Milli-Q IX 7003 User manual

User Manual

Milli-Q®IX 7003/7005/7010/7015

®

Table of contents

INTRODUCTION 1

System identication 1

Intended use 1

Installation component 2

Water process 3

QUICK START 5

Navigate the screen interface 5

Dispense pure water 7

Manage dispense reports 9

Exit screensaver 10

View & manage Alerts and Alarms 11

CONSUMABLE MENU 12

View & manage Alerts and Alarms 12

Consumables identication with card reading 13

INFORMATION MENU 14

System 14

History 14

Flow schematic 15

Troubleshooting 15

Contacts 16

SETTINGS MENU 17

Manager access (& password) 19

System conguration 20

Accessories 22

Alarm conguration 23

Connectivity 24

Date Time & Language 24

Units 25

MAINTENANCE MENU 26

Consumable installation wizards 27

Cleaning & Sanitization 30

ech2o® UV lamps - mercury free 30

Depressurization 31

SELF HELP GUIDE 32

Troubleshooting tips 32

Icons 34

REQUIREMENTS AND SPECIFICATIONS 35

Water specications 35

System specications 37

Power and water consumption 39

Dimensions and weights 40

Ordering information 43

LEGAL INFORMATION & WARRANTY 45

1

Congratulations!

Thank you for buying a Milli-Q® water purication system.

The Milli-Q® IX 7003/7005/7010/7015 water purication system produces pure water from a tap

water source. Installation of this product should be performed by a qualied service representative

with access to installation documentation.

This user manual is a guide to be followed during the normal operation and maintenance of a

Milli-Q® IX 7003/7005/7010/7015 water purication system. It is highly recommended to fully

read this manual and comprehend its contents before using the water purication system.

System identication

System Catalogue number Production

ow rate Voltage Frequency

Milli-Q® IX 7003 ZIX7003T0 3 L.h-1 100-240 V 50-60 Hz

Milli-Q® IX 7005 ZIX7005T0 5 L.h-1 100-240 V 50-60 Hz

Milli-Q® IX 7010 ZIX7010T0 10 L.h-1 100-240 V 50-60 Hz

Milli-Q® IX 7015 ZIX7015T0 15 L.h-1 100-240 V 50-60 Hz

Manufacturing site:

Millipore SAS, 67120 Molsheim, France

For more information on your Milli-Q® system, please call your local representative or visit

our website www.emdmillipore.com (North America) or www.merckmillipore.com (Rest of the

World).

Intended use

The Milli-Q® IX 7003/7005/7010/7015 system is intended to produce pure (type 2) water from

a tap water source primarily for use in research and quality control in a variety of laboratories

worldwide.

The product is designed to produce pure water with specic characteristics (refer to the

requirements and specications section) when it leaves the E-POD® unit, provided that it is fed

with water quality within specications and properly maintained as required by the supplier.

Merck KGaA, Darmstadt, Germany does not warrant the product for any specic application. It is up to

the user to determine if the quality of the water produced by the product matches their expectations,

ts with norms/legal requirements and to bear responsibility resulting from the usage of the water.

The product is not intended to produce: water for injection, water for dialysis, sterile water for

irrigation or injection, bacteriostatic water for injection, sterile puried water in containers, and

sterile water for injection in container or ingestion. The product is not intended to be used in

explosive environments according to ATEX Directive – equipment & protective systems intended

for use in potentially explosive atmospheres. In addition the product is not intended as a Medical

Device, including In-Vitro Devices.

INTRODUCTION

Introduction 2

Installation components

Milli-Q® IX 7003/7005/7010/7015 consists of at least 3 different components: water system

(Milli-Q® IX 7003 on the photographs below), tank, and E-POD® unit.

1Front view of a Milli-Q® IX 7003 water

system 6E-POD® unit (Point of Dispense of pure

water) with screen interface

2Front cover 7POD dispenser (equipped with a Milli-

pak® nal lter on the photograph)

3

Front view of a Milli-Q® IX 7003 water

purication unit, with the front cover

removed

8Dispensing wheel

4Accessories holder 9POD base

5

Rear view of a Milli-Q® IX 7003 system

with its hydraulic and electrical connec-

tions

10 Storage tank (50L capacity on the pho-

tograph)

Note: The system can either have one IPAK Gard® cartridge (Milli-Q® IX 7003/7005 system)

or two (Milli-Q® IX 7010/7015 system). On the photograph, the accessories holder is used to

store the sanitization port tool and the RO cleaning tablets bottle (ROProtect C - SDS available

on www.merckmillipore.com or www.emdmillipore.com).

