Mikro MK 3000L User manual

MK 3000L

V1.1

Combined Overcurrent and Earth Fault Relay

3 stages phase overcurrent and earth fault

IDMT and definite time

Thermal overload protection

Fault, alarm and event records with timestamp

Disturbance records

CB Maintenance

Multi-shot autoreclose

Trip circuit supervision

RS232 and RS485 MODBUS-RTU communication

Negative sequence overcurrent

Circuit breaker open/close control

Programmable LED

Inrush blocking

2

Table of Contents

1.0 Introduction...........................................................................................................3

1.1 Symbols and Definitions............................................................................................................3

1.2 Main Functions ..........................................................................................................................4

2.0 Front Panel.............................................................................................................5

2.1 LCD Display..............................................................................................................................5

2.2 Keypad.......................................................................................................................................5

2.3 LEDs ..........................................................................................................................................6

2.4 RS232 Port.................................................................................................................................6

2.5 Default Display..........................................................................................................................6

2.6 Alarm Condition.........................................................................................................................6

2.6.1 Alarm Auto Scrolling..............................................................................................................6

3.0 Password.................................................................................................................7

3.1 Password Protection...................................................................................................................7

3.2 Password Entry ..........................................................................................................................7

3.3 Changing Password....................................................................................................................7

4.0 Menus......................................................................................................................7

4.1 Menu Contents...........................................................................................................................7

MEASUREMENTS Menu...............................................................................................................9

RECORDS Menu...........................................................................................................................12

CONFIGURATION Menu.............................................................................................................14

PROTECTION G1 Menu ..............................................................................................................17

PROTECTION G2 Menu ..............................................................................................................22

INPUT Menu..................................................................................................................................22

OUTPUT Menu..............................................................................................................................24

COMMUNICATION Menu...........................................................................................................26

MISC CONTROL Menu................................................................................................................27

5.0 Functions and Descriptions................................................................................31

5.1 Circuit Breaker Failure Protection...........................................................................................31

5.2 Inrush Blocking........................................................................................................................31

5.3 Thermal Overload Protection...................................................................................................32

5.4 Trip Circuit Supervision...........................................................................................................33

5.5 Disturbance Recorder...............................................................................................................35

5.6 Autoreclose ..............................................................................................................................35

5.7 Open CB & Close CB Control.................................................................................................36

5.8 Characteristic Curves...............................................................................................................37

6.0 Case Dimensions..................................................................................................39

7.0 Connection Diagram and Terminal...................................................................39

7.1 Terminal Connection at Rear View..........................................................................................39

7.2 Typical Connection Diagram ...................................................................................................41

8.0 Technical Data......................................................................................................42

9.0 MODBUS Protocol..............................................................................................47

9.1 MODBUS Functions................................................................................................................47

9.2 MODBUS Register..................................................................................................................49

9.3 MODBUS Mapping Format ....................................................................................................57

3

1.0 Introduction

The purpose of this manual is to provide information necessary to install, operate and maintain the

Mikro MK3000L relay.

MK3000L provides protections for 3 independent phase overcurrent elements and one non-

directional earth-fault element. All these elements are connected to the current transformers of the

feeders to be protected. There are 2 sets of current inputs, for 1Aand 5A rated CTs.

The relay comes with liquid crystal display (LCD) with 2 x 16 back-lit alphanumerical characters

and 7 LEDs in which 4 of the LEDs are programmable. An 8 button keypad can be used to access

all measurements, alarm or trip records and settings. Dedicate Open CB (circuit breaker) and Close

CB button is used to manually open and close CB.

There is a RS232 port available on the front panel and a RS485 port on the rear terminals. Using

MODBUS RTU protocol, all stored information including alarm, trip and disturbance records can

be read and settings can be modified with a PC loaded with setting software.

MK3000L has 4 configurable output relays. They can be activated by any of the protection

functions available in the relay. There is also 1 output relay for internal fault indication. There are 2

configurable logic inputs for various functions.

