Operating Instructions

Ultrasonic sensor with one

analogue output

pms-15/CI/A1 pms-15/CU/A1

pms-25/CI/A1 pms-25/CU/A1

pms-35/CI/A1 pms-35/CU/A1

pms-100/CI/A1 pms-100/CU/A1

Product Description

The pms sensor has a stainless steel

housing and is designed for applica-

tions with hygienic requirements.

The ultrasonic transducer surface of

the pms sensors is laminated with a

PTFE film (Teflon film). The transdu-

cer itself is sealed against the hous-

ing by a joint ring.

The pms sensor with a D12 adapter

shaft can be fitted in a mounting clip

which meets hygiene standards like the

sensor screw connection BF-pms/A1.

The special housing design ensures

that any cleaning fluids are able to

run off completely, regardless of the

intstallation situation.

The pms sensor is ECOLAB certified.

The pms sensor variant D12 adapter

shaft offers a non-contact measure-

ment of the distance to an object

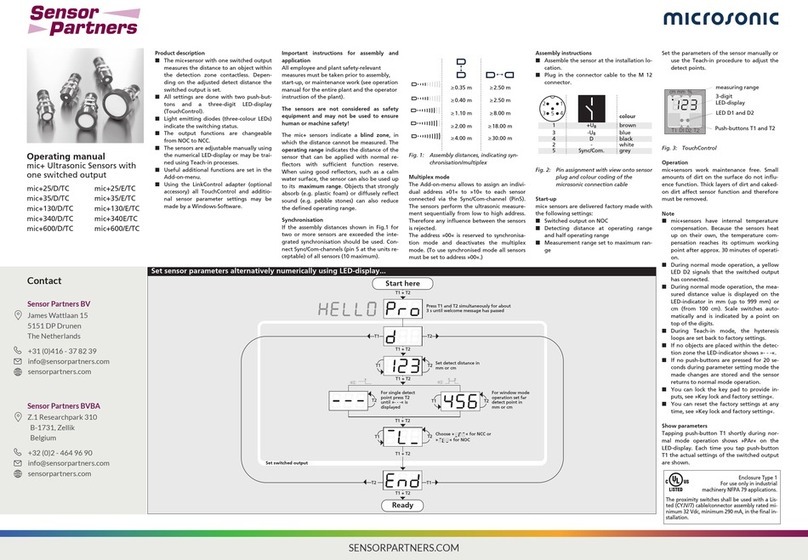

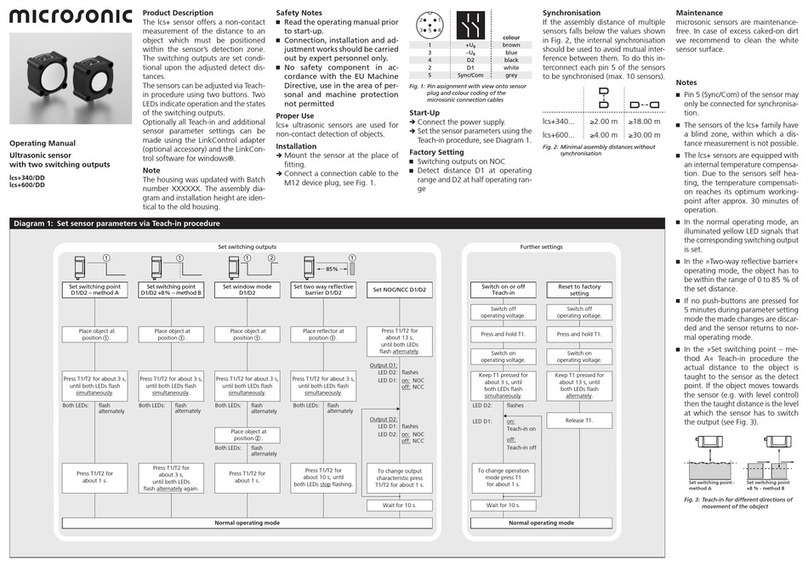

Sensor adjustment with Teach-in procedure

Place object

at position

Connect Com for

about 3 s to +UB

Place object

at position

Connect Com for about

1 s to +UB

Set rising/falling output

characteristic curve

Connect Com for

about 13 s to +UB

To change output

characteristic connect

Com for about 1 s to +UB

While Com is connected to -UBswitch

on

power supply

Keep Com connected to

-UBfor about 13 s, until both LEDs stop

flashing

Disconnect Com from -UBbefore switch-

ing off power supply

present within the sensor’s detection

zone. Depending on the set window

limits, a distance-proportional ana-

logue signal is the result.

For sensor setting, the accessory

LinkControl adapter LCA-2 is recom-

mended in combination with Link-

Control software for Windows©. Al-

ternatively, the sensor can also be set

by Teach-in via pin 2.

Safety Notes

Read the operating instructions

prior to start-up.

Connection, installation and

adjustment works should be car-

ried out by expert personnel only.

No safety component in

accordance with the EU Machine

Directive.

Proper use

pms ultrasonic sensors are used for

non-contact detection of objects.