8

9

1

5 6 710

2 3 4

Introduction 3

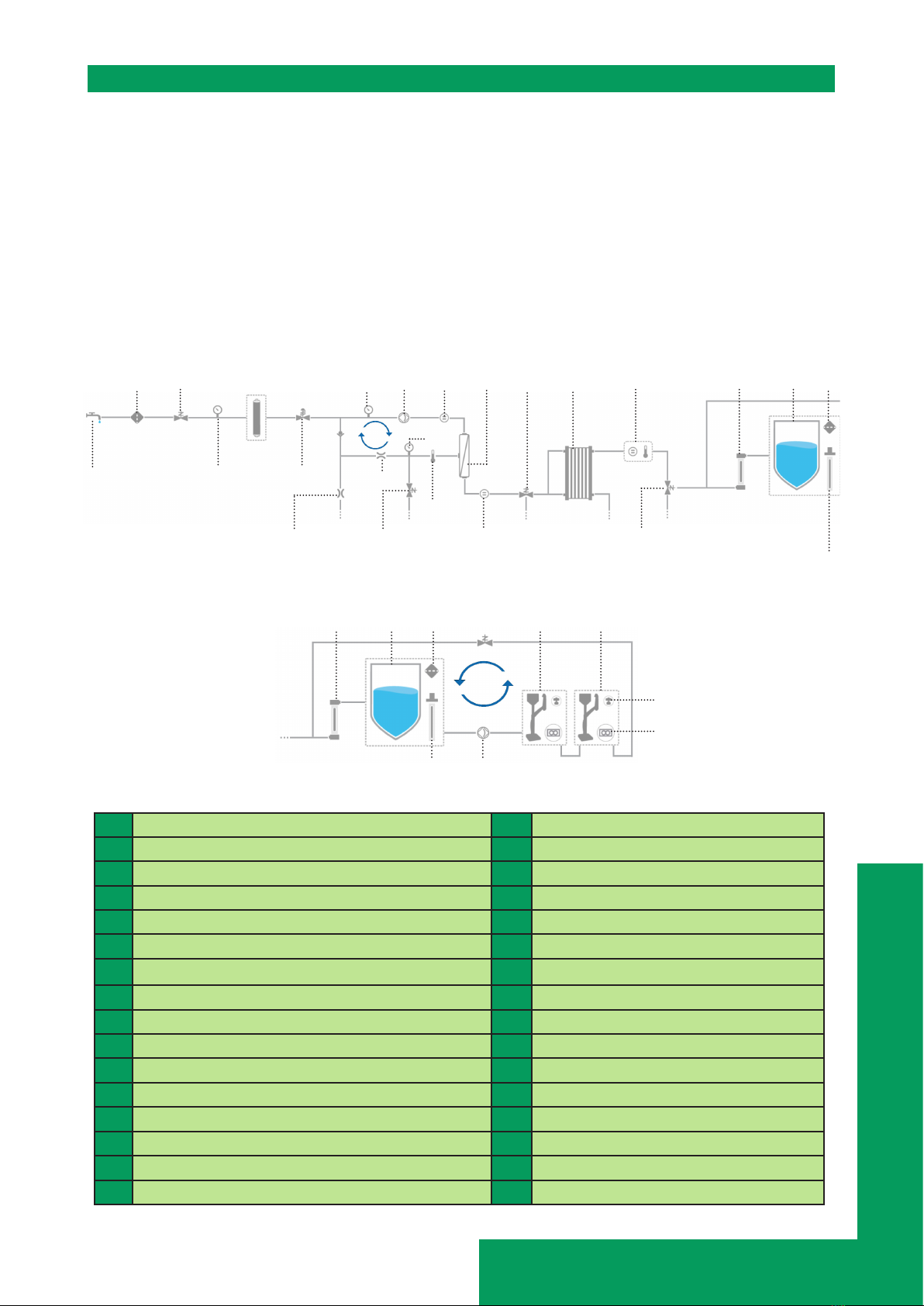

Water process

The Milli-Q® IX 7003/7005/7010/7015 manages the production and the distribution of pure

(Type 2) water from a tap water source. It is composed of three different sections:

• Water purication unit manages the production of pure water.

• Storage tank stores and maintains the pure water quality.

• Point of dispense (E-POD®unit) integrates the screen interface and manages the dispensing of

pure water. At least one E-POD®

unit is necessary and up to 2 E-POD® units can be installed in total.

Production ow-schematic

Distribution ow-schematic

1

3

46

7 11

58

10

12 13

14

15

1Tap feed water 17 Permeate conductivity cell

2Inlet strainer 18 Permeate 3 ways valve

3Inlet solenoid valve 19 Elix® EDI module

4System feed pressure sensor 20 Pure water resistivity cell

5IPAK Gard® (1 or 2 depending on system type) 21 Pure water 3 ways valve

6Pressure regulator 22 ech2o® bactericidal lamp

7Reverse osmosis (RO) reject capillary 23 Storage tank (25, 50 or 100L)

8RO pump feed pressure sensor 24 Tank vent lter

9RO recovery loop 25 ech2o® ASM lamp

10 Flow controller 26 Distribution inlet solenoid valve

11 RO ush solenoid valve 27 Recirculation loop

12 RO pump 28 Distribution pump

13 Feed conductivity cell 29 Primary E-POD® unit (mandatory)

14 RO pressure sensor 30 Secondary E-POD® unit (optional)

15 Thermistor 31 Application POD-Pak

16 RO membrane (1 or 2 depends on syst type) 32 Flowmeter

16

17

18 19 20

21

22 23

25

24

26

28

29 30

22 23 24

25

2

9

31

32

27

Introduction 4

This system uses potable tap water as feed and produces pure (Type 2) delivered by 1 or 2

independent E-POD® unit(s).

The system is divided into three sections. These are the production, the storage and the

distribution.

Production: Tap water is rst puried by the IPAK Gard® pretreatment pack

which contains the pleated lter and carbon block. Particles, colloids and

free chlorine are efciently removed before the reverse osmosis purication.

The intelligent reverse osmosis (RO) purication that controls water consumption, ensures a

constant product ow rate and optimal water quality. A large percentage of contaminants are

removed at this stage such as the ions, particles, bacteria and large organics. The puried RO

water then enters the patented electrodeionization (EDI) module, where ion-exchange resins

are continuously regenerated by a small electrical eld. The pure water then passes through the

mercury-free ech2o bactericidal lamp where bacteria is further eliminated resulting in pure (type

2) water then stored in the storage tank.

Storage and distribution: Pure water is stored in high-quality polyethylene tank, which is equipped

with a vent lter and the mercury-free ech2o® automated sanitization module (ASM) lamp. The

tank vent lter maintains the consistent purity of stored water and provides effective protection

against airborne contaminants. The ech2o® ASM lamp further protects the integrity of the stored

water with regular exposure to bactericidal UV light. Throughout the distribution, resistivity,

temperature and pressure are monitored. Tank is congured with 2 or 5 meters connectors to

the main production unit depending on the laboratory setting.

The E-POD®(s) unit(s) is/are the main interface(s) with the user. They are congured with 2 or

5 meter connectors to the main production unit depending on the laboratory setting. The arm

holding the dispenser on the mast can be moved up/down, right/left and can be unhooked to

adapt to laboratory glassware. Its dispensing ‘wheel’ delivers water from low ow up to 2 L/min

owrate. The E-POD® unit large 5” touchscreen offers a wide range of applications for users. It

also has an USB port to easily export data. At the outlet of the dispenser, the nal purication is

performed by the application-specic POD-Pak (recommended).

When not in active use, the water within the units will recirculate for three minutes every hour.

This is to maintain water quality and to avoid contamination. The system should not be turned

off as this will stop the periodic recirculation taking place.

