Page Number - 10

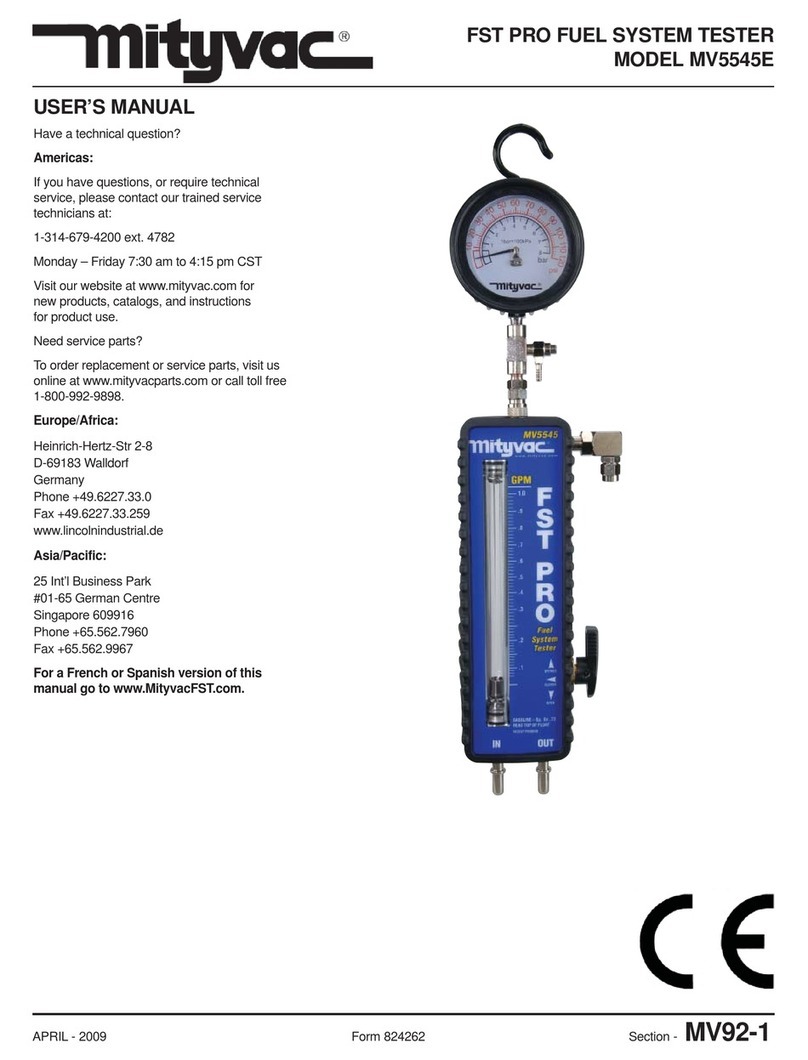

Fuel Pressure Test Kit

MODEL MV5546

Form 824129

Fuel System Pressure Testing

Fuel Systems

There are two basic types of electronic fuel injections: Throttle

Body Injection (TBI) and Multi-port or Multi-point injection

(MFI). The tests outlined in this manual are for testing fuel

system pressure on these types of systems. On most vehicles,

two basic tests are performed when checking fuel system

pressure:

“Key on, engine on” (engine running) test1.

“Key on, engine off” (engine not running) test Connecting2.

to the Fuel System

Connecting to Systems with Existing Test Ports

Be sure the vehicle transmission is in park or neutral, the1.

parking brake is engaged, and the engine is off.

Follow the vehicle manufacturer’s recommended proce-2.

dure to relieve the pressure from the vehicle fuel delivery

system.

Locate the test port on the engine’s fuel rail.3.

Attach the correct test port adapter. The 90° adapters can4.

be used if the test port is in a tight space.

