Mikro MPR500 User manual

MPR500 Motor Protection Relay User's Guide

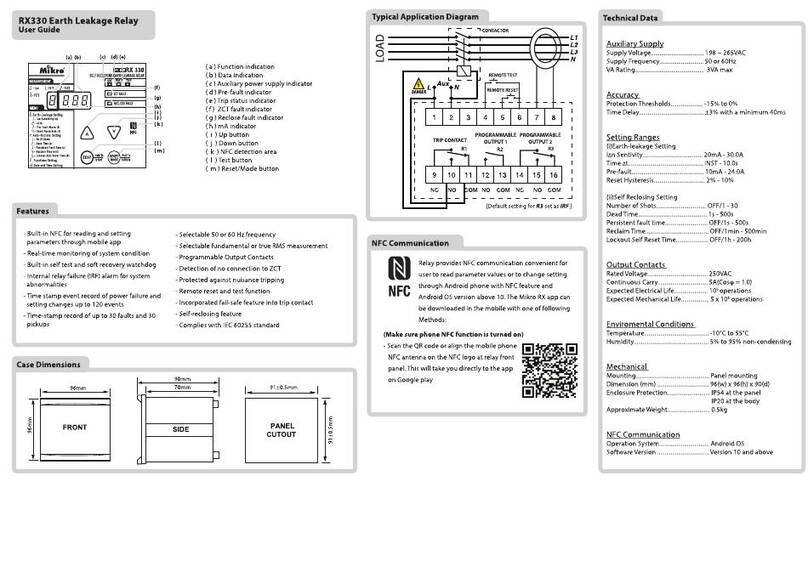

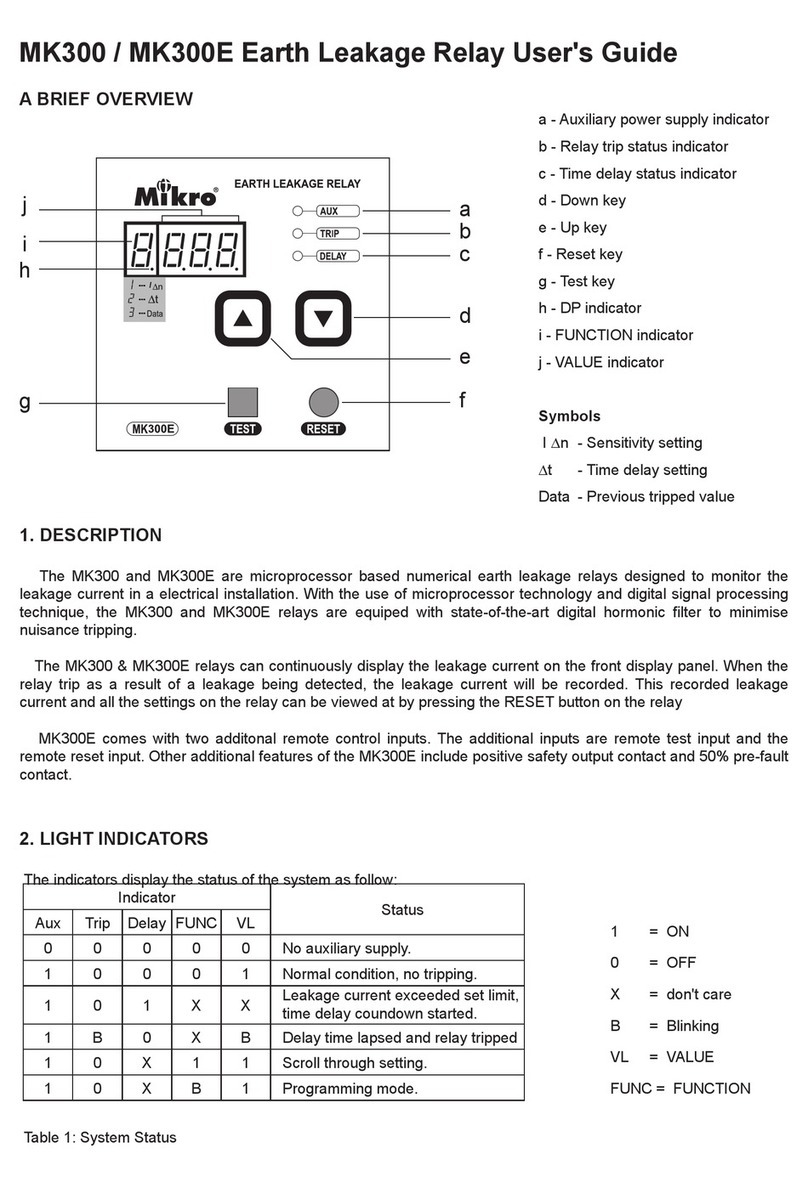

Brief Overview

a

b

c

d

e

f

g

h

a – Run LED

b – Trip/Pickup LED

c – Thermal LED

d – Down key

e – Up key

f – Reset/Mode key

g – Test key

h – Data LED

i – Function LED

1. General Description

MPR500 is a motor protection relay that combines

thermal overload, short circuit, undercurrent, unbalance,

phase loss, phase sequence, lock/stall rotor and earth

fault protections.

MPR500 incorporates a 4-digit LED indicator which

allows direct numerical readout of set values, actual

measured value and system indication.

MPR500 has 2 relay outputs (R1 and R2). R1 is On

under normal operating condition to allow motor running,

and off during tripping. R2 is programmable to give signal

in various conditions.

A programmable binary input is provided to perform

various operations upon binary input triggering.

2. Display

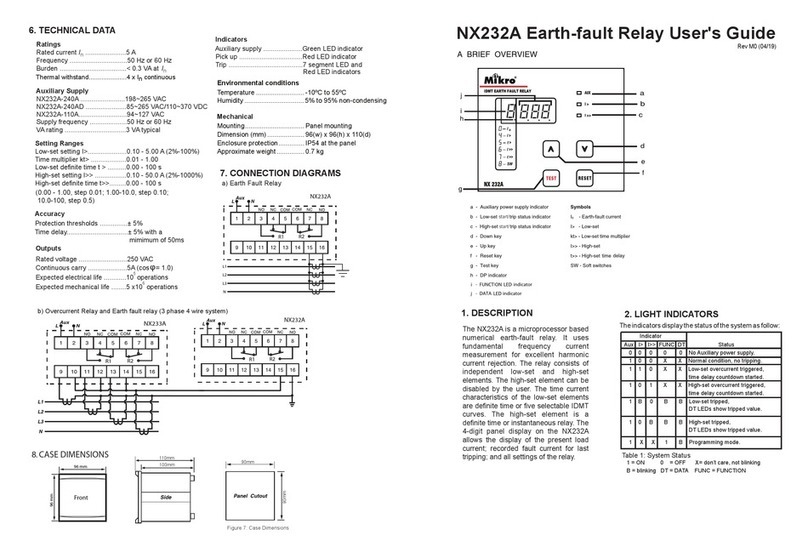

2.1 Current and Thermal Capacity Display

During power up, when the relay is not under tripping

condition, the display shows current in ampere or

thermal capacity %. The Function LED indicates which

