*B8746*

MV-DO-097102-508091

Technical data

0 to 30 mm

250 mm

0 to 85 mm

350 mm

350 mm

Please see detection zone

600 mm

Please see detection zone

0 to 200 mm

1.300 mm

0 to 350 mm

3.400 mm

2.000 mm

Please see detection zone

5.000 mm

Please see detection zone

0 to 600 mm

6.000 mm

8.000 mm

Please see detection zone

Resolution, sampling rate

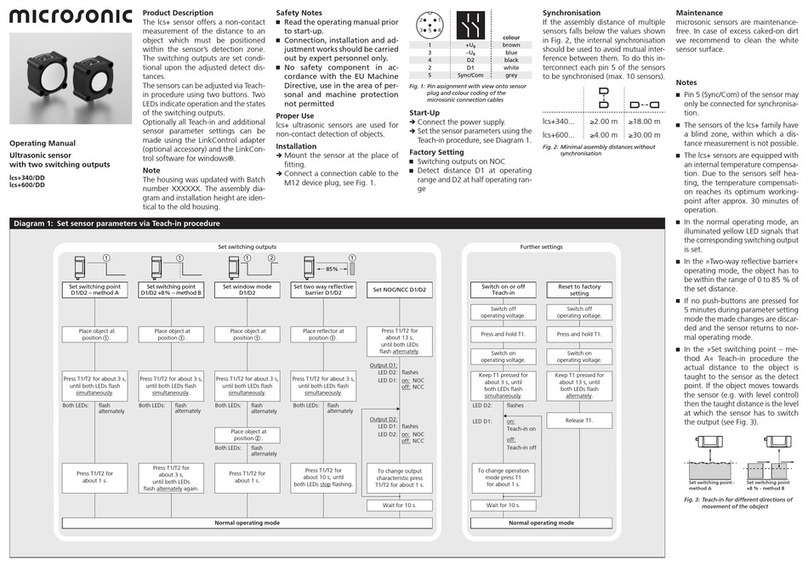

Detection zones

for different objects:

The dark grey areas are determind

with a thin round bar (10 or 27 mm dia.)

and indicate the typical operating range

of a sensor. In order to obtain the light grey

areas, a plate (500 x 500 mm) is introduced

into the beam spread from the side.

In doing so, the optimum angle between

plate and sensor is always employed.

This therefore indicates the maximum

detection zone of the sensor.

It is not possible to evaluate ultrasonic

reflections outside this area.

320 kHz

0.025 mm bis 0.10 mm, depending on the

360 kHz

0.025 mm bis 0.17 mm, depending on the

analogue window analogue window

± 0.15 %

± 1 % (Temperature drift internal compensated,

± 0.15 %

± 1 % (Temperature drift internal compensated,

may be deactivated1), 0.17%/K without compensation)

9 V to 30 V DC, short-circuit-proof

may be deactivated1), 0.17%/K without compensation)

9 V to 30 V DC, short-circuit-proof

200 kHz

0.18 mm bis 0.57 mm, depending on the

120 kHz

0.18 mm bis 1.50 mm, depending on the

analogue window analogue window

80 kHz

0.18 mm bis 2.40 mm, depending on the

analogue window

± 0.15 %

± 1 % (Temperature drift internal compensated,

± 0.15 %

± 1 % (Temperature drift internal compensated,

may be deactivated1), 0.17%/K without compensation)

9 V to 30 V DC, short-circuit-proof

may be deactivated1), 0.17%/K without compensation)

9 V to 30 V DC, short-circuit-proof

± 0.15 %

± 1 % (Temperature drift internal compensated,

may be deactivated1), 0.17%/K without compensation)

