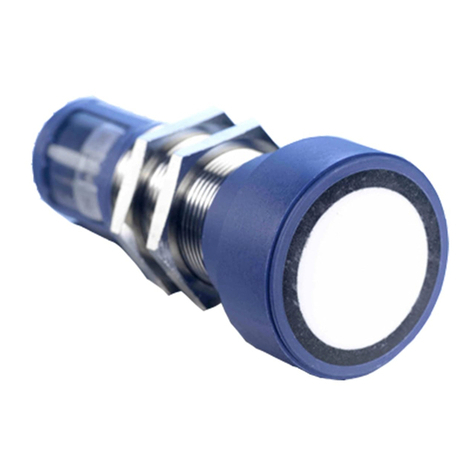

Product Description

The nano sensor offers a non-contact

measurement of the distance to an

object that has to be present within

the sensor’s detection zone. Depen-

ding on the set window limits, a dis-

tance-proportional analogue signal is

output.

The window limits of the analogue

output and its characteristic can be

adjusted with the Teach-in procedure.

A duo-LED indicates operation and the

state of the analogue output.

Proper Use

nano ultrasonic sensors are used for

non-contact detection of objects.

Safety Notes

Ԏ

Read the operating manual prior

to start-up.

ԎConnection, installation and ad-

justment works should be carried

out by expert personnel only.

Ԏ

No safety component in ac-

cordance with the EU Machine

Directive, use in the area of per-

sonal and machine protection

not permitted

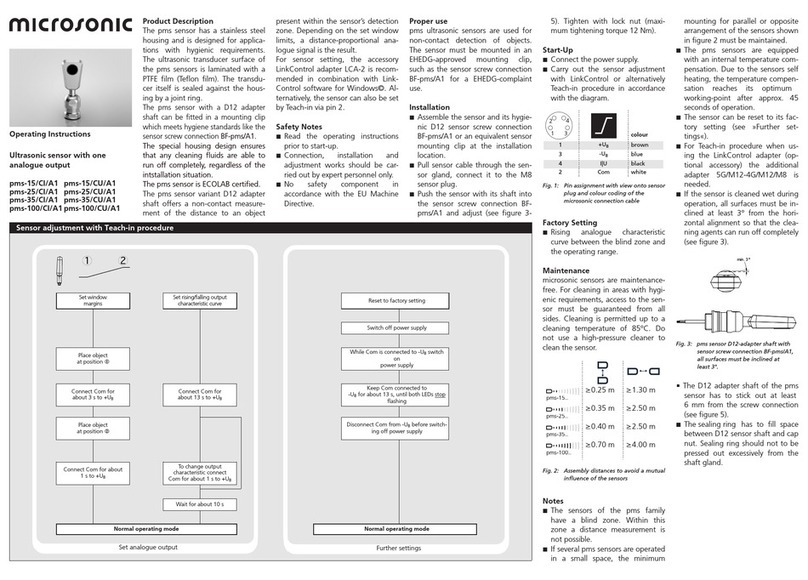

Installation

Î

Mount the sensor at the installation

site.

ÎConnect a connection cable to the

M12 device plug, see Fig. 1.

Î

The assembly distances shown in

Fig. 2 for two or more sensors

should not be fallen below in order

to avoid mutual interference.

12

colour

1 +UBbrown

3 –UBblue

4 I/U black

2 Teach-in white

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the microso-

nic connection cable

Inbetriebnahme

ÎConnect the power supply.

ÎAdjust the sensor according to Dia-

gram 1.

Factory Setting

Ԏ

Rising analogue characteristic curve

between the blind zone and the

operating range

Notes

Ԏ

Every time the power supply is swit-

ched on, the sensor detects its ac-

tual operating temperature and

transmits it to the internal tempera

-

ture compensation. This results in a

slight correction of the analogue

output value after 45 seconds.

Ԏ

If the sensor was switched off for at

least 30 minutes and after power

on an object is placed in the middle

of the adjusted analogue window

for 30 minutes (the analogue out-

put value is in the range of 11 to 13

mA or 4.4 to 5.6 V) a new adjust-

ment of the internal temperature

compensation to the actual moun-

ting conditions takes place.

