•All instructions and warnings must be read and understood before using equipment.

•All users must understand all OSHA regulations, ANSI standards, and other relevant regulations and standards

pertaining to fall protection equipment.

•To minimize the potential for accidental disengagement, a competent person must ensure system compatibility.

•All equipment must be visually inspected before each use.

•All equipment must be inspected by a qualified person on a regular basis.

•Equipment must not be altered in any way. Repairs are to be performed by the manufacturer or authorized agent only.

•Any product exhibiting deformities, unusual wear, or deterioration must be immediately discarded.

•Any equipment subject to fall arresting forces must be removed from service.

•Employers must provide for prompt rescue in the event of a fall.

•This product is designed for personal fall protection. Never use fall protection equipment for purposes other than for

which it is designed. Never use fall protection equipment for towing or hoisting.

•Always check for obstructions below the work area to make sure potential fall path is clear.

•All synthetic material must be protected from slag, hot sparks, open flames, or other

heat sources.

•Equipment must be protected from electrical hazards and moving machinery.

•Environmental hazards should be considered when selecting equipment. Use in corrosive or caustic environments

dictates a more frequent inspection and servicing program to ensure that the integrity of the product is maintained.

•FOR USE BY ONE PERSON ONLY.The designed working load is 400 LBS, unless labeled otherwise.

•Only trained and competent personnel should install and use this device and its components.

•Do not use the product if any component does not operate properly or appears to be damaged.

•Use only locking snap hooks or locking carabiners with this product.

•Tie-off in a manner which avoids the hazards of a swing fall.

•Fall arrest systems used with this connector must be rigged in accordance to regulatory requirements.

•The structure that this product is attached to must be capable of supporting a 5,000 lb. static load in the direction of

pull or meet OSHA 1926.502 requirements for a safety factor of two.

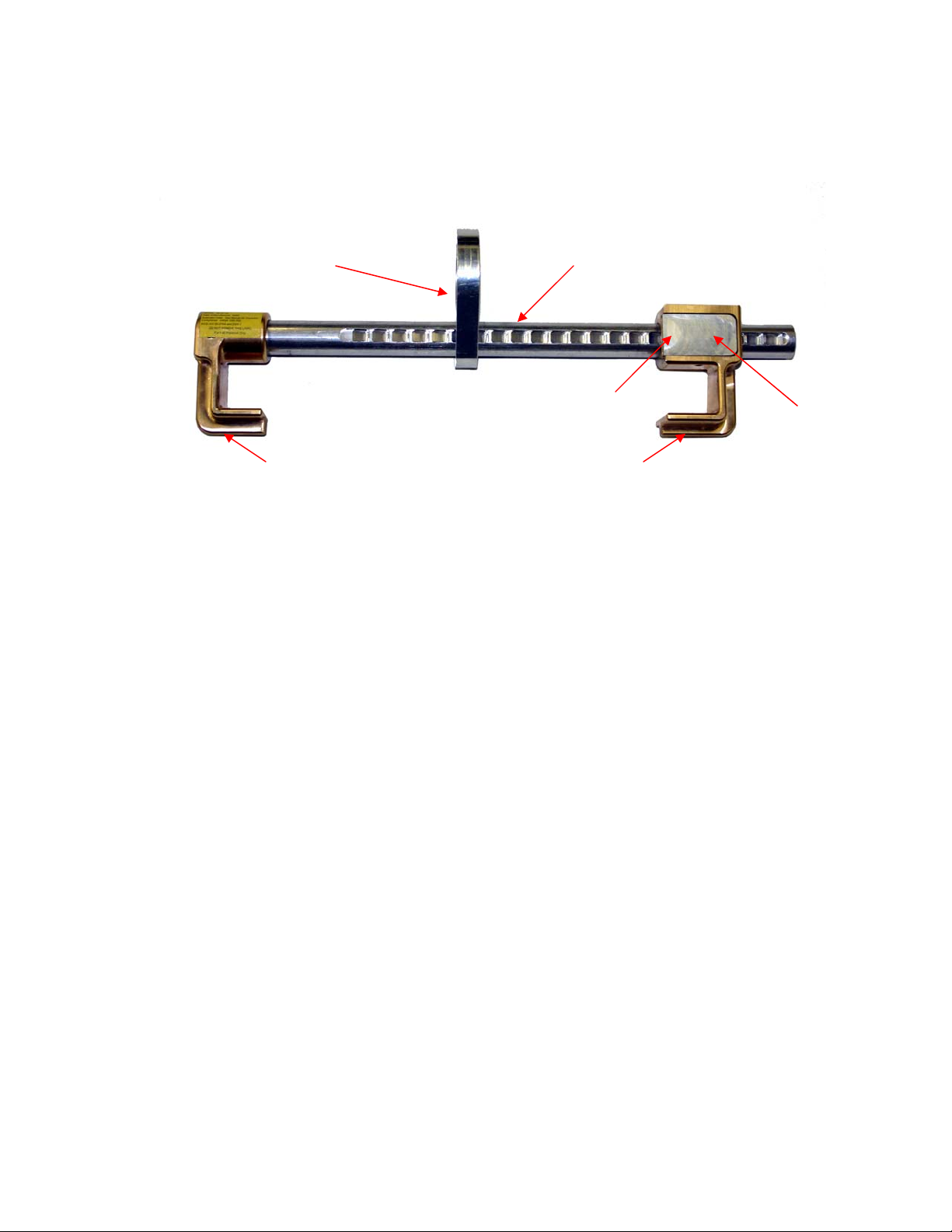

•This device must only be used on beams where a fall will not cause the device to slide along the beam and increase

the fall distance.