1.1 Symbols and Definitions

In this manual and on the relay, unless the context otherwise requires, the following symbols and

abbreviations shall apply throughout:-

AC : Alternating current

Ack : Acknowledge

Alrm : Alarm

Aux : Auxiliary

CT : Current transformer

CB : Circuit breaker

CBFP : Circuit Breaker Failure Protection

Chg : Change

CLPU : Cold Load Pickup

DC : Direct current

Dmd : Demand

Dmnd : Demand

DMT : Definite time

EF : Earth fault

E/Gnd : Earth/Ground

Genrl : General

IDMT : Inverse definite minimum time

IL1 : Phase 1 current

IL2 : Phase 2 current

IL3 : Phase 3 current

I> : Phase overcurrent first threshold

I>> : Phase overcurrent second threshold

I>>> : Phase overcurrent third threshold

Io/IN : Earth (fault) current

Io> : Earth fault first threshold

Io>> : Earth fault second threshold

Io>>> : Earth fault third threshold

I2> : Negative sequence overcurrent first

threshold

I2>> : Negative sequence overcurrent second

threshold

Invrse : Inverse

Ip : Input

IRF : Internal Relay Failure

LED : Light emitting diodes

Lockd : Locked

OC : Overcurrent

OL : Overloaded

PU : Pickup

RCRD : Record

Reclsr : Recloser

Rmote : Remote

Rst : Reset

Strt : Start

TCS : Trip circuit supervision

Thml : Thermal

tI> : Phase overcurrent first threshold trip

tI>> : Phase overcurrent second threshold trip

tI>>> : Phase overcurrent third threshold trip

tIo> : Earth fault first threshold trip

tIo>> : Earth fault second threshold trip

tIo>>> : Earth fault third threshold trip

tI2> : Negative sequence overcurrent first

threshold trip

tI2>> : Negative sequence overcurrent

second threshold trip

1.2 Main Functions

The following table shows the functions available for MK3000L

ANSI codes Features

50P/51P Three-phase overcurrent

50N/51N Earth fault overcurrent

49RMS Thermal overload (True RMS)

46N Negative sequence overcurrent

Cold load pickup

Instantaneous/start contact

86 Latching output contacts

Setting groups

50BF Circuit breaker failure detection

74TC Trip circuit supervision

94/69 Circuit breaker monitoring and control

68 Blocking logic

Inrush blocking

Auxiliary timers

79 Multi-shot autoreclose

Test of output relays (maintenance)

CB control local/remote

General Features

Number of digital inputs 2

Number of outputs relays 5

Events recording 250

Fault recording 50

Alarms 30

Disturbance recording 6*

Setting group 2

Auxiliary timers 2

Communication ports Front RS232, Rear RS485

Communication Modbus RTU

Time synchronization Via communication port, via digital input

Measurements Currents values & frequency, max and average currents values

* Disturbance recording options: 6 x 3s, 4 x 4s, 3 x 5s, 2 x 7s, 1 x 9s

5

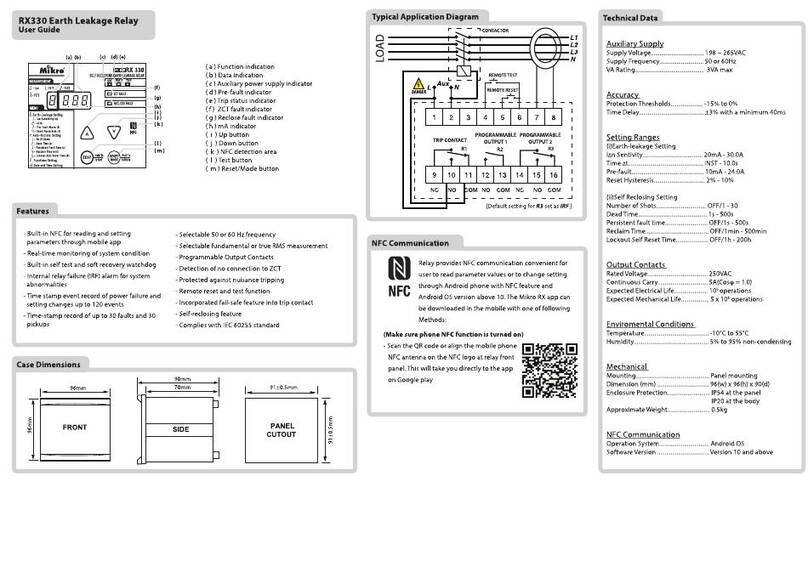

2.0 Front Panel

Using the front panel, the user can easily navigate through the user friendly menu, read

measurements and change settings. The relay status and alarm or trip records are displayed on the

back-lit LCD also.

MK3000L Front panel

2.1 LCD Display

The LCD has 2 lines with 16 characters each. Back light is on when a key is pressed and remain on

for predefined time duration. The brightness can be adjusted to suit the lighting conditions.

2.2 Keypad

There are 8 keys on the front panel.