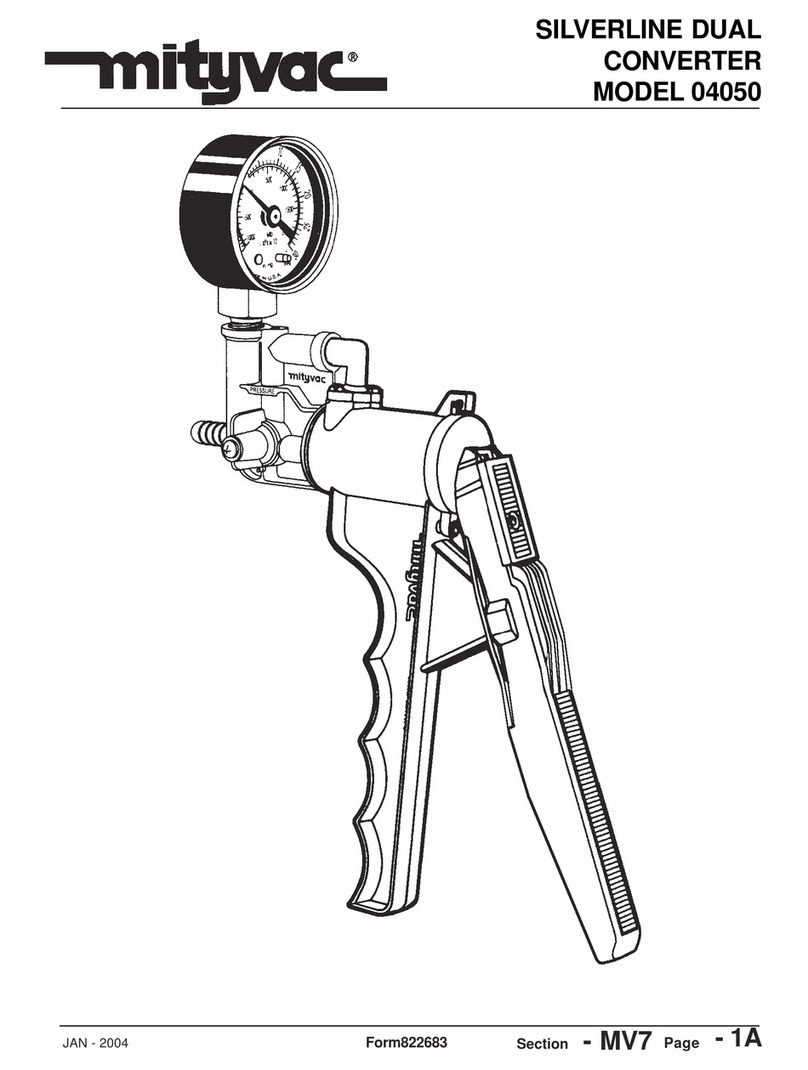

Connect the test port adapter to the extended pressure5.

hose

Connect the extended pressure hose to the pressure6.

gauge

Before proceeding:7.

Doublechecktheconnections.•

Route and secure the clear pressure relief hose into•

an approved gasoline container

Route any hoses away from any rotating engine com-•

ponents, belts, fans, and hot exhaust components

Reconnect components such as PCV tubes, wiring•

harnesses, vacuum tubes, etc., that were discon-

nected to gain access to the test port.

8. Re-enable the fuel pump (if previously disabled), and

cycle the ignition switch to the ON position for a brief time,

andthenbackOFF.Donotstarttheengine.

On most vehicles, cycling the ignition ON and OFF will

allowthefuelpumptorunbriey,andprimethesystem.

After cycling the ignition, check all fuel connections for

leaks.Ifallttingconnectionsaresecure,theinstallation

is complete and the fuel pressure tester is ready to be

used for diagnostic tests.

Connecting to System with Fuel System Adapters

Be sure the vehicle transmission is in park or neutral, the1.

parking brake is engaged, and the engine is off.

Follow the vehicle manufacturer’s recommended proce-2.

dure to relieve the pressure from the vehicle fuel delivery

system.

Locate the fuel supply line to the engine’s fuel rail, and3.

select the best location to disconnect the supply line and

install the inline pressure test assembly.

For additional assistance, consult the vehicle manufac-

turer’s service information.

If the engine has a cover, it will most likely have to be

removed to gain appropriate access.

Remove or disconnect any obstacles required to gain ac-4.

cess to the connection, and place shop towels under and

around the connection to absorb fuel from the disconnect-

ed line. To minimize fuel spillage and reduce the amount

of time the fuel line is disconnected, try to identify the type

of connection before disconnecting the fuel line, and have

the required fuel connection adapter(s) readily available.

Follow the vehicle manufacturer’s service information for5.

the proper method to disconnect the fuel line. Special

wrenches or disconnect tools may be required.

WARNING: Avoid spilling fuel on hot engine parts. Clean-

up any fuel spills immediately after they occur.

Install the appropriate adapter into the fuel supply line6.

extending from the tank.

Connect the inline pressure test assembly to the inlet and7.

outlet fuel line adapters

Connect the extended pressure hose to the tee in inline8.

pressure test assembly.