parameter is being displayed. The Data LED showing

value.

Press “UP” or “DOWN” to scroll through the parameters.

1

Motor

Protection

Relay

t

>>

I

<<

t

<<

t

6X

t

Start

I

o

>>

t

o

>>

CT

t

Stall

I

B

t

SW

I

>>

I

S

>>

i

Symbols

t6X – Thermal overload time constant

I>> – Short circuit/High set Overcurrent

t>> – Short circuit/High set Overcurrent

delay time

I< – Undercurrent

t< – Undercurrent delay time

– Unbalance

t – Unbalance delay time

I0> – Earth fault

t0> – Earth fault delay time

IS>> – Prolonged starting/stall rotor

tStart – Prolonged starting delay time

tStall – Stall rotor delay time

IB – Base/full load current

CT – External current transformer ratio

SW – Soft switch

IL1

IL2

IL3

I0

Thermal

Figure 1: Front panel overview

Figure 2: Current and thermal capacity display

For current more than 1000A, a dot is shown behind

least significant digit. Eg: 1.25. = 1.25kA

IL1 - Phase 1 current

IL2 - Phase 2 current

IL3 - Phase 3 current

I0- Zero sequence/Earth fault current

Thermal % - Thermal capacity % (Thermal overload trip-

ping at 100%)

During Thermal capacity display, thermal capacity can be

cleared to 0% by pressing "UP" and "DOWN" simultane-

ously for longer than 1.5 seconds.