9 V to 30 V DC, short-circuit-proof

Voltage ripple

No-load supply current

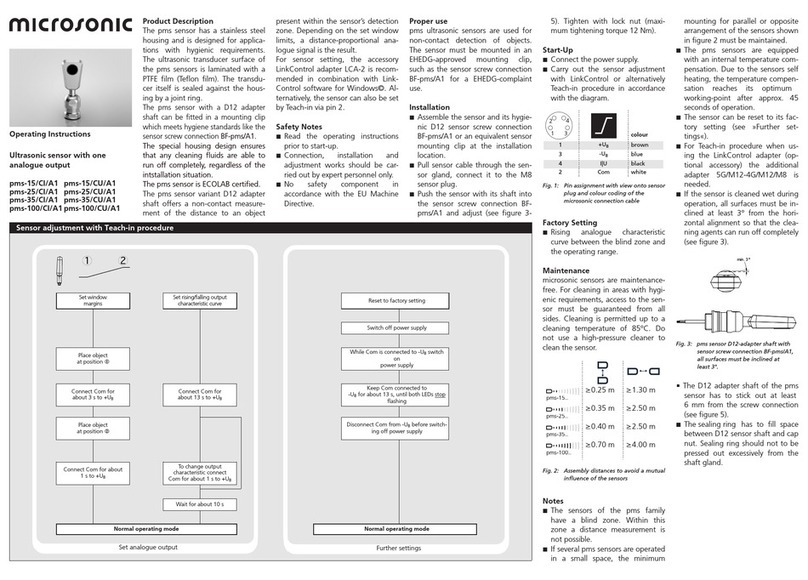

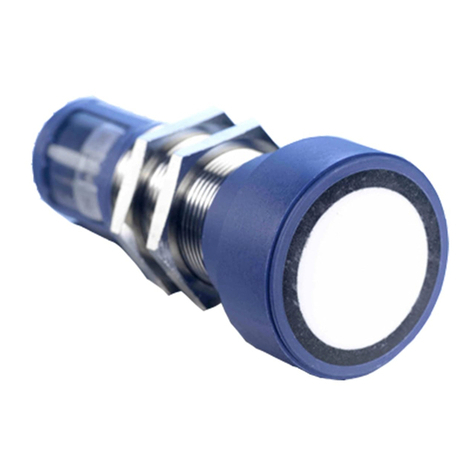

Housing

±10 %

±10 %

≤80 mA

Stainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFE

Stainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFE

Class of protection to EN 60529

Norm conformity

Type of connection

IP 67 IP 67

EN 60947-5-2

