Nanoliter 2000

World Precision Instruments iii

Copyright © 2012 by World Precision Instruments, Inc. All rights reserved. No part of this publication

may be reproduced or translated into any language, in any form, without prior written permission of

World Precision Instruments, Inc.

CONTENTS

ABOUT THIS MANUAL .....................................................................................................1

INTRODUCTION..................................................................................................................2

General Notes.................................................................................................................2

Parts List............................................................................................................................2

Unpacking........................................................................................................................3

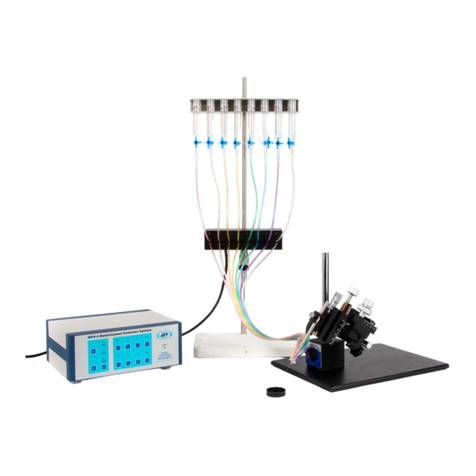

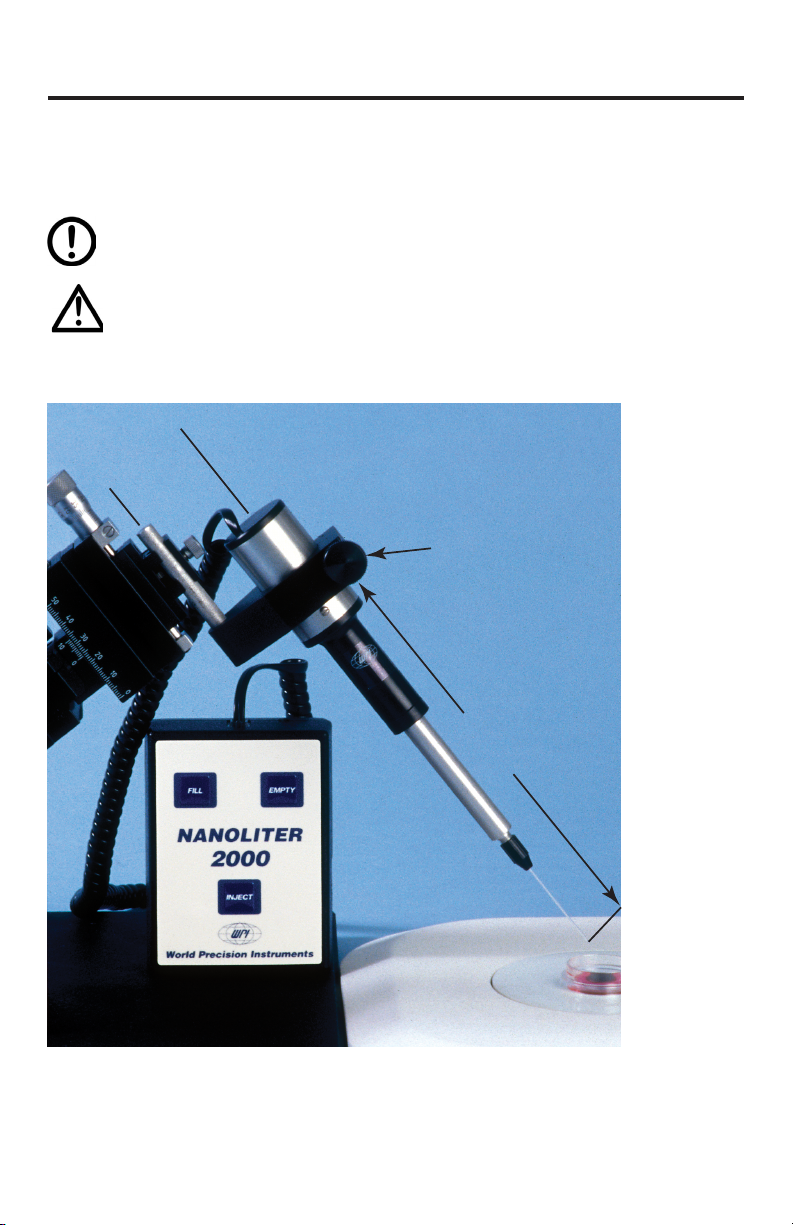

INSTRUMENT DESCRIPTION..........................................................................................4

Instrument Description ................................................................................................4

