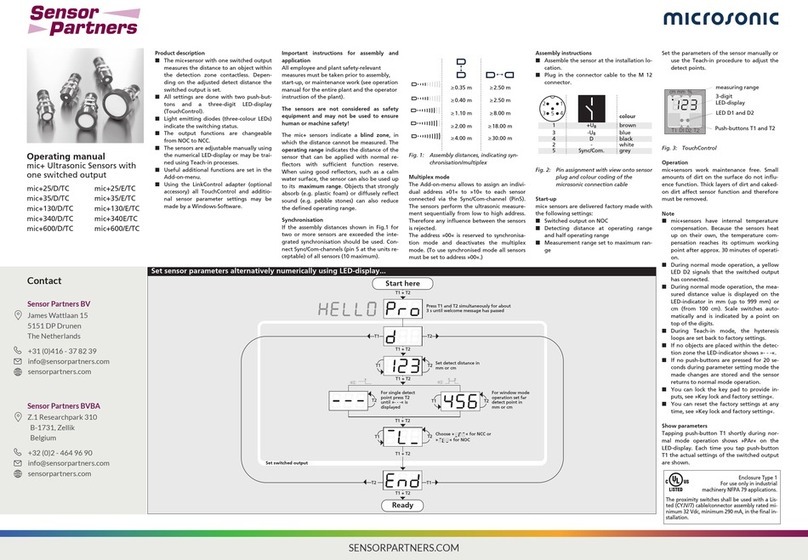

Instrucion manual

lcs-Ultrasonic Sensors with

one analogue output

lcs-25/IU/QP

lcs-35/IU/QP

lcs-130/IU/QP

Ultrasonic Sensors

Product description

■The lcs-sensor with one analogue output

measures the distance to an object within

the detection zone contactless. A signal pro-

portional to distance is created according to

the adjusted window margings of the ana-

logue characteristic curve.

■The sensor automatically detects the

load put to the analogue output and

switches to current output or voltage

output respectively.

■Choosing between rising and falling

output characteristic is possible.

■Light emitting diodes (three-colour

LEDs) indicate the operation conditions.

■The sensors can be trained using Teach-

in processes.

■Using the LinkControl adapter (optional

accessory) all sensor parameter settings

may be made by a Windows-Software.

Important instructions for assembly and

application

All employee and plant safety-relevant

measures must be taken prior to assembly,

start-up, or maintenance work (see operation

manual for the entire plant and the operator

instruction of the plant).

The sensors are not considered as safety

equipment and may not be used to ensure

human or machine safety!

The lcs-sensors indicate a blind zone, in

which the distance cannot be measured. The

operating range indicates the distance of the

sensor that can be applied with normal re-

flectors with sufficient function reserve.

When using good reflectors, such as a calm

water surface, the sensor can also be used up

to its maximum range. Objects that strongly

absorb (e.g. plastic foam) or diffusely reflect

sound (e.g. pebble stones) can also reduce

the defined operating range.

Assembly instructions

☞Assemble the sensor at the installation

location.

☞Plug in the connector cable to the M 12

connector.

