Montalvo

S-4

Digital Tension controller

p.2

[email protected] /

www

.montalvo.com

/

Technical details subject to change without notice. S4-technical manual-us © Montalvo TECHNICAL MANUAL

1 General Description ...................................................................................................................... 3

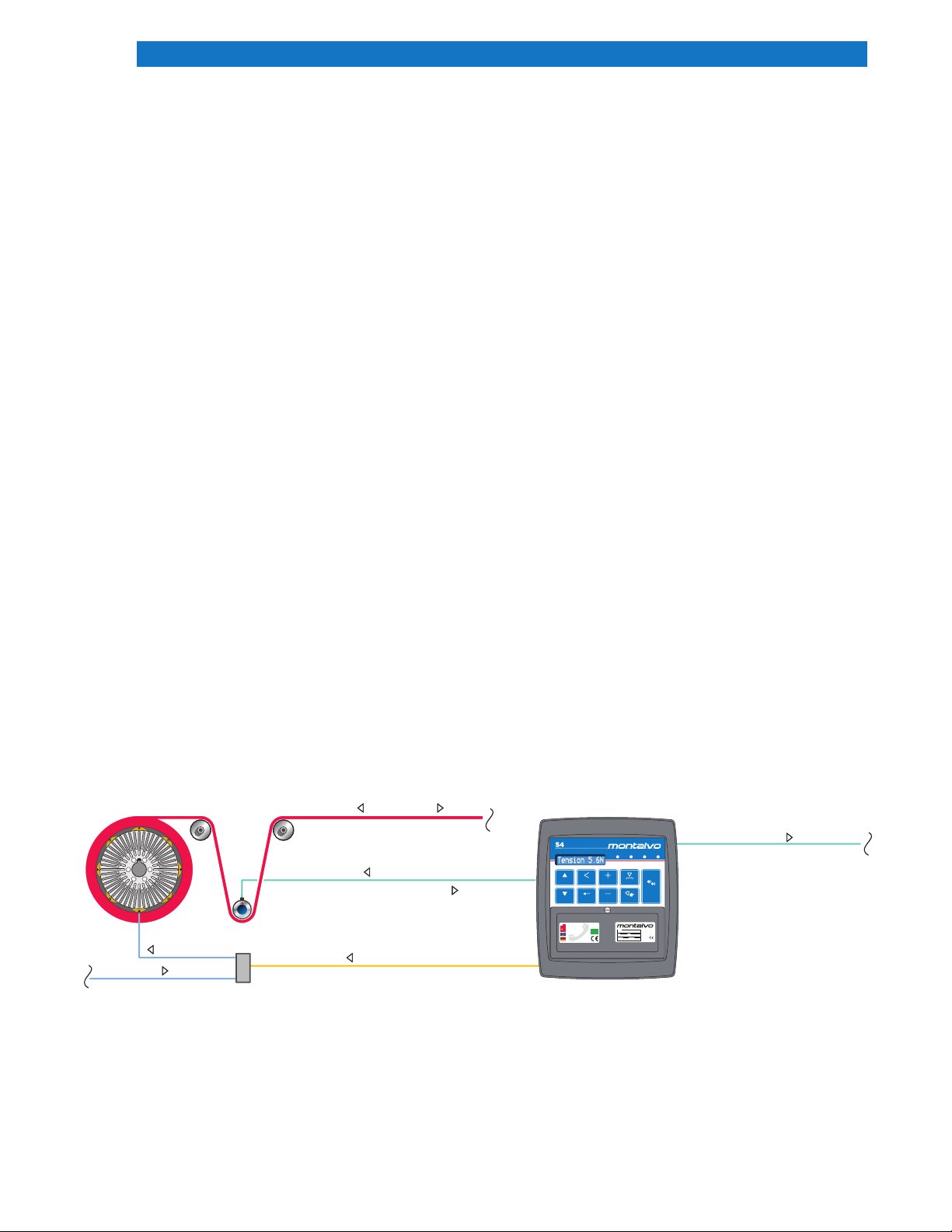

2 System Operation........................................................................................................................... 3