Controller Buttons ....................................................................................................5

Plunger in “HOME” Position..................................................................................6

OPERATING INSTRUCTIONS...........................................................................................7

Micropipette Pulling......................................................................................................7

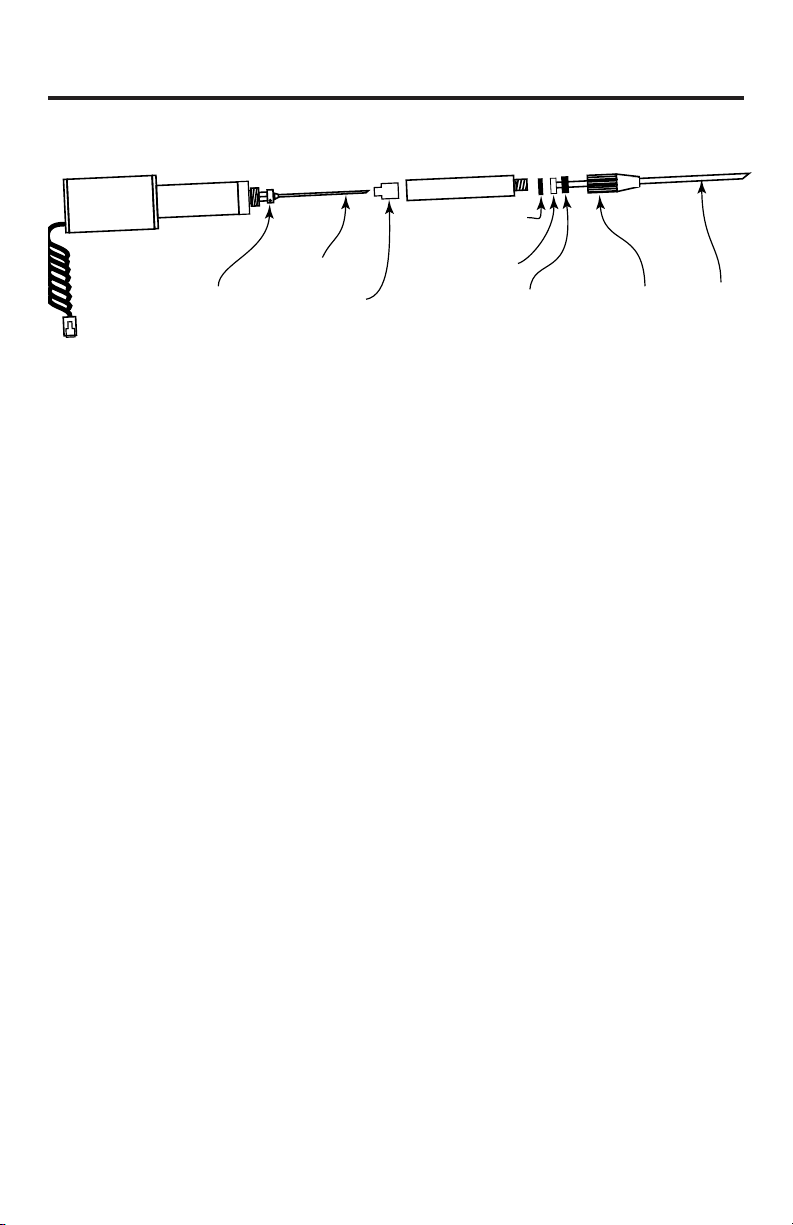

Securing the Micropipette to the Injector..............................................................7

Micropipette Filling Techniques...........................................................................8

Back Filling..................................................................................................................8

Front Filling.................................................................................................................9

Typical Technique.....................................................................................................9

Injecting ...........................................................................................................................9

Setting the Aliquot Volume and Injection Speed.............................................10

MAINTENANCE.................................................................................................................11

Replacing O-Rings ...................................................................................................... 11

Replacing the Wire Plunger ....................................................................................11

Cleaning Recommendations...................................................................................12

OPTIONAL ACCESSORIES............................................................................................. 12

TROUBLESHOOTING...................................................................................................... 13

SPECIFICATIONS............................................................................................................... 13

APPENDIX: NANOLITER 2000/MICRO4 VOLUME SETTINGS......................... 14

Setting the Correct Volume on the Micro4........................................................15

INDEX ..................................................................................................................................17

DECLARATION OF CONFORMITY..............................................................................18

WARRANTY .......................................................................................................................19

Claims and Returns....................................................................................................19

Repairs............................................................................................................................19