MVK-MAN-DIAS-REV.4, 17/09/2018

INTRODUCTION

In professional and domestic kitchens large quantities of cooking oils and fats are used which

are extremely flammable. The extinguishing agent used for fires from cooking oil & fats is

Wet Chemical.

Wet Chemical agent is Carboxylic Acid Salt Solution which suspends fires by creating a

saponified layer (

crust

) that prevents oxygen from interacting with the burning surface, cools

down the area and eliminates the possibilities for re-ignition. The low acidity level (PH: 9 at

20°C) prevents any damage to surfaces made of stainless steel found in Professional

Kitchens.

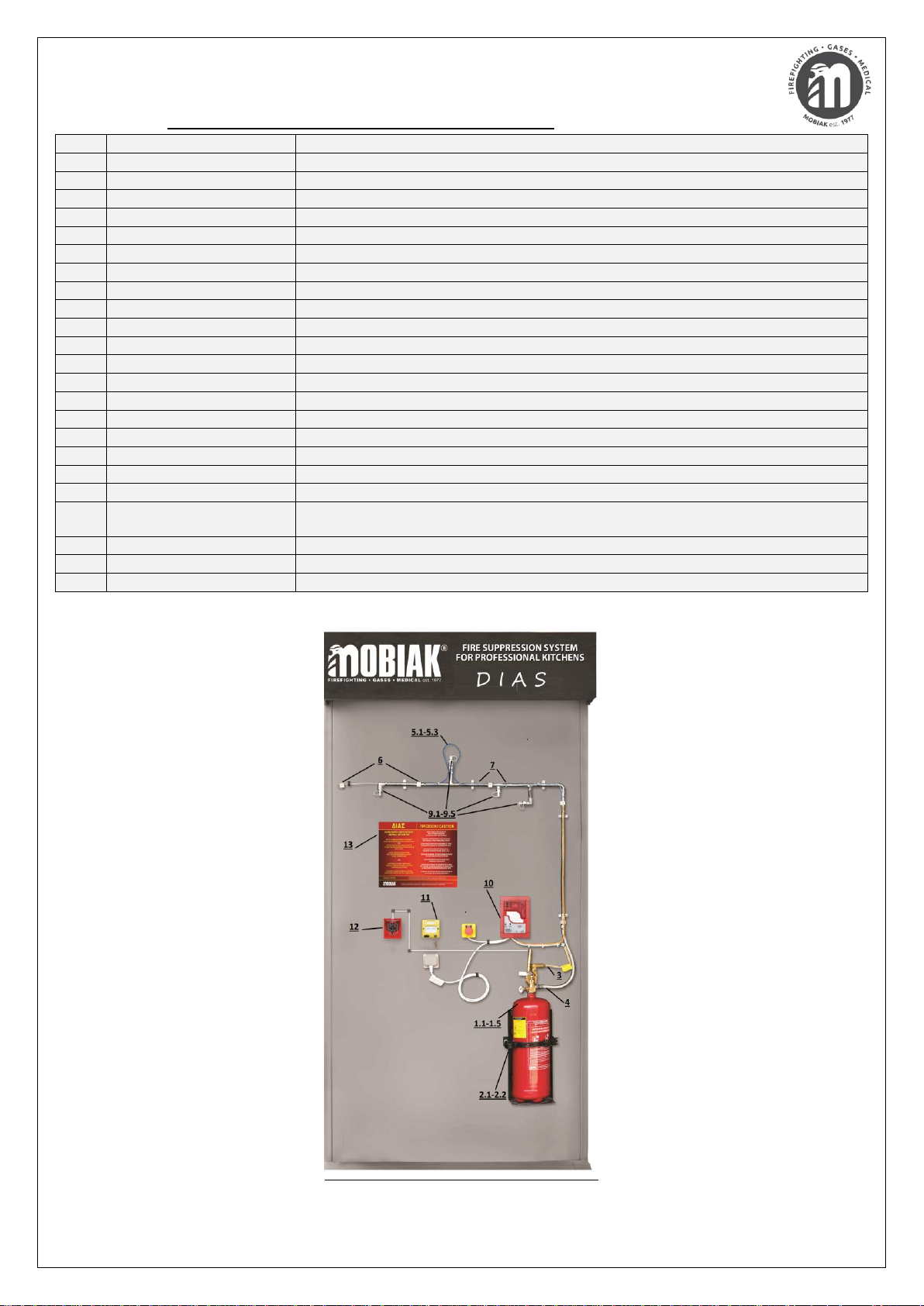

Dias Fire Detection-Suppression System is designed by MOBIAK for protecting Kitchen

Devices under Kitchen Hood, the Kitchen Hood itself and the Hood Air Ducts.

The system consists of a Wet Chemical Local Application Fire Extinguisher of both Automatic

and Manual operation, Control Panel, Fire Detection Unit and Discharge Nozzles designed for

protecting different Kitchen Devices.

Fire Detection is executed by an approved (UL/FM) Linear Heat Detection Cable (LHDC) of

138°C, 180°C or 250°C Activation Temperatures, the installation of which is particularly quick

& simple offering unique reliability & safety because it can detect fire all over the area of the

protected Kitchen Devices, Kitchen Hood and inside the Air Ducts. The LHDC is under

continuous monitoring by system’s Fire Detection-Suppression Control Panel.

In Automatic Operation, incase of Fire the Control Panel executes Alarm Signal and

simultaneously activates the System by transmitting a Signal to the fuse of the Fire

Extinguisher Valve resulting the flow of the Wet Chemical Agent through Stainless steel Tube

Network and Discharge through special type Nozzles.

In Manual Operation the system can be activated by Electrical Means by a) an Extinguish

Button that is built-in to the Control Panel or b) an System Activation Call Point that must be

installed near to the Kitchen Exit or by Mechanical Means by a) a Metal Wire Mechanism that

must be installed near to the Kitchen Exit or b) by pulling the Valve Rod of the Fire

Extinguisher Valve.

SYSTEM OPERATION

Linear Heat Detection Cable detects heat anywhere along its length. The cable is comprised

of two steel conductors individually insulated with a heat sensitive polymer. The insulated

conductors are twisted together to impose a spring pressure between them, then wrapped

with a protective tape and finished with an outer jacket suitable for the environment in which

the Detector will be installed.

Linear Heat Detection Cable is a fixed temperature sensor and is therefore capable of

initiating an alarm once its rated activation temperature is reached. At the rated temperature,

the heat sensitive polymer insulation yields to the pressure upon it, permitting the inner

conductors to move into contact with each other thereby initiating an alarm signal.

This action takes place at the first heated point anywhere along the Detector’s length. It does

not require that a specific length be heated in order to initiate an alarm nor is system

calibration necessary to compensate for changes in the installed ambient temperature. Linear

Heat Detection Cable provides the advantages of line coverage with point sensitivity.

In case of fire, during the Automatic Operation of the System, the Detection Cable is

activated and the Fire Detection-Suppression Panel executes constant Visual-Acoustic Alarm

through a built-in Siren with Beacon.