Functional overview

The Mityvac digital compression test kit can

perform wet and/or dry compression tests to

determine the pressure produced in the

cylinders of a gasoline engine. It can meas-

ure, display, and store compression values of

up to psi (20 bar) (2,000 kPa) for up to

cylinders. It can also be used as a tool for

pressurizing an engine cylinder to hold the

valves closed while performing repairs.

When using this tester to perform a

compression test on a cylinder, the current

peak compression value is displayed in large

numbers at the center of the LCD. This value

is automatically transferred to memory, and

displayed in smaller numbers at the bottom

right of the display. When the pressure relief

button is depressed, the current compres-

sion reading returns to zero, but the peak

value is retained in memory and continues

to be displayed in the bottom right corner of

the LCD. Repeated tests can be run on the

same cylinder, and the new current peak

value will be displayed by the large numbers.

This new peak value will not be retained in

memory unless it surpasses the value of the

previous test, or the CLEAR button was

pressed to erase the old value from memory.

Peak compression values can be stored for

up to cylinders. Each is displayed on the

LCD along with the cylinder number. During

and/or after completion of testing all cylin-

ders, the peak values can be reviewed by

pressing the CYLINDER button to scroll

through the memory. Individual peak values

can be erased from memory by pressing the

CLEAR button when the appropriate cylinder

and value are displayed. Pressing the CLEAR

button for seconds at any time will clear

the memory for all cylinders and return the

display to cylinder .

How to perform a

comression test

Precautions and diagnostic

notes:

WARNING

Do not use the ignition switch during

the compression test on fuel-injected

vehicles. Use of a remote starter switch

to crank the engine is recommended.

Fuel injectors on many late model

vehicles are triggered by the ignition

switch during the cranking mode, this

could result in a fire hazard or contami-

nation of the engine’s oil with fuel.

An engine in good operating condition will

produce a certain amount of pressure in

each cylinder. Normally, the cylinders should

be within percentage points of one

another and within the manufacturer’s spec-

ifications. The pressure should rise smoothly

on each stroke of the engine, until it reaches

a peak.

If the pressure reading fails to rise, or it

remains the same for several strokes of the

engine and begins to rise, the likely cause of

the problem is a sticking valve.

If two adjacent cylinders show pressure

readings of or more pounds below the

other cylinder readings, suspect a blown

head gasket.

If a cylinder shows a pressure reading of

psi (1 bar) (100 kPa) or more pounds

higher than the other cylinders, the probable

cause is carbon build-up inside the cylinder.

The Mityvac digital compression test kit

can perform two tests: the dry compression

test and the wet compression test. The result

of performing these tests will provide an

indication of the condition of the piston rings,

cylinders, and valve-train.

Contact MityVac

If you have questions, or require technical

service, please contact our trained service

technicians at:--- ext.

Monday - Friday : am to : pm

CST

Visit our website at www.mityvac.com for

new products, catalogs and instructions for

product use.

To order replacement or service parts,

visit us online at www.mityvacparts.com or

call toll free ---.

