Contents

Legal Information............................................................................................5

Safety Information...........................................................................................6

Recycling.........................................................................................................7

Preface.............................................................................................................8

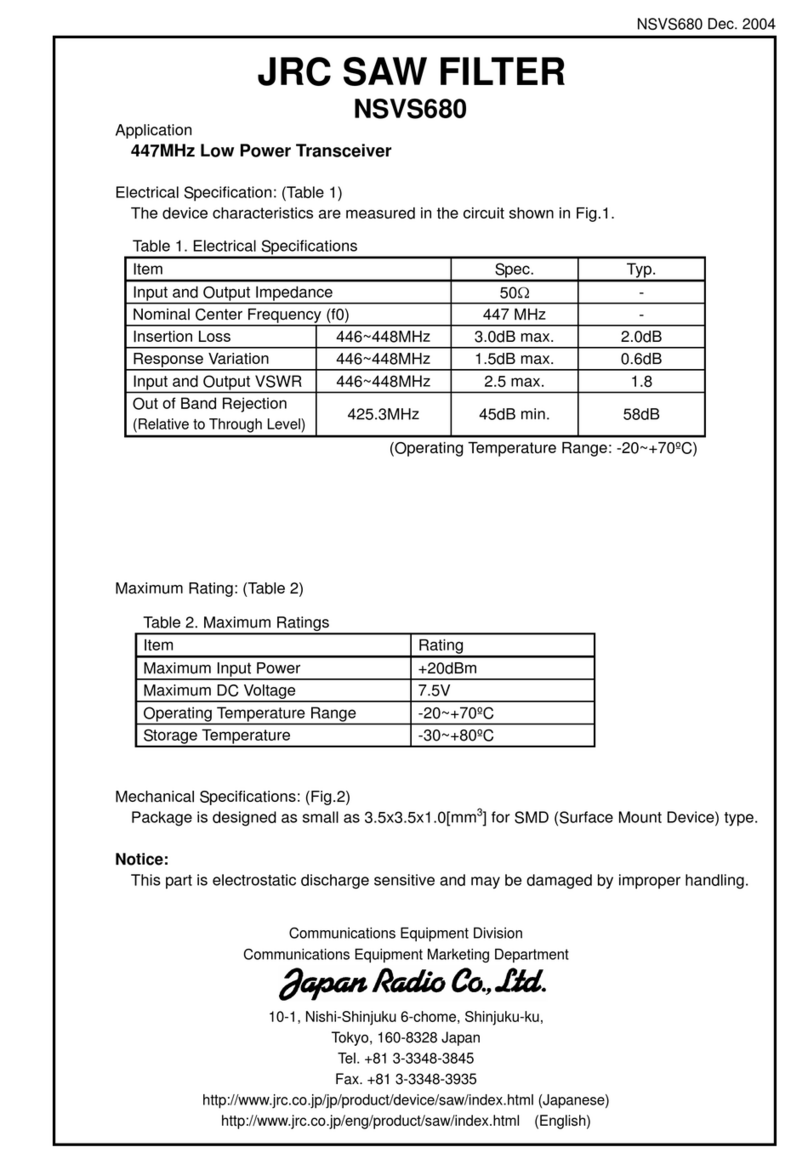

Specifications..................................................................................................9

Feed Water Specifications..........................................................................................10

Product Water Specifications......................................................................................10

System Dimensions....................................................................................................12

Weight Specifications..................................................................................................13

Electrical Specifications..............................................................................................13

Environmental Specifications......................................................................................14

System Overview.......................................................................................... 15

Operating Principle .................................................................................................... 16

Distribution loop management and configurations......................................................17

System Display..............................................................................................18

How to Navigate Between Overview and Workspace Screens.................................. 18

Overview Screen.........................................................................................................19

How to Change the System from Standby to Ready.................................................. 23

Workspace Screens....................................................................................................25

Glance Workspace.............................................................................................26

Maintenance Workspace................................................................................... 30

Configuration Workspace...................................................................................32

How to View Hidden Applications......................................................................35

Alarms and Alerts - Definition..................................................................................... 36

How to Acknowledge Alarms and Alerts............................................................37

Screensaver................................................................................................................38

Maintenance.................................................................................................. 39

How to Use Maintenance Wizard................................................................................40

RO Cleaning tools.......................................................................................................41

RO Cleaning............................................................................................................... 42

Communication Ports & Software...............................................................43

How to Change the Network Configuration.................................................................44

How to Power On and Power Off the Water System..................................46

How to Use the Distribution Schedule........................................................47

How to Flush the Tank..................................................................................49

Contents | 3