Warning: Clearing thermal capacity effectively reset

to cold start condition, user is not encouraged to

clear thermal capacity unless it is sure that motor is

cool enough to run/start within its thermal limit.

V1.3

2.2 Auto Scroll

When auto scroll is enabled, the display scrolls between

currents and thermal reading every 10 seconds. To

toggle auto scroll mode, press "UP" and "DOWN"

simultaneously.

2.3 LED Display

a) Run LED

Run LED shows the motor status. Refer to 3.2.1 Motor

Starting.

2

Off

Motor stopping

Blink

Motor starting

On

Motor running

b) Trip LED

Trip LED is normally off. During tripping pickup, where

tripping delay is counting down, Trip LED blinks. Trip

LED on during tripping.

Off

Normal

Blink

Pickup

On

Tripping

c) Thermal LED

Thermal LED blinks when motor current is more than

105% of IB. Thermal LED on during thermal overload

tripping, and when thermal capacity is more than 40%

after overload tripping (in which R1 is off, motor not

allowed to start)

Off

Normal

Blink

Thermal overload warning

On Thermal overload tripping

3. Settings and Protection Features

3.1 Setting Display

When the relay is not under tripping condition, pressing

"RESET/MODE" will scroll through various settings.

Function LED showing number or alphabet to indicate

which setting is being view as shown in Figure 3. Table 1

gives description of each setting.

Tip: To quickly jump back to current/thermal display

during setting display, press and hold "RESET/MODE"

for 1.5 second.

1 t6X Thermal overload time constant

Current/Thermal Display

3 t>> Short circuit delay time

4 I<< Undercurrent

5 t<< Undercurrent delay time

2 I>> Short circuit

b t Start >> Prolonged starting delay

time

7 t Unbalance delay

time

A IS>> Prolonged starting / stalled rotor

8 I0>> Earth fault

6 Unbalance

9 t0>> Earth fault delay time

Tripping History

c t >> Stalled rotor delay

time

d IB

Base/full load current

E External CT ratio

F1 Auto/Manual Reset

F2 Binary input

F3 Relay 2 function

Stall

Figure 3: Display mode when pressing

Reset/Mode

F4 Phase Sequence/ Phase Loss option

F5 Frequency

Thermal LED will on if after thermal trip and user press reset but thermal % still > 40%

Thermal capacity high, R1 off

3.2 Programming Setting

Step 1: Press "RESET/MODE" until the Function LED shows the required setting.

Step 2: Press "UP" and "DOWN" simultaneously toenter programming mode.

The Function LED blinks to indicate the relay is in programming mode.

Step 3: Press "UP" or "DOWN" to change the value.

Step 4: To save the new value, press "UP" and "DOWN" simultaneously again. Programming mode exits,

function LED stop blinking.

To exit programming mode without saving, press "RESET/MODE" once

3

Setting

Function

Setting Range

Description

1

t6X Thermal overload

time constant

1-40s. In steps of 0.1s

for 1-10s, in steps of

1s for 10-40s.

Time constant for thermal overload

2

I>> Short circuit

off, 2-12 x IB. In steps

of 1 x IB

Short circuit setting in multiples of IB

3

t>> Short circuit delay

time

0-25s. In steps of 0.1s

for 0-10s, in steps of

1s for 10-25s

Delay time for short circuit

4

I<< Undercurrent

off, 20-90% of IB. In

steps of 1%

Undercurrent setting in % of IB

5

t<< Undercurrent delay

time

0-60s. In steps of 0.1s

for 0-10s, in steps of

1s in 10-60s.

Delay time for undercurrent

6

Unbalance

off, 10-50%. In steps

of 1%

Phase unbalance setting in %

7

t Unbalance delay

time

0-25s. In steps of 0.1s

for 0-10s, in steps of

1s for 10-25s.

Delay time for phase unbalance

8

I0>> Earth fault

off, 10-60% of IB. In

steps of 1%

Earth fault setting in % of IB

9

t0>> Earth fault delay

time

0-25s. In steps of 0.1s

for 0-10s, in steps of

1s for 10-25s.

Delay time for earth fault

A

IS>> Prolonged starting

/stalled rotor

off, 2-12 x IB. In steps

of 0.1 x IB

Prolonged starting/stalled rotor setting in

multiples of IB

b

tStart >> Prolonged

starting delay

time

0-60s. In steps of 0.1s

for 0-10s, in steps of

1s for 10-60s.