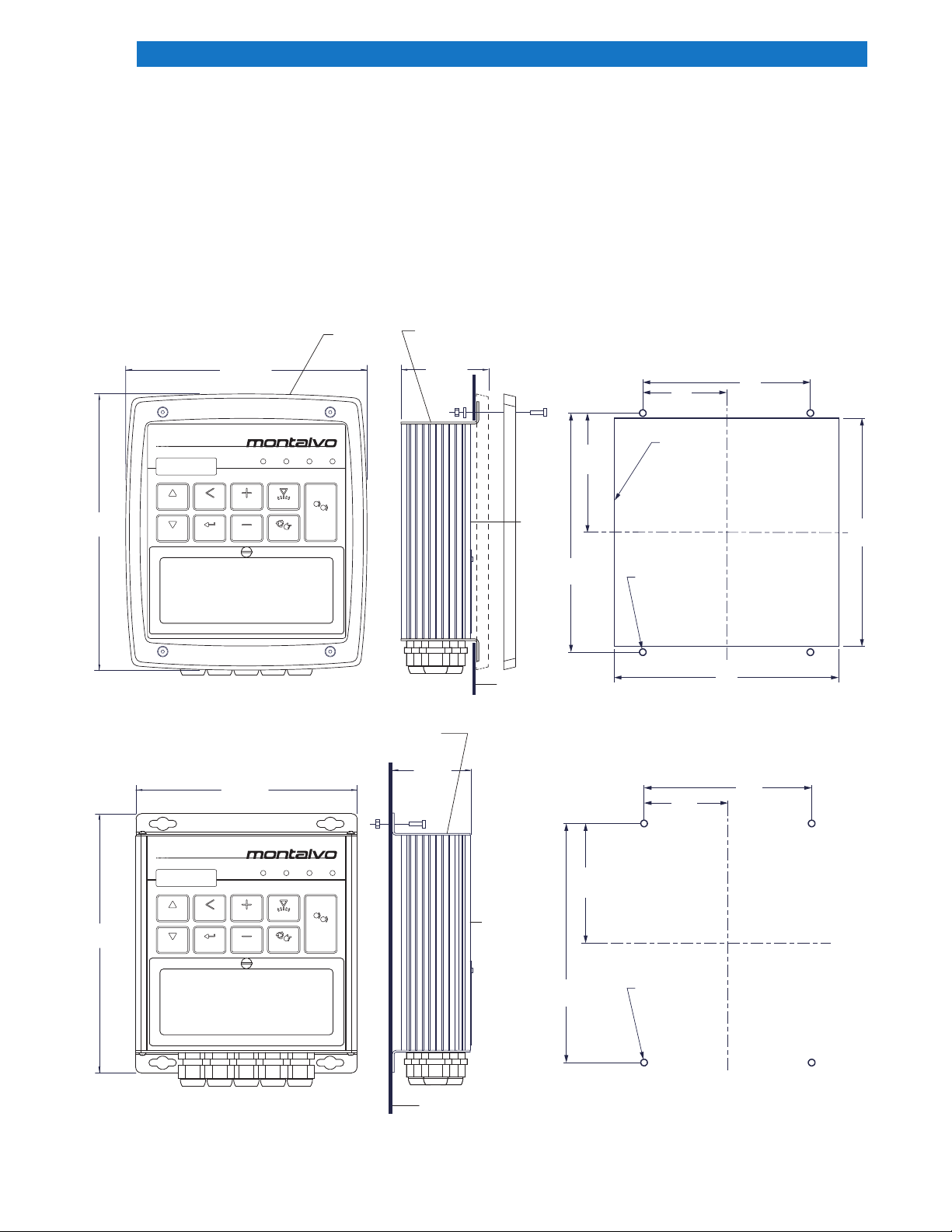

3 Installation ........................................................................................................................................... 4

3.1 Flush Mount ........................................................................................................................................... 4

3.2 Surface Mount........................................................................................................................................ 4