5

QUICK START

Navigate the screen interface

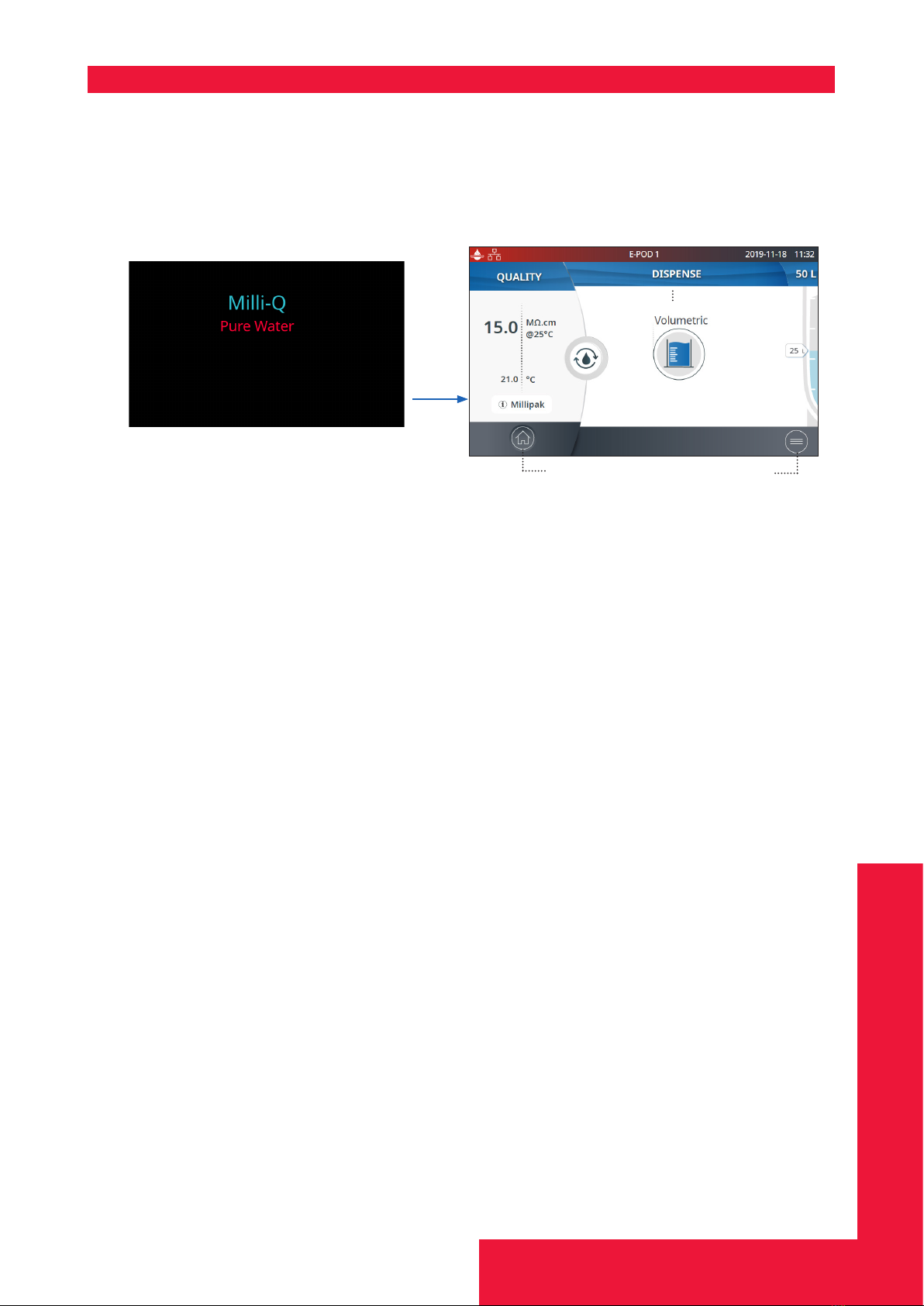

HOME SCREEN

MAIN MENUS

Home

- Water quality

information

- Dispensing functions

- Alerts & Alarms

(when generated by the

system)

- Dispense report

(when generated by the

system)

Menu

- Consumables

- Information

- Settings

- Maintenance

- Login

Go to

Consumables

Menu

Go to

Information

Menu

Go to

Settings

Menu

Go to

Maintenance

Menu

Go to

Manager access

Quick start 6

Apps

Indicates how many screens are present and where you are.

Swipe left & right anywhere on screen to switch between screens.

Pops-up

When a text box is selected, the keypad

will automatically appear.

To remove the keypad click on or

on any zone outside the keypad.

Note: When in a menu or app level screen, 1 minute of inactivity generates a time-out back

to the home screen.

When in a pop-up level screen, there is no time-out, therefore the user remains on this

screen until the pop-up is manually closed.

Important! If multiple E-POD® units are installed and a pop-up in the settings or

maintenance menus is not closed, dispensing will remain unavailable on all E-POD® units until

the pop-up is manually closed.

•••

When there

are multiple

lines, a

scroll bar is

present to

swipe up &

down

Quick start 7

Dispense pure water

Before dispensing pure water

It is a good practice to always recirculate water before dispensing. The recirculation lasts 3 minutes

and is triggered every 60 minutes.

To do this, press on the recirculation icon , this also refreshes the water quality parameters:

• EDI resistivity

• Temperature

When connected to a storage tank, always make sure there is enough water present before

dispensing. This information is always displayed on the main screen.

Dispensing pure water in free ow mode

There are several options to dispense pure water:

Manual Dispensing Full ow

To start low ow dispensing, turn the dis-

pense wheel one notch counter-clockwise.

+

To start dispensing in full ow, press the

wheel once and quickly release.

Adjust ow rate Stop

To increase the ow rate, keep turning the

wheel counter-clockwise until full ow is

reached. To decrease the ow rate, turn the

wheel clockwise.

Low ow High ow

_

+

To stop any ongoing dispensing, press down

on the wheel one additional time or rotate

the wheel clockwise until no more water ows

from the dispenser.

