4

RECEIVING TOOL

The VE12 tool is individually packaged in a

heavy cardboard container. Upon receipt,

check to be certain all necessary parts are

included.

Included should be:

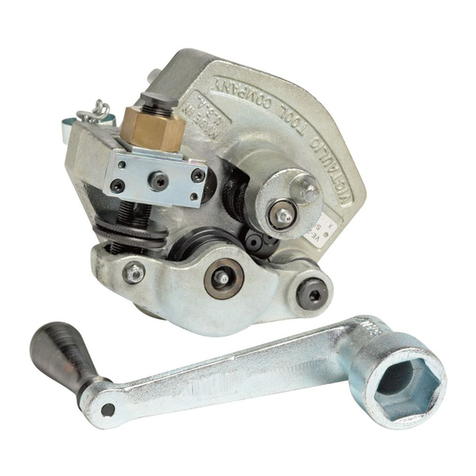

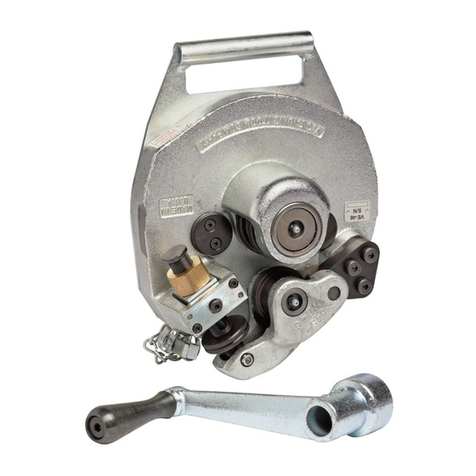

(1) Victaulic VE12 tool

(1) Set of feeler gauges (attached to tool)

(1) Crank

(2) Operating Instruction Manual

If incomplete, contact your Victaulic Distributor

or the Victaulic Tool Company.

PRE-OPERATION

Pipe Preparation

For proper tool operation, and production of

proper pipe grooves, carefully observe the fol-

lowing pipe preparation tips.

1.

Pipe ends must be square cut (see column 2

notation on “Standard Roll Groove Specifica-

tions - Steel and other IPS Pipe”, page 9).

2.

Internal or external weld bead or seams

must be ground flush with the pipe surface

extending 2" back from the pipe end.

3.

The end of the pipe, both inside and out,

must be cleaned of coarse scale, dirt and other

foreign material.

Foreign material such as coarse scale or dirt might

interfere with or damage the grooving rolls or dis-

tort the groove. Rust is an abrasive material and

will tend to wear out the surface of the grooving

rolls. For maximum grooving roll life, remove for-

eign material and loose rust.

TOOL AND PIPE SET UP

This tool can be used to groove pipe clamped

in a pipe vise or pipe that is in place.

Pipe Vise Set Up

The choice of grooving location in the shop or

field should take into account the following fac-

tors:

■

Pipe handling requirements

■

Working space requirements for the tool

and pipe

Procedure

1.

Securely mount pipe vise (chain type)

on a secure stand or workbench able to

support the tool (16 lbs.), the pipe, and

resist the torque (approx. 20 ft.-lb.)

required to operate the tool.

Pipe vise

should be mounted flush with or overhanging

the edge of the stand or workbench so that

when the tool is mounted on the pipe, the tool

will rotate freely around the pipe and not be

obstructed by the bench or stand.

2.

Secure pipe in pipe vise. Position the pipe to

overhang the pipe vise approximately 5 - 12" as

shown so that the tool can rotate in an unob-

structed manner.

Groove-In-Place Set Up

Previously installed piping may be grooved

with the VE12 providing the piping is securely

supported, depressurized and drained.

Pipe hangers must be able to accommodate the

weight of the 16-lb. VE12 plus the manual effort to

operate the tool (approximately 20 ft.-lb. torque)

during grooving.

VE12

TM-VE12.0743 Rev.A Page 4 Tuesday, May 29, 2001 6:04 PM