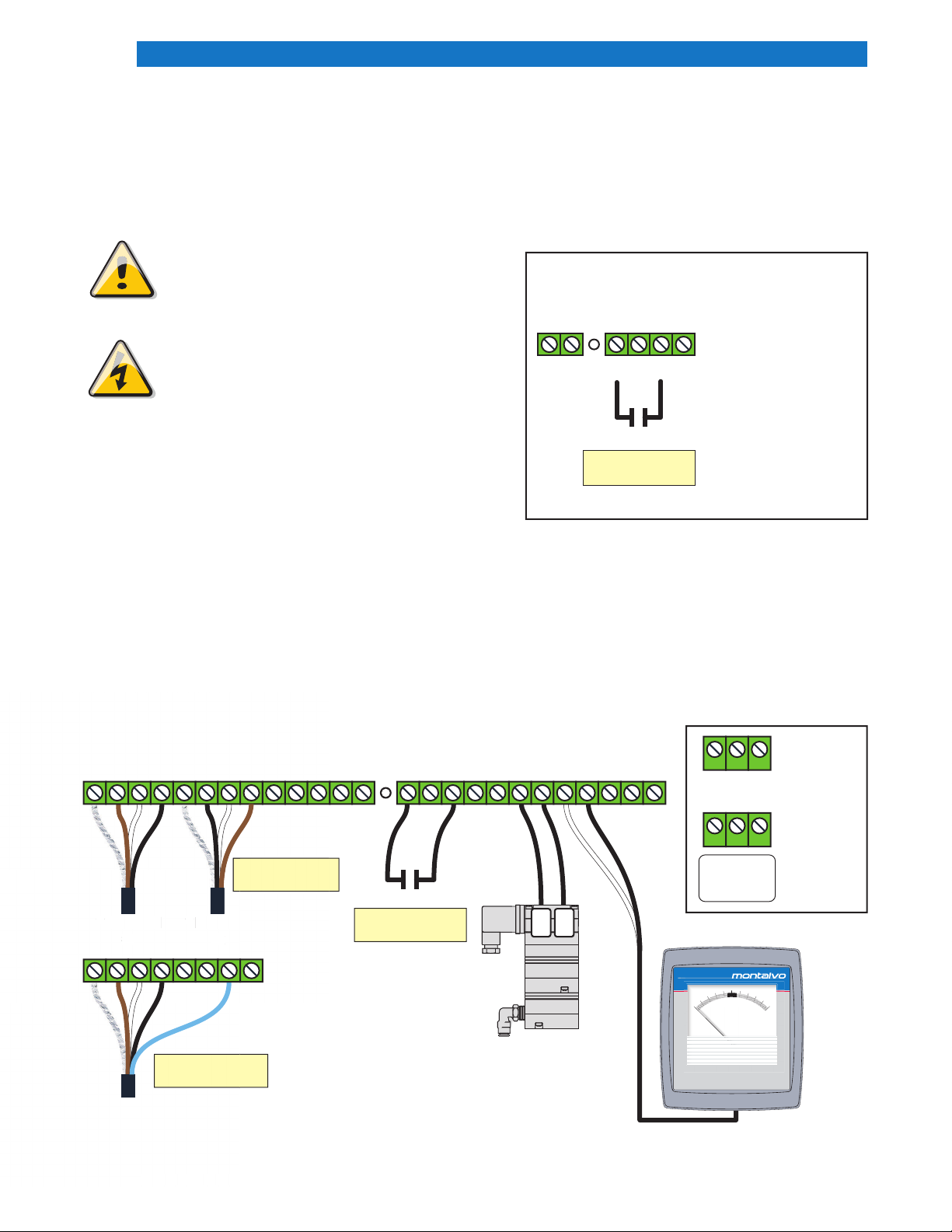

4 Electrical Connections ................................................................................................................ 5

5 Description of Adjustments ..................................................................................................... 6

6 Description of Front Panel Display ..................................................................................... 7

