Milwaukee M12 FRAIWF38 User manual

Other Milwaukee Tools manuals

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee HEAVY DUTY M12 FTB User manual

Milwaukee

Milwaukee M18 GG User manual

Milwaukee

Milwaukee 135 User manual

Milwaukee

Milwaukee M18 HCC75 User manual

Milwaukee

Milwaukee HEAVY DUTY BTT User manual

Milwaukee

Milwaukee M18 BOS125 User manual

Milwaukee

Milwaukee M18 User manual

Milwaukee

Milwaukee FUEL FTR User manual

Milwaukee

Milwaukee M18 FDDEL32 User manual

Milwaukee

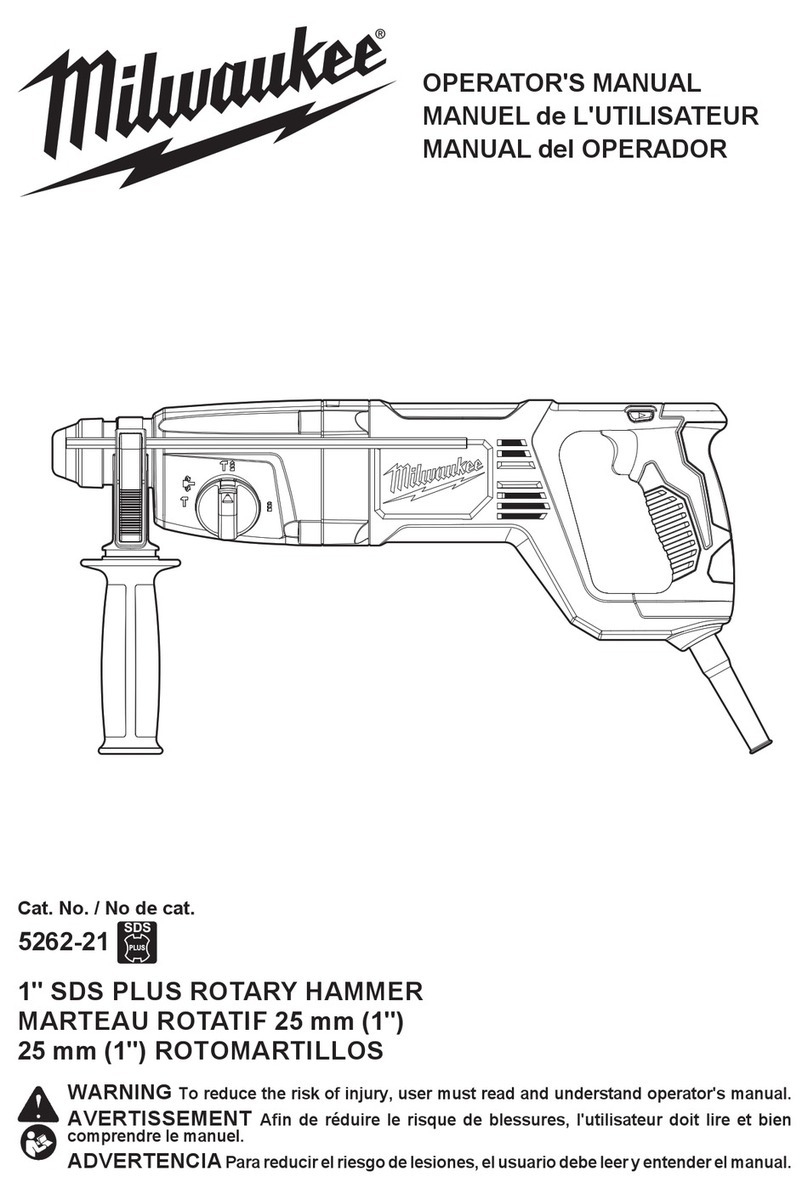

Milwaukee K 1528 H User manual

Milwaukee

Milwaukee 5339-20 Setup guide

Milwaukee

Milwaukee M12HPT-0 User manual

Milwaukee

Milwaukee 2646-20 User manual

Milwaukee

Milwaukee M18 FAP180 User manual

Milwaukee

Milwaukee HEAVY DUTY TRB 1 User manual

Milwaukee

Milwaukee M18 FUEL 2819-20 User manual

Milwaukee

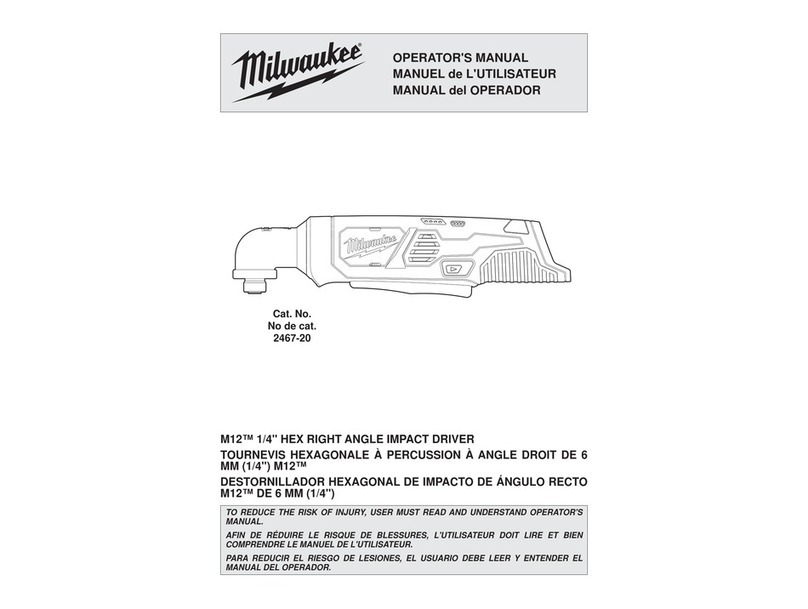

Milwaukee M12 2467-20 User manual

Milwaukee

Milwaukee 5336-22 User manual

Milwaukee

Milwaukee M18 FORCELOGIC 2773-20L User manual