OWNER’S MANUAL

ORIGINAL INSTRUCTIONS −PRINTED IN USA ©2020 Miller Electric Mfg. LLC

OM-269238D 2020−03

Standard Running Gear/Cylinder Rack (301239)

1. Safety Symbol Definitions

DANGER! −Indicates a hazardous situation which, if not

avoided, will result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained

in the text.

DANGER ! - Indique une situation dangereuse qui, si elle

n’est pas évitée, entraînera la mort ou des blessures

graves. Les éventuels risques sont représentés par les

symboles joints ou expliqués dans le texte.

Fsafe1 2013-10

Wear safety glasses with side shields.

Porter des lunettes de sécurité avec écrans latéraux.

Fsafe8 2013-10

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible ha-

zards are shown in the adjoining symbols or explained in

the text.

Indique une situation dangereuse qui, si elle n’est pas

évitée, entraînera la mort ou des blessures graves. Les

éventuels risques sont représentés par les symboles

joints ou expliqués dans le texte.

Fsafe2 2013-10

Tipping equipment can injure, and damage equipment. Do

not move cart where two wheels are at different heights

and cart could tip −avoid tipping. Be careful when moving

unit over uneven surfaces.

Do not use an oversized cylinder or exceed maximum

cylinder weight.

Un appareil qui bascule peut s’endommager ou causer

des blessures. Pour éviter un renversement, ne pas dé-

placer un chariot sur un terrain incliné. Demeurez prudent

lors du déplacement sur un sol inégal.

Ne pas utiliser de bonbonnes surdimensionnées et ne

pas dépasser le poids maximum d’une bonbonne.

Fsafe23 2013-10

NOTICE

AVIS

Indicates statements not related to personal injury.

Signale des consignes non associées aux dommages

corporels.

Indicates special instructions.

Fournit des instructions spéciales.

Fsafe3 2013-10

Cylinders contain gas under high pressure and can ex-

plode if damaged. Never let a welding electrode touch

any cylinder. Always secure cylinder to running gear, wall,

or other stationary support.

Les bonbonnes contiennent du gaz sous haute pression

et peuvent exploser si elles sont endommagées. Ne

jamais toucher une bonbonne avec une électrode. At-

tacher toujours une bonbonne à un mur ou à un support

fixe.

Wiresafe1 2013-10

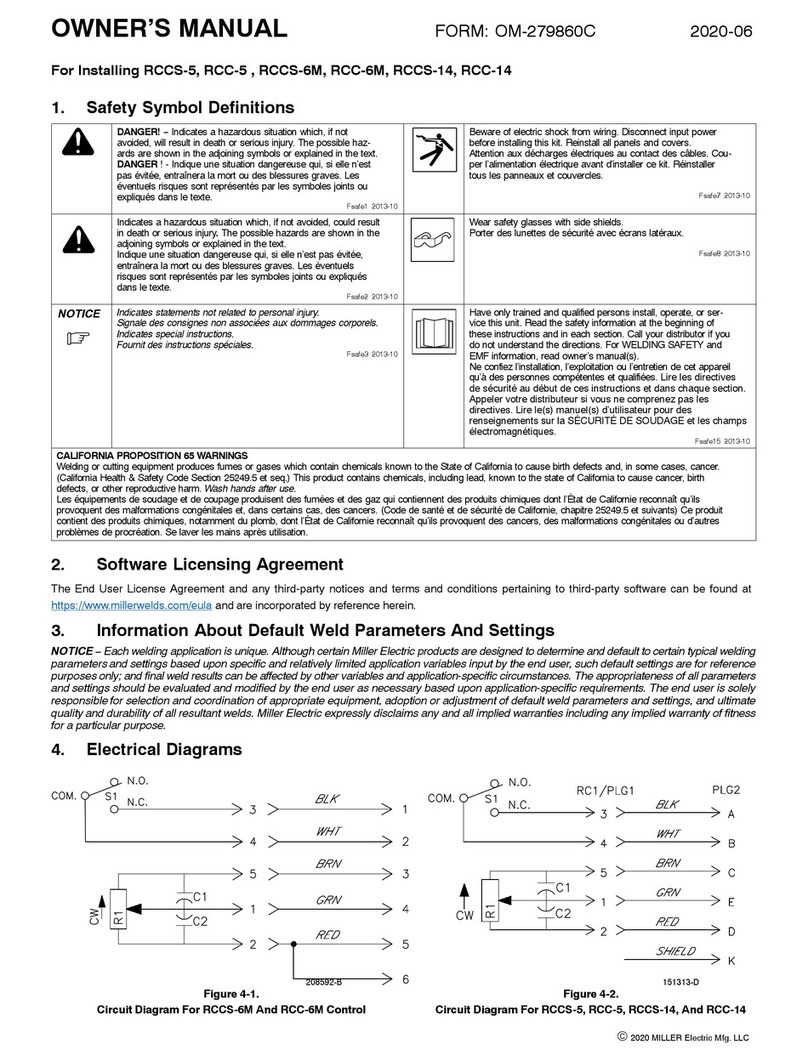

Beware of electric shock from wiring. Disconnect input

power before installing this kit. Reinstall all panels and

covers.

Attention aux décharges électriques au contact des

câbles. Couper l’alimentation électrique avant d’installer

ce kit. Réinstaller tous les panneaux et couvercles.

Fsafe7 2013-10

Falling equipment can injure, and damage equipment.

Never put any body part under unit while lifting. Lifting

forks must extend out opposite side of base. Lift and sup-

port unit only with proper equipment and correct proced-

ures. Follow the guidelines in the Applications Manual for

the Revised NIOSH Lifting Equation (Publication No.

94−110) when manually lifting heavy parts or equipment.

La chute de l’équipement peut provoquer des blessures

ou des dommages matériels. Ne jamais mettre une partie

du corps sous l’appareil pendant le levage. Les fourches

de levage doivent ressortir du côté opposé de la base. Ne

soulever l’appareil qu’avec un équipement en bon état

selon les procédures correctes. Suivre les consignes du

Manuel des applications pour l’équation de levage NIOSH

révisée (publication Nº 94–110) lors du levage manuel de

pièces ou équipements lourds.

Fsafe19 2013-10

CALIFORNIA PROPOSITION 65 WARNINGS

WARNING: Cancer and Reproductive Harm −www.P65W

arnings.ca.gov

PROPOSITION CALIFORIENNE 65 AVERTISSEMENTS

AVERTISSEMENT : cancer et troubles de la reproduction −www.P65W

arnings.ca.gov

.

Fsafe26 2018-01