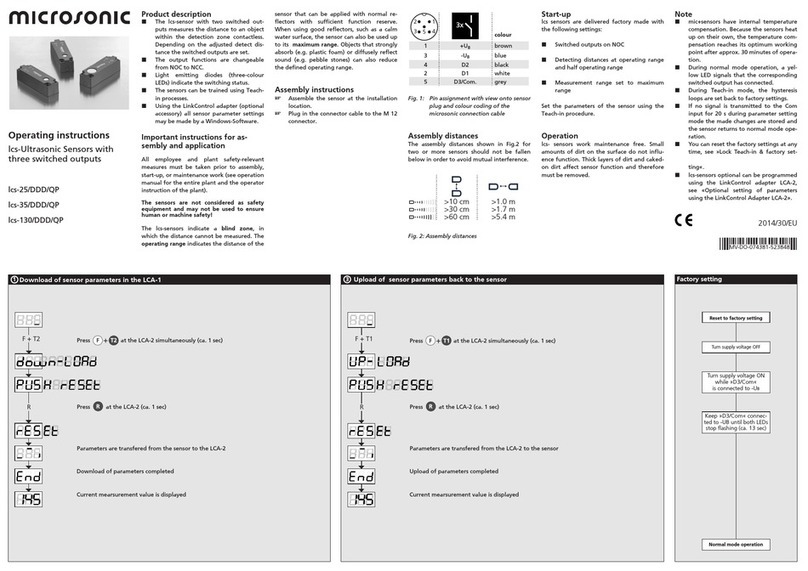

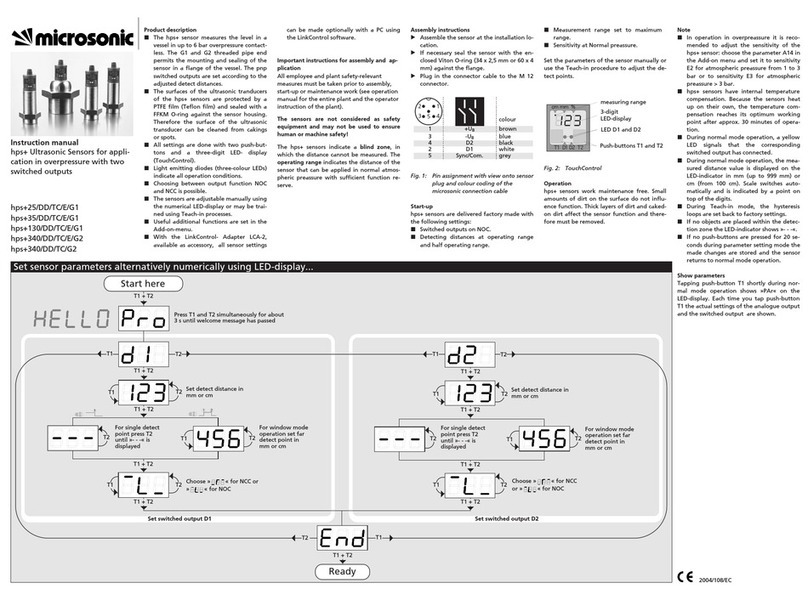

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cable

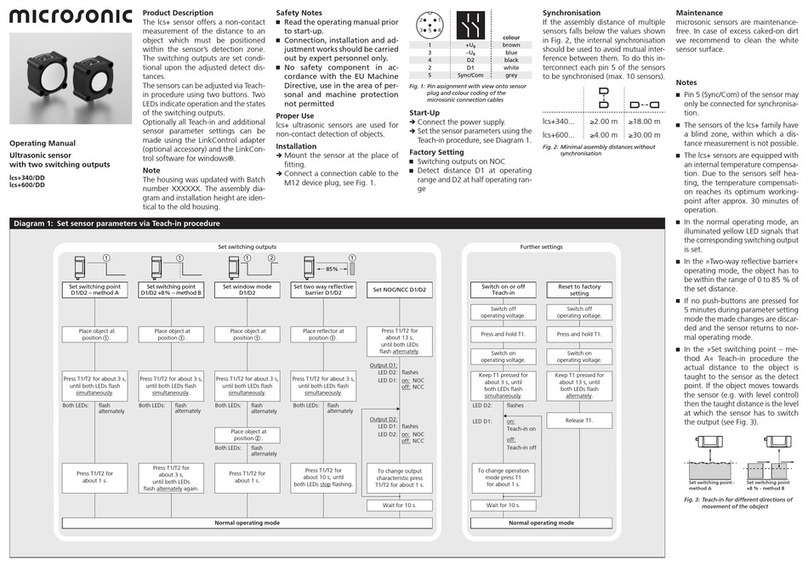

Assembly distances

The assembly distances shown in Fig.2 for

two or more sensors should not be fallen

below in order to avoid mutual interference.

1

3

colour

+UB

-UB

brown

blue

4

2

5

-

I/U

black

white

Com. grey

1

5

2

34

Fig. 2: Assembly distances

Start-up

lcs-sensors are delivered factory made with

the following settings:

■Rising analogue characteristic

■Window margins for the analogue out-

put set to blind zone and operating

range

■Measurement range set to maximum

range

Set the parameters of the sensor using the

Teach-in procedure.

>10 cm

>30 cm >1,0 m

>1,7 m

>60 cm >5,4 m

ABOperation

lcs- sensors work maintenance free. Small

amounts of dirt on the surface do not influ-

ence function. Thick layers of dirt and caked-

on dirt affect sensor function and therefore

must be removed.

Note

■lcs-sensors have internal temperature

compensation. Because the sensors heat

up on their own, the temperature com-

pensation reaches its optimum working

point after approx. 30 minutes of opera-

tion.

■If an object is within the set window

margins of the analogue output, then

LED D1 lights up green, if the object is

outside the window margins, then LED

D1 lights up red.

■The load put to the analogue output is

detected automatically when turning

supply voltage on.

■If the signal at the Com line does not

change for 20 seconds during parameter

setting mode the made changes are sto-

red and the sensor returns to normal

mode operation.

■You can reset the factory settings at any

time, see »Lock Teach-in & factory set-

ting«.

■lcs-sensors optional can be programmed

using the LinkControl adapter LCA-2,

see «Optional setting of parameters

using the LinkControl Adapter LCA-2».

