Milwaukee M18 User manual

Other Milwaukee Tools manuals

Milwaukee

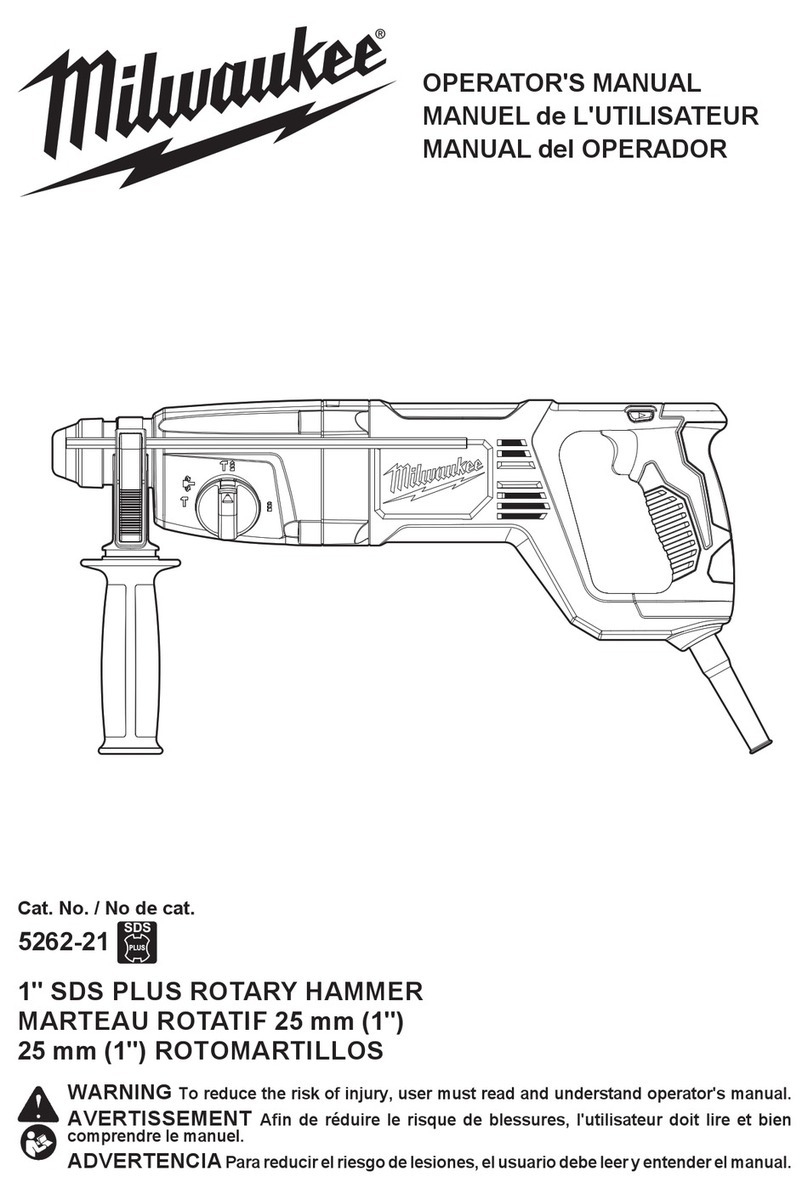

Milwaukee 5262-21 User manual

Milwaukee

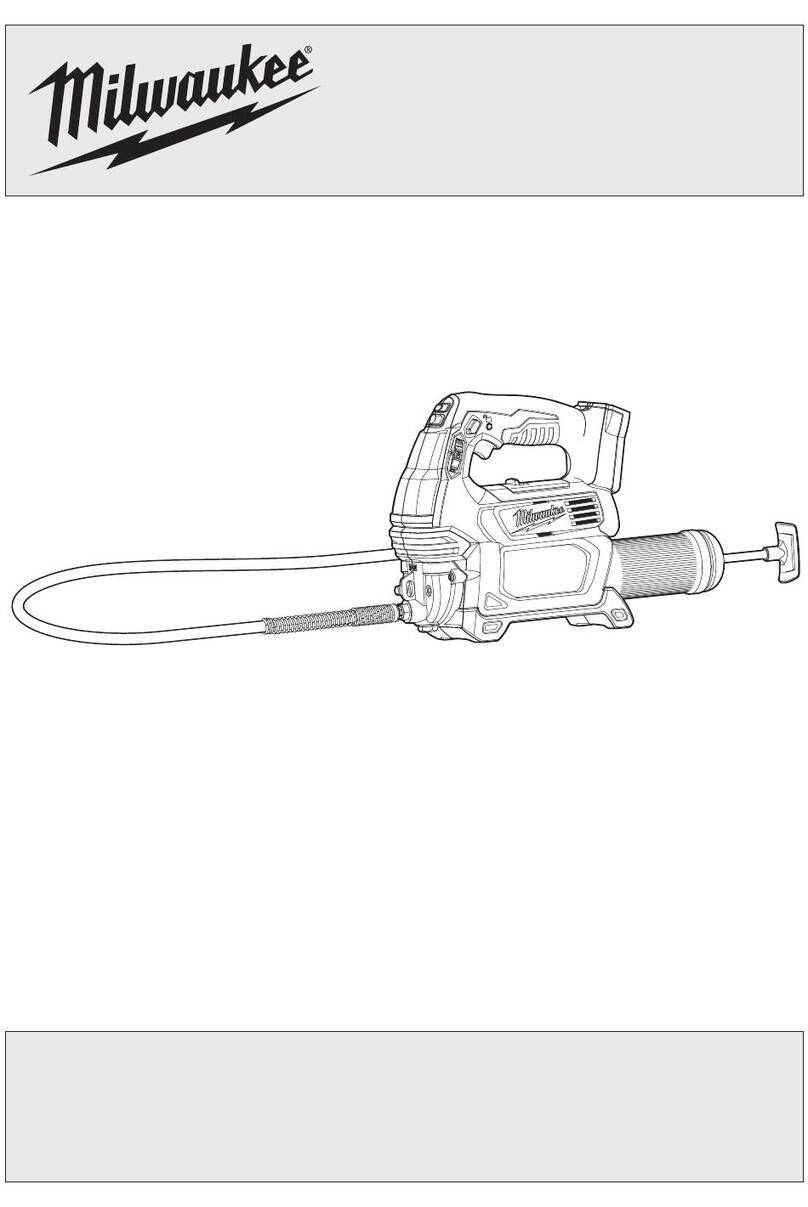

Milwaukee M18 GG User manual

Milwaukee

Milwaukee M18 2676-20 User manual

Milwaukee

Milwaukee 48-22-4179 User manual

Milwaukee

Milwaukee M12 PCSS User manual

Milwaukee

Milwaukee M12 FRAIWF38 User manual

Milwaukee

Milwaukee 5339-20 Setup guide

Milwaukee

Milwaukee M18 ONEFHIWF1D User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee M12 BPRT User manual