•The device shall be connected such that it will not slide off the end of a beam and should not be attached to a beam

which is inclined or sloped greater than 15° from horizontal.

•This device is designed for use on W-shape and other flanged beams.

•Never disable or restrict locking keepers or alter connecting devices in any way.

•Always visually check that each snap hook freely engages D-ring or anchor point and that its keeper is completely

closed.

•Do not attach multiple lanyards together.

•Do not tie knots in lanyards. Do not wrap lanyards around, or allow to come in contact with, sharp, rough edges or

small diameter structural members.

•The use of a shock absorbing lanyard or self-retracting lifeline is required for fall protection applications.

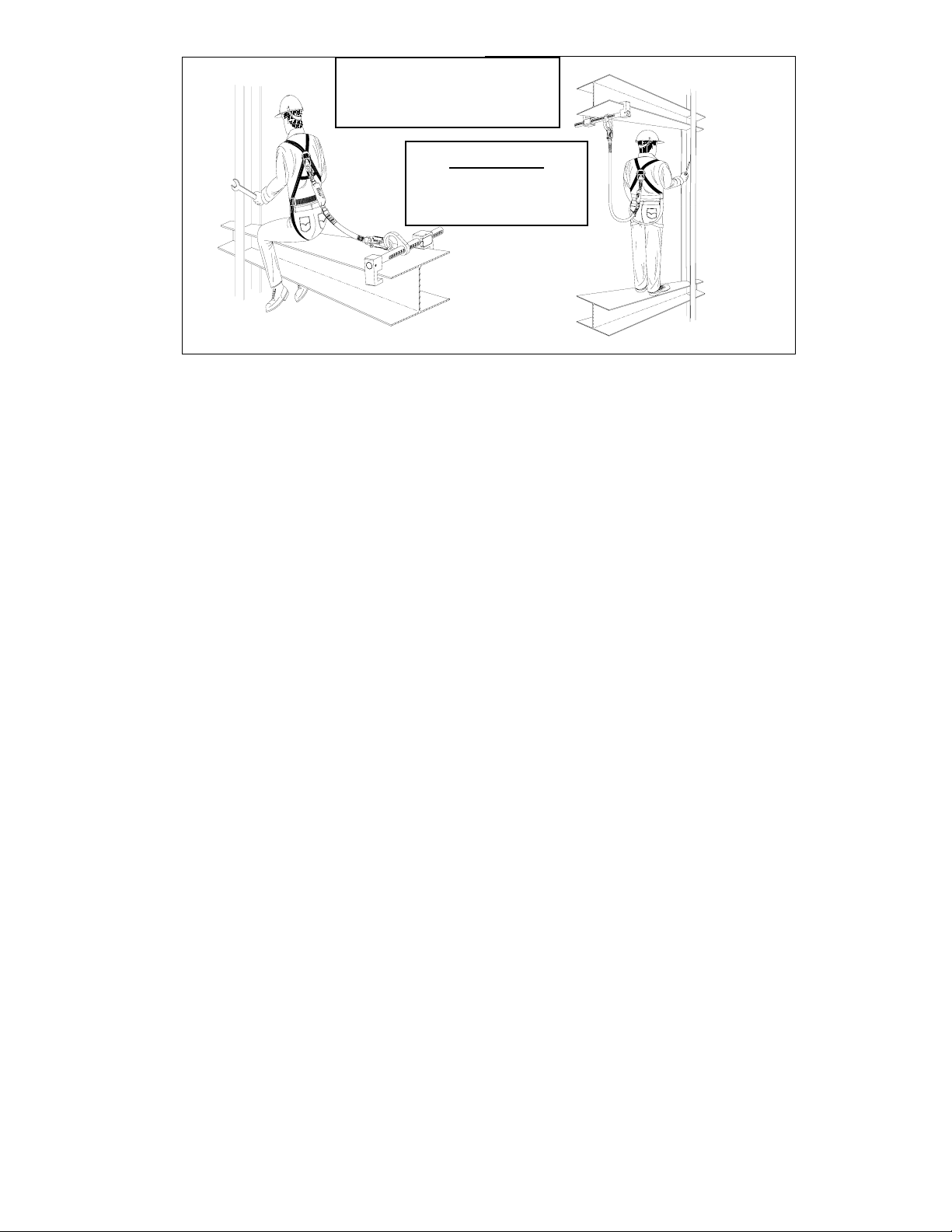

•Whenever possible, the ShadowLite™ beam anchor should be positioned to limit the worker’s free-fall distance to six

feet or less. When the only available beam is at the worker’s feet, the free-fall must be kept to a maximum of twelve

feet and the personal fall arrest forces must be kept to a maximum of 1800 lbs.

•For applications that require the ShadowLite™ beam anchor to be attached to the beam at the worker’s feet, the Miller

and Titan double pack shock absorbing lanyards must be used. Approved models include the Miller SofStop Max,

BackBiter Max, Titan X2 Lanyard and Titan X2 T-BAK.

•Allow sufficient clearance in the event of a free fall. NOTE: Shock absorbers may elongate up to 3-1/2 feet upon

activation.

•Never use a steel cable lanyard for fall arrest unless used in conjunction with a shock absorber.

•Never use natural materials (manila, cotton, etc.) as part of a fall protection system.

•Do not tie-off onto an object which is not compatible with lanyard snap hooks.

•Make sure snap hook is positioned so that its keeper is never load bearing.