Delay time for prolonged starting

c

tStall>> Stalled rotor

delay time

0-60s. In steps of 0.1s

for 0-10s, in steps of

1s for 10-60s.

Delay time for stalled rotor

d

IBBase/full load current

2-10A

Base/full load current of motor

E

1-800:1

External CT ratio. 1=direct.

F1

Auto/Manual Reset

0 - Manual reset

1- Auto reset

Manual or auto reset of tripping

Thermal overload is always auto reset

F2

Binary input

0 - Block relay 1

1 - Reset tripping

2 - Instant tripping

Setting for binary input

F3

Relay 2 function

0 - On any tripping

1 - On thermal tripping

2 - On thermal

warning

Relay 2 function

Table 1: Description of settings

External CT ratio

F4 Phase sequence (PS)/

phase loss (PL) option

0 - PS and PL off

1 - PS on

2 - PL on

3 - PL and PS on

Phase sequence and phase loss option

F5 Frequency 50 or 60Hz Nominal value of network frequency

3.2.1 Motor Status

Run LED shows the motor status. Upon power on the

relay, if there is no tripping, Relay 1 turns on.

If motor current is more than 1.1 x IB, motor is

considered starting, Run LED blinks. If motor current is

less than 1.05 x IB, motor is running, Run LED on. Motor

is stopping when motor current drops below 0.1 x IB.

If motor starts abnormally for longer than 60s, Run LED

stops blinking and turns off, Relay 1 also turns off. This

condition reset when motor current drops below 0.1 x IB.

3.2.2 Thermal Overload

The protection is based on mathematical model of motor

thermal image. The thermal capacity is calculated

continuously when motor is starting, overloading or even

after tripping. Tripping takes place when the thermal

capacity of the motor reaches 100%. This could happen

when the motor current is higher than 1.05 x IB. After

tripping a new start is not allowed until the motor cools

down to less than 40% of thermal capacity. Thermal

capacity can be cleared to 0% by pressing "UP" and

"DOWN" simultaneously for longer than 1.5 seconds

during thermal capacity display.

Warning: Clearing thermal capacity effectively reset

to cold start condition, user is not encouraged to

clear thermal capacity until motor is cool enough to

start/run within its thermal limit.

3.2.3 t6X Thermal overload Time Constant

t6X sets the themal overload time constant (heating

constant), which is the maximum period of time when

motor current is allowed to reach a 6 x IB. Cooling

constant time is defined as 4 times of heating constant

time and is applicable when motor current is less than

0.2 x IB. Refer to the thermal tripping curve on Figure 4.

3.2.4 Short Circuit

This protection is to trip the relay quickly when high

current is detected due to short circuit. I>> is normally

set higher than motor starting current to avoid false

tripping during motor starting and t>> is set to very short

duration.

Tripping takes place when any phase of motor current is

larger than I>> for longer than t>>. It can be disabled by

setting t>> to 'off'.

3.2.5 Undercurrent

Undercurrent protection is activated when average motor

current is larger than 0.1 x IB. Tripping takes place when

average motor current is smaller than I<< for longer than

t<<. It can be disabled by setting t<< to 'off'.

4

(a) With 0% thermal capacity (cold start)

time

t6x

I/IB

10s

1s

2s

3s

5s

21 3 4

5

6

20s

30s

40s

1min

2min

3min

5min

10min

20min

30min

1hour

2hour

2s

5s

10s

20s

30s

40s

1s

where:

Imax is the maximum phase current among the 3 phases.

Imin is the minimum phase current among the 3 phases.

Tripping takes place when unbalance value is more than

unbalance setting % for longer than unbalance delay. It

can be disabled by setting unbalance delay to 'off'.

time

t6x

I/IB

10s

1s

2s

3s

5s

20s

30s

40s

1min

2min

3min

5min

10min

20min

30min

1hour

2hour

2s

5s

10s

20s

30s

40s

1s

Figure 4: Thermal tripping curve

(b) With prior 50% thermal capacity

3.2.6 Unbalance

Unbalance is calculated as:

Imax - Imin

Imin

X 100 %

21 3 4

5

6

1.05

1.05

3.2.12 External CT Ratio

The CT ratio shall be set accordingly for the display to

show primary current. For example when using 150/5

CT, set the value to:

5

3.2.7 Phase Loss

Phase loss fault is detected when average motor current

is larger than 0.28 x IBbut any phase current is less than

0.1 x IB. Tripping takes place in less than 120ms when

phase loss is detected.