5-pin initiator plug, PBT

EN 60947-5-2

5-pin initiator plug, PBT

±10 %

±10 %

Stainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFE

Stainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFE

±10 %

Stainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFE

IP 67 IP 67

EN 60947-5-2

5-pin initiator plug, PBT

EN 60947-5-2

5-pin initiator plug, PBT

IP 67

EN 60947-5-2

5-pin initiator plug, PBT

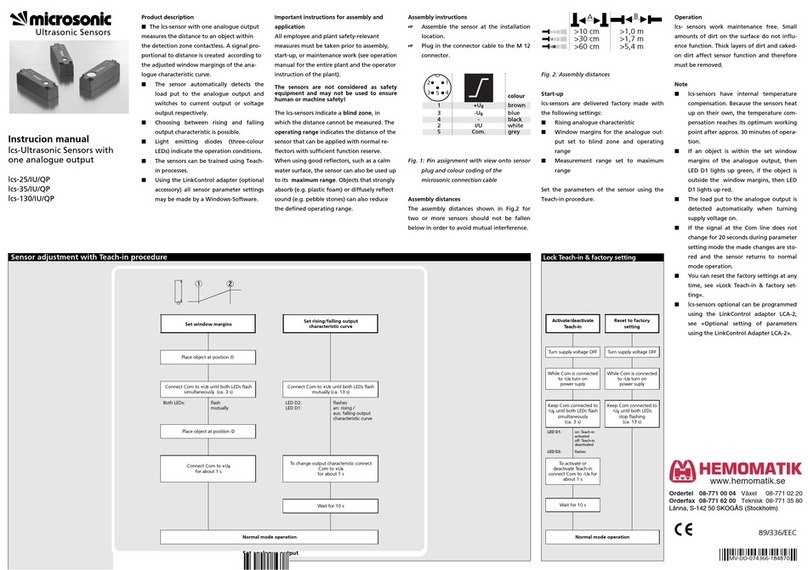

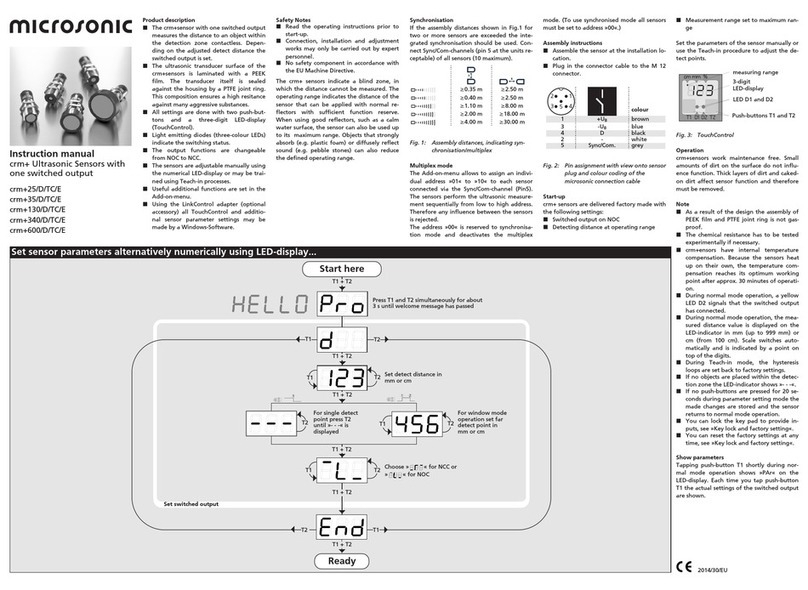

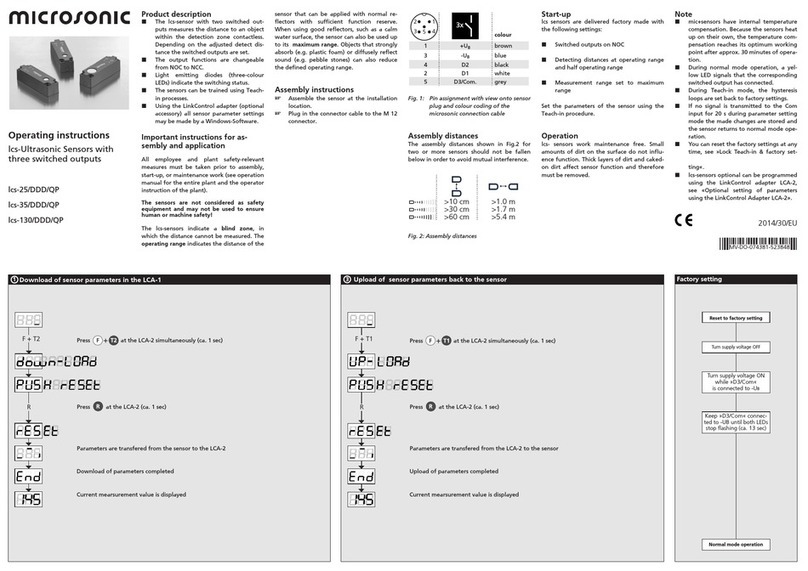

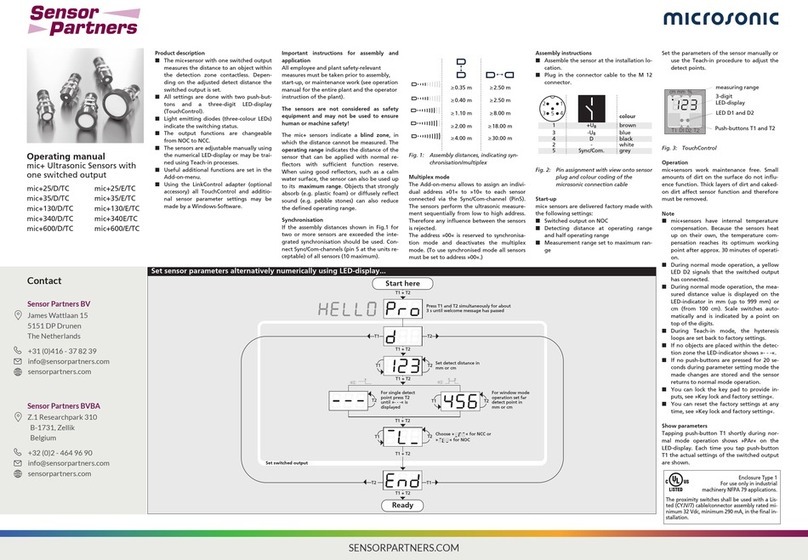

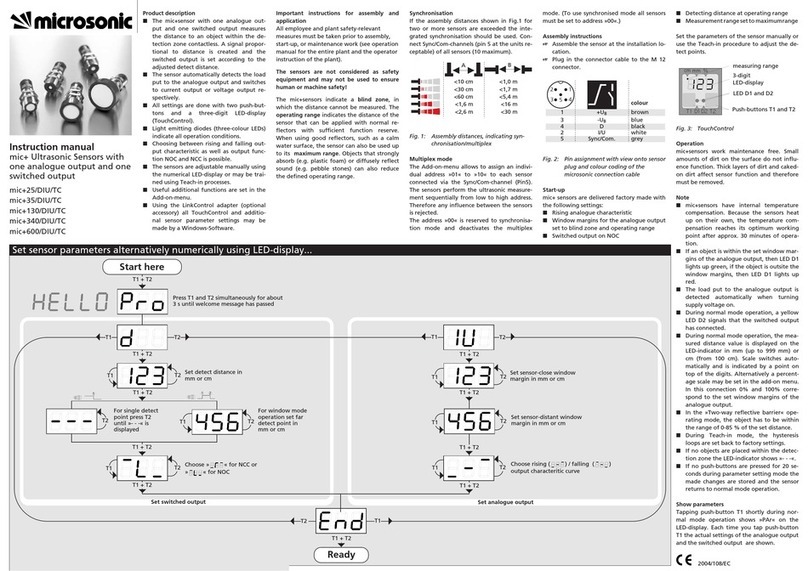

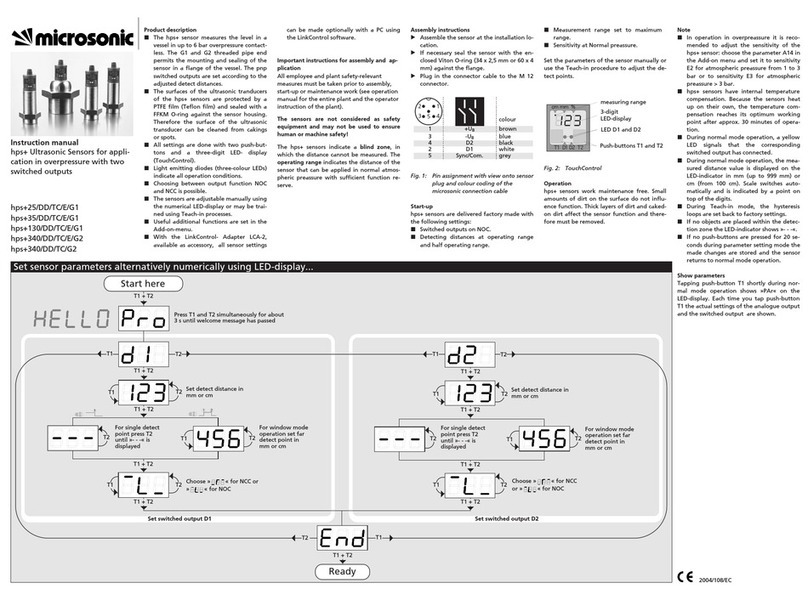

Controls

Indicators

Programmable

Operating temperature

2 push-buttons (TouchControl)

3-digit LED-display, 2 three-colour LEDs

2 push-buttons (TouchControl)

