5

10/06 AWB2300-1433GB

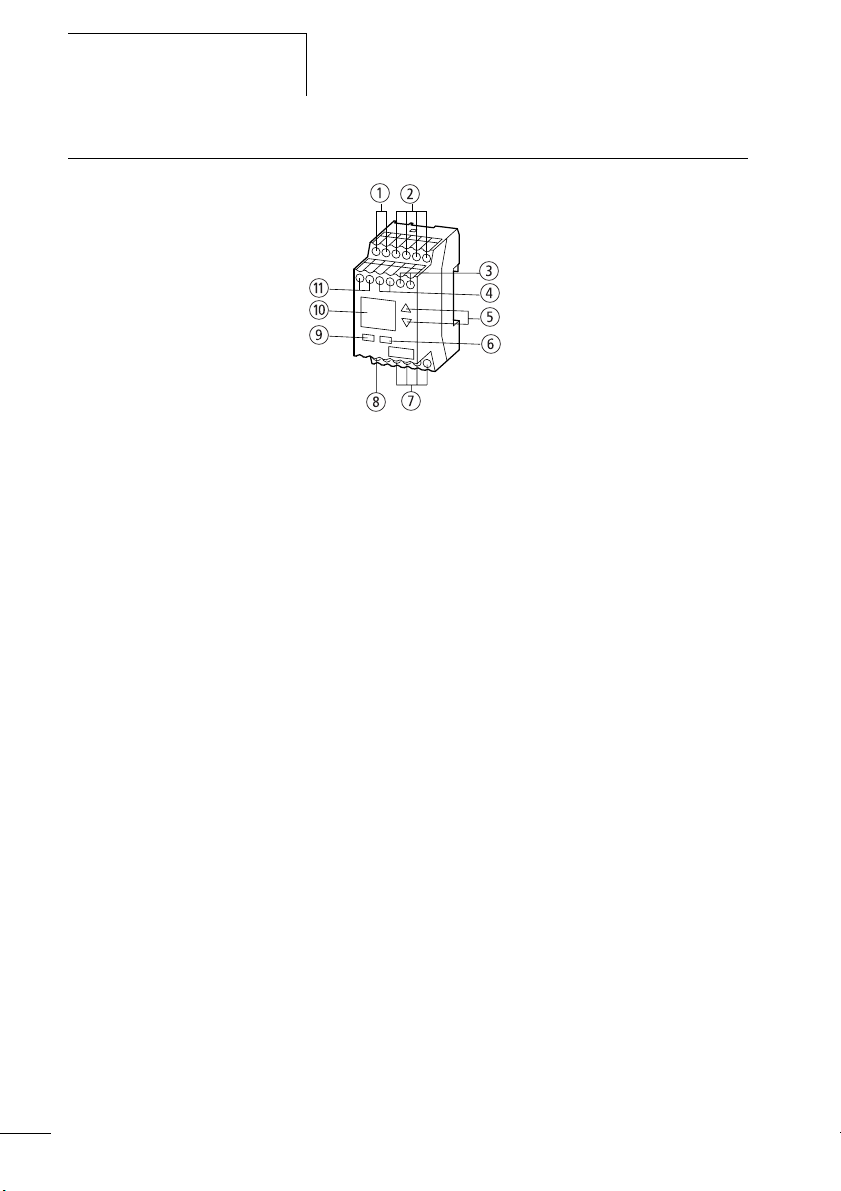

1 Motor-protective system ZEV

Preface In addition to the degree of protection specified in the

standards EN 60079-14 and VDE 0165 Part 1, further

provisions have been made to ensure safety from ignition for

motors operated in potentially explosive atmospheres. EN

50019 prescribes additional measures to be taken for the

operation motors with "increased safety" type of protection

"e". These measures improve the degree of safety and

prevent impermissible high temperature and development of

sparking and arcing, which is usually not found when motors

are operated under normal conditions. The motor protective

devices used for this are operated outside of the EEx e area

and must be certified by an accredited certification authority.

The guidelines on the application of Directive 94/9/EC

(ATEX 100a) on the approximation of the laws of the

Member States concerning equipment and protective

systems intended for use in potentially explosive

atmospheres will be enforced as of 06.30.2003.

The motor-protective system ZEV is approved by the PTB

according the 94/9/EC (ATEX 100a) Directives.

hNumber of the EU Certificate of Compliance:

PTB 01 ATEX 3233.

((