The sensor must be mounted in an

EHEDG-approved mounting clip,

such as the sensor screw connection

BF-pms/A1 for a EHEDG-complaint

use.

Installation

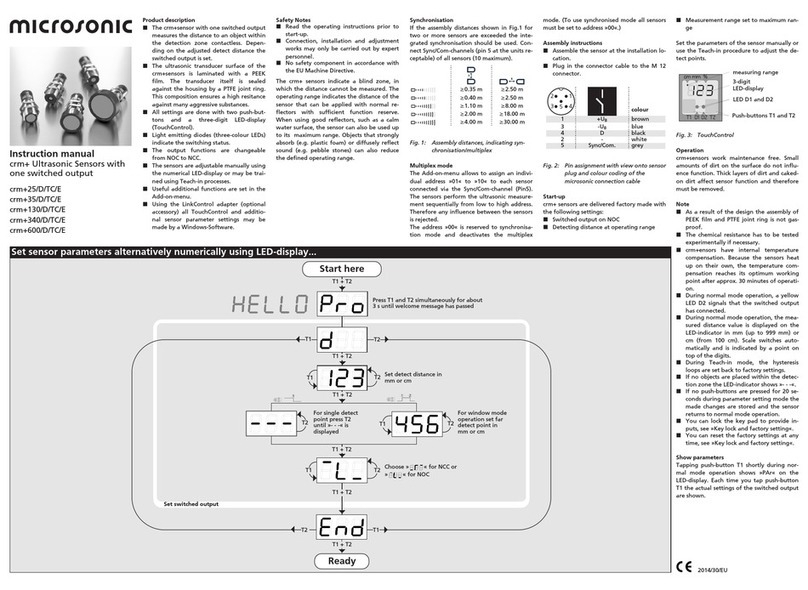

Assemble the sensor and its hygie-

nic D12 sensor screw connection

BF-pms/A1 or an equivalent sensor

mounting clip at the installation

location.

Pull sensor cable through the sen-

sor gland, connect it to the M8

sensor plug.

Push the sensor with its shaft into

the sensor screw connection BF-

pms/A1 and adjust (see figure 3-

5). Tighten with lock nut (maxi-

mum tightening torque 12 Nm).

Start-Up

Connect the power supply.

Carry out the sensor adjustment

with LinkControl or alternatively

Teach-in procedure in accordance

with the diagram.

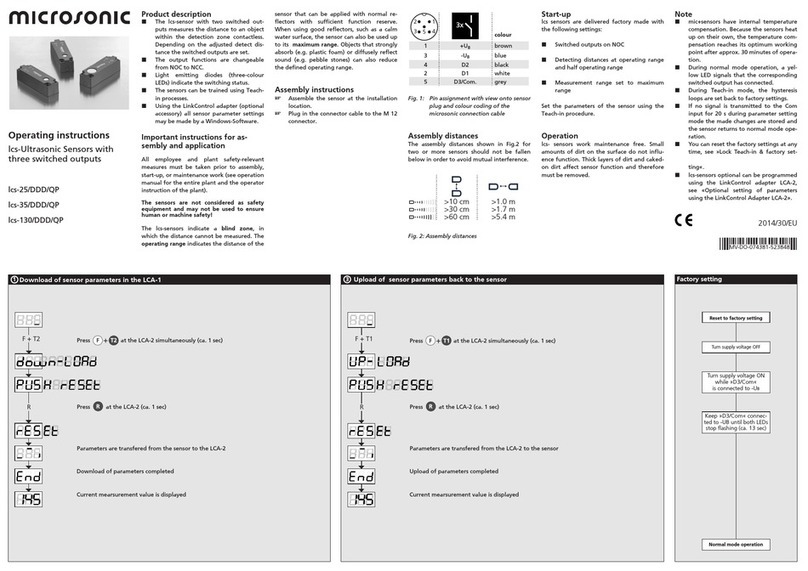

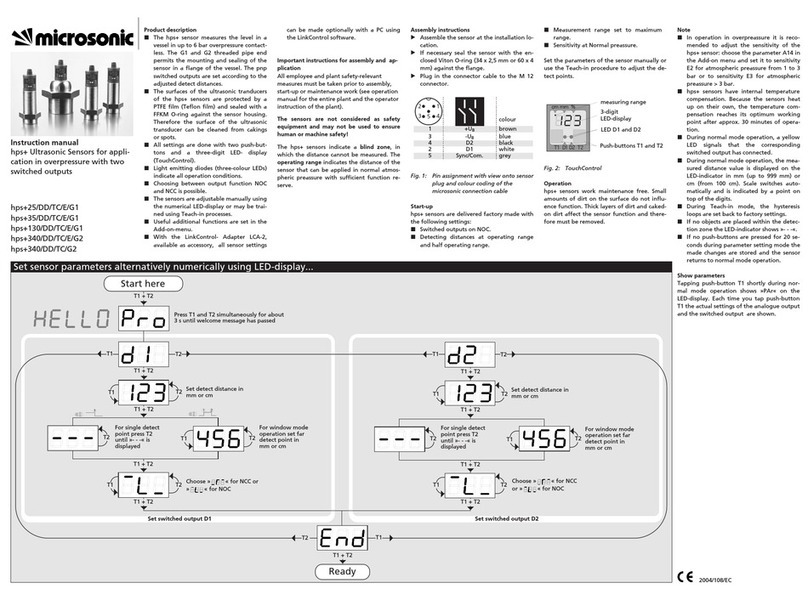

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cable

Factory Setting

Rising analogue characteristic

curve between the blind zone and

the operating range.