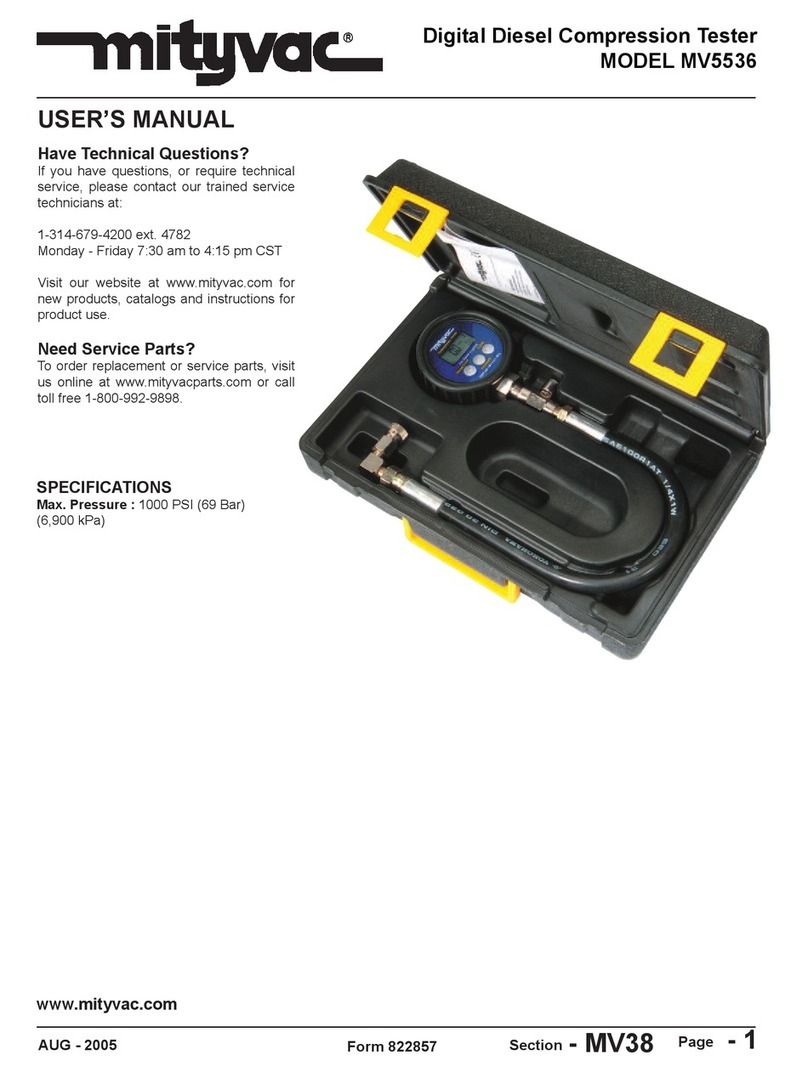

Specifications

Maximum pressure : psi ( Bar)

(, kPa)

