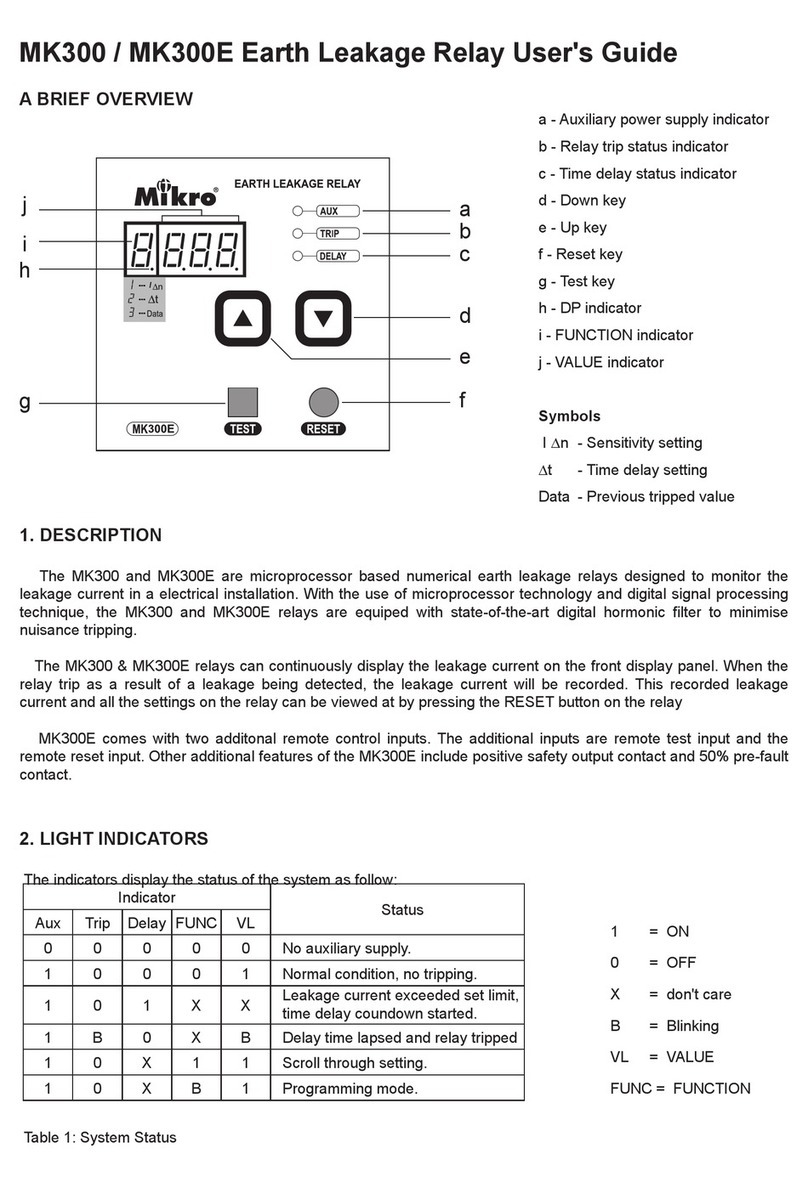

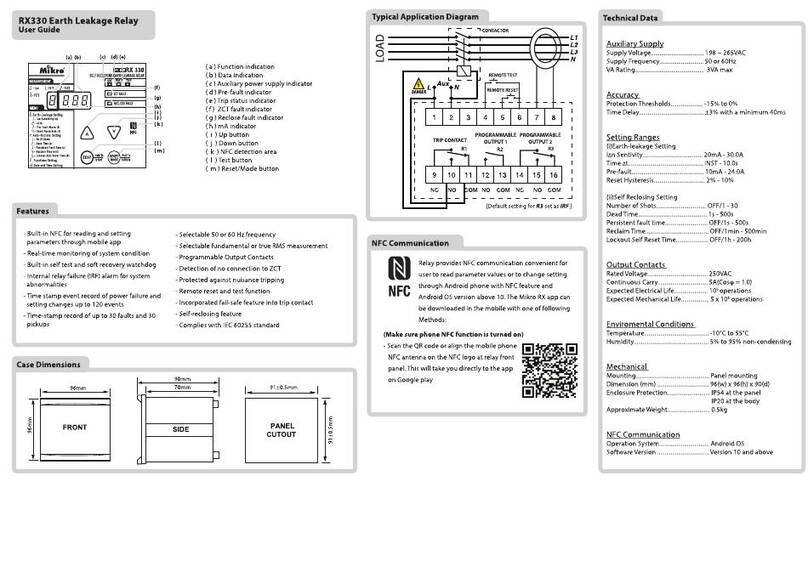

e. Parameters Setting

•Step 1: Press [RESET] button to step to desired [FUNC] or parameter.