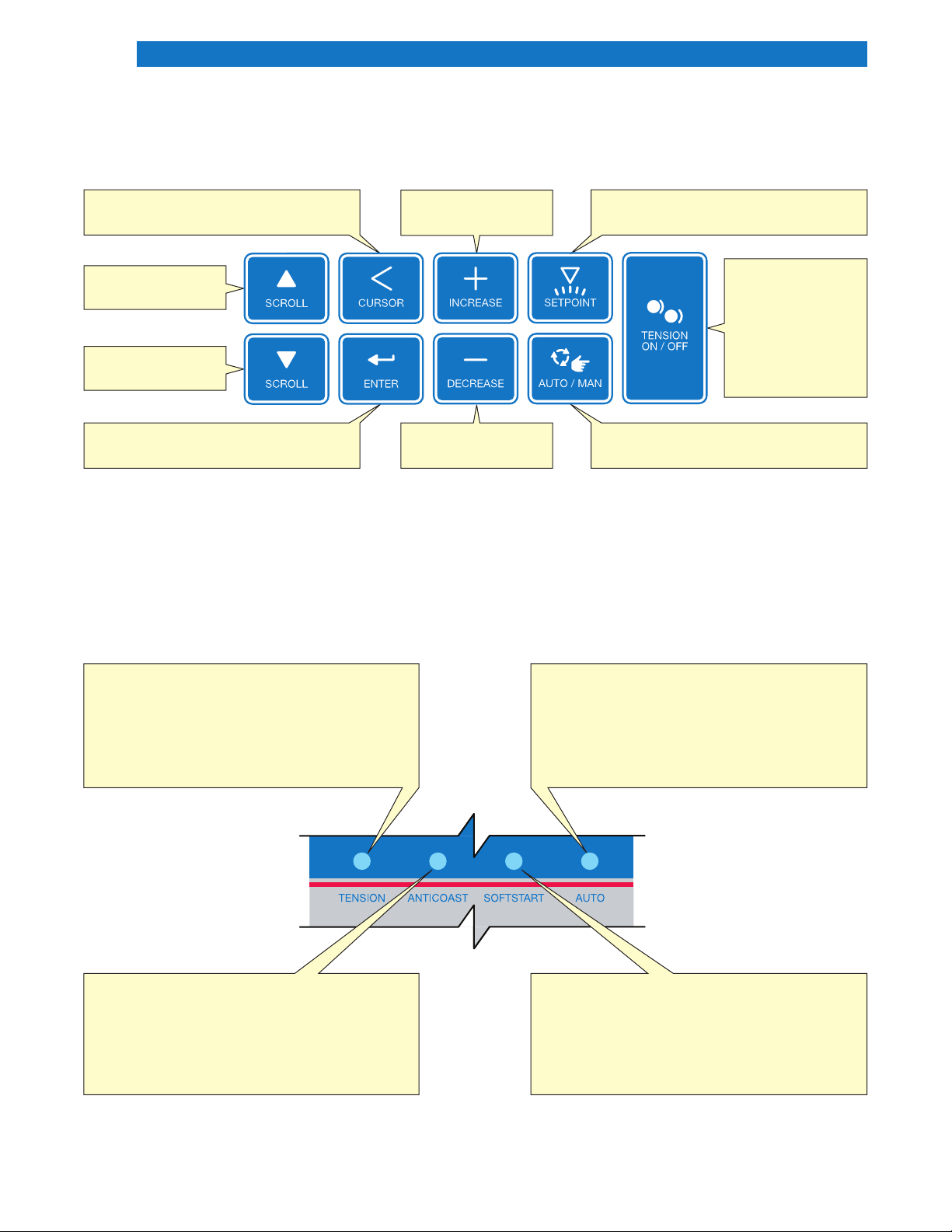

6.1 Keypad................................................................................................................................................... 8

6.2 Status Indicator Lights............................................................................................................................ 8

7 Standard Pneumatic Setup...................................................................................................... 9

8 Calibration ......................................................................................................................................... 10

9 Standard Unwind Features..................................................................................................... 11

9.1 Soft Start.............................................................................................................................................. 11

9.2 Anti-Coast ............................................................................................................................................ 12

9.3 Splice ................................................................................................................................................... 12

10 Tuning the S4................................................................................................................................... 13

11 Standard Rewind Features..................................................................................................... 14

11.1 Inertia Compensation (see also Section 13.3 p.23 for more information) ............................................. 14

11.2 Taper Tension ..................................................................................................................................... 15

12 System Setup Menu Options................................................................................................ 16

12.1 Access to Menu........................................................................................................................................ 16

12.2 New Roll Default ................................................................................................................................. 16

12.3 Out Scale ........................................................................................................................................... 16

12.4 Meter Dampening............................................................................................................................... 16

12.5 Tension Display: Total or PLI ............................................................................................................... 16

12.6 Set Units............................................................................................................................................. 17

12.7 Web Break ......................................................................................................................................... 17

12.8 Remote Setpoint ................................................................................................................................ 18

13 Appendix ............................................................................................................................................ 19

13.1 Unwind Message Map........................................................................................................................ 19

13.2 System Setup Menu ........................................................................................................................... 21

13.3 Rewind Message Map ........................................................................................................................ 22

13.3.1 Rewind and Inertia Compensation ................................................................................................... 24

13.4 Parameter Settings............................................................................................................................. 25

13.5 Jumper Re-Conguration.................................................................................................................... 26

Table of Contents