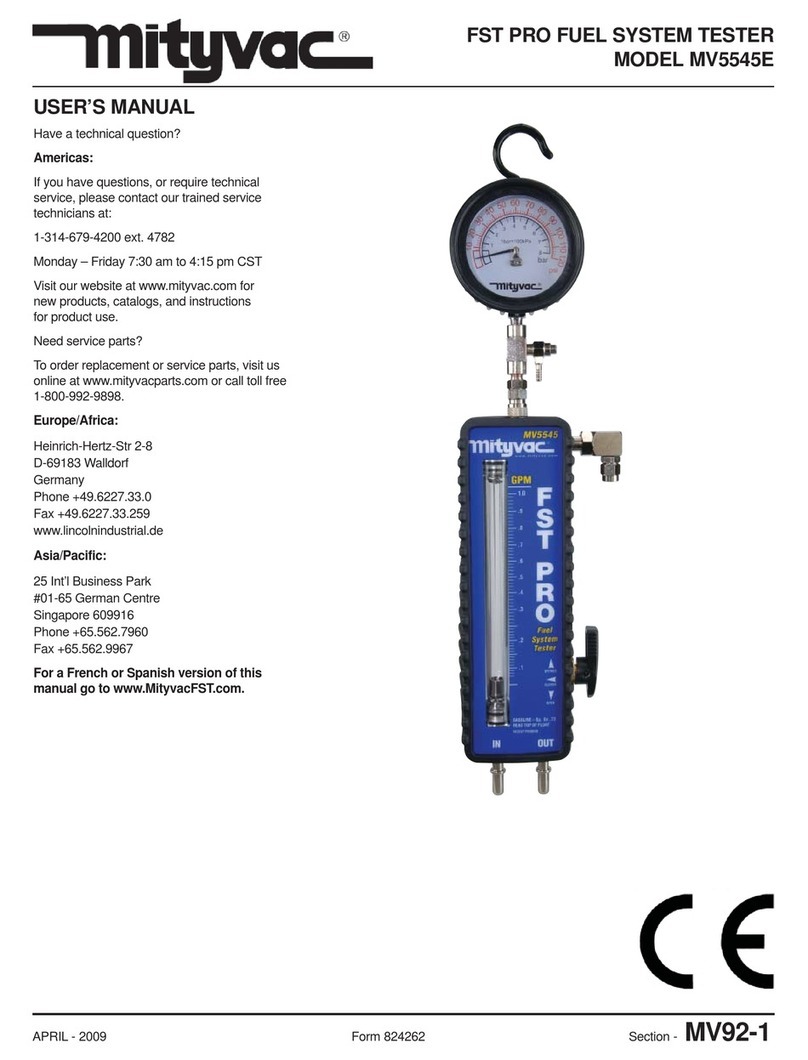

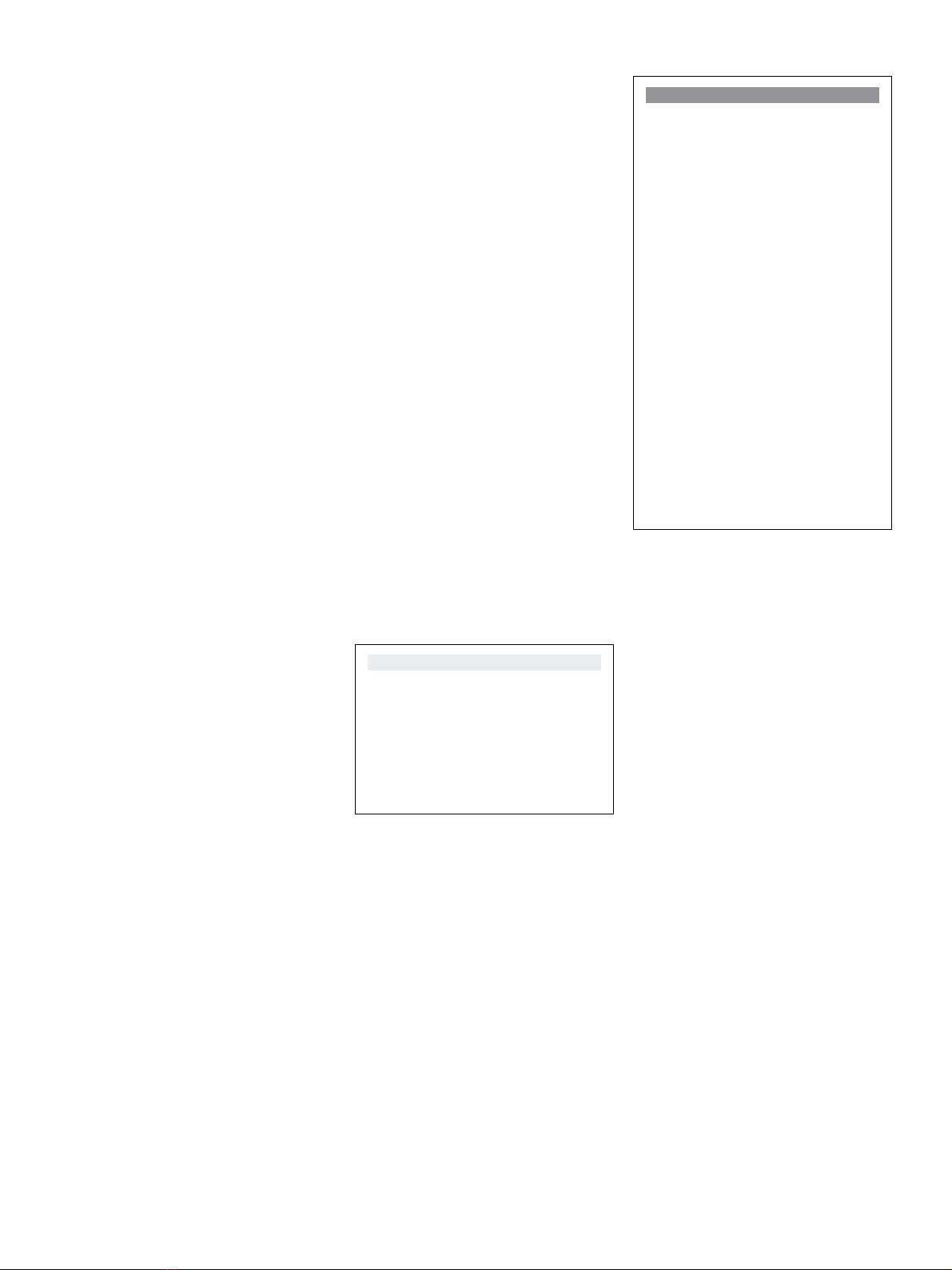

Included in this kit

• Digital Compression Tester comprising of

test gauge with rubber boot,

in (254 mm) long, high pressure hose,

and internal quick release coupler.

• () - Extended hose compression test

adapters:

– mm standard reach thread x

. in (165 mm) long

– mm standard reach thread x

in (305 mm) long

– mm long reach thread x

in (305 mm) long

– mm standard reach thread x

in (305 mm) long

• () - Plug style compression test adapters:

– mm long reach external thread x

mm standard reach internal thread

– mm external thread for Ford Triton

engines x mm standard reach inter-

nal thread

– mm external thread x mm stand-

ard reach internal thread

– mm external thread x mm stand-

ard reach internal thread

• Air hold adapter

• Custom blow-molded case

• Field service kit