Up, Down, Enter and Esc are used to navigate through the menus and adjust the settings.

Up : Scroll up the menus or increase setting value.

Down : Scroll down the menus or decrease setting value.

Esc : To exit from menus, submenus or to cancel setting value change. Press and

hold for 1.5 seconds to return to default display from any submenu.

Enter : To enter submenus or to confirm setting value change.

Clear : To reset tripping, reset latched relay. If “CLEAR” Scroll is enabled (under

Configurations-> Display menu) and during no alarm status, it can be

used to scroll through Phase Overcurrent and Earth Fault settings, and to

return to default display from any submenu if pressed and hold for 1.5

seconds.

Record : To display Alarm records. To display successive records, press Record key

again.

LCD Display

Keypad

Front

RS232

Port

Fixed

function

LED

Programmable

LED

6

Open CB : To open circuit breaker from front panel.

Close CB : To close circuit breaker from front panel.

2.3 LEDs

Aux LED : Indicates auxiliary power to the device

Trip LED : Indicates tripping.

Alarm LED : Blinks to indicate non acknowledge alarm (or tripping). Steady on when

the alarm is acknowledged by pressing any key

Programmable LED : 4 Programmable LED can be programmed to turn on when one or more

linked function trigger.

2.4 RS232 Port

The front panel RS232 port has the same MODBUS RTU protocol as the RS485 port on the rear

terminal, though with fixed communication settings: 38400bps, 1 stop bit, even parity, address 1.

All stored information can be read and settings can be modified with a PC loaded with the supplied

setting software.

2.5 Default Display

By default the LCD displays the current value measured for IL1, IL2, IL3 and Io. Input and output

status as well as date and time can be shown by pressing Up key or Down key to change the default

display page. Pressing Esc key always return to current value display.

As soon as an alarm or trip is detected, the display jumps to alarm record display to show the latest

record.

2.6 Alarm Condition

During an alarm or tripping condition, Alarm LED blinks. Alarm record pops up. Any keypress

change the Alarm LED to steady on.

Example of Alarm record title page, showing record 1 out of total 2

records. Press Enter to enter sub page for this record. Press

Record/Down to show next alarm. Press Up to show previous alarm.

Press Esc to return to Default Display. Press Clear to clear the alarm.

If the condition still persists, the alarm cannot be cleared.

Alarm record sub page, showing record date and time. Press

Esc/Enter/RECORD to return to Alarm Record title page.

Clearing all record menu is shown when Up is pressed during display

of Record 1's title page, or RECORD/Down is pressed during display

of Last records title page. Press Clear to clear all Alarm record or Esc

to cancel.

2.6.1 Alarm Auto Scrolling

10 seconds after alarm record pops up, the Alarm display will be auto scrolled to show sub page and

tI> trip 1/2

L2 500A

Date: 03/02/2015

Time: 08:23:44am

Clear all alarm?

Clear=CLEAR

7

subsequently next records until all the records are shown and repeats. Each page is shown for 5

seconds. Example when there are 2 alarm records:

Record 1 Title Page Record 1 Sub Page Record 2 Title Page Record 2 Sub Page Record

1 Title Page ….

Any key pressed stops auto scrolling. After 2 minutes of no activity, with which display still

showing the alarm record, auto scrolling starts again.

3.0 Password

3.1 Password Protection

Relay settings can be view anytime but locked from being changed. A password is required for

changing setting and CB Open, CB Close button pressed.

The password consists of four digit numbers. The factory default password is set as 0000.

The programming mode is indicated with the letter "P" on the right hand side of the display. The

letter "P" remains present as long as the password is active. (2 minutes if there is no key action).

3.2 Password Entry

The input of the password is requested as soon as a modification of a parameter is made or

Open/Close CB button is pressed. The user enters each one of the 4 digits by using up or down key

and validates each digit with Enter. If Esc is pressed in between, the password entering is

terminated.

“Password OK” is shown if correct password is entered. “Password ERROR” is shown if wrong

password is entered.

The display returns to the point of the preceding menu. Pressed Enter again to modify the setting.

If no key is pressed after 2 minutes, the settings are locked. A new password

request is associated with any subsequent setting change.

3.3 Changing Password

To change the password, go to Op Parameter -> Password menu. Enter current password to unlock,

after that the display shows current password. Press Enter again to enter the new password.

4.0 Menus

The menu is divided into 9 main menus and their corresponding submenus. To enter Main menu,

press Enter during default display.