Quick start 8

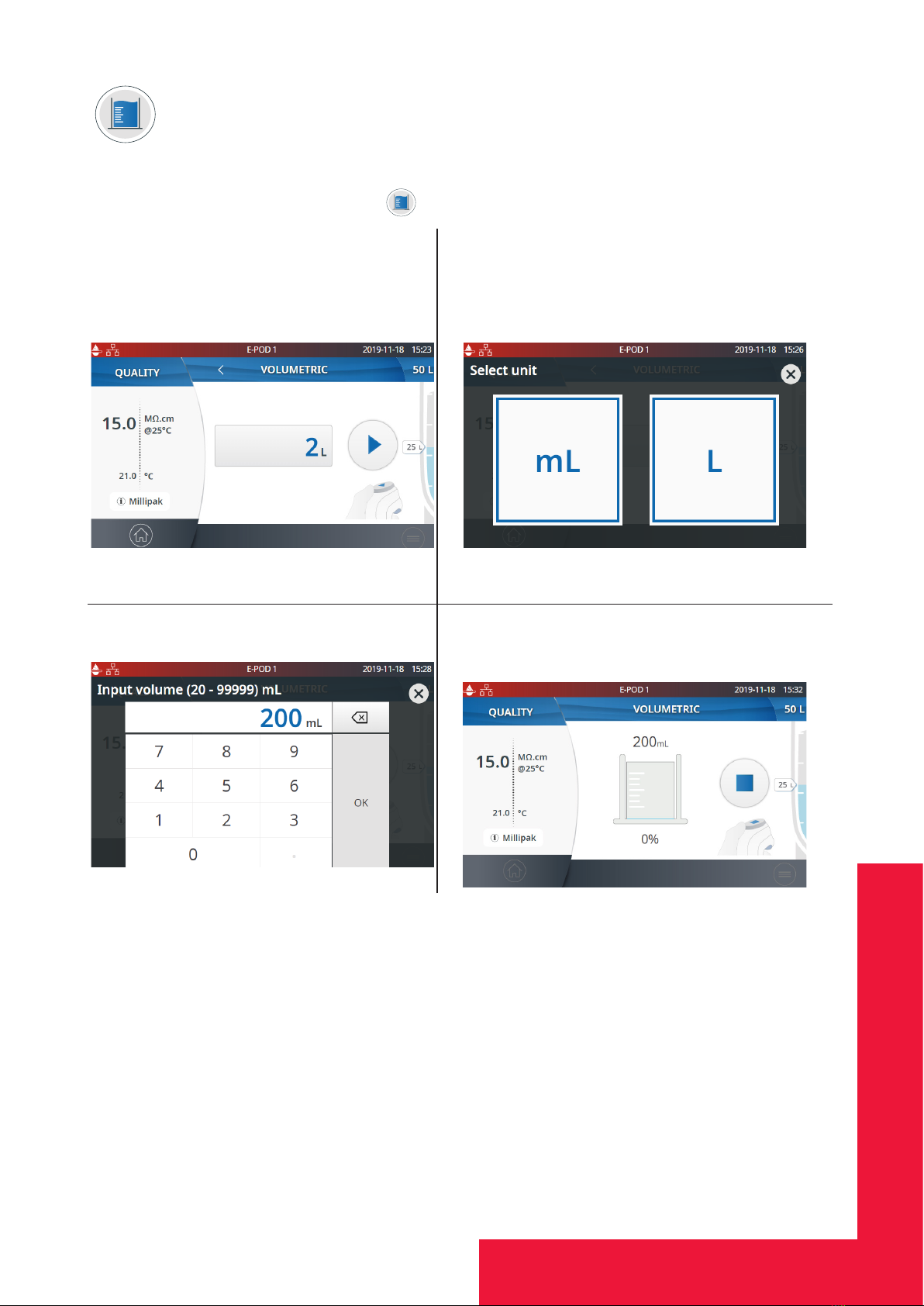

Dispensing pure water in volumetric dispensing mode

Enables a user to auto dispense a pre-selected volume (20mL to 100L, depending upon the

tank capacity). Simply press the icon of the Home screen to start a volumetric dispensing.

1- Press the pre-selected volume box to

set the desired volume to dispense. If the

volume is already ok, either press the start

button on the screen or the dispensing

wheel to initiate the dispense.

2- Select the unit.

3- Select the desired volume and press OK

to validate.

4- Press the start button on the screen, the

dispense wheel or the foot pedal to start

dispensing

5- The system will automatically stop once the input volume is dispensed. Either press the stop

button on the screen, the dispense wheel or the foot pedal to stop dispensing

Note: The system records the last volume dispensed. To repeat a volumetric dispense, click on

the start icon, press the foot pedal or press the dispensing wheel.

Quick start 9

Manage dispense reports

A dispense report is automatically produced after each dispensing operation. A dispensing

operation is considered to be all dispenses with less than 10 second intervals between them. This

can be interrupted at any time by pressing on the dispense report icon that becomes available

on the home screen as soon as a dispensing is initiated.

1. Consult the report data

Click on the dispense report icon:

2. Personalize (assign a name or experiment number)

In the user ID eld, enter the content of your choice (max 15 characters)

3. Export

- Scan the QR code® from a mobile device to instantly retrieve the report.

- Click on the export button to save the report on a USB key.

4. Automatic archiving

The dispense report icon on the home screen will automatically disappear after 5 minutes of

inactivity. Each dispense report, whether consulted or not, is automatically archived and can be

retrieved anytime by going in the history report section available in the information menu. Go to

page 14 Information > History for further information.

Dispense

report

Quick start 10

Exit screensaver

If the setting is active and there has been a certain time of user inactivity, the screensaver will

be displayed on the E-POD® touch-screen.

Tap anywhere on the screen or initiate a manual dispense by pressing the dispenser wheel to

exit the screensaver.

Home screen

Status bar

Home Menu

Quick start 11

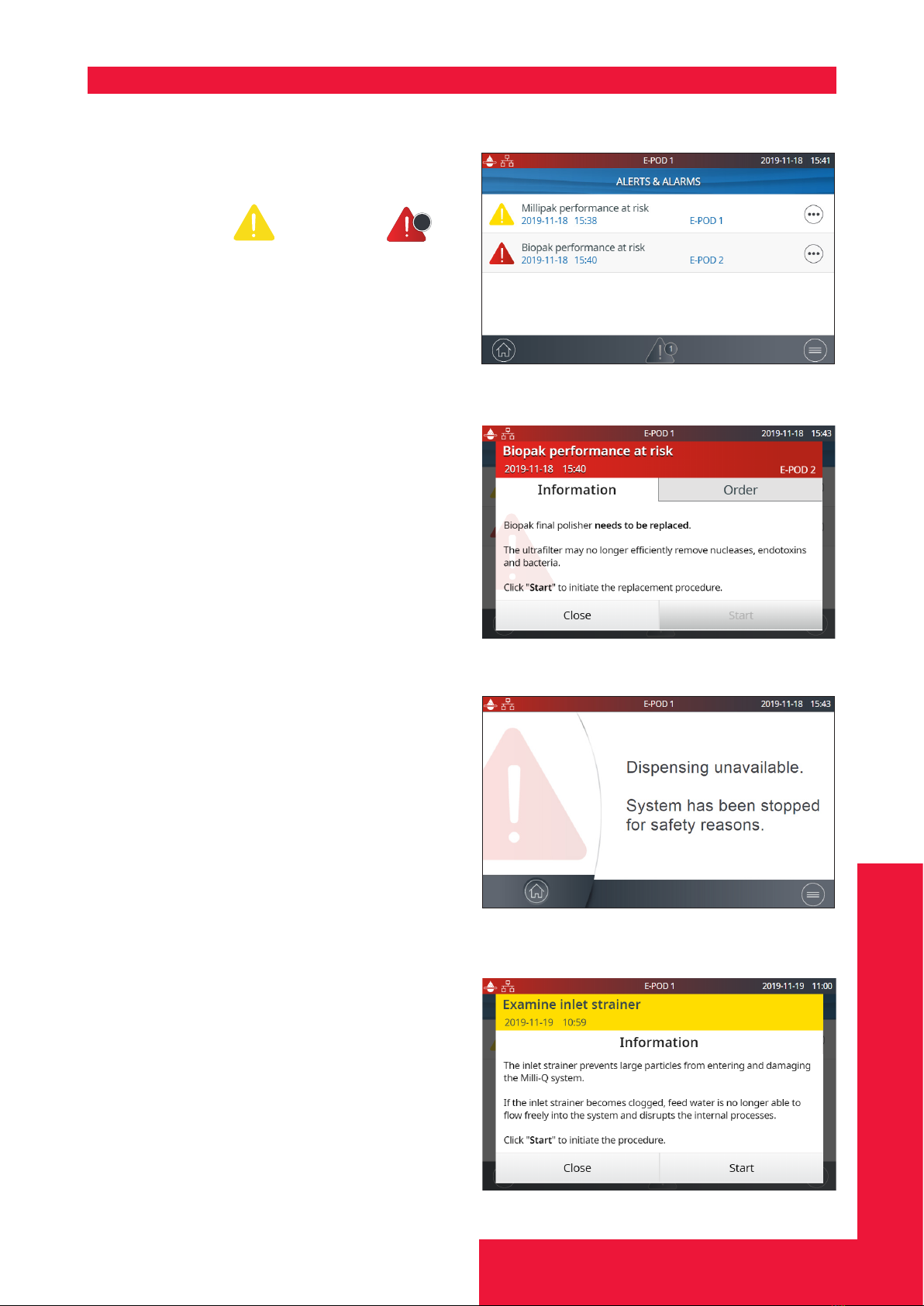

View & manage Alerts and Alarms

Alerts give you advanced warning when maintenance is required and Alarms notify you when

the system has encountered a technical issue.