MV-DO-074366-184870

89/336/EEC

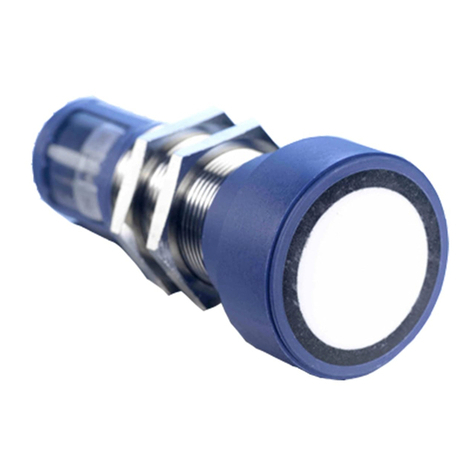

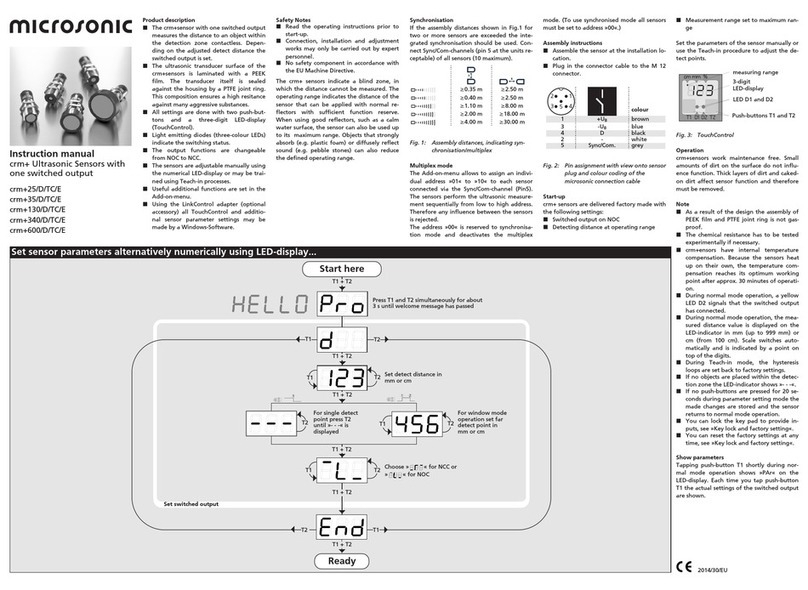

Lock Teach-in & factory setting

Activate/deactivate

Teach-in

Reset to factory

setting

Turn supply voltage OFF

While Com is connected

to -UBturn on

ower su

l

Turn supply voltage OFF

While Com is connected

to -UBturn on

ower su

l

Keep Com connected to

-UBuntil both LEDs flash

simultaneously

(ca. 3 s)

LED D1:

LED D2:

on: Teach-in

activated

off: Teach-in

deactivated

flashes

To activate or

deactivate Teach-in

connect Com to -UBfor

about 1 s

Wait for 10 s

Keep Com connected to

-UBuntil both LEDs

stop flashing

(ca. 13 s)

Normal mode operation

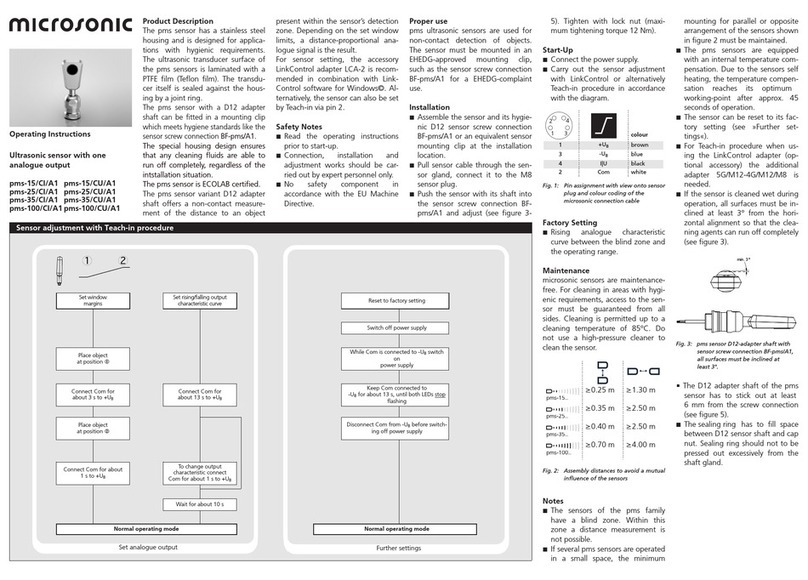

Sensor ad

ustment with Teach-in

rocedure

Set window margins

Place object at position ➀

Set rising/falling output

characteristic curve

Connect Com to +UBuntil both LEDs flash

simultaneousl

(ca. 3 s)

Both LEDs:

Place object at position ➁

flash

mutually

Connect Com to +UB

for about 1 s

Connect Com to +UBuntil both LEDs flash

mutuall

(ca. 13 s)

LED D2:

LED D1:

flashes

an: rising /

aus: falling output

characteristic curve

To change output characteristic connect

Com to +UB

for about 1 s

Wait for 10 s

Normal mode operation

Set analogue output

www.hemomatik.se

Ordertel 08-771 00 04 Växel 08-771 02 20

Orderfax 08-771 62 00

Länna, S-142 50 SKOGÅS (Stockholm)

Teknisk 08-771 35 80