The menu can be navigated by pressing Up, Down, Enter and Esc keys. There is no need of a

password when reading settings and measured values.

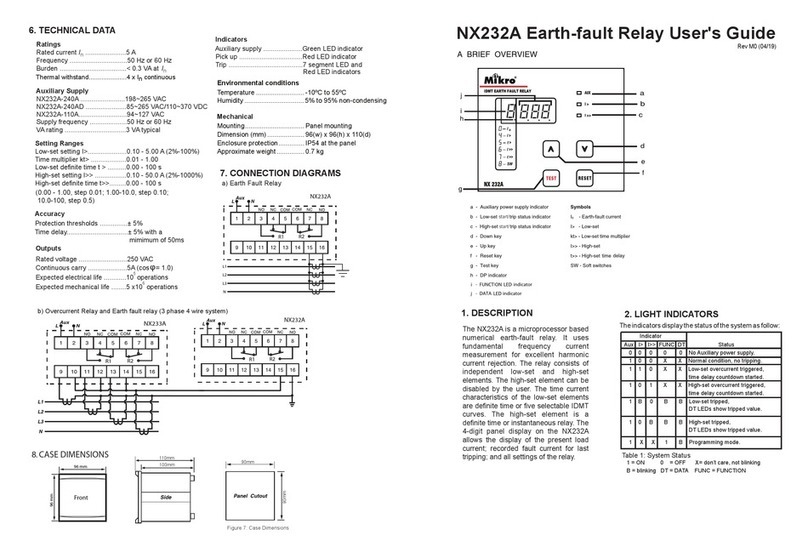

4.1 Menu Contents

The Main menu consists of 9 items. The menu structure is shown below:

8

LED x Ena le?

I>?

tI>?

I>>?

tI>>?

I>>>?

tI>>>?

Io>?

tIo>?

Io>>?

tIo>>?

Io>>>?

tIo>>>?

MainDisplay

Page 1

Main Display and Menu Contents

IL1:0.00 IL2:0.00

IL3:0.00 I0 :0.00

Page 2

Output 1 2 3 4

0 0 0 0

Page 3

Input 1 2

0 0

Page 4

Date XX/XX/XXXX

Time XX:XX:XX

1.MEASUREMENTS

IL1

IL2

IL3

Io

I2

Thermal θ

Frequency

IL1 Max

IL2 Max

2.RECORDS

2.1 Fault Rcrds 2.2 Event Rcrds 2.3 Distur Rcrd

Records Num er

Pre-Time

Distur Rec Trig

3.CONFIGURATION

3.1 Op Parameter 3.2 CT Ratio 3.3 Date & Time

Date

Date Format

Time

Time Format

Password

Description

Firmware

Frequency

Active Group

Serial Num er

Phase CT Pri

Phase CT Sec, In

Earth CT Pri

Earth CT Sec, Ion

3.4 Group Select

Chg Group y..

Setting Group

3.5 Display

LCD On Time

Lcd Brightness

"CLEAR" Scroll?

3.6 LED

3.6.1-3.6.4 LED 1-4

tI2>?

tI2>>?

Input 1?

Input 2?

Aux 1?

Aux 2?

Thml Alrm?

Thml Trip?

CB Fail?

Reclsr Run?

Reclsr Lockd?

Io Max

IL1 Avg

IL2 Avg

IL3 Avg

Io Avg

Max & Avg I RST

Time Window

9

Input Func

Input Type

(Func is Aux 1/2)

Aux Timer

4.PROTECTION G1

4.1 Phase OC

I>?

I>

I> Delay Type

I> IDMT Curve

ktI>

tI>

I>>?

I>>

tI>>

I>>>?

I>>> Sample

I>>>

tI>>>

4.2 Earch Fault

Io>?

Io>

Io> Delay Type

Io> IDMT Curve

ktIo>

tIo>

Io>>?

Io>>

tIo>>

Io>>>?

Io>>> Sample

Io>>>

tIo>>>

4.3 Neg Seq OC

I2>?

I2>

I2> Delay Type

I2> IDMT Curve

ktI2>

tI2>

I2>>?

I2>>

tI2>>

4.4 Thermal OL

Thermal OL?

Iθ>

Tθ

k

θ Trip

θ Alarm

5.PROTECTION G2

Similar to

PROTECTION G1

4.5 Autoreclose

Autoreclose?