Press on the alert or the alarm

1

icon

present in the bottom bar to display the alert(s)

or/and alarm(s) which are active.

Note: The notication number indicates how many active alarms are present. When there are

no active alerts or alarms, the relevant icon disappears.

Select a specic alert or alarm to get further

information and better understand the root cause.

Advice is provided in the information section to

help the user troubleshoot.

If the issue is not resolved and depending upon

the alert and alarm, either select the Contact tab

to nd the technical support hotline number for

further assistance or the Order tab containing

ordering information when applicable.

To protect the system and user applications,

alarms of a serious nature will automatically stop

the system from dispensing water.

Note: These are displayed on the screensaver to

tell the user when the system is not in active use.

Alerts provide advanced warning of any

maintenance actions that will be required. These

can be “closed” to be reminded again in 24h or

can be “cleared” permanently.

An Order tab can also be present when

applicable.

12

CONSUMABLE MENU

View consumables status

Colour icons allow to instantly view the status of all installed consumables.

Press on the

•••

icon to get the

consumable ID, ordering information and a

description of the purication technology.

Note: Certicates of quality are now available online www.mymilliqconsumables.com

All cartridges have been designed to be easily replaced by a user. A short-cut is available to the

replacement wizard by clicking on the “replace pack” button in the pop-up.

Important! Mercury-free ech2o® UV lamps should not be replaced by users. Contact the tech-

nical support hotline to organize a replacement visit.

Green:no action required

Yellow: notice for a maintenance action

Red: maintenance required!

Consumable Menu 13

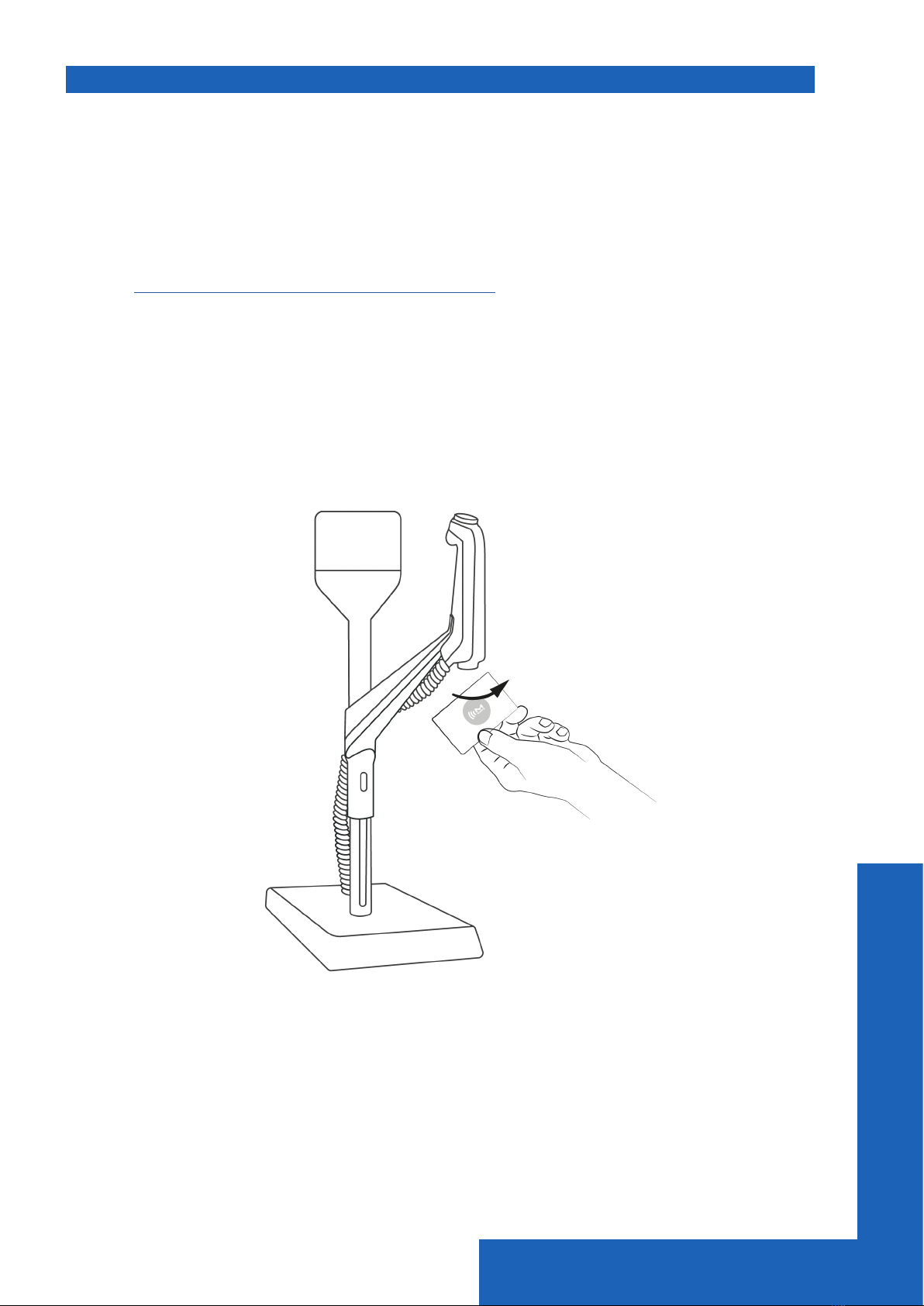

Consumables identication with card reading

For each consumable, the following pieces of information are available:

• lot number

• catalog number

• installation date

The IPAK Gard® and application POD-paks information is automatically registered during their instal-

lation.

The tank vent lter comes with a RFID card enabling the transfer of the data into the system. Go to

page 29 Maintenance>Consumables installation wizard for further information.