3.2.8 Phase Sequence

Phase sequence fault is detected when the phase

sequence in any 2 or all the phases are reversed.

Tripping takes place in less than 120ms when phase

sequence fault is detected.

Phase loss and phase sequence protection can be

enabled and disabled separately. Refer to

3.2.16 Phase

sequence / phase loss option

3.2.9 Prolonged Starting and Stalled Rotor

For prolonged starting and stalled rotor there is one IS>>

setting and separate delay time setting for each

protection. IS>> shall be set below the motor starting/

stalled current. These protections are useful when

thermal overload protection is not fast enough to protect

the motor during stalling.

Delay time for prolonged starting, tStart>> shall be set

longer than specified motor starting time. Tripping takes

place when any phase current is larger than IS> for

longer than tStart during motor starting.

Delay time for stalled rotor, tStall>> is activated upon

completing the motor starting. Tripping occurs when any

phase current is larger than IS>> for longer than tStall>>

during motor running.

Both protections can be disabled by setting IS>> to 'off'.

To disable only one of the protection, set the respective

delay time for the protection to be disabled to much

longer than specified.

3.2.10 Earth Fault

Earth fault protection is based on zero sequence current

calculation. Tripping takes place when the current is

larger than earth fault setting in % of IBfor longer than

t0>. It can be disabled by setting t0>> to 'off'.

3.2.11 Base Current

Base current is the motor full load current. The range of

setting is model dependent.

The formula is:

For example to use the relay with motor that has full load

current of 138A, using external CT of 150/5,

Motor full load current

IB = X CT ratio

1

138

= 4.6A

IB =

5

150

X

150

5

= 30

3.2.13 Manual or Auto Reset

The relay can be set to manual or auto reset when the

relay trips. Resetting of relay is allowed when the tripping

condition cleared. Manual reset is performed by pressing

the "RESET/MODE" (or using binary input if it is

configured as 1 - Reset trip). Thermal overload is always

auto reset.

3.2.14 Binary Input

The binary input is a dry contact input that can be

configured to perform various functions.

0 - Block relay 1

The input, when triggered, will force relay 1 off.

1 - Reset tripping

The input is used to manually reset a tripping.

2 - Instant tripping

The input will generate a tripping condition. Refer to

4.4 Binary Input Tripping.

3.2.15 Relay 2

The relay 2 output can be configured to turn on in these

conditions:

0 - On any tripping

Relay 2 on during any tripping.

1 - On thermal tripping

Relay 2 on during thermal tripping only.

2 - On thermal warning

Relay 2 on when motor current is more than 1.05 x IB.

3.2.16 Phase sequence / phase loss option

Phase sequence and phase loss detection can be on

(enabled) and off (disabled) separately.

0 - Phase sequence and phase loss off

1 - Phase sequence on

2 - Phase loss on

3 - Phase sequence and phase loss on

3.2.17 Frequency

Nominal value of the network frequency. Select either 50

or 60 Hz.

External CT ratio =

6

4. Tripping

4.1 Tripping Display

During tripping, Trip LED on, Thermal LED also on

during thermal overload tripping. Function LED and Data

LED blinks showing tripping current or source as shown

below:

4.2 Tripping Reset

During tripping condition, press "RESET/MODE" to

reset, the relay will reset if condition permits. If relay is

set to auto reset, the relay will reset automatically if the

tripping condition is cleared with a 5% hysteresis.

4.3 Tripping Test

Press and hold "TEST" for 3.5 seconds to simulate a

tripping condition, Trip LED blinks when "TEST" is

pressed. During Test Tripping, "tESt" blinks, R1 off and

R2 on if set to "On any tripping". Press "RESET/MODE"

to reset. Tripping Test is disabled when motor is

starting/running.

4.4 Binary Input Tripping

When Binary input is set to 2 - Instant tripping, binary

input will generate a tripping condition. "triP" will blink,

R1 off and R2 on if set to "On any tripping". Press

"RESET/MODE" to reset. If relay is set to auto reset, the

relay will reset after the input is normal for 1s.