Dead Time tD1

Dead Time tD2

Dead Time tD3

Dead Time tD4

Reclaim Time tR

Inhi it Time tI

Phase Cycles

Earth Cycles

CYCLES 1 2 3 4

tI>

tI>>

tI>>>

tIo>

tIo>>

tIo>>>

tAux 1

6.INPUT

6.1-6.2 Input 1-2

(Func is Reset)

Rst Trip/Alarm

Rst Thermal θ%

(Func is Blocking)

Block I>?

Block I>>?

Block I>>>?

Block Io>?

Block Io>>?

Block Io>>>?

Block Thml OL?

Block I2>?

Block I2>>?

(Func is TCS)

TCS Delay

10

Relay 2-4 Func

Reset

(Func is Trip)

tI>?

tI>>?

tI>>>?

tIo>?

tIo>>?

tIo>>>?

Thml OL?

tAux 1?

tAux 2?

Remote

tI2>?

tI2>>?

7.OUTPUT

7.1 Relay 1

(Func is Start/Other)

I>?

I>>?

I>>>?

Io>?

Io>>?

Io>>>?

Thml OL(Alarm)?

Aux 1(Alarm)?

Aux 2(Alarm)?

TCS(Alarm)?

Demand(Alarm)?

I2>?

I2>>?

CB Close?

CB Fail?

Reclsr Run?

Reclsr Locked?

CB Alarm?

(Func is CBFP)

Delay

Include Aux?

Relay 1 Func (Trip only)

Reset

tI>?

tI>>?

tI>>>?

tIo>?

tIo>>?

tIo>>>?

Thml OL?

tAux 1?

tAux 2?

Remote

tI2>?

tI2>>?

7.2-7.4 Relay 2-4 7.5 Maint Mode

9.MISC CONTROL

9.1 CB Monitor

CB Opening Time

CB Closing Time

CB Operations

ΣAmps(n) IL1

ΣAmps(n) IL2

ΣAmps(n) IL3

Reset All Value

9.2 CB Alarm

CB Opening Time?

CB Opening Time

CB Closing Time?

CB Closing Time

CB Operations?

CB Operations

ΣAmps(n)?

ΣAmps(n)

n

8.COMMUNICATION

Communication?

Remote Set?

Baud Rate

Parity

Stop Bit

Relay Address

9.3 Inr Blocking

Inr Blocking?

Inr H2 Ratio

Inr tReset

Inr Blocking I>?

Inr Blocking I>>?

Inr Blocking I>>>?

Inr Blocking Io>?

Inr Blocking Io>>?

Inr Blocking Io>>>?

Inr Blocking I2>?

Inr Blocking I2>>?

CLPU Level

CLPU tCL

CLPU I>?

CLPU I>>?

CLPU I>>>?

CLPU Io>?

CLPU Io>>?

CLPU Io>>>?

CLPU Thml OL?

CLPU I2>?

CLPU I2>>?

9.4 Cold Load PU 9.5 Demand Alarm

Demand Alarm?

Idemand>

tIdemand>

11

MEASUREMENTS Menu

Various measurement values can be read under MEASUREMENTS menu. (The values are shown

for illustrative purpose).

Heading of MEASUREMENTS menu. Press Enter to enter submenu

content.

Displays phase 1 current value. Taking into account of Phase CT Pri

ratio.

Displays phase 2 current value. Taking into account of Phase CT Pri

ratio.

Displays phase 3 current value. Taking into account of Phase CT Pri

ratio.

Displays earth current value. Taking into account of E/Gnd CT Pri

ratio.

Displays negative sequence value. Taking into account of Phase CT Pri

ratio.

Displays thermal % state. Calculated on true RMS current values.

Press Clear to clear the % values.

Displays current frequency calculated from phase 1 currents.

Displays peak phase 1 current value.

Displays peak phase 2 current value.

Displays peak phase 3 current value.

Displays peak earth current value.

IL1

52.0A

IL2

88.2A

IL3

64.2A

Io

4.23A

Thermal θ

RST=CLEAR

Frequency

50.01Hz

IL1 Max

120A

IL2 Max

234A

IL3 Max

1.23kA

Io Max

1.23kA

1.MEASUREMENTS

I2

4.23A

12

Displays average phase 1 current value.

Displays average phase 2 current value.

Displays average phase 3 current value.

Displays average earth current value.

To clear the maximum and average values of the currents. Press Clear

to clear these values.

Set the value for the time window (rolling) during which maximum

and average values are stored. Press Enter to change the value.

RECORDS Menu

Heading of RECORDS menu. Press Enter to enter submenu content.

