INTRODUCTION

The MinXray HF100H is a mono-block type high frequency portable x-ray unit designed for general

purpose medical radiography. The HF100H can be used with conventional x-ray film or with digital

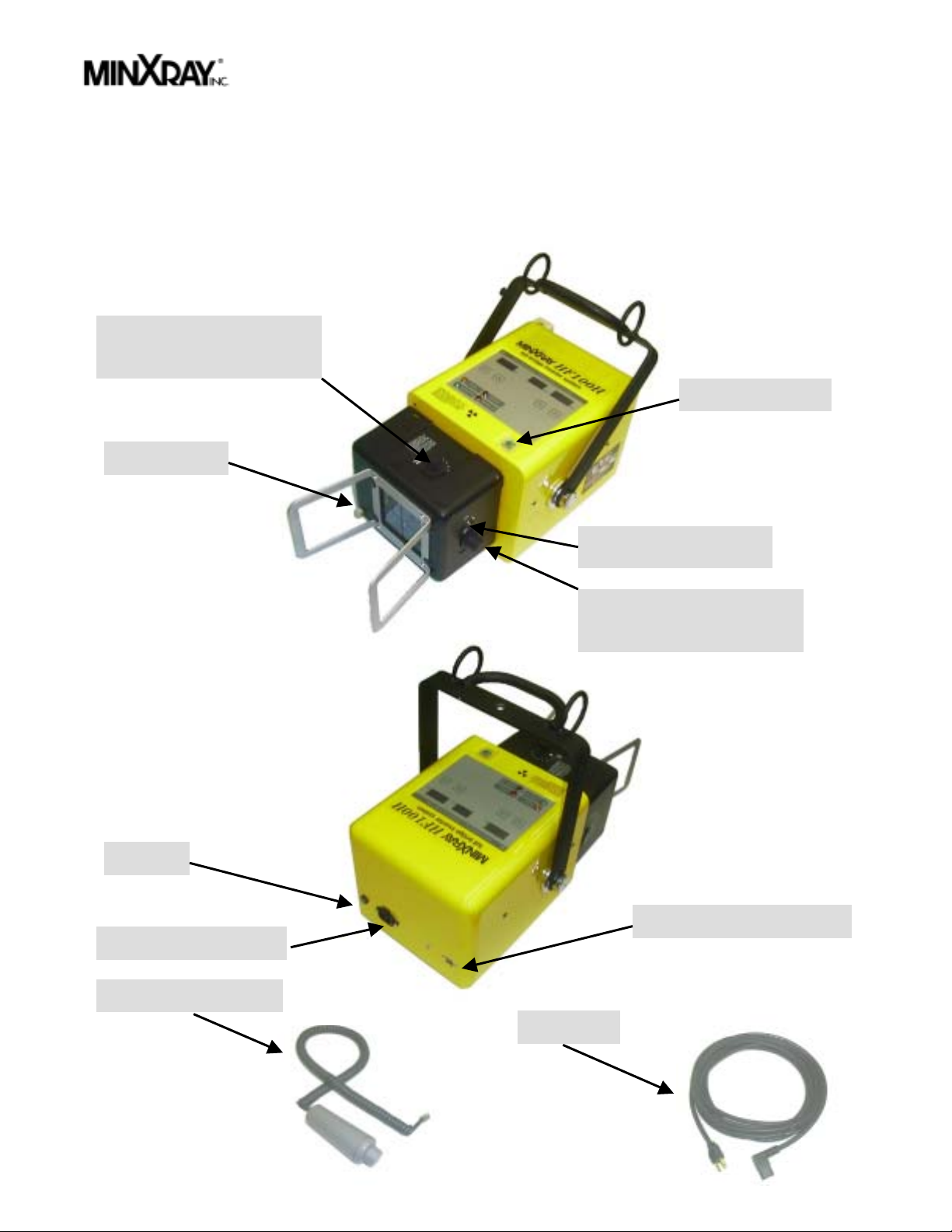

imaging media. It consists of an x-ray tubehead/control attached to which is a continuously

adjustable light beam collimator. A trunnion enables the HF100H to be attached to a suitable stand,

such as the MinXray XGS series of portable mobile stands. The HF100H is supplied with a

detachable AC power cord, and a detachable exposure cord with a 2-stage exposure switch.

CARELESS OR IMPROPER USE OF X-RAY EQUIPMENT CAN BE EXTREMELY HAZARDOUS. It

is imperative that this equipment be operated and serviced only by trained personnel familiar with

the safety precautions required to prevent excessive exposure to primary X-ray radiation, the

dangers of exposure to X-ray radiation, and the proper use of the equipment discussed in this

manual.

All personnel authorized to operate or service this equipment should be fully acquainted with the

established maximum permissible doses, safety recommendations, and procedures derived from the

following sources:

A. National Council on Radiation Protection Report No.33 (Medical X-Ray and Gamma Ray

Protection for Energies up to 10 MEV - Equipment Design and Use); from NRCP

Publications; P.O. Box 30175, Washington, D.C. 20014.

B. National Bureau of Standards Handbook No.76 (Medical X-Ray Protection up to Three

Million Volts); from the Superintendent of Documents, Government Printing Office,

Washington, D.C. 20401.

C. All documents relating to the Performance Standard for Diagnostic X-Ray Systems, 21

CFR Subchapter J, Part 1020; obtainable from FDA Center for Devices and Radiological

Health, Department of HHS, 2098 Gaither Road, Rockville, MD 20850.

D. State and local regulations governing radiation protection and the use of diagnostic X-ray

equipment.

E. Requirements of the user’s in-house radiation protection program.

F. Instructions and precautionary notices of this manual.

Although this equipment incorporates protective design features for limiting both the direct (primary)

x-ray beam and the secondary radiation produced by this beam, design factors alone cannot prevent

human carelessness, negligence, or lack of knowledge. This apparatus is sold with the

1