access range (dez) index format access range (dez) index format access range (dez)

detect point 1 0x40 UINT16 R/W 306-3,609 (21-248 mm) 1) 0x40 UINT16 R/W 436-5,065 (30 - 348 mm) 1) 0x40 UINT16 R/W 946-8,704 (65 - 598 mm) 1) 0x40 UINT16 R/W 1,747-18,892 (120 - 1,298 mm) 1)

return detect point 1 0x41 UINT16 R/W 320-3,624 (22-249 mm) 1) 0x41 UINT16 R/W 451-5,080 (31 - 349 mm) 1) 0x41 UINT16 R/W 961-8,718 (66 - 599 mm) 1) 0x41 UINT16 R/W 1,761-18,907 (121 - 1,299 mm) 1)

detect point 2 0x47 UINT16 R/W 335-65,512 (23 - 250 mm) 1) 0x47 UINT16 R/W 466-65,512 (32 - 350 mm) 1) 0x47 UINT16 R/W 975-65,512 (67 - 600 mm) 1) 0x47 UINT16 R/W 1,776-65,512 (122 - 1,300 mm) 1)

> 3,638: window mode deactivated > 5,094: window mode deactivated > 8,733: window mode deactivated > 18,922: window mode deactivated

return detect point 2 0x48 UINT16 R/W 320-65,512 (22 - 250 mm) 1) 0x48 UINT16 R/W 451-65,512 (31 - 349 mm) 1) 0x48 UINT16 R/W 961-65,512 (66 - 599 mm) 1) 0x48 UINT16 R/W 1,761-65,512 (121 - 1,299 mm) 1)

> 3.638: window mode deactivated > 5,094: window mode deactivated > 8,733: window mode deactivated > 18,922: window mode deactivated

switching mode 0x42 UINT8 R/W 00: NCC, 02: NOC 0x42 UINT8 R/W 00: NCC, 02: NOC 0x42 UINT8 R/W 00: NCC, 02: NOC 0x42 UINT8 R/W 00: NCC, 02: NOC

filter 0x43 UINT8 R/W 00-02: F00 - F02 0x43 UINT8 R/W 00-02: F00 - F02 0x43 UINT8 R/W 00-02: F00 - F02 0x43 UINT8 R/W 00-02: F00 - F02

filter strength 0x44 UINT8 R/W 00-09: P00 - P09 0x44 UINT8 R/W 00-09: P00 - P09 0x44 UINT8 R/W 00-09: P00 - P09 0x44 UINT8 R/W 00-09: P00 - P09

foreground suppression 0x49 UINT16 R/W 0-1,878 (0-129 mm) 1) 0x49 UINT16 R/W 0-3,246 (0-223 mm) 1) 0x49 UINT16 R/W 0-4,236 (0-291 mm) 1) 0x49 UINT16 R/W 0-12,969 (0-891 mm) 1)

Teach-in via Pin 5 in SIO mode 0x4A UINT8 R/W 00: deactivated, 16: activated 0x4A UINT8 R/W 00: deactivated, 16: activated 0x4A UINT8 R/W 00: deactivated, 16: activated 0x4A UINT8 R/W 00: deactivated, 16: activated

system commands index access value index access value index access value index access value

Teach-in detect point – method A 0x02 W 161 0x02 W 161 0x02 W 161 0x02 W 161

Teach-in detect point – method B 0x02 W 162 0x02 W 162 0x02 W 162 0x02 W 162

Teach-in two way reflective barrier 0x02 W 164 0x02 W 164 0x02 W 164 0x02 W 164

reset to factory settings 0x02 W 168 0x02 W 168 0x02 W 168 0x02 W 168

1) Distance values, e.g. detect points, are given as multiple of the internal resolution of the measurement value = 0,069 mm (example: 320 ≙22 mm). The values in the table are decimal.

*B10097*MV-DO-153977-785098