Fault Records Menu

Heading of Fault Record submenu. Press Enter to enter submenu

content.

Example of Fault Record title page, showing trip element, source,

value and record number 1. Press Up or Down to show another record

of Enter to enter sub page for this record. Press Clear to clear this

record.

Fault record sub page 1, showing record date and time. Press down to

show next sub page. Press Esc/Enter to return to Fault Record title

page.

Fault record sub page 2, showing active protection setting group

during fault. Press Up/down to change sub page. Press Esc/Enter to

return to Fault Record title page.

IL1 Avg

323A

IL2 Avg

80.4A

IL3 Avg

78.2A

Io Avg

6.24A

Max & Avg I RST

RST=CLEAR

Time Window

10min

2.RECORDS

2.1 Fault Rcrds

tI> trip [1]

L3 15.2A

Date: 03/01/2016

Time: 10:19:52am

Active Set Group

1

13

Fault record sub page 3, showing L1 current during fault. Press

Up/down to change sub page. Press Esc/Enter to return to Fault

Record title page.

Fault record sub page 4, showing L2 current during fault. Press

Up/down to change sub page. Press Esc/Enter to return to Fault

Record title page.

Fault record sub page 5, showing L3 current during fault. Press

Up/down to change sub page. Press Esc/Enter to return to Fault

Record title page.

Fault record sub page 6, showing Lo current during fault. Press Up to

previous sub page. Press Esc/Enter to return to Fault Record title page.

Event Records Menu

Heading of Event Record submenu. Press Enter to enter submenu

content.

Example of Event title page. Press Enter to enter sub page for this

record.

Event record sub page, showing record date and time. Press Esc/Enter

to return to Fault Record title page.

Disturbance Records Menu

Heading of Disturbance Record submenu. Press Enter to enter

submenu content.

Set the disturbance record length and number. Press Enter to change

between None (disable), 6 Rec x 3 sec, 4 Rec x 4 sec, 3 Rec x 5 sec, 2

Rec x 7 sec and 1 Rec x 9 sec.

Note: Changing the record length and number will cause existing records being

deleted. If necessary, read all wanted records before making changes.

Set the disturbance record pre-time. Step 0.1s.

Criteria which will start the disturbance record function. Setting

choices are ON INST (starts recording on start/instantaneous

thresholds) or ON TRIP (starts recording on a tripping).

IL1 Magnitude

4.86A

IL2 Magnitude

4.52A

IL3 Magnitude

15.2A

Io Magnitude

1.2A

2.2 Event Rcrds

Genrl strt [1]

Date: 03/02/2011

Time: 08:23:44am

2.3 Distur Rcrd

Records Num er

6 Rec x 3 sec

Pre-Time

0.1s

Distur Rec Trig

ON INST

!

!!

!

14

CONFIGURATION Menu

Heading of CONFIGURATION menu. Press Enter to enter submenu

content.

Op parameter Menu

Heading of Op Parameter submenu. Press Enter to enter submenu

content.

This password is required when changing relay settings. Press Enter to

enter a new password. The user needs to enter existing password to

unlock, after that the display shows current password. Press Enter

again to enter the new password.

Model name of this relay

Version of the firmware.

Set the nominal value of the line frequency. Press Enter to change this

value.

Currently active protection group.

CT Ratio Menu

Heading of CT Ratio menu. Press Enter to enter submenu content

Set the rated primary current of the Phase/Line CT.

Set the rated secondary current of the Phase CT according to the CT

input terminal used. This setting affects disturbance record current

scaling only.

Set the rated primary current of the Earth/Ground CT.

Set the rated secondary current of the Earth/Ground Phase CT

according to the CT input terminal used. This setting affects

3.CONFIGURATION

3.1 Op Parameter

Password

****

Description

MK3000L

Firmware

1.0

Frequency

50Hz

3.2 CT Ratio

Phase CT Pri

500A

Earth CT Pri

200A

Active Group

50Hz

Phase CT Sec, In

5A

Earth CT Sec, Ion

1A

15

disturbance record current scaling only.

Note: The CT secondary should be connected to 5A or 1A CT input terminal according to the CT

secondary current rating. The display current is calculated by the formula:

Current at CT input terminal / CT input terminal type x CT Pri (setting above)

For example:

Current at CT input terminal = 3A,

CT input terminal type = 5A,

CT Pri = 200A,

The display value = 3/5 x 200 = 120A

Current at CT input terminal = 3A,

CT input terminal type = 1A,

CT Pri = 100A,

The display value = 3/1 x 100 = 300A

Date & Time Menu

Heading of Date & Time menu. Press Enter to enter submenu content.