14

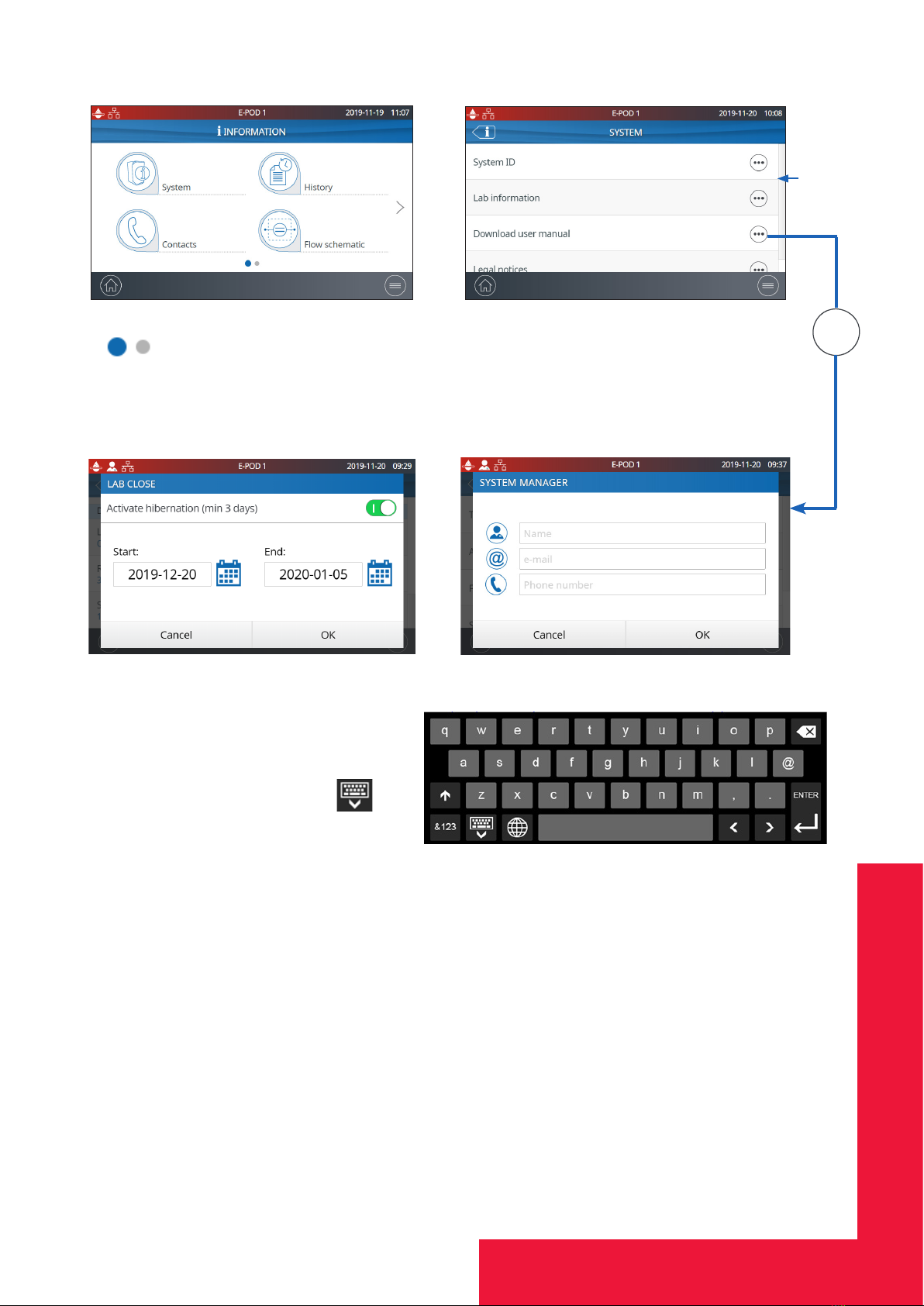

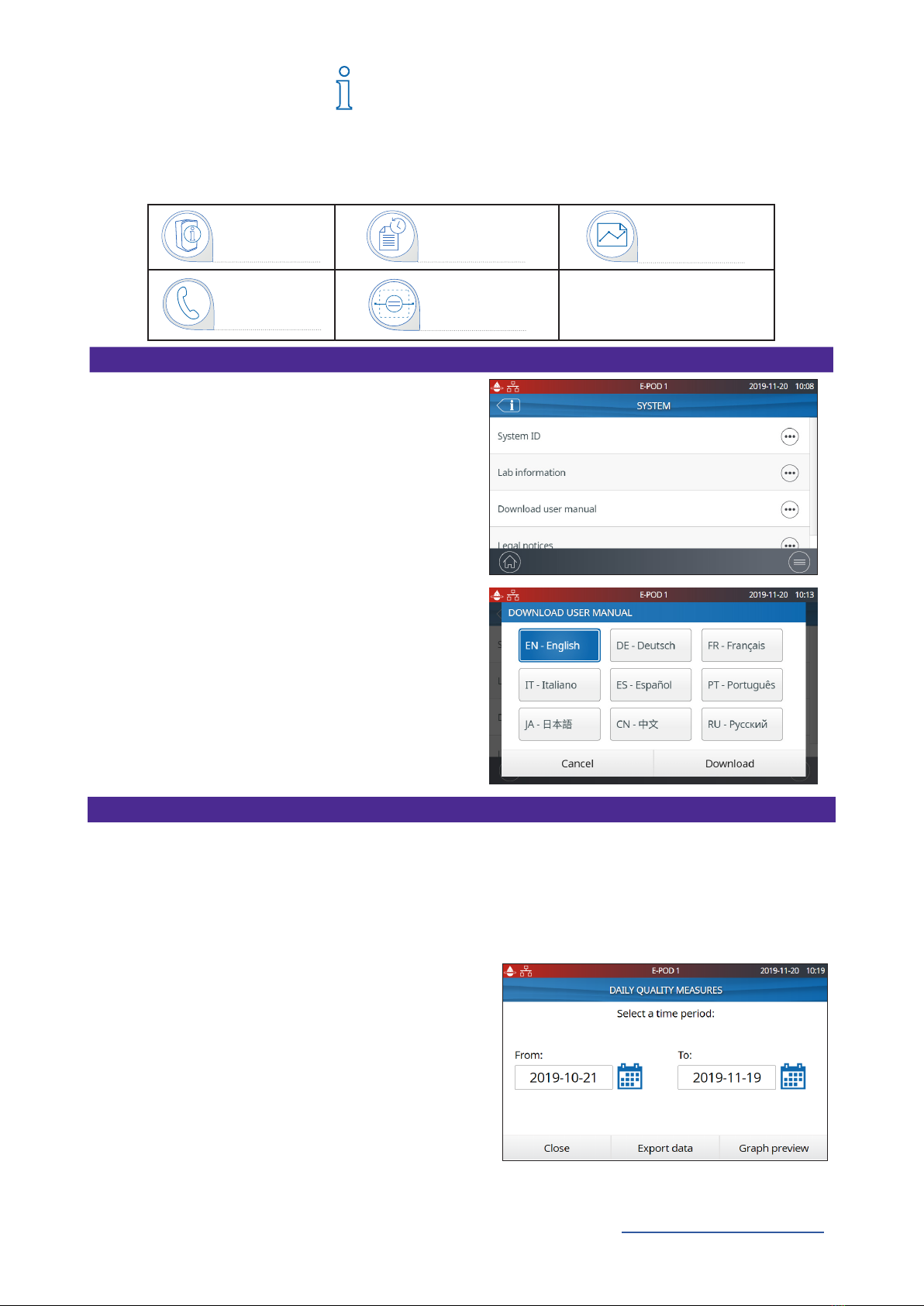

INFORMATION MENU

This menu contains useful system information and provides a system status. Dispensing is

available while in this menu.

Available apps:

System

Find system details

Select System ID to nd the information on the

water system model and installation details.

Download user manual

The user manual is available in 9 languages

and it can be downloaded through an USB key

or if connected to a network, to any computer

device.