Ԏ

The sensors of the nano family have

a blind zone. Within this zone a di-

stance measurement is not possible.

ԎIn the normal operating mode, an

illuminated yellow LED signals the

object is within the adjusted win-

dow limits.

ԎThe sensor can be reset to its facto-

ry setting (see »Further settings«).

Operating Manual

Ultrasonic sensor

with one analogue output

nano-15/CI nano-15/CU

nano-24/CI nano-24/CU

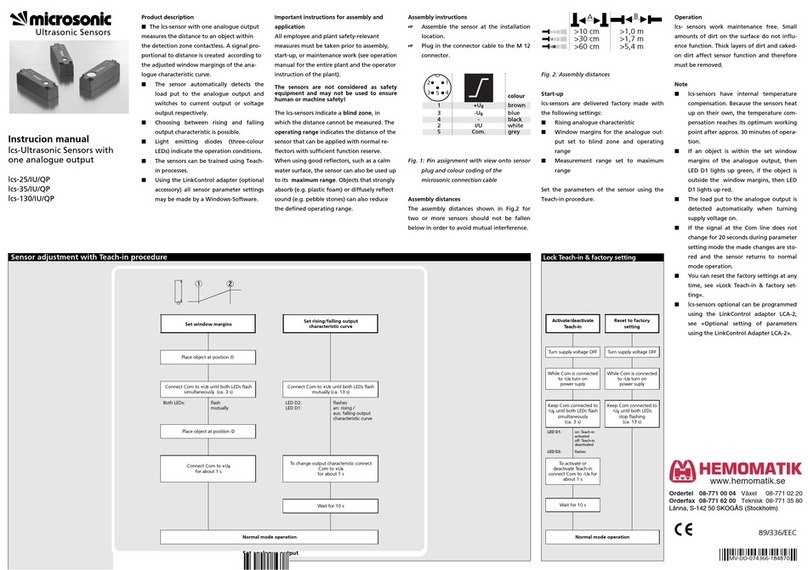

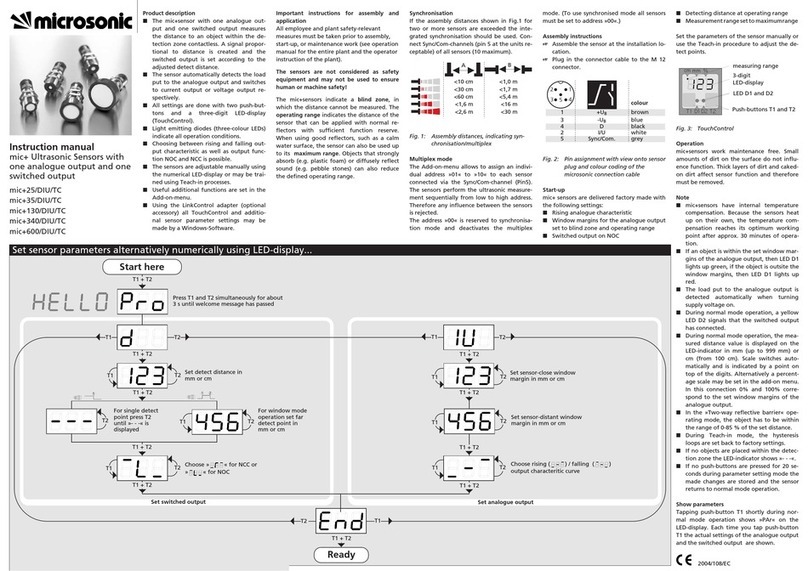

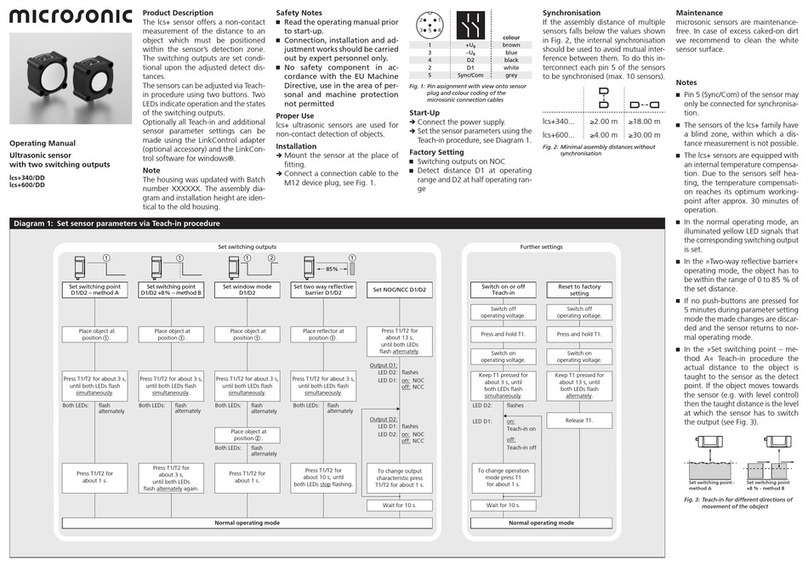

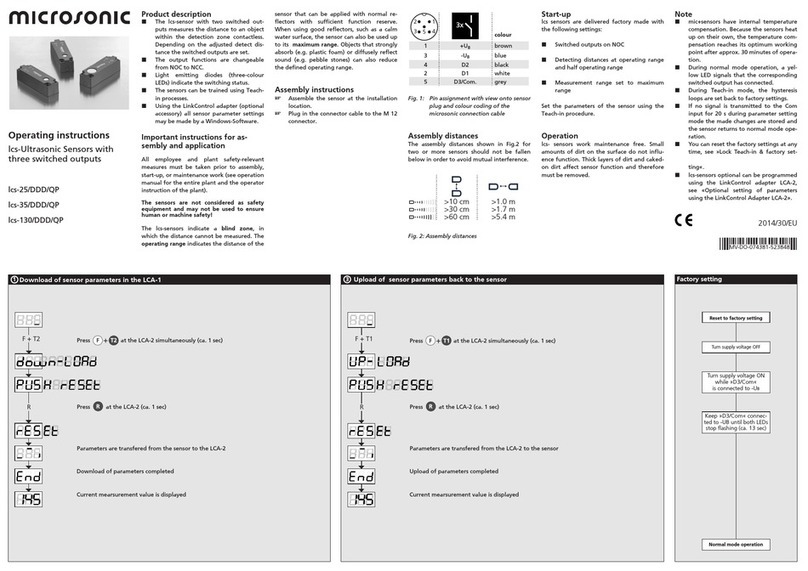

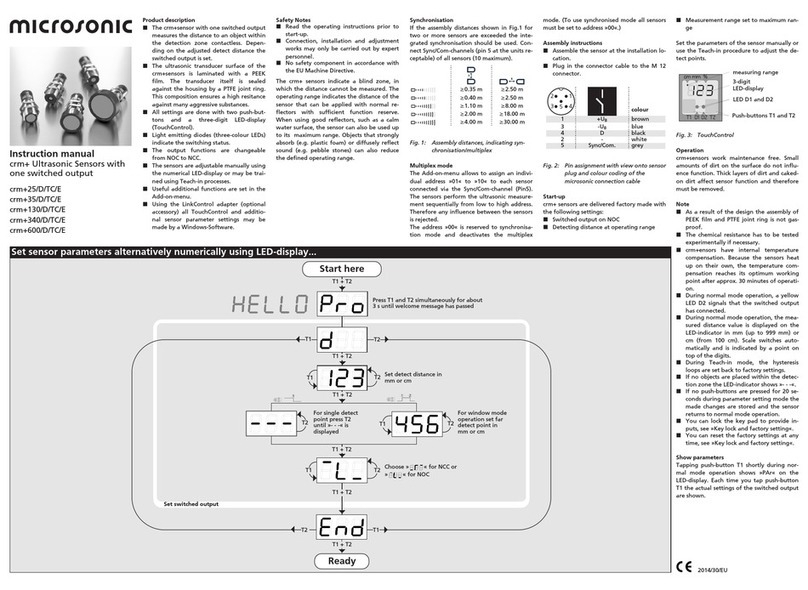