4.5 Tripping History Display

During Current/Thermal display, press "RESET/MODE"

to jump to Tripping History Display. Display shows the

previous tripping status with a 'dot' blinking at Function

LED. To clear tripping history, press "UP" and "DOWN"

simultaneously.

5. Typical Application Diagram

Trip LED

Thermal

LED

Function

LED

Data LED

Description

On

On

t

oL

Thermal Overload

On

Off

2

tripping current

Short circuit tripping

On

Off

4

tripping current

Undercurrent tripping

On

Off

6

Ub

Unbalance tripping

On

Off

6

PS

Phase sequence error

tripping

On

Off

6

PL

Phase loss tripping

On

Off

8

tripping current

Earth fault tripping

On

Off

A

tripping current

Prolonged

starting/Stalled rotor

tripping

On

On

t

ESt

Trip Test

On

Off

t

riP

Binary input tripping

Aux

6

2

3

4

5

L

R1

R2

N

9

10

11

12

13

14

7

15

8

16

1

MPR 500

Table 2: Tripping display

L1

L2

L3

M

K1

N

K1

H1

S2

S1 K1

BlockR1/

Reset/

Trip

Start

Stop

NO

NC

COM

COM

NC

NO

Binary

input

Figure 5: Example of application

F1F2F3

F4

tripping

3-Phase Motor

Aux

6

2

3

4

5

L

R1

R2

N

9

10

11

12

13

14

7

15

8

16

1

MPR 500

L

M

K1

N

K1

H1

S2

S1

K1

Block R1/

Reset/

Trip

Start

Stop

NO

NC

COM

COM

NC

NO

Binary

input

F1

F2

Single-Phase Motor*

* To use MPR500 for single-phase protection, Io>> Earth

fault, Phase sequence and phase loss protection should be

set to off.

Figure 6

7

6. Techinical Data

SETTING RANGES

Thermal Overload time constant, t6X

Short circuit, I>>

Short circuit delay time, t>>

Undercurrent, I<<

Undercurrent delay time, t<<

Unbalance,

Unbalance delay time, t

Earth fault, I0>>

Earth fault delay time, t0>>

Phass loss

Phase sequence

Prolonged starting/stalled rotor, IS

Prolonged starting delay time, tStart

Stalled rotor delay time, tStall

CT RATINGS

Rated current

Rated frequency

Burden

Thermal withstand

BINARY INPUT

Rated input voltage

AUXILIARY SUPPLY

Model MPR 500-240A

Supply frequency

Maximum power consumption

CONTACTS

Contact arrangement

Contact rating

Contact material

Operating time

Expected electrical life

Expected mechanical life

INDICATORS

Run

Trip/Pickup

Thermal

ENVIRONMENTAL CONDITIONS

Temperature

Humidity

MECHANICAL

Mounting

Front panel

Approximate weight

CASE DIMENSION

110mm

100mm

90mm

90mm

96 mm

96 mm

Front

: 1

–

40s. In steps of 0.1s for 1-10s, in steps of 1s for 10-40s

: off, 2

–

12 x IB. In steps of 1 x IB

: 0

– 25s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-25s

: off, 20 – 90% of IB.

In steps of 1%

: 0 – 60s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-60s

: off, 10 – 50%. In steps of 1%

: 0 – 25s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-25s

: off, 10 – 60% of IB. In steps of 1%

: 0 – 25s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-25s

: <120ms

: <120ms

: off, 2 – 12 x IB.

In steps of 0.1 x IB

: 0 – 60s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-60s

: 0 – 60s.

In steps of 0.1s for 1-10s, in steps of 1s for 10-60s

: 2-10A

: 50 or 60Hz

: <0.3VA at rated current

: Continuous: 2 x maximum rated

For 30s: 6 x maximum rated

For 1s: 10 x maximum rated

: 12V (Supplied internally)

: 85 ~ 265 V AC

110 ~ 370 V DC

: 50 or 60 Hz

: 3 VA typical

: Change-over

: 5A, 250V AC (cosf = 1)

: Silver alloy

: 15ms max

: 100,000 operations at rated current

: 5 x 106operations

: Green indicator

: 7-segment display and red indicators

: Yellow indicator

: -5ºC to +55ºC

: 56 days at 93% RH

and 40ºC non-condensing

: Panel mounting

: Standard DIN

96 mm x 96mm

: 0.75kg

Table of contents

Other Mikro Relay manuals