History

2 user reports exist:

• Daily quality measures report

Each row represents a day (24h) and is dated. It contains daily averages for product

resistivity and temperature. Also included is the total volume dispensed during the day.

• Dispensing events report

Each row is a dispense operation. It is an archive of all the dispense reports.

To export data or preview a graph:

1. Select a time period of interest with a start and

end date.

2. A graph pre-view of the last 30 records is

available on the E-POD® screen.

3. Export the report in .ods (open document

source) format to visualize the full data and

integrate them into a data management system.

Note: A complete history report with all system activity is available. By default it is only

available when logged-in as the system manager. This can be modied by de-activating

the system manager prole in the settings menu, go to page 19 Settings>Manager access.

System

Contacts

History Troubleshooting

Flow schematic

Information 15

Flow schematic

This is a graphic representation of the hydraulic components of the water purication system.

Components change colour depending on the state and system status.

Grey - inactive Blue - active

Yellow - maintenance alert Red - technical issue alarm

Production ow schematic

Distribution ow schematic

Troubleshooting

Access a diagnostic summary.

This app contains all the necessary information in one location for effective troubleshooting

when in contact with the technical support hotline.

• System information & last service visit

• Water quality & consumables (installed dates)

• Active alerts, alarms & auto-test results

• Diagnostics

Information 16

Contacts

To edit contact information, login as the system manager, go to page 19 Settings>Manager

access. The user parameters are used on various reports generated by the system and can

quickly help users identify the right contact for any questions or issues.

Technical support hotline

Application specialist

Field service engineer

System manager

Maintenance operator

In case of troubleshooting

Application enquiries or quote requirements

Only in selected countries, contact technical support

Responsible for system conguration & quality settings

Responsible for maintaining the system

17

Different settings are available to customize the water purication system operation.

Depending on the user prole (end-user operator / system manager) some of the settings will

have either read-only or read & write access.

Available apps:

°C / °F

Note: Dispensing while in this menu is not available.