Milwaukee

Milwaukee M12 UDEL User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee DR 250 TV User manual

Milwaukee

Milwaukee M18 FIW212 User manual

Milwaukee

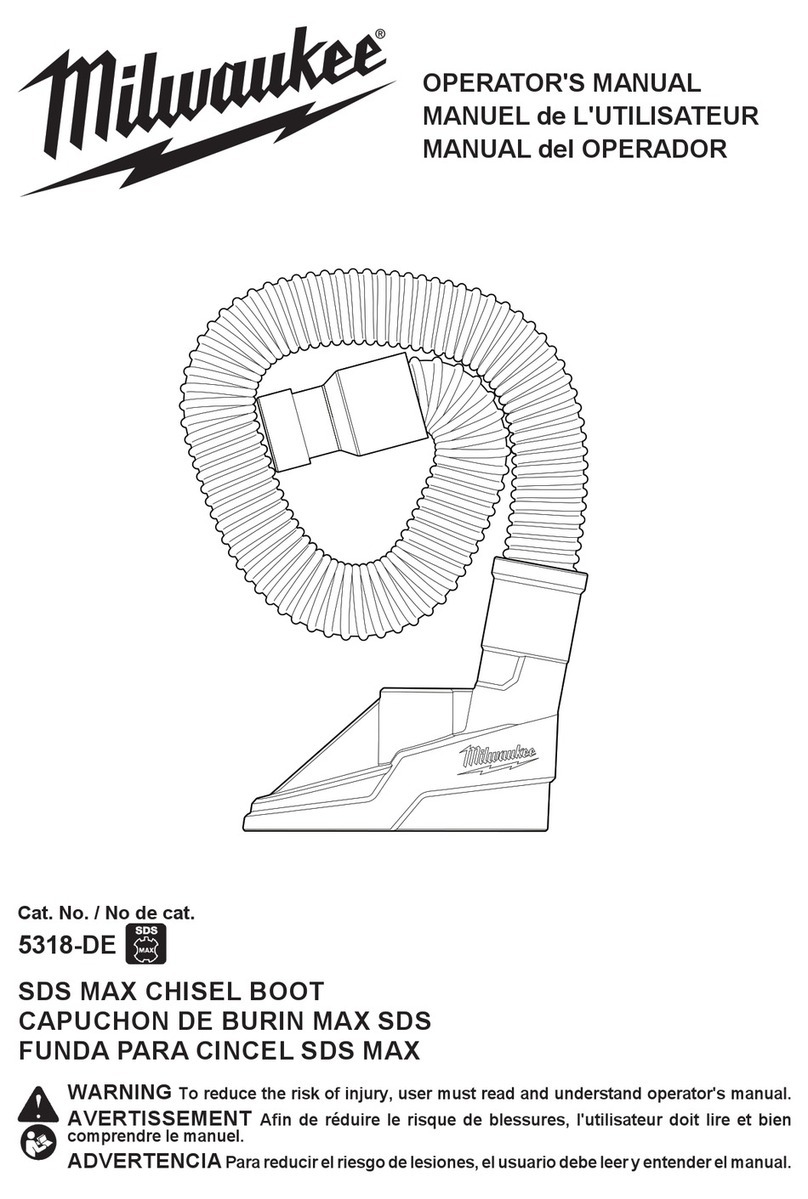

Milwaukee 5318-DE User manual

Milwaukee

Milwaukee M18 BP User manual

Milwaukee

Milwaukee TRAPSNAKE 2574 SERIES User manual

Milwaukee

Milwaukee BSPE 110 X User manual

Milwaukee

Milwaukee M18 FUEL FPT114-0C User manual

Milwaukee

Milwaukee 135 User manual