3-digit LED-display, 2 three-colour LEDs

Yes, with TouchControl and LinkControl

-25°C to +70°C

Yes, with TouchControl and LinkControl

-25°C to +70°C

Storage temperature

Weight

-40°C to +85°C

150 g

-40°C to +85°C

150 g

3 mm

25 Hz

5 mm

12 Hz

2 push-buttons (TouchControl)

3-digit LED-display, 2 three-colour LEDs

2 push-buttons (TouchControl)

3-digit LED-display, 2 three-colour LEDs

Yes, with TouchControl and LinkControl

-25°C to +70°C

Yes, with TouchControl and LinkControl

-25°C to +70°C

2 push-buttons (TouchControl)

3-digit LED-display, 2 three-colour LEDs

Yes, with TouchControl and LinkControl

-25°C to +70°C

-40°C to +85°C

150 g

-40°C to +85°C

210 g

20 mm

8 Hz

50 mm

4 Hz

-40°C to +85°C

270 g

100 mm

3 Hz

Time delay before availibility

Order No.

32 ms

< 300 ms

64 ms

< 300 ms

crm+25/DIU/TC crm+35/DIU/TC

Switched output

Current output 4 – 20 mA

pnp, UB- 2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

pnp, UB- 2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

RL ≤100 Ωat 9 V ≤UB≤20 V;

RL ≤100 Ωat 9 V ≤UB≤20 V;

RL ≤500 Ωat UB≥20 V

92 ms

< 300 ms

172 ms

< 300 ms

crm+130/DIU/TC crm+340/DIU/TC

240 ms

< 300 ms

crm+600/DIU/TC

2 x pnp, UB- 2 V, Imax = 2 x 200 mA

switchable NOC/NCC, short-circuit-proof

pnp, UB- 2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

RL ≤100 Ωat 9 V ≤UB≤20 V;

RL ≤100 Ωat 9 V ≤UB≤20 V;

pnp, UB- 2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

RL ≤100 Ωat 9 V ≤UB≤20 V;

Voltage output 0 – 10 V

1) Can be programmed with TouchControl and LinkControl

Rising/falling output characteristic

RL ≥100 kΩat UB≥15 V, short-circuit-proof

Rising/falling output characteristic

RL ≥100 kΩat UB≥15 V, short-circuit-proof

Rising/falling output characteristic Rising/falling output characteristic

Rising/falling output characteristic

RL ≥100 kΩat UB≥15 V, short-circuit-proof

Rising/falling output characteristic

RL ≥100 kΩat UB≥15 V, short-circuit-proof

Rising/falling output characteristic Rising/falling output characteristic

Rising/falling output characteristic

RL ≥100 kΩat UB≥15 V, short-circuit-proof

Rising/falling output characteristic

1 pnp switched output + analogue output

+UB

-UB

IU

D

Sync/Com

1

2

4

5

3

U

crm+35…

0 cm

5 cm

10 cm

15 cm

20 cm

25 cm

30 cm

35 cm

Plate

Round bar

10 cm

5 cm

0 cm

5 cm

10 cm

0 cm

10 cm

20 cm

30 cm

40 cm

50 cm

60 cm

Plate

Round bar

20 cm

10 cm

0 cm

10 cm

20 cm

35 cm

0 m

0,4 m

0,8 m

1,2 m

1,6 m

2 m

1,3 m

Plate

Round bar

0,8 m

0,4 m

0 m

0,4 m

0,8 m

0 m

0,8 m

1,6 m

2,4 m

3,2 m

4 m

4,8 m

5,6 m

3,4 m

Plate

Round

1,6 m

0,8 m

0 m

0,8 m

1,6 m

0 m

1,2 m

2,4 m

3,6 m

4,8 m

6 m

7,2 m

8,4 m

Plate

Round bar

2,4 m

1,2 m

0 m

1,2 m

2,4 m

microsonic

GmbH

/

Phoenixseestraße

7

/

44263

Dortmund

/

Germany

/

T+49

231

975151-0

/

F+49

231

975151-51

/

E[email protected] / Wmicrosonic.de

The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.