•Step 2: Press [ ] and [ ] buttons simultaneously and hold for 1.5s to enter programming mode.

The [FUNC] digit blink to indicate the relay has enter into the programming mode.

•Step 3: Press [ ] or [ ] button to increase or decrease the parameter value.

•Step 4: To save the selected value, press [ ] and [ ] buttons simultaneously and hold for 1.5s. It

will exit the programming mode with [DATA] displaying the new setting.

To exit programming mode without saving the selected setting, press the [[RESET] button once.

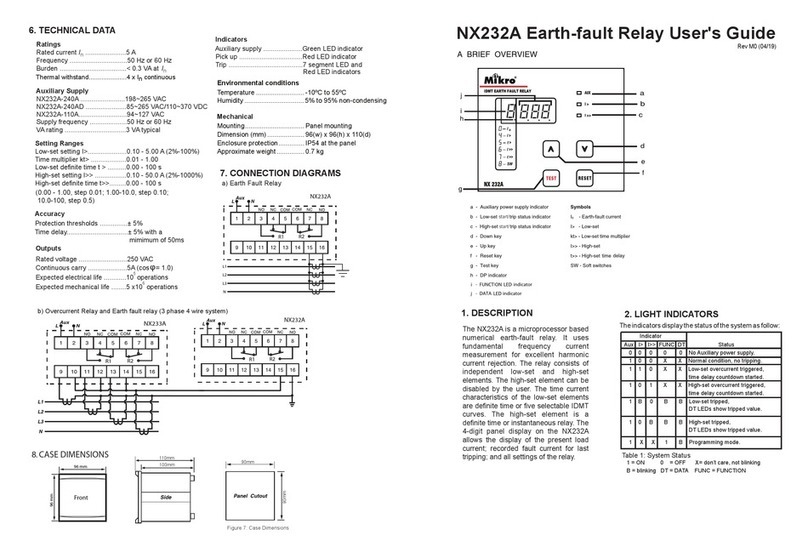

4. DIGITAL INPUT PORT *

a. This digital port is for remotely reset the relay when tripped or ZCT connection fault.

b. To reset the relay, make a connection between terminals 4 and 5 of the relay.

5. OUTPUT CONTACTS

Activated and latch by leakage fault trip, manual test trip or ZCT connection fault

Contact *

Activated when the relay is power up and function correctly with no tripping.

Pre-fault Alarm

Contact * Activated when the measured leakage current > 50% of the I∆n and self reset when the

measured leakage current < 45% of the I∆n.

Activated and latch when the relay is tripped.

Table 3: Output contact description

6. RECORDS

a. Record the 3 latest tripped faults current or “tSt” for manual trip test.

b. The records are stored in non-volatile memory.

c. To clear the entire record database:

•Step 1: When the relay is healthy, press [RESET] button to step to most recent trip fault record or

[FUNC] digit shown “A”.

•Step 2: Press [ ] and [ ] buttons simultaneously and hold for 3.5s or the [DATA] show “0”. It will

clear the entire fault records database.

7. TECHNICAL DATA

AUXILIARY SUPPLY

DIN310-230A(6)............................................................. 184~276 VAC

DIN310E-230A(6)...........................................................184~276 VAC

Rated frequency............................................................. 50Hz or 60Hz

VA rating.........................................................................3 VA typical

SETTING RANGES

Sensitivity adjustment.....................................................30mA, 50mA,

0.10~1.00A (step=50mA),

1.00~10.0A (step=1.00A)

Delay time adjustment....................................................Instantaneous,

0.1~3.0s (step=0.1s)

RECORD

Fault record.................................................................... 3 latest trip fault current or “tSt” for manual trip test

Storage...........................................................................Non-volatile memory

DIGITAL INPUT PORT

Remote reset..................................................................N.O. Dry contact

OUTPUT CONTACTS

Contact rating................................................................. 5A(NO) / 3A(NC) / 250V AC1

Contact arrangement......................................................Change over

Expected electrical life....................................................10,000 at rated current

Expected mechanical life................................................5,000,000 operations

▲▼

▲▼

▼

▲

▲▼