14 | DAILY START-UP PROCEDURES AND HUMAN MILK ANALYSIS Miris HMA™ User Manual Miris HMA™ User Manual DAILY START-UP PROCEDURES AND HUMAN MILK ANALYSIS | 15

This chapter describes routines for human milk sample analysis with the Miris HMA™.

For the rst start-up of a new instrument, refer to the start-up procedure in Chapter 1.

Follow the cleaning instructions in Chapter 3, zero-setting check procedure in Chapter 4

and the instructions for milk sample preparation in Chapter 5 accordingly.

When performing a measurement or zero-setting check it is very important to leave the

syringe on the inlet for the entire procedure, see Figure 13. Leave some of the uid in the

syringe to avoid introduction of air into the cuvette, as this may lead to inaccurate results.

For detailed instructions, go to the specic chapters referenced

in this SOP.

For further details on use and handling of Miris Ultrasonic Proces-

sor, refer to instructions in the Miris Ultrasonic Processor manual.

Notes on sample handling (further information in Chapter 5)

Control the integrity of each sample before use by checking that

specied storage temperature has been maintained and that there

are no signs of leakage or breakage of the sample container.

Defrost frozen samples at room temperature or in a refrigerator, or

in a cold water bath.

Control the sample for quality issues: e.g. the milk is churned, if a

distinct smell from free fatty acids is noticeable, if during, or after,

preparation of the sample, white particles are visible on the walls

of the sample container, fat droplets oat on the surface of the

sample. If any of these issues are noted the analysis might not be

accurate and the sample should be discarded.

STANDARD OPERATING PROCEDURE (SOP)

Figure 13.

Leave the syringe on the inlet during

the measurement.

Equipment Consumables

Miris HMA™

Ultrasonic processing device, Miris Ultrasonic Processor

Heating bath at 40°C (104°F)

Thermometer (not provided by the manufacturer)

Note! All solutions must be 35-40°C (95-104°F) when injected

into the instrument.

Miris Check™

Miris Cleaner™

Distilled/deionised water (not provided by the manufacturer)

Syringes, 2 ml and 5 ml

Waste container (not provided by the manufacturer)

Emery cloth for the ultrasonic processing device

Miris Calibration Control Kit™

Always keep sample containers securely sealed in order to avoid

evaporation, only remove the lid briey to take out samples.

Mix the milk thoroughly by gentle inversion or swirling of the

sample container. No shaking in order to avoid foaming.

If foam is formed in the sample, this needs to disintegrate com-

pletely before sample withdrawal for analysis.

A sample withdrawn by syringe must be immediately injected into

the instrument and immediately analysed.

A new sample withdrawal and injection needs to be made for each

analysis.

Avoid multiple sample container transfers.

Injection technique:

make sure liquids are injected with correct pressure. Too high

pressure (>3 bar) will divert the liquid via the valve at the side of

the CPG (see Chapter 1, in- and outlets).

Table 1. Standard Operating Procedure A

A1. Set-up Defrost frozen samples at room temperature or in a refrigerator or a cold water bath

Turn on the heating bath to warm up to 40°C (104°F)

Prepare working solutions of Miris Check™ and Miris Cleaner™

Pour the daily requirement of working solutions of Miris Check™ and Miris Cleaner™, and of distilled water, into

separate bottles to use for the day’s work

Place bottles of distilled water, and working solutions of Miris Check™ and Miris Cleaner™ in the heating bath

Turn on the Miris Ultrasonic Processor and the Miris HMA™

Place a waste container by the Miris HMA™ outlet

Wait at least 30 minutes before proceeding to A2

A2. Instrument preparation Select ‘Analysis’ in the main menu

Set the Miris Ultrasonic Processor on the correct processing time (1.5 s/ml)

Control that the Miris Ultrasonic Processor probe is clean and that the tip is evenly polished