Displays the date. Press Enter to change the date.

Set the date format for display. Press Enter to change between

DD/MM/YYYY, MM/DD/YYYY.

Displays the time. Press Enter to change the time, starts from hour,

minute and am/pm (if 12 hour format is selected). Second will be reset

to 0 when enter is pressed for any of the digit.

Set the time format. Press enter to change between 12 and 24 hour.

Group Select Menu

Heading of Group Select menu. Press Enter to enter submenu content.

Set whether the protection group setting is change by Menu or Input.

One of the input function must be set to 'Select Group' if Input is

selected. Press Enter to change.

If above is set to Menu, this will set the active protection group. Press

Enter to change.

3.3 Date & Time

Date

18/01/2016

Date Format

DD/MM/YYYY

Time

10:46:23am

Time Format

12-hour

3.4 Group Select

Chg Group y...

Menu

Setting Group

1

16

Display Menu

Heading of Display menu. Press Enter to enter submenu content.

Set how long the LCD backlight remains on after no key is pressed.

Press Enter to change.

Set the brightness of the LCD backlight. Press Enter to change.

Set if Clear key can be used (during no alarm or trip state) to scroll

through the default display pages, Phase OC and Earth OC settings

(for currently selected group), as well as to return to Default Display

from Record display. This is useful when Up, Down, Enter and Esc

key is inaccessible due to the front panel is covered and locked.

LED Menu

LED4 to LED 7 configuration is used to assign a protection function to a LED output. The LED

lights up when the protection function is active. For tI>, tI>>, tI>>>, tIo>, tIo>>, tIo>>>, tI2> and

tI2>> trip, the LED is latched by its respective alarm record, LED is off when its alarm record is

cleared.

Heading of LED Menu. Press Enter to enter submenu content

LED 4 to LED 7 menu has similar content. The LED 4 menu content is shown below:

Heading of LED 4 Menu. Press Enter to enter submenu content.

Enable or disable LED 4 operation.

If yes is selected, the following menu is shown:

I>? Yes Assigned I> start to LED

tI>? Yes Assigned tI> trip to LED

I>>? Yes Assigned I>> start to LED

tI>>? Yes Assigned tI>> trip to LED

I>>>? Yes Assigned I>>> start to LED

tI>>>? Yes Assigned tI>>> trip to LED

Io>? Yes Assigned Io> start to LED

tIo>? Yes Assigned tIo> trip to LED

3.5 Display

LCD On Time

10min

LCD Brightness

Medium

“CLEAR” Scroll?

No

3.6 LED

3.6.1 LED 4

LED 4 Ena le?

Yes

17

Io>>? Yes Assigned Io>> start to LED

tIo>>? Yes Assigned tIo>> trip to LED

Io>>>? Yes Assigned Io>>> start to LED

tIo>>>? Yes Assigned tIo>>> trip to LED

tI2>? Yes Assigned I2> start to LED

tI2>>? Yes Assigned tI2> trip to LED

Input 1? Yes Assigned Input 1 status to LED

Input 2? Yes Assigned Input 2 status to LED

Aux 1? Yes Assigned Aux1 Alarm/trip to LED

Aux 2? Yes Assigned Aux2 Alarm/trip to LED

Thml Alrm? Yes Assigned thermal alarm to LED

Thml Trip? Yes Assigned thermal trip to LED

CB Fail? Yes Assigned CB fail to LED

Reclsr Run? Yes Assigned recloser running to LED

Reclsr Lockd? Yes Assigned recloser locked to LED

TCS Alrm? Yes Assigned TCS alarm to LED

PROTECTION G1 Menu

Heading of PROTECTION G1 (Group 1) menu. Press Enter to enter

submenu content.

Phase OC Menu

Heading of Phase OC (Overcurrent) menu. Press Enter to enter

submenu content.

I> menu

Set to Yes to enable phase overcurrent first threshold (I>). Then the

following menu is displayed.

Set the value for the current threshold I>.

NOTE : When delay type is IDMT, the maximum setting

recommended should be 2.00In.

Set the time delay type of I>. Setting choices are: IDMT (inverse

definite time curve) and Definite Time.

4.PROTECTION G1

4.1 Phase OC

I>?