SETTINGS MENU

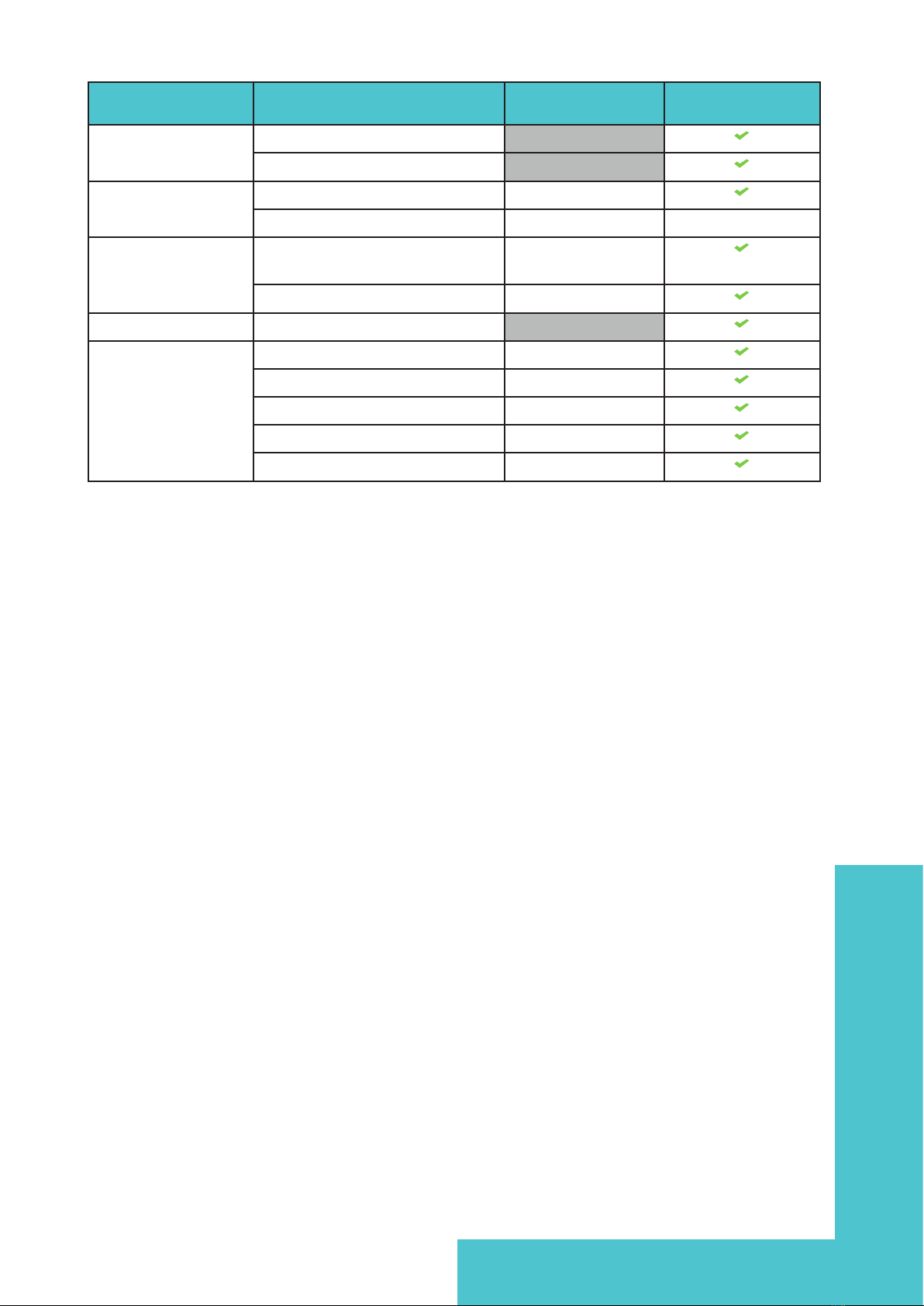

Settings End-user System

Manager

General system

Conguration

Screen saver Read only

Water sensor Read only

Alarm relay Read only

Production

conguration

Periodic EDI rinsing check time Read only

Periodic EDI rinsing duration Read only Read only

Periodic EDI rinsing period Read only Read only

Tank conguration Tank capacity Read only Read only

Tank rell setpoint Read only

ech2o® ASM lamp cycle start hour Read only

Distribution

conguration

Lab close

Recirculation Duration Read only Read only

Safety ow stop Read only

Production alarm

conguration

EDI resistivity Read only

Permeate conductivity Read only

RO ionic rejection Read only

RO feed conductivity RO high Read only

RO feed conductivity tap high Read only

Inlet strainer clean Read only

Cl2 clean Read only

IPAK Gard lifetime

IPAK Gard volume

Tank alarm

conguration

Vent Filter

Tank empty Read only

System

Conguration

POD

Conguration

Date, Time &

Language

Password

Alarm

Conguration Connectivity Units

Settings 18

Settings End-user System

Manager

Distribution alarm

conguration

Millipak®

Millipak® Gold

Connectivity Local network Read only

Wi-Fi conguration Read only Deactivation only

Date, Time & Lan-

guage

Time zone - Date - Time Read only

Select language Read only

Password System manager

Units Resistivity / Conductivity Read only

Temperature Read only

Storage tank Read only

Temperature compensation mode Read only

Pressure Read only

This manual suits for next models

7

Table of contents

Other Milli-Q Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Spirotech

Spirotech SPIROVENT Installing and operating instructions

Calpeda

Calpeda PF operating instructions

Elecro Engineering

Elecro Engineering H.R.UV-C Installation & operating manual

PoolRite

PoolRite InnoChlor P15 user manual

Gardena

Gardena Filter Set 3000 operating instructions

fish mate

fish mate 2000P-UV quick guide

Bestfilters

Bestfilters UCT200 Installation, use & care guide

Osmio

Osmio Clarity user manual

Graf

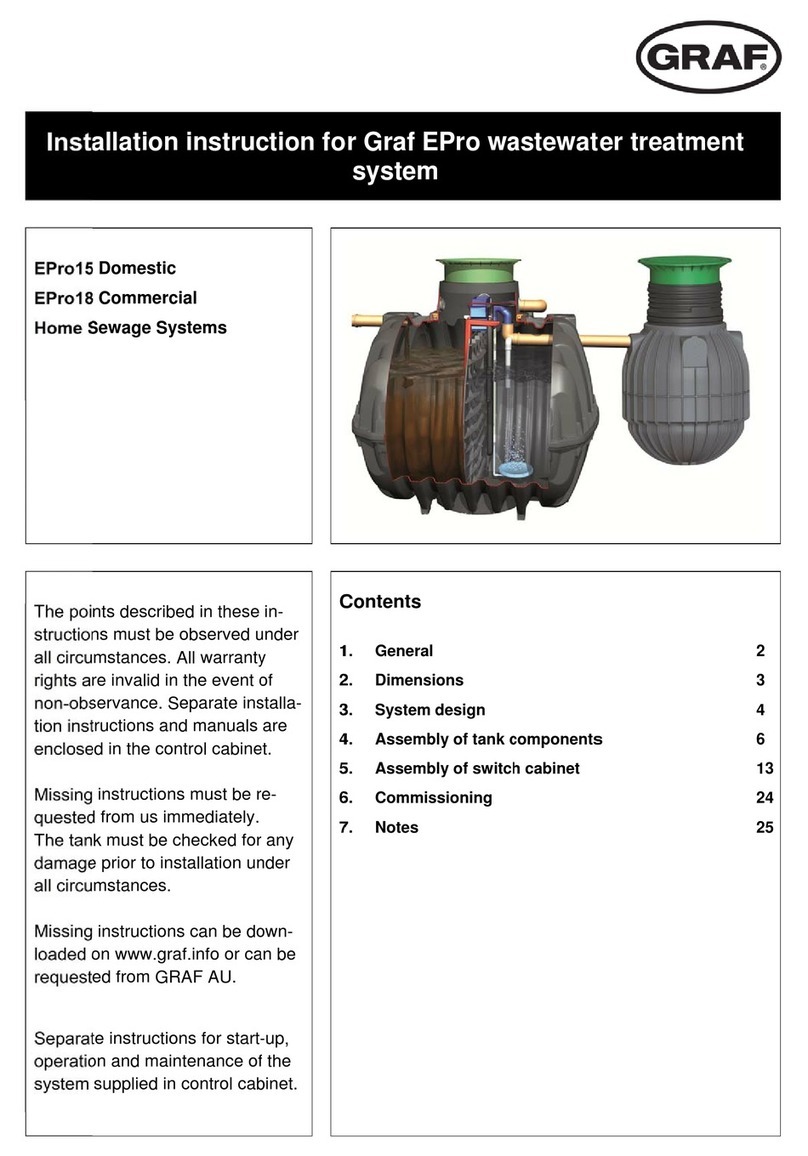

Graf EPro Series Installation instruction

Pico Macom

Pico Macom CEF/750 Installation and operation manual

Dormont

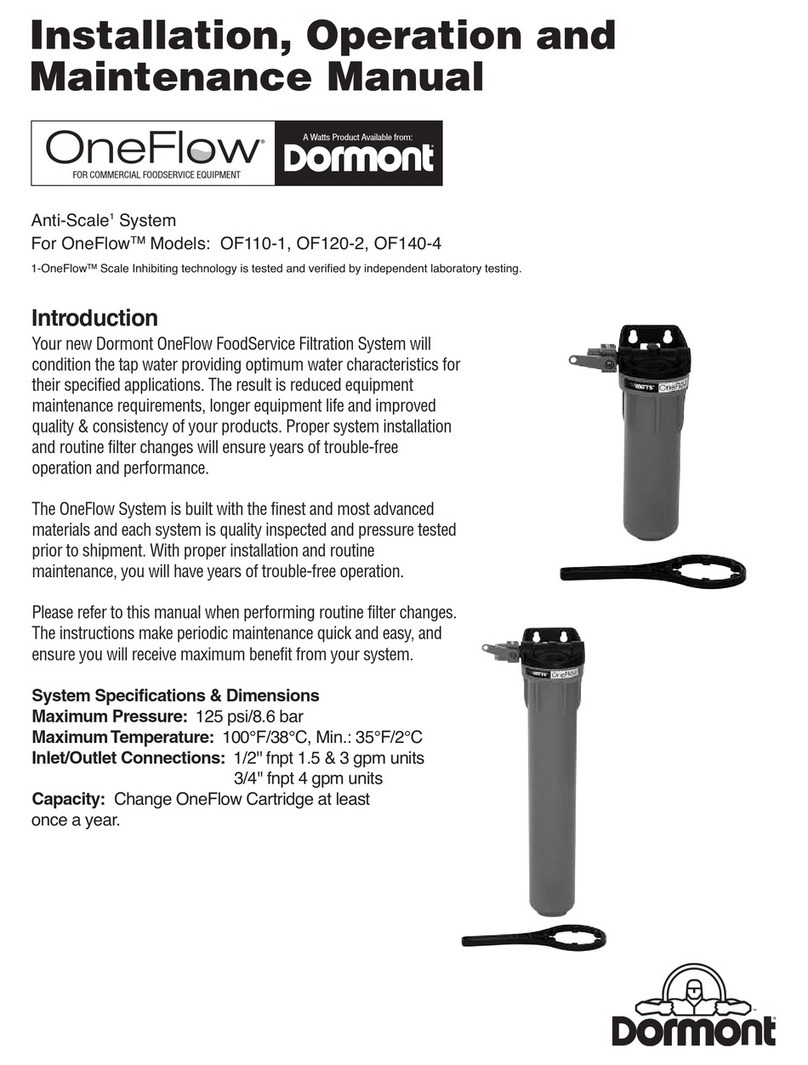

Dormont OneFlow OF110-1 Installation, operation and maintenance manual

Merck

Merck Milli-Q Advantage A10 System Quick reference guide