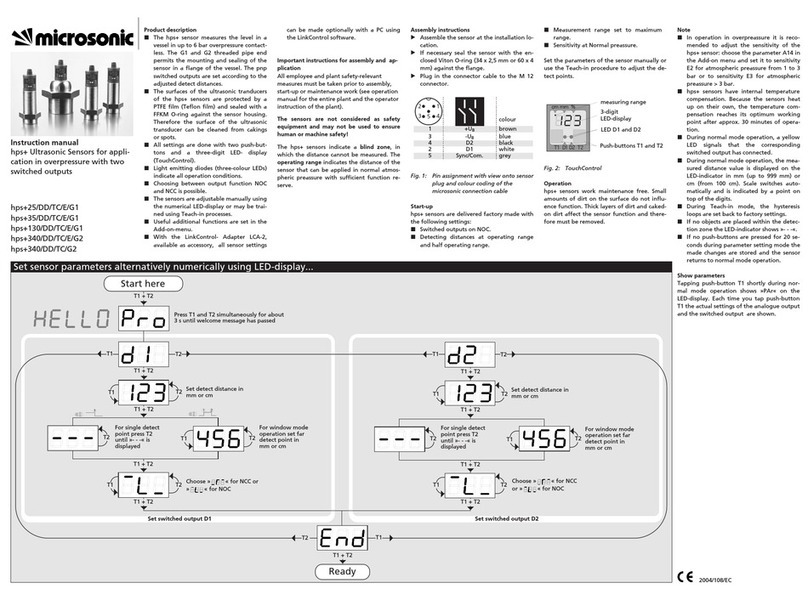

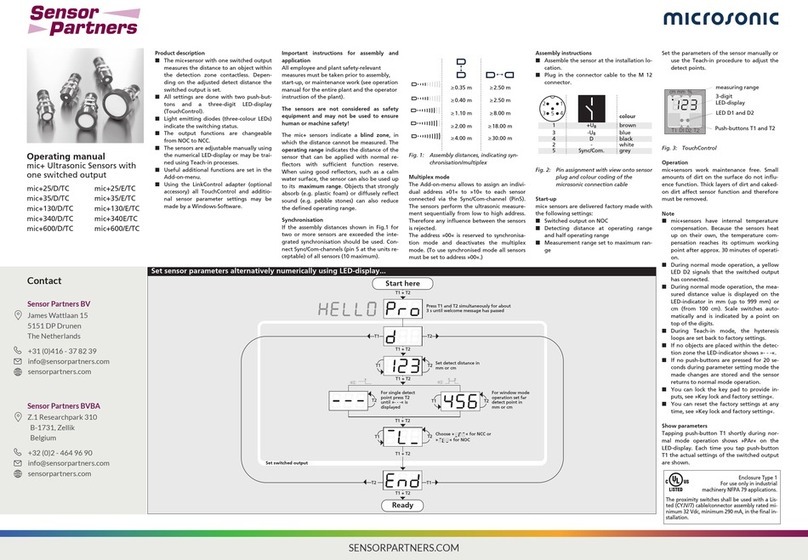

Diagram 1: Set Sensor via Teach-in procedure

Place object at position .

1

Place object at position .

2

Set window limits Set rising/falling output

characteristic curve

Wait for about 10 s.

characteristc

curve

green, green/yellow:

rising

green:

falling

Normal operating mode

Set analogue output

Connect Teach-in

for about 3 s to +UB,

until LEDs flashes yellow.

Connect Teach-in for about

13 s to +UB, until

LED flashes alternately

green/yellow.

Connect Teach-in

for about 1 s to +UB.

To change

output characteristic

connect Teach-in

for about 1 s to +UB.

LED flashes:

LED: flashes

green/yellow

1 2

Reset to factory setting

Disconnect Teach-in

from +UBwithin 5 s

before switching off

power supply.

Keep Teach-in connected

to +UBfor about 13 s,

until LED flashes

green/yellow alternately.

Normalbetrieb

Further settings

Switch off

operating voltage.

Switch on

operating voltage.

Connect Teach-in to +UB.

nano-15... ≥0.25 m ≥1.30 m

nano-24 ≥0.25 m ≥1.40 m

Fig. 2: Minimum mounting distances

Maintenance

microsonic sensors are maintenance-

free. In case of excess caked-on dirt

we recommend cleaning the white

sensor surface.