Yes

I>

2.00In

I> Delay Type

IDMT

18

If Definite Time is selected, the following menu is displayed:

Set the value for the time delay of I> definite time.

If IDMT is selected, the following menu is displayed:

Set the type of curve.

Set the time multiplier setting value for the curve.

I>> menu

Set to Yes to enable phase overcurrent second threshold (I>>). Then

the following menu is displayed.

Set the value for the current threshold I>>.

Set the value for the time delay of I>> definite time.

I>>> menu

Set to Yes to enable phase overcurrent third threshold (I>>>). Then the

following menu is displayed.

Set to yes to enable I>>> operated on current sample base. Otherwise

it operates on fundamental value. Sample base method will ensure fast

tripping on highly saturated current signal.

Set the value for the current threshold I>>>.

Set the value for the time delay of I>>> definite time.

Earth Fault Menu

Heading of Earth Fault menu. Press Enter to enter submenu content.

tI>

1.00s

I> IDMT Curve

Normal Invrse

ktI>

0.20

I>>?

Yes

I>>

9.00In

tI>>

100ms

I>>>?

Yes

I>>> Sample

Yes

I>>>

20.0In

tI>>>

30ms

4.2 Earth Fault

19

Io> menu

Set to Yes to enable earth fault first threshold (Io>). Then the

following menu is displayed.

Set the value for the current threshold Io>.

NOTE : When delay type is IDMT, the maximum setting

recommended should be 0.5Ion..

Set the time delay type of Io>. Setting choices are: IDMT and Definite

Time.

If Definite Time is selected, the following menu is displayed:

Set the value for the time delay of Io> definite time.

If IDMT is selected, the following menu is displayed:

Set the type of curve.

Set the time multiplier setting value for the curve.

Io>> menu

Set to Yes to earth fault second threshold (Io>>). Then the following

menu is displayed.

Set the value for the current threshold Io>>.

Set the value for the time delay of Io>> definite time.

Io>>> menu

Set to Yes to enable earth fault third threshold (Io>>>). Then the

following menu is displayed.

Set to yes to enable Io>>> operated on current sample base. Otherwise

it operates on fundamental value. Sample base method will ensure fast

tripping on highly saturated current signal.

Io>?

Yes

Io>

0.10Ion

Io> Delay Type

IDMT

tIo>

1.00s

Io> IDMT Curve

Normal Invrse

ktIo>

0.20

Io>>?

Yes

Io>>

1.00Ion

tIo>>

100ms

Io>>>?

Yes

Io>>> Sample

Yes

20

Set the value for the current threshold Io>>>.

Set the value for the time delay of Io>>> definite time.

Neg Seq OC

Heading of Neg Seq OC (Negative Sequence Overcurrent) menu.

Press Enter to enter submenu content.

I2> menu

Set to Yes to enable negative overcurrent first threshold (I2>). Then

the following menu is displayed.

Set the value for the current threshold I2>.

NOTE : When delay type is IDMT, the maximum setting

recommended should be 0.5Ion..

Set the time delay type of I2>. Setting choices are: IDMT and Definite

Time.

If Definite Time is selected, the following menu is displayed:

Set the value for the time delay of I2> definite time.

If IDMT is selected, the following menu is displayed:

Set the type of curve.

Set the time multiplier setting value for the curve.

I2>> menu

Set to Yes to earth fault second threshold (I2>>). Then the following

menu is displayed.

Set the value for the current threshold I2>>.

Io>>>

20.0Ion

tIo>>>

30ms

4.3 Neg Seq OC

I2>?

Yes

I2>

0.10In

I2> Delay Type

IDMT

tI2>

1.00s

I2> IDMT Curve

Normal Invrse

ktI2>

0.20

I2>>?

Yes

I2>>

1.00In

Table of contents

Other Mikro Relay manuals

Popular Relay manuals by other brands

ABB

ABB Relion 620 Series Operation manual

Siemens

Siemens 5TT3 424 operating instructions

Guard master

Guard master Minotaur MSR7R manual

Mitsubishi Electric

Mitsubishi Electric MELPRO-A Series instruction manual

Muuntosahko

Muuntosahko Superintend Trafox VR-16 Short Operating Manual

Notifier

Notifier N-ANN-RLY product manual

Siemens

Siemens SIRIUS 3RF23 0 Series Original operating instructions

Velleman

Velleman VMA332 user manual

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-787-2 manual

ABB

ABB CM Series Operating and installation instructions

SSP

SSP T2 Series operating manual

GE

GE T35 instruction manual