Maintenance

microsonic sensors are maintenance-

free. For cleaning in areas with hygi-

enic requirements, access to the sen-

sor must be guaranteed from all

sides. Cleaning is permitted up to a

cleaning temperature of 85°C. Do

not use a high-pressure cleaner to

clean the sensor.

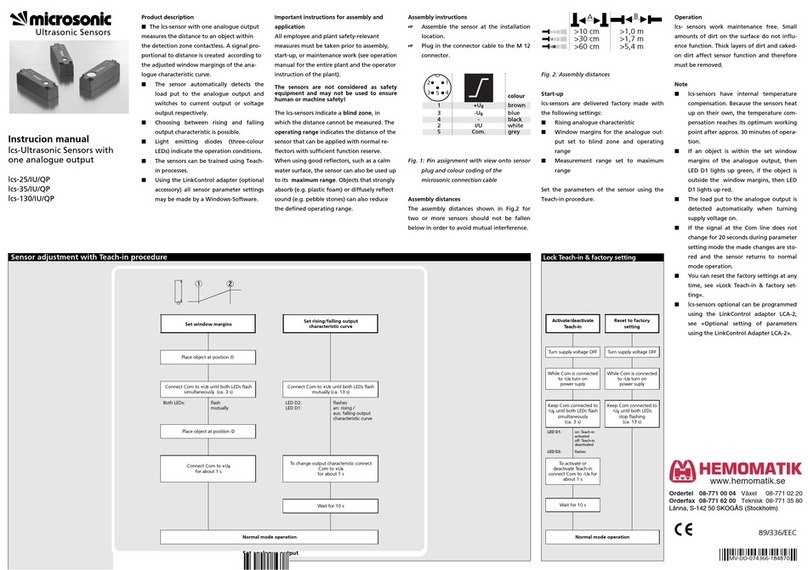

Fig. 2: Assembly distances to avoid a mutual

influence of the sensors

Notes

The sensors of the pms family

have a blind zone. Within this

zone a distance measurement is

not possible.

If several pms sensors are operated

in a small space, the minimum

brown

blue

4

2

I|U

Com

black

white

mounting for parallel or opposite

arrangement of the sensors shown

in figure 2 must be maintained.

The pms sensors are equipped

with an internal temperature com-

pensation. Due to the sensors self

heating, the temperature compen-

sation reaches its optimum

working-point after approx. 45

seconds of operation.

The sensor can be reset to its fac-

tory setting (see »Further set-

tings«).

For Teach-in procedure when us-

ing the LinkControl adapter (op-

tional accessory) the additional

adapter 5G/M12-4G/M12/M8 is

needed.

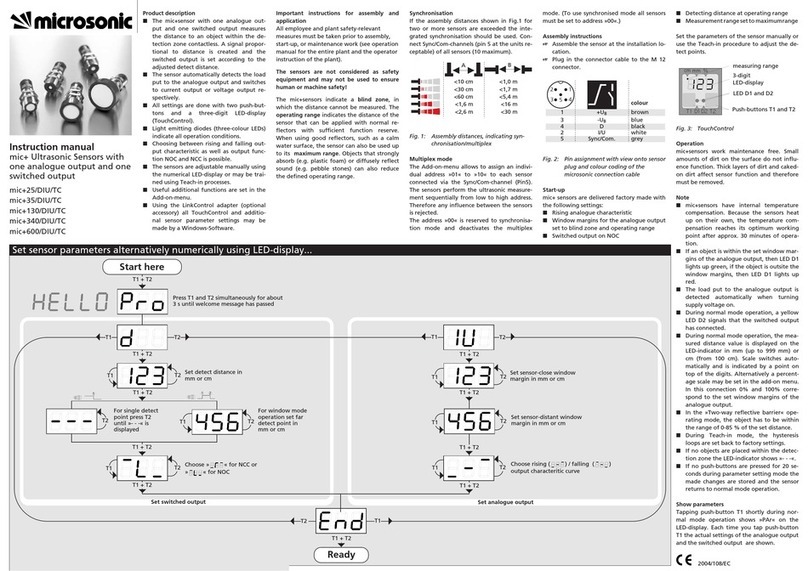

If the sensor is cleaned wet during

operation, all surfaces must be in-

clined at least 3° from the hori-

zontal alignment so that the clea-

ning agents can run off completely

(see figure 3).

Fig. 3: pms sensor D12-adapter shaft with

sensor screw connection BF-pms/A1,

all surfaces must be inclined at

least 3°.

■The D12 adapter shaft of the pms

sensor has to stick out at least

6 mm from the screw connection

(see figure 5).

The sealing ring has to fill space

between D12 sensor shaft and cap

nut. Sealing ring should not to be

pressed out excessively from the

shaft gland.