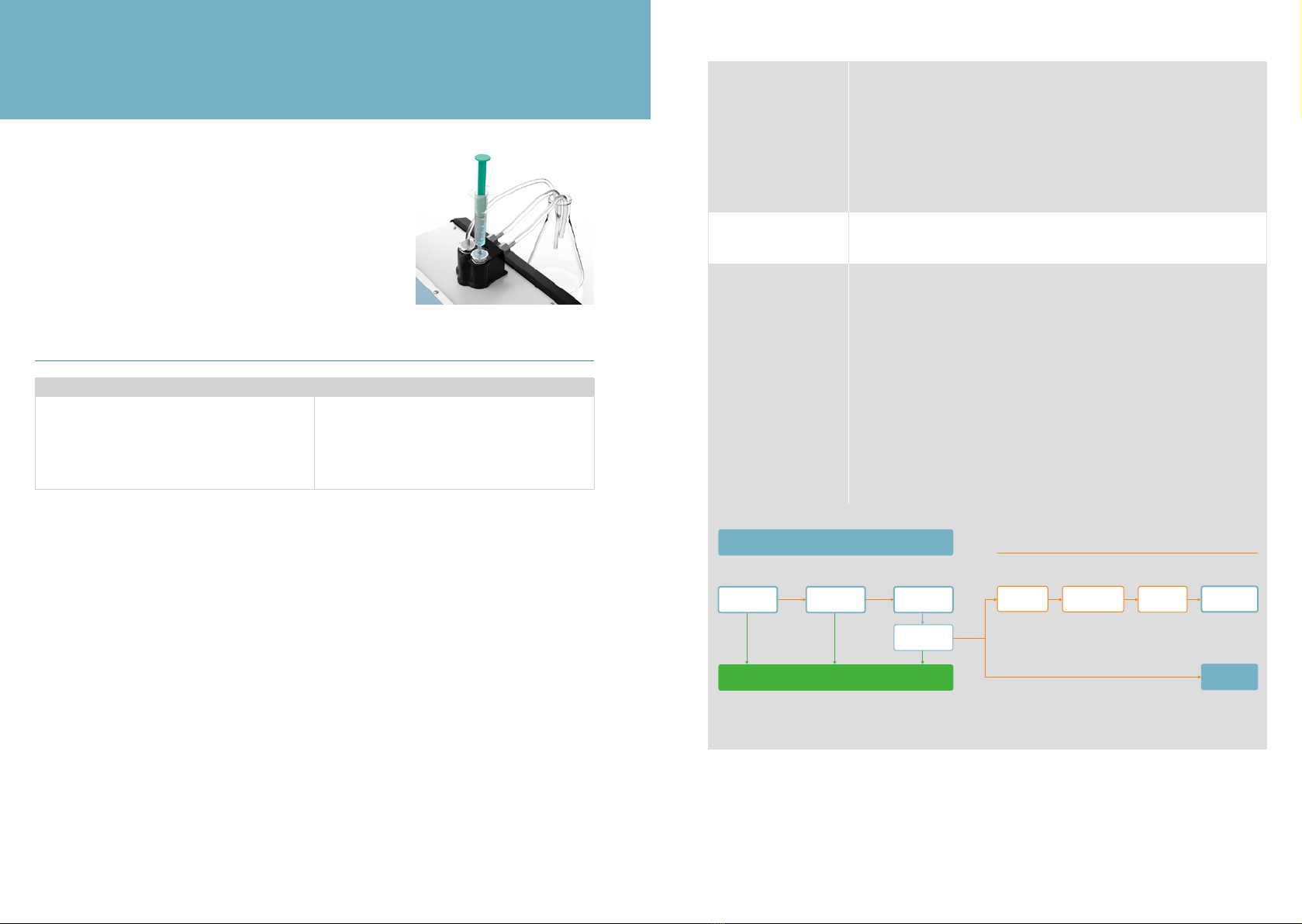

A3. Zero-setting check

Further information in Chapter 4

Watch the ‘Zero-setting check

procedure’-video at

MirisSolutions.com for details

Select ‘Analysis’ in the main menu

STEP I: Inject 3 ml Miris Check™

Press ’Check’ and wait for the result, approximately one minute

Display message “No adjustment necessary”: continue to A4

Display message “Adjustment necessary”: go to STEP II

STEP II: Inject 2 ml Miris Check™

Press ‘Check’ and wait for the result, approximately one minute

Display message “No adjustment necessary”: continue to A4

Display message “Adjustment necessary”: go to STEP III

STEP III: Press ‘Adjust’, wait for the display message “New adjustment done”

Inject 1 ml Miris Check™ Press ‘Check’ and wait for the result, approximately one minute

Display message “No adjustment necessary”: continue to A4

Display message “Adjustment necessary”: repeat STEP III

MIRIS HMA™ USER GUIDE

Chapter 2 DAILY START-UP PROCEDURES AND HUMAN MILK ANALYSIS

Check

zero-level

Start up / After 10 analyses and cleaning

Start quality control procedures / continue analysis

Check

zero-level

Adjust

zero-level

Check

zero-level

TROUBLESHOOTING GUIDE

STEP I STEP II STEP III

Not ok Not ok

Not ok

Ok Ok Ok

Clean the

cuvette

Prepare new

Check solution

Clean the

inlet lter

Repeat from

STEP I

Contact Miris

Support

After rst Adjust

After second Adjust

Overview of the Miris HMATM zero-setting check procedure with troubleshooting guide. ‘Check zero-level’ includes injection of Miris CheckTM solution and starting the

Check analysis. After completing the zero-setting